User Manual

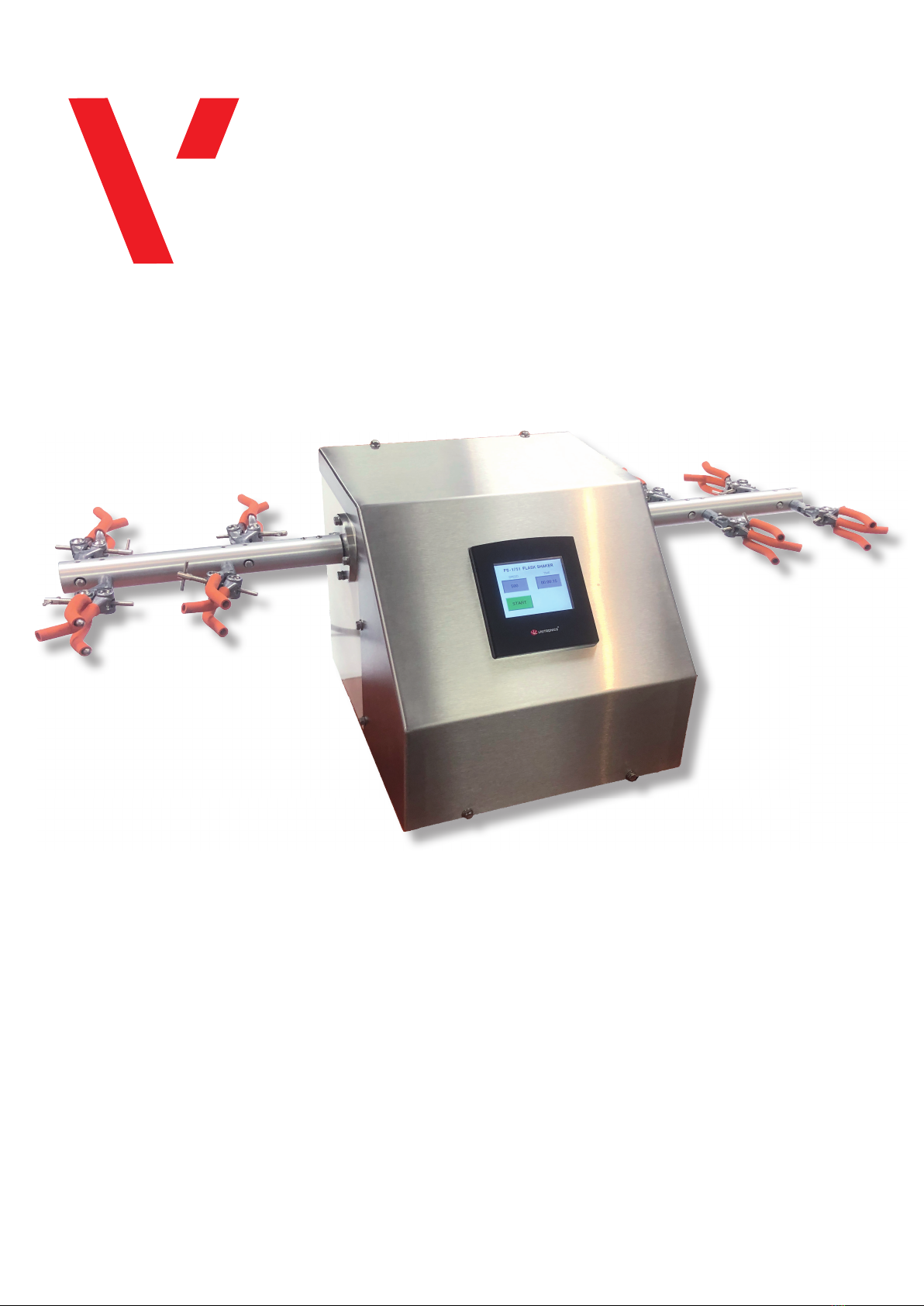

FLASK SHAKER FS-1751

Airofiller Equipment Solutions BV.

