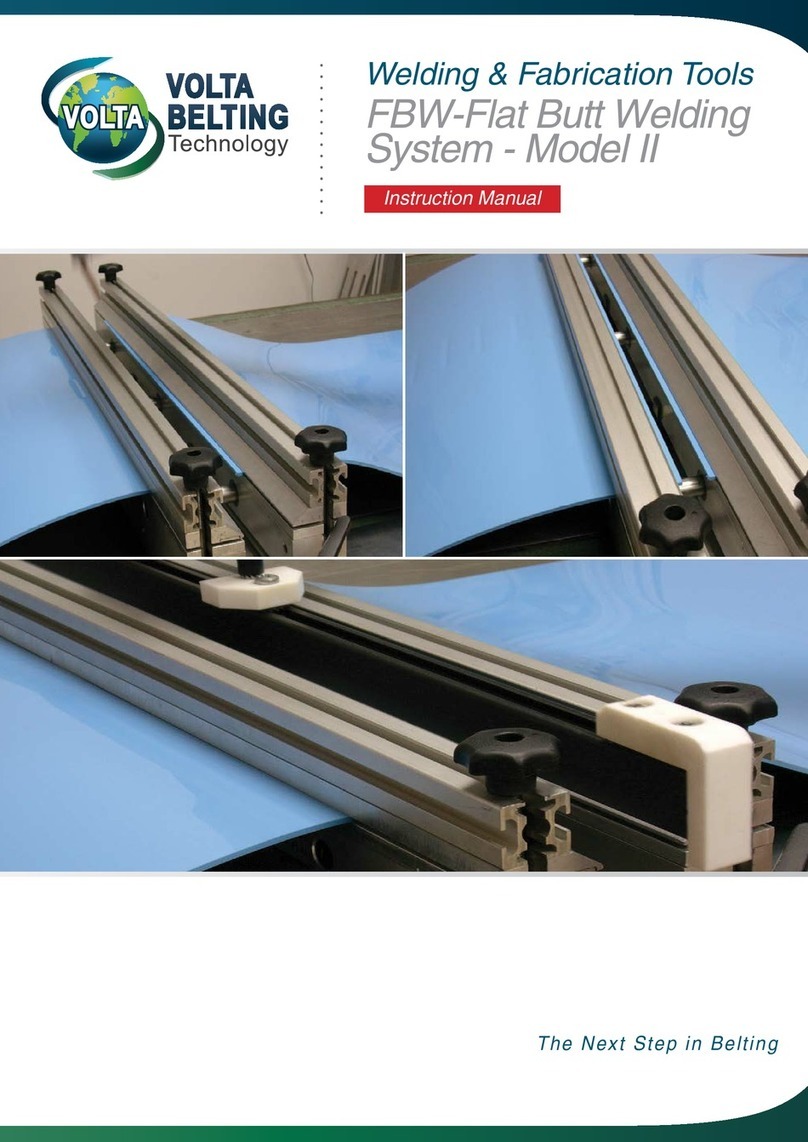

Volta sleeves are made from tubular extrusions with

standard thicknesses of 2-3mm (the table below shows

thesizeswhicharedenedbyinnerandouterdiameters

I.D.andO.D.)andarecuttolengthforcoatingrollersin

situationswhereaproductrequirescushioningwhilemoving

acrossarollerbedorconveyor.Applicationsincludepotato

intakes and ceramic tile lines.

