6

Transaction

Information

Transaction Information

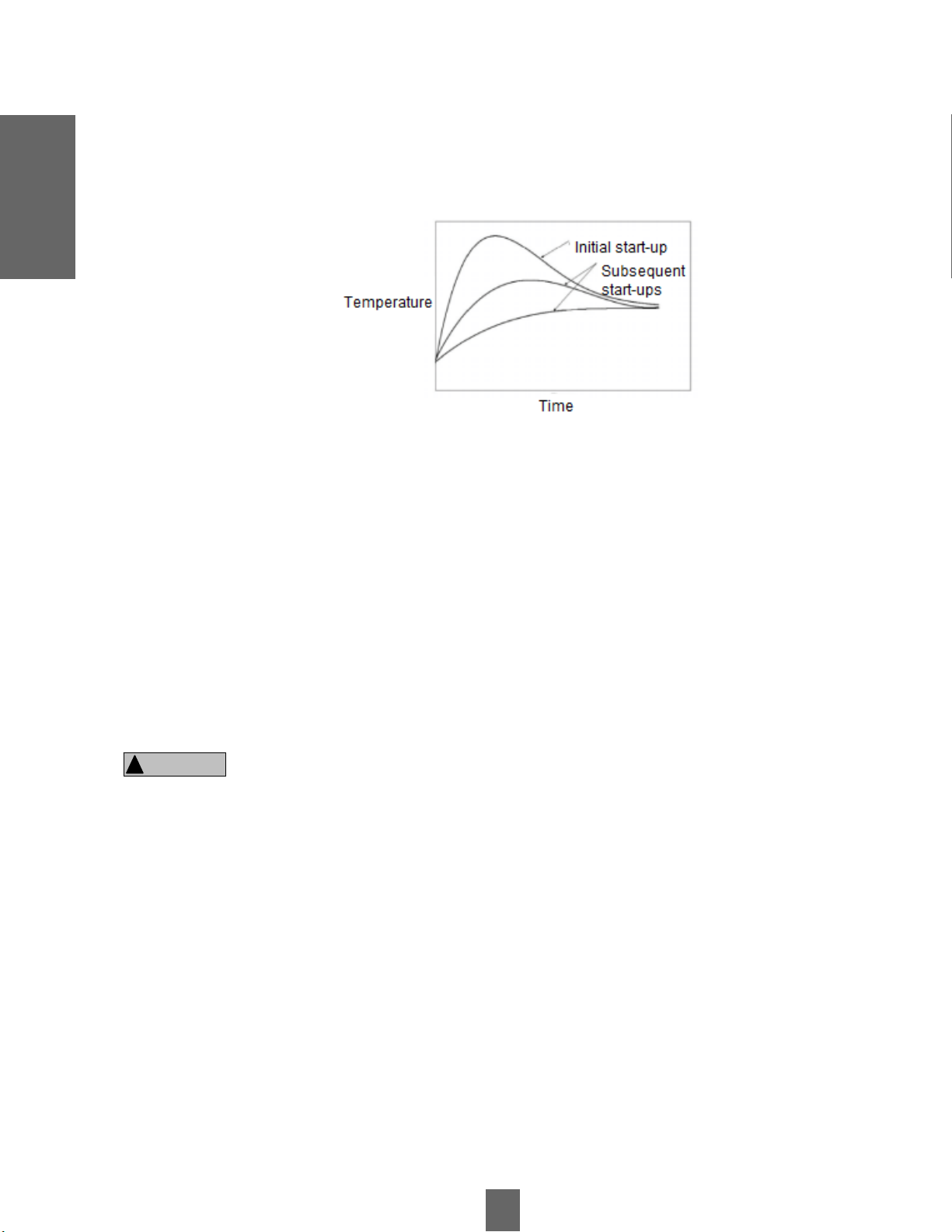

The pump performs its pumping work by means of the centrifugal rotary action of the impeller rotating inside the casing

and for everything to work properly the following considerations must be kept in mind:

1. Complete check of the entire pumping system prior to start-up. Piping properly aligned to the pump, valves in good

condition, controls operational, pump alignment and belt tension checked, etc.

2. GAP between impeller and suction disk should be checked. This should be between 1 and 2 [mm], to increase

efficiency and decrease recirculation inside the equipment.

3. Activate the water seal system before starting the pulp pump, adjust flow and pressure according to the equipment

requirements. This operation is performed with the pump in commissioning to verify water flow through the jacket.

4.1 Pump Baseplate

Before leaving the factory, the pump and its motor unit are mounted on a level base that serves as an assembly stand.

For alignment in the field, compensating bases (slats) are used to lift the motor if necessary for the correct assembly of

the motor-pump assembly. The bases installed on the foundation in the equipment installation area will support the base

of the assembly. Once the base of the assembly is installed and tightened against the foundation, the alignment of the

equipment is started, using the lag bolts if necessary.

4.2 Foundations

The foundation supporting the pump-motor assembly must be able to withstand vibrations of both the pump and the

motor and should be as close as possible to the source of the fluid to be conveyed. The motor pump assembly should

be supported on a generously sized foundation. This foundation must be completely flat, smooth and level. The unit shall

be tied to this foundation by means of suitable anchor bolts to avoid possible vibrations due to operation. The space

required for a pumping unit and the placement of anchor bolts are defined by the drawings supplied by the

manufacturer.

4.3 Alignment of the Axis

Regardless of whether they are direct coupled or belt driven, the pump and motor shaft must be precisely aligned.

4.4 Pipelines

For optimum operation of the pump-motor unit, the piping should not exert stresses on it, since the unit can deform,

misalign or break when the piping is not correctly aligned with the suction and discharge shafts of the pump. The

position of the flanges must be totally parallel, with their concentric axes, in order to minimize stresses in the pump

necks that deform the pump or produce a misalignment of axes. The bolts or studs must be able to pass loosely through

the holes in the flanges. Do not use the pump as an installation fastening point. The suction and delivery piping must not

cause stresses on the pump flanges that could exceed their maximum values. The piping should be fixed to the walls or

floors of the pump room in such a way that the pump is not subjected to the weight of the piping.