1-3. Initial Inspection

○Prior to shipment of this power supply was inspected and found free of mechanical or electrical defects

from the factory. Upon unpacking of the power supply, inspect for any damage, which may have

occurred in transit. Initial inspection should confirm that there is no exterior damage to the power

supply such as broken knobs or connectors and that the front panel and display panels are not

scratched or cracked. Keep all packing material until the inspection has been completed. If damage

is detected, file a claim with carrier immediately and notify VuPOWER(www.vupower.com) or

authorized service facility nearest you.

○This User Guide & Power Cable is included in the package.

○Product Warranty is at the end of this User Guide. Please record the ‘Product Series’, ‘Model Name’,

‘Purchased Date’, ‘Purchased From’, and ‘Serial Number’, for future use.

1-4. Environmental Conditions

○OXXOTM Series “K”Model power supply safety approval applies to the following operating conditions:

➢Ambient temperature: 0°C to 40°C

➢Maximum relative humidity: 80% (no condensation)

➢Altitude: up to 2000m

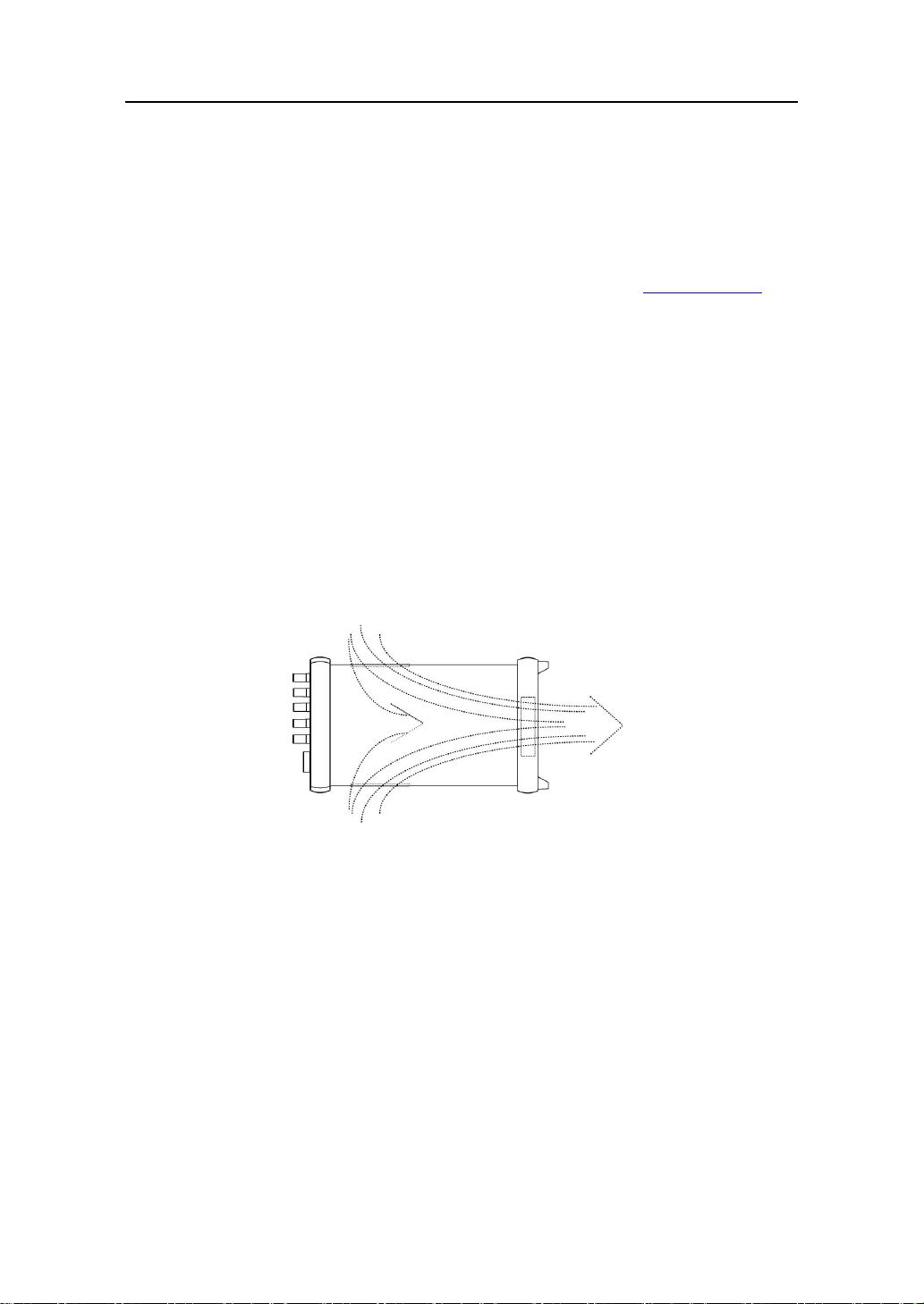

○OXXOTM Series “K”Model power supply is cooled by internal fan. Care must be taken to allow

unrestricted air space at the front and the rear of the unit for proper cooling of power supply. The air

intake is at the side panel ventilation inlets and exhaust is at the rear panel.

[Air Flow of OXXOTM Series “K”Model Power Supply]

○When mounting on equipment rack remove the front and rear bumpers and mount with caution.

Do not obstruct the air exhaust at the rear panel of the unit.

○Please operate this power supply in an environment with no humidity and vibrations.

1-5. Cleaning

○To prolong the life of OXXOTM Series “K”Model power supply periodic cleaning is necessary.

○To clean, disconnect the unit from the AC supply and allow 60 seconds for discharging internal voltage.

○Exterior panels should be cleaned with a mild solution of non-alcoholic detergent and water applied

onto a soft cloth.

○Internal cleaning should be done by removing the cover and blowing away the dust in the heat sink

and the cooling fan. Use low pressure compressed air to blow dust from the unit. Using sharp

metal objects to clean the dust is not recommended due to possibility of causing damage to the unit.