Thesleevesareextrudedfromafoodapproved(FDA/EU),

smooth durable 85A Shore white TPU material to avoid

marking products. Some sizes are available with a ribbed

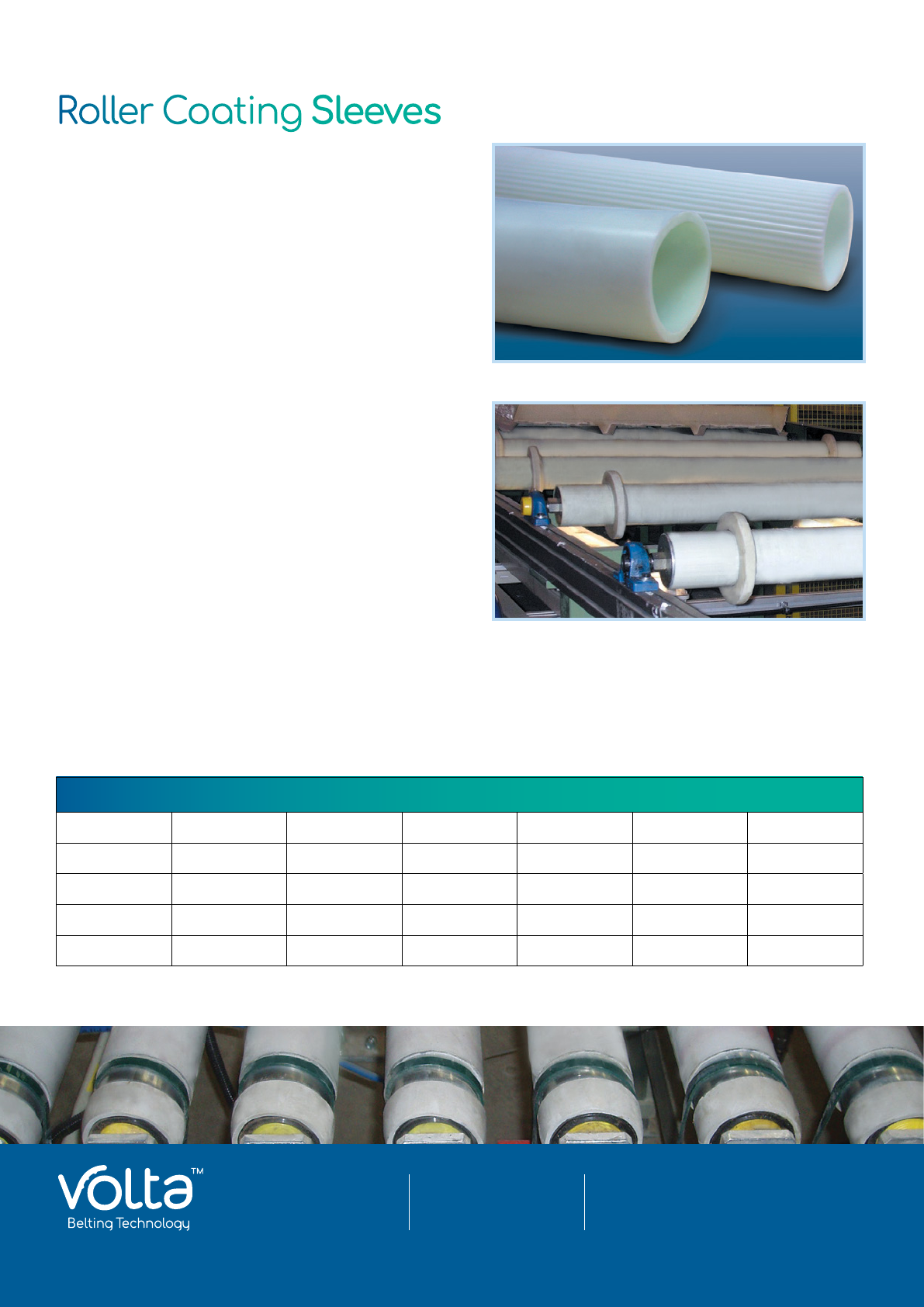

outersurface.Oncecuttolengththeycanbemounted

ontotherollerbysurface.Canbemountedontotheroller

bymeansoftheVoltaSleeveMountingToolwhichuses

compressedairtoinatethetubedimensionenoughto

permittheinsertionoftheroller.Oncetheairsupplyiscuto

thetubeassumesitsoriginaldiameterandtstightlyoverthe

roller–noadhesiveisrequired.

Nomenclature:

Thesleevedesignationcontainstwonumbers.Therst

number is the diameter of the metal roller to be covered. The

secondnumberisthedesiredoutsidediameter(O.D.)after

thesleeveismountedontheroller.Forexample,a50x55

sleeve is designed to cover a roller with an outside diameter

of50mmandtheoutsidediameterofthecoveredroller

willbe55mm.Thisidenticationsystemisusedforboth

standard and ribbed sleeves.

Packaging:

Sleevesupto50x55mmarein30m/100inchrolls.

Sleevesfrom60x65mmaresuppliedas3m/10inchtubes.

Note: Contact your local distributor for further details regarding the dimensions and availability of Ribbed Sleeves.

Sleeve Dimensions (mm)

10x14 30x35 40x45 50x55 60x65 80x85 90x95

22x27 32x37 40x50 63.5x68.5 85x90

25x30 35x40 42x47 65x73 88.9x94

27x32 38x43 45x50 73x78

48x53 77x82

Non-marking surface protects products

Ribbed and Standard (smooth surface)

Copyright

©

Volta Belting Technology Ltd.

CAT700EN00 - Ver.C - April 2020

Volta Belting makes no warranty with respect to any of its products

for a particular purpose. See Volta General Terms and Conditions.

www.voltabelting.com

Roller CoatingSleeves

CORPORATE

HEADQUARTERS

Sales and Manufacturing

sales@voltabelting.com

EUROPE

Tel. +31 546 580166

voltaeu@voltabelting.com

USA

Tel. +1 973 276 7905

Toll Free. 1-877-VOLTAUS

voltaus@voltabelting.com

now-branding.co.il