Dispensing Platform™/ Lab™s / Equipment Solutions™/ Full Service™/ Authorized Filler Network™

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

1GENERAL INFORMATION..................................................................................................... 3

1.1 Purpose of Use.................................................................................................................... 3

1.2 General Description ............................................................................................................ 3

2SAFETY ............................................................................................................................... 4

2.1 Health and Safety Risks....................................................................................................... 4

2.2 Safety Procedures ............................................................................................................... 4

2.2.1 Personal protective equipment ............................................................................... 4

2.2.2 Preparations for safe use ........................................................................................ 4

2.2.3 Safety during inspection and maintenance ............................................................ 4

3TRANSPORT AND STORAGE................................................................................................. 4

3.1 Transport ............................................................................................................................ 4

3.2 Storage................................................................................................................................ 4

4INSTALLATION .................................................................................................................... 5

4.1 Environmental Conditions .................................................................................................. 5

4.2 Prerequisites ....................................................................................................................... 5

4.3 Installation .......................................................................................................................... 5

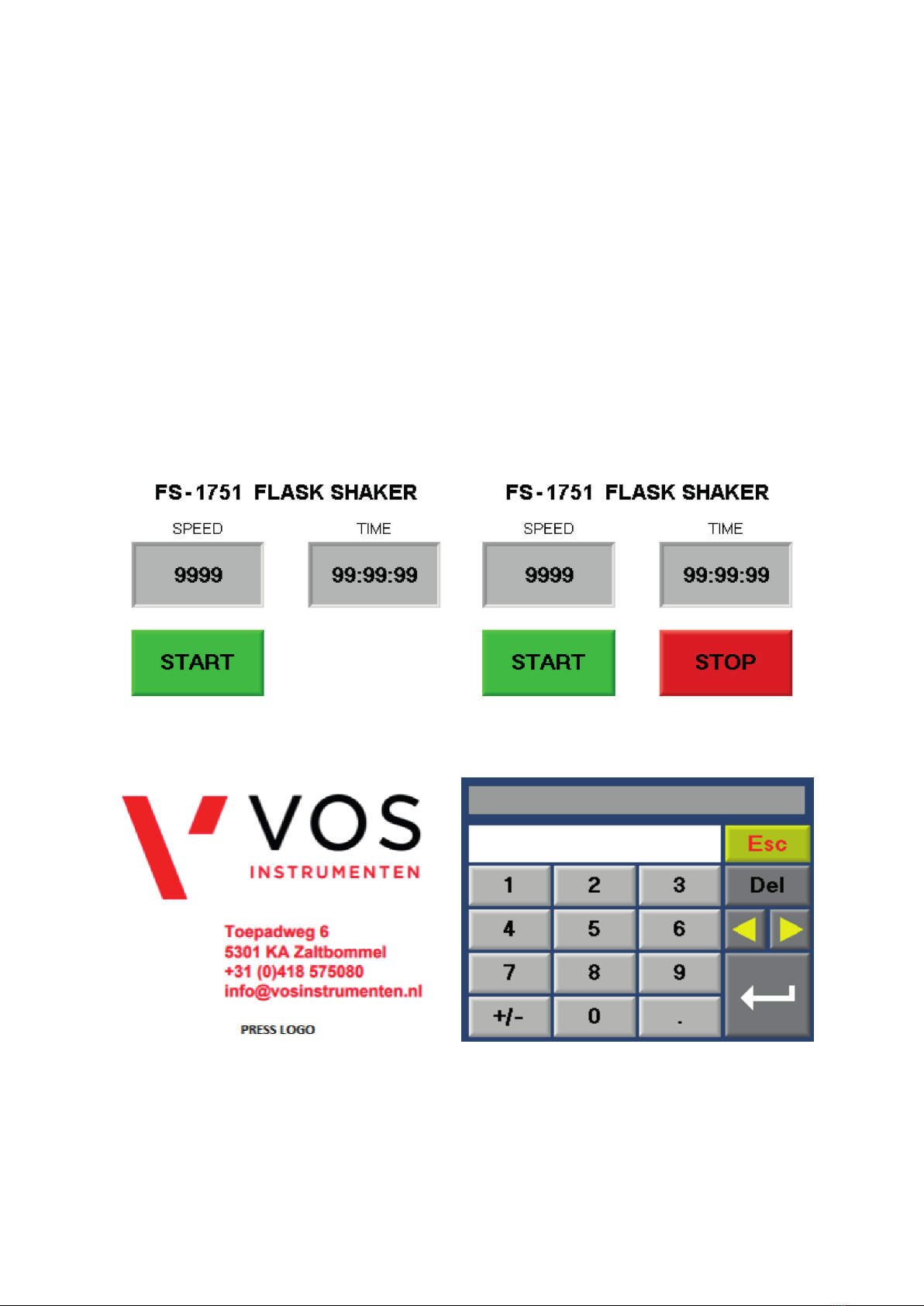

5OPERATING INSTRUCTIONS................................................................................................. 6

6MAINTENANCE AND SPARE PARTS ...................................................................................... 7

6.1 Maintenance....................................................................................................................... 7

6.2 Spare parts.......................................................................................................................... 7

7WARANTY .......................................................................................................................... 7

2