2

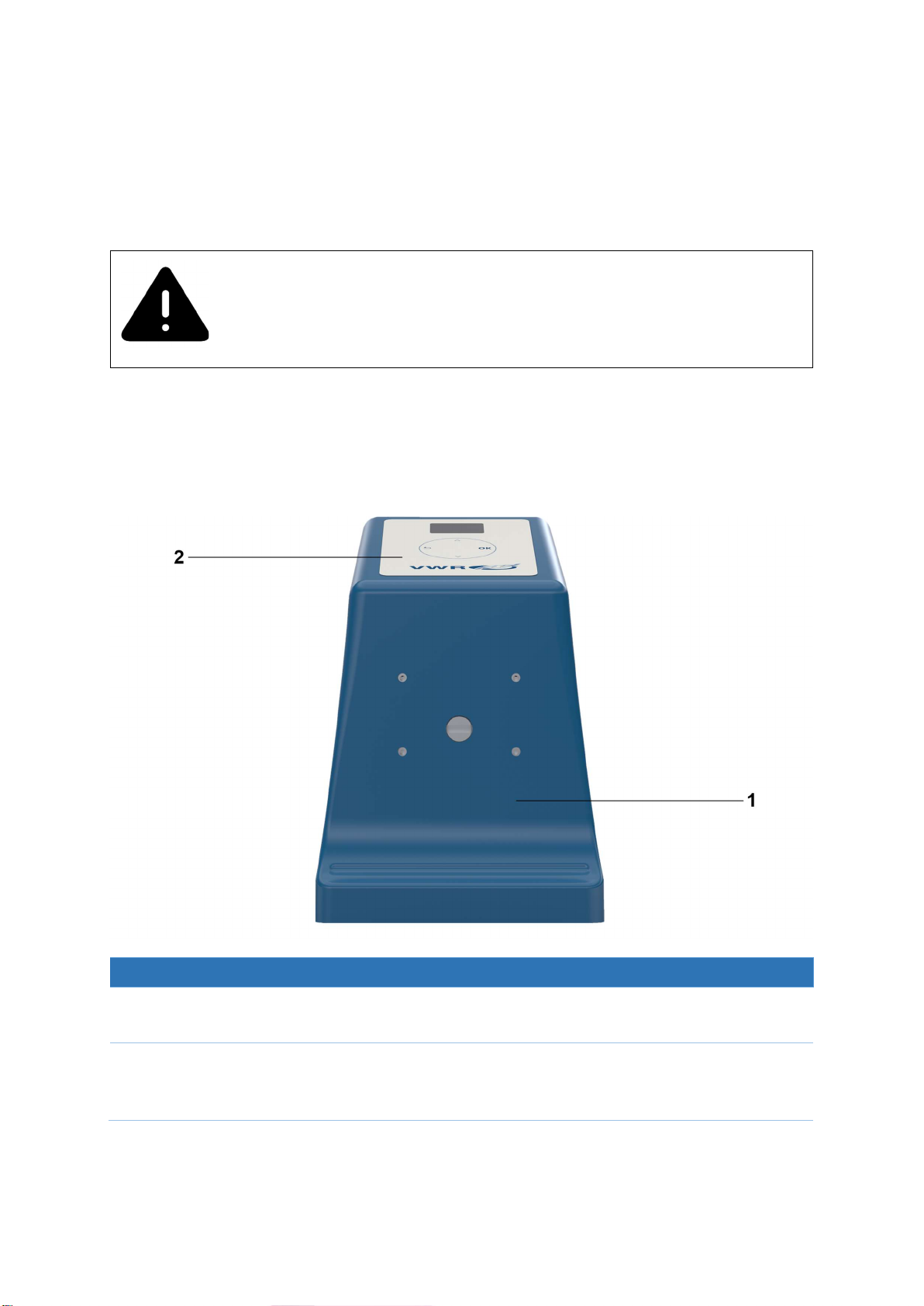

ATTENTION!

The pump head, tube or a cassette should only be changed when the pump is stopped.

The pump heads have rotating parts. They may only be operated when closed or fully

loaded with cassettes. Pump tubes have a certain gas permeability depending on the

material and pressure conditions. They can also become statically charged during op-

eration. This can cause hazards if tubes are installed in EX-protected zones.

Special care must be taken to ensure that no parts of the body such as fingers, hair,

etc. or loose objects such as jewellery and similar can get into the rotating parts of the

pump drive or the assembled pump head.

If liquid could leak out, due to a leakage on the tube or at tube connection points, the

appropriate safety precautions must be taken before commissioning.

Before use, check all media-carrying components for leaks.

Observe all general safety regulations for the working environment, such as the wear-

ing of protective clothing, safety goggles and protective gloves when using the corre-

sponding liquids.

Observe the notes and regulations from the reagent manufacturer.

Ensure that neither you nor any other person is endangered. Never work facing in the

direction of another person. Avoid splashing and use suitable collecting vessels. Al-

ways dispense onto the interior wall of the collecting vessel rather than directly onto its

base or the contents contained within it.

Never use force!

Ensure that the device is standing securely.

Use only original accessories and original spare parts.

Stop working immediately in the event of malfunctions, e.g. leaks or broken compo-

nents. Before continuing to use the device, observe the instructions for cleaning and

problem solving. If necessary, send the unit to the manufacturer for repair.

To avoid the risk of electric shock, do not place the device or the power supply unit in

water or other liquids!

Make sure that the voltage of the mains supply corresponds to the voltage indicated on

the power supply unit.

If the cable or power supply unit is damaged in any way, the power supply unit must

not be used any more.

Never touch the plug of the power supply unit with wet hands!

The power supply unit may only be used indoors. Protect it from moisture!