9

Transportation,

Storage and

Handling

!WARNING

4.2 Factory Packaging and Protections

After the painting phase, VOGT S.A. performs the following:

•All openings are sealed by means of plastic parts, or plasticized adhesives.

•AM Series pumps are delivered in packaging consisting of a fully enclosed cardboard box mounted on a wooden

pallet. In all cases, the equipment is firmly secured to prevent movement during transport and handling. These

protections are exclusively for transport and at most for short term storage. In any case, the following storage

instructions must be followed.

CAUTION

4.3.1 Before Storage !

•Storage should be in a place protected from the outside, away from shocks, solar radiation, dust, humidity and

flooding.

•The pumping equipment should not be stacked on top of each other, even if the type of packaging makes this

possible.

•The pump and auxiliary lines should be kept clear of the pumping fluid.

•It is recommended to coat the unpainted parts of the pump with a protective material (e.g. petroleum jelly or

similar).

•Apply from the suction inlet oil or some anti-rust liquid in the wear ring areas, to avoid seizure.

•The electric motor shall be disconnected and the connection cables shall be removed and the terminal box shall be

closed with its cover.

•The electric boards shall remain in vertical position and disconnected.

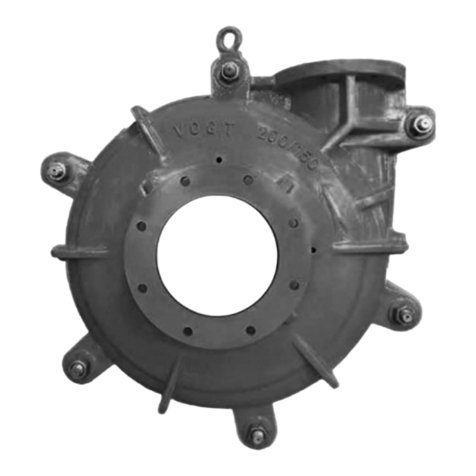

Figure 6

Transportation, Storage and Handling

The pump and its components are heavy. Improper handling during handling and hoisting could cause serious personal injury

and/or damage to the equipment.

4.1 Transportation and Handling

The transport and handling of the equipment must be carried out with means suitable for the weight to be supported; the weight

is generally indicated on the delivery note, if this is not the case and there is no certainty of being able to handle the equipment,

please contact VOGT S.A. to indicate the same. For the handling, the equipments that require it have appropriate eyebolts on the

bench. However, remember that the equipment must never be lifted by means of the eyebolts of each one of its elements, e.g.,

engine and pump eyebolts, which are exclusive for their independent transport. Neither should the suction and discharge ports

of the pump, nor pipes or connecting elements, e.g. couplings, be used. In any case, if the equipment is to be lifted by means of

slings, these must pass under the pump and motor bodies.

4.3 Storage Instructions

These instructions are for storage less than 12 months from the date of shipment. If longer, please request instructions for long

term storage.