excluded in the event of repairs carried out on your own, improper operation.

- Ensure that children do not insert any objects into the fan blade and heat pump.

- Ensure that the electrical system to which the heat pump is connected has an earth conductor.

- If the unit would be installed where is vulnerable to lightning stroke, lightning protection

measurements must be carried out.

ATTENTION!

- The manufacturer declines any responsibility for the damage caused with the people,objects and of

the errors due to the installation that disobey the manual guideline. Any use that is without

conformity at the origin of its manufacturing will be regarded as dangerous.

- Please always keep the heat pump in the ventilation place and away from anything which could

cause fire.

- Don’t weld the pipe if there is refrigerant inside machine. Please keep the machine out of the

confined space when make gas filling by the authorized technician.

- Please always empty the water in heat pump during winter time or when the ambient temperature

drops below 0℃, or else the Titanium exchanger will be damaged because of being frozen, in such

case, it will be out of warranty for this machine.

- Please well keep the display controller in a dry area to protect the display controller from being

damaged by humidity.

Content

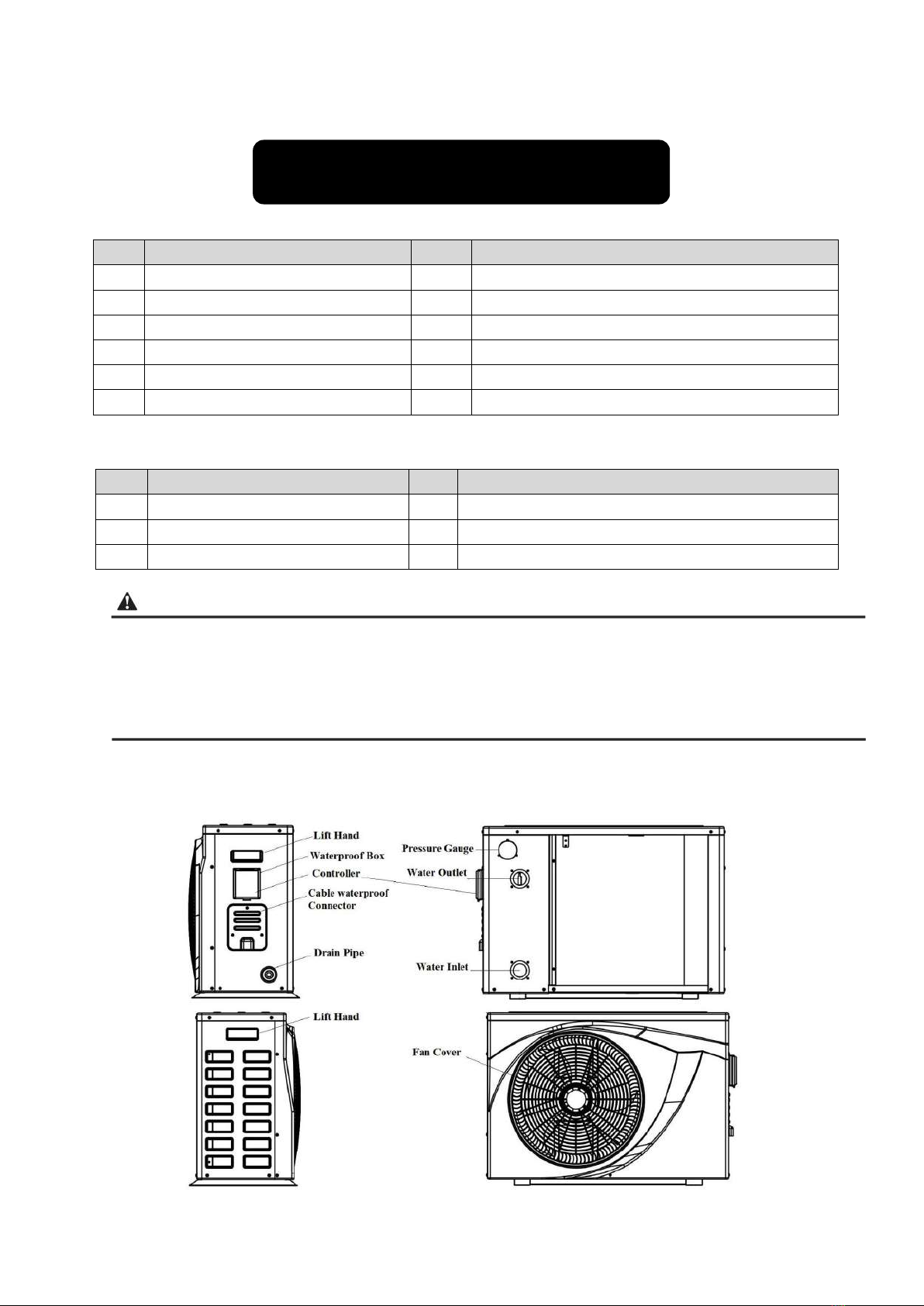

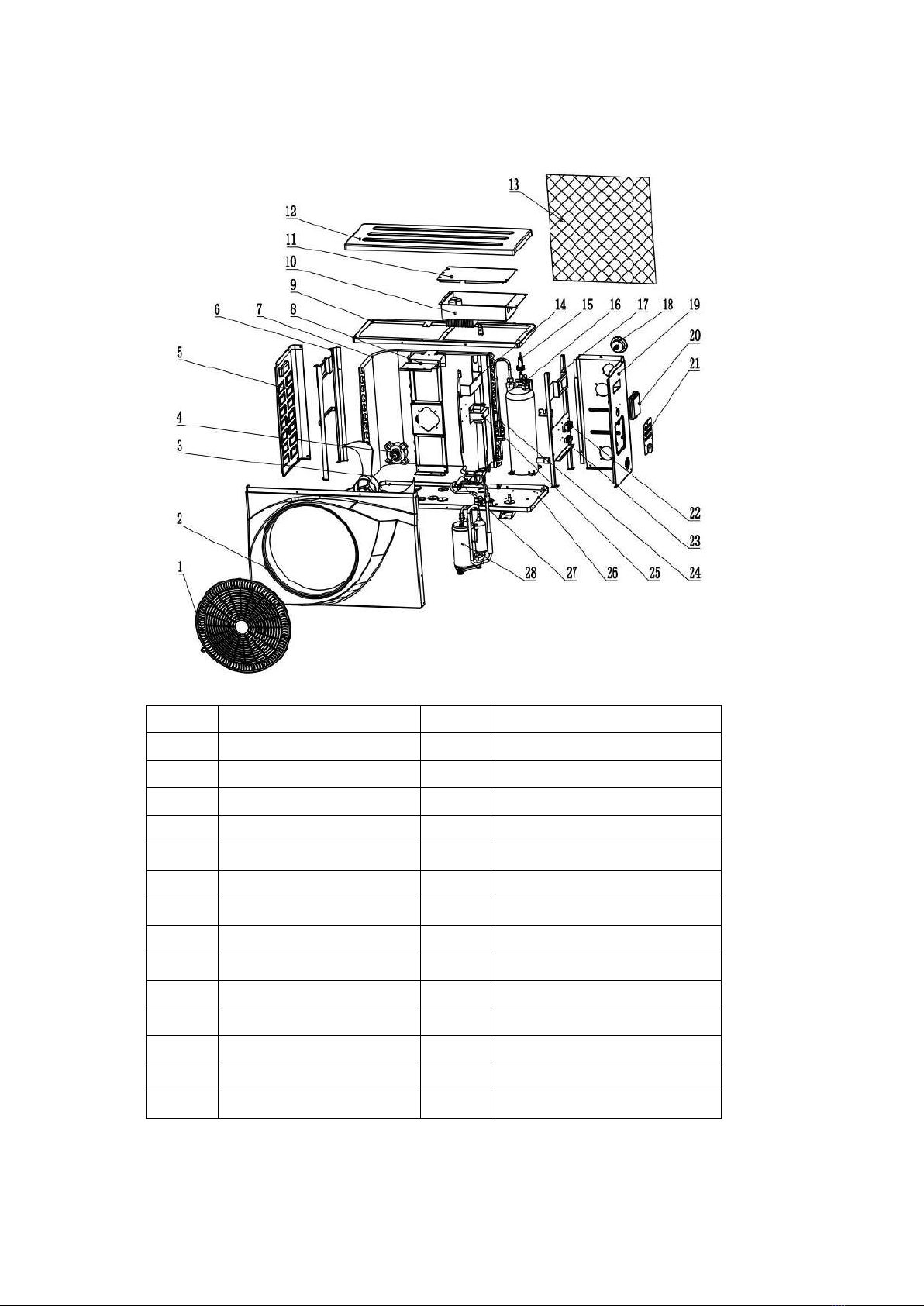

Accessories description............................................................................3

