P 120

The front end is bolted to the upper side mem-

bers, front cross-member and front pillar. The front

mudguards are pressed in one piece and bolted

to the wheel arch plate. The front section forms

the front part of the front end as well as the air

duct to the radiator. The body is noise- and heat-

i

nsulated. The insulation consists of "waffle" board

which is stuck on to the plate.

Bonnet

The bonnet is pivoted at the rear on two hinges.

I

n the closed position, the bonnet is secured by a

bonnet lock fitted on the front section. The lever

for the bonnet lock is operated by means of a

control

placed underneath the dashboard inside

the vehicle.

Doors sand openings

The doors are built up of an outer and inner plate

together with door arch which is flanged and spot-

welded in one unit. The hinges are fitted to the

i

nner plate. The doors are adjustable both longitu-

dinally,

vertically

and laterally. The doors are

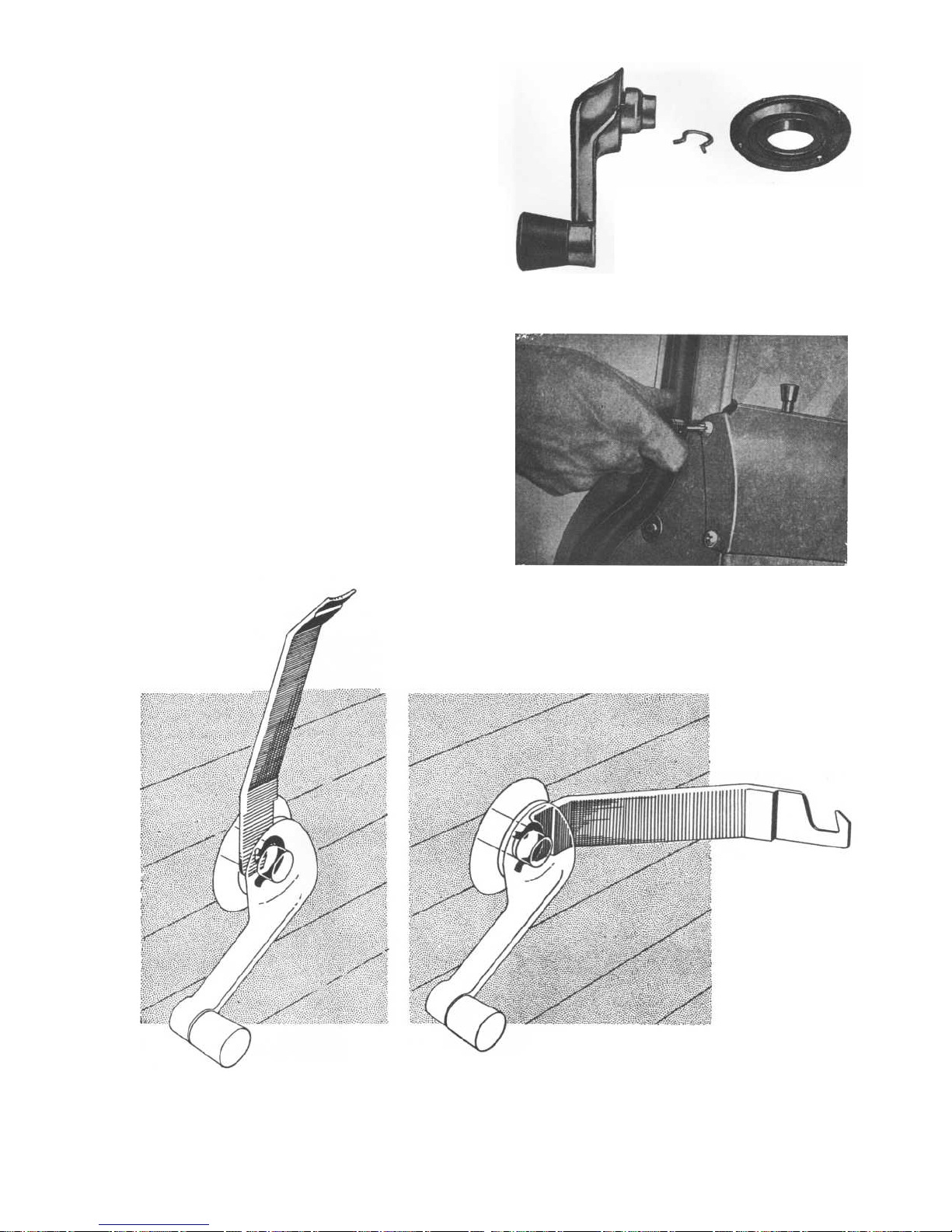

provided with a door check. This consists of a flat

bar attached to the door pillar and runs against a

roller in the door. In the open position the flat

bar obstructs the movement of the roller and thus

li

mits the movement of the door. The door checks

are fitted to the doors with screws. The press-

button of the outside door handles operates a lever

which in turn disengages a rotating toothed roller

(tumbler). The inside door handles are fitted to the

remote control which is attached to the inner door

plate with screws. The handle transmits the move-

ment to the toothed roller by means of a link rod.

The lock insert is fitted in the press-button on the

door handle. The doors can be locked from inside

the vehicle by pressing down the locking knobs.

The window winders are of the cable and chain

type. The movement of the window winding handle

i

s transmitted to the window itself by a cable and

chain which are joined together forming an endless

"drive

This is mounted on two pulleys and a

sprocket. The lower pulley is provided with a spring

device for tensioning.

The luggage compartment lid is built up of an outer

and inner plate. The catch for the locking device

i

s fitted on the lower edge of the luggage compart-

ment lid. The hinges are fitted at the upper edge

of the lid. The hinges are bolted to the plate under

the rear window through a reinforcing plate. The

Fig. 4.

Roof section (2- and 4-door)

On 4-door models the side section (Fig. 3)

consists of the front pillar (9), intermediate pillar (11),

rear pillar (6), intermediate and outer cantrails (8

and 7), roof former (1), windscreen pillar (10), rear

wheel arch (2) with wheel arch member (5), rear

mudguard (4), back plate and joining plate (3). The

cantrail and wheel arch member are manufactured

of galvanized sheet metal.

The roof section (Fig. 4) consists of a number of

pressed steel plates. The roof plates form the

upper part of the scuttle section, windscreen open-

i

ng, the roof itself, the opening for the rear window

and the upper limit of the luggage compartment.

The front mudguards, front section and bonnet

make up the front end.

Fig. 3.

Side section (4-door)