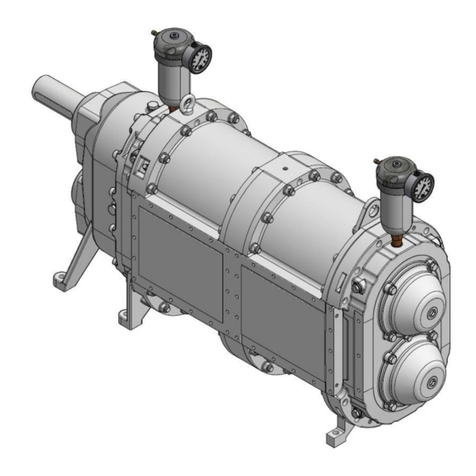

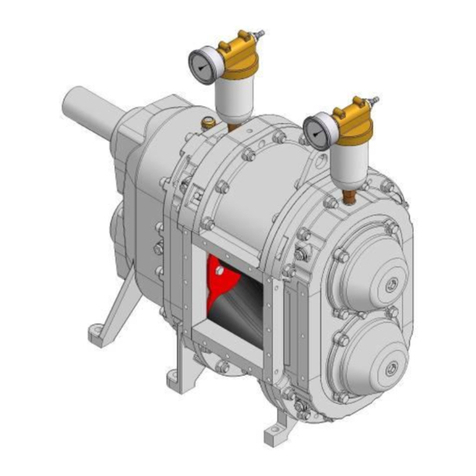

Vogelsang VX Q Series User manual

This manual suits for next models

3

Table of contents

Other Vogelsang Water Pump manuals

Vogelsang

Vogelsang VX136Q..QD..QDM2 Series User manual

Vogelsang

Vogelsang VX136QD User manual

Vogelsang

Vogelsang VX136QDM2 User manual

Vogelsang

Vogelsang VX136Q User manual

Vogelsang

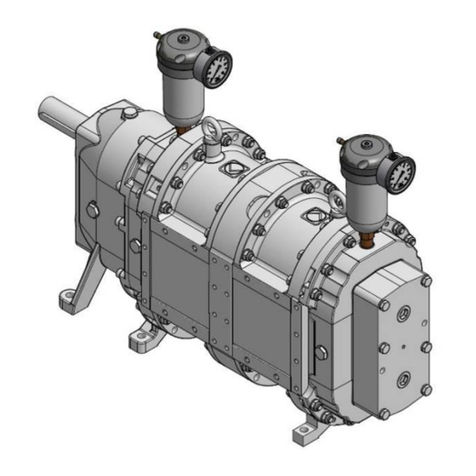

Vogelsang FX116 User manual

Vogelsang

Vogelsang VX215QD User manual

Vogelsang

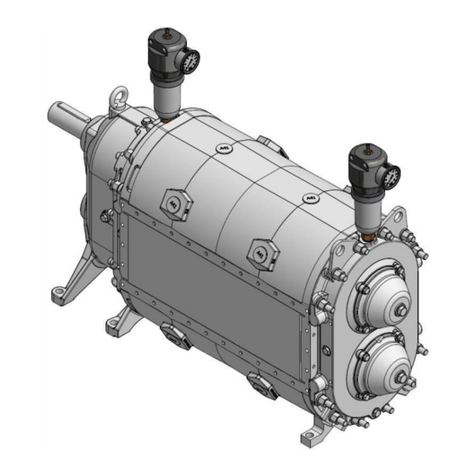

Vogelsang VX186Q User manual

Vogelsang

Vogelsang VX186QD User manual

Vogelsang

Vogelsang VX186QDM2 User manual

Vogelsang

Vogelsang VX100Q User manual

Popular Water Pump manuals by other brands

Graco

Graco E-Flo EC1140 Instructions-parts list

Emil Lux

Emil Lux 420610 manual

Edwards

Edwards nXL110i instruction manual

Solidpump

Solidpump TBD Series Operation & service manual

Tallas Pumps

Tallas Pumps P1 330W Instruction for installation and maintenance

FLOWTECH

FLOWTECH flowpress WMDA Operation and maintenance manual

Crane

Crane ELRO IP 100 Installation and operation manual

Beckett

Beckett Fountain Pump M60AUL Specifications

ProMinent

ProMinent gamma XL operating instructions

Richter

Richter V&A RMI Series Installation and operating manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS SUPER T T6A60S-4045T Series Installation, operation, and maintenance manual with parts list

Bestway

Bestway AlwayzAire P3153 owner's manual