Attention for safety..................................................................................4

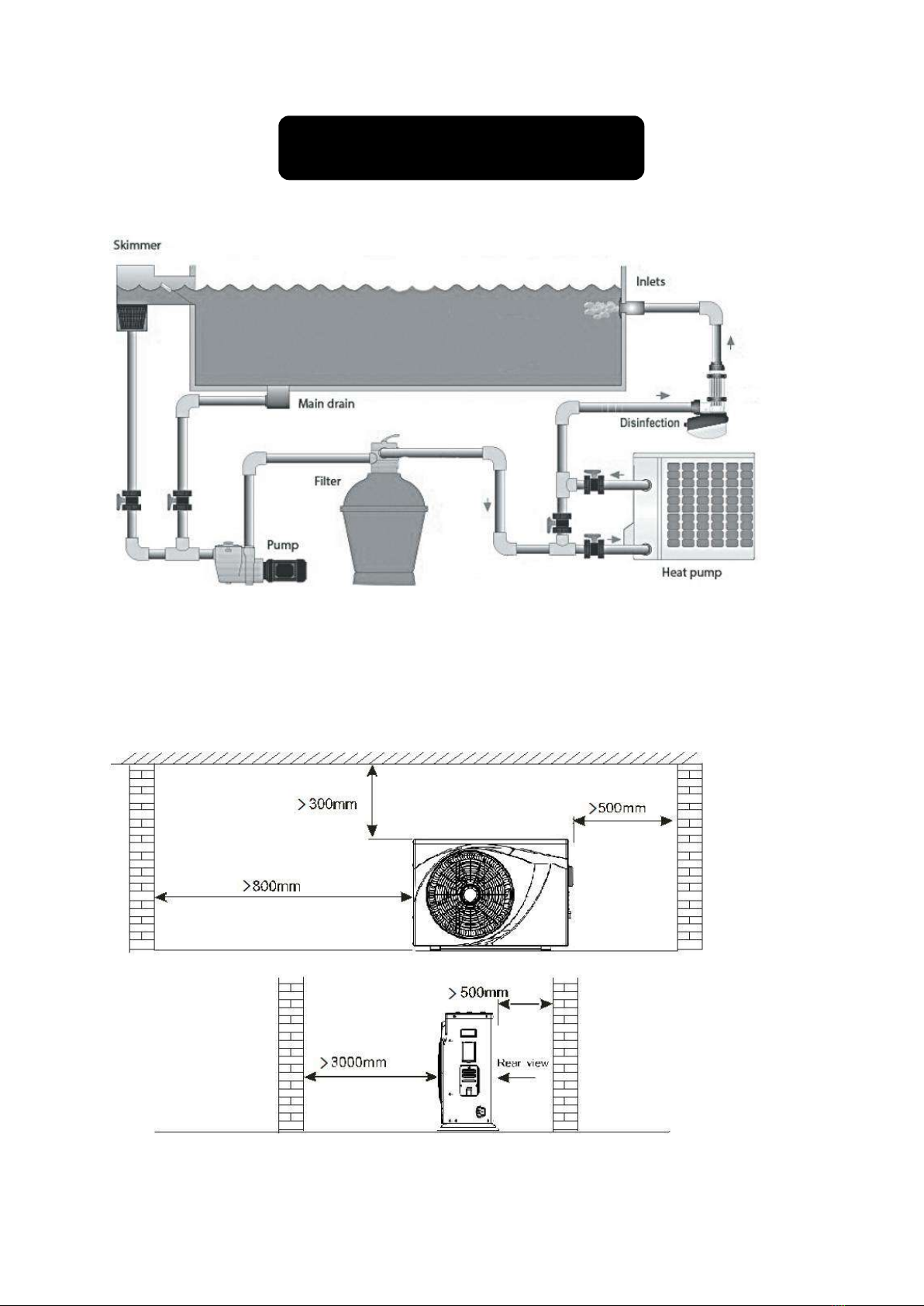

Installation of the unit.............................................................................5

Specifications..........................................................................................9

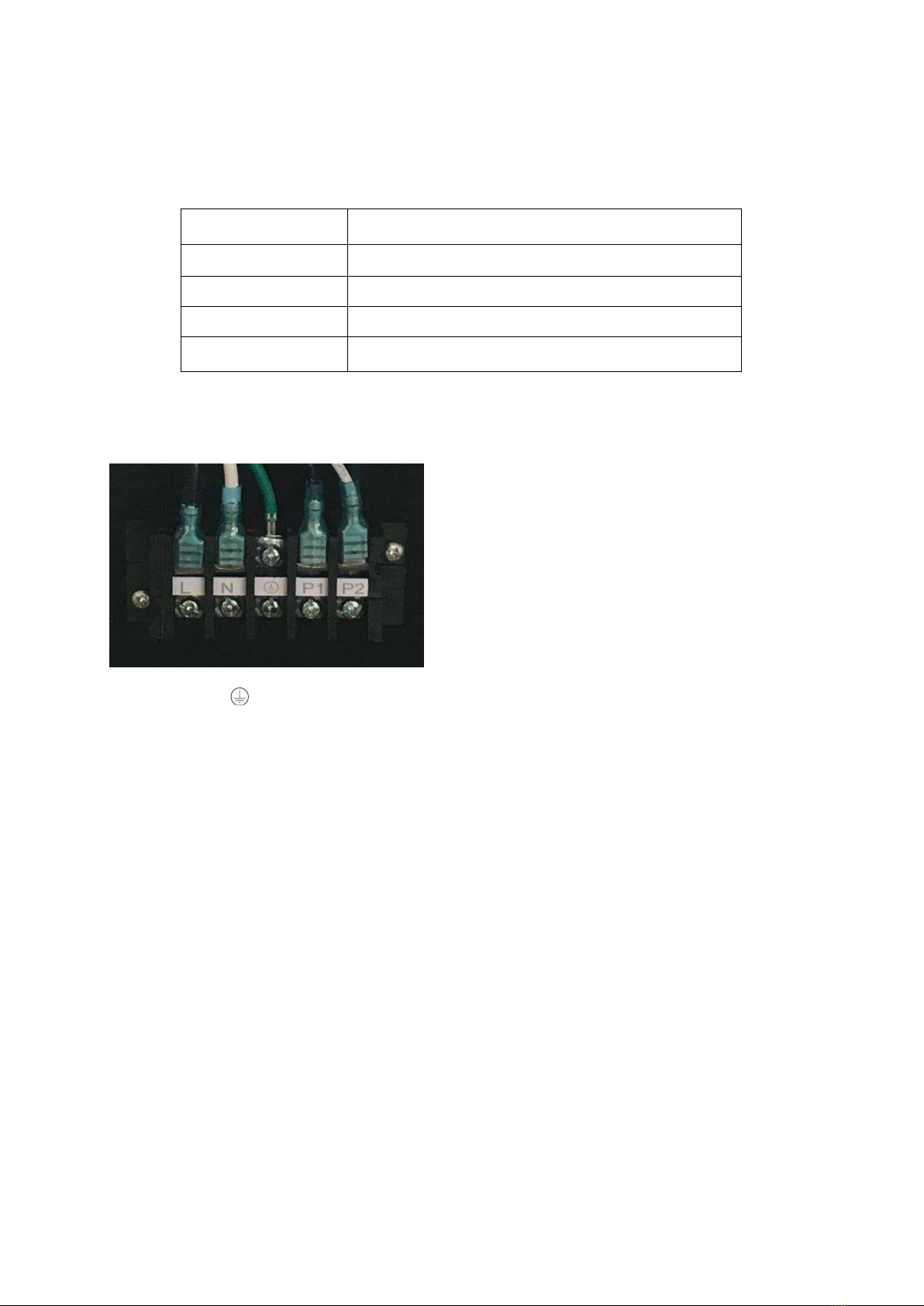

Electrical Wiring.....................................................................................10

Instruction of operation ........................................................................12

Adjusting and Initial operation...............................................................18

Operation and maintenance..................................................................19

Error codes & Solutions...................................................................... ...21

WiFi-Function........................................................................................23