WACKER Group DPU 25..H.. User manual

www.wackergroup.com

Operator´s Manual

Vibratory plate

DPU 25..H..

0109976en 002

10.2007

T00940GB.fm 3

Important information

This machine has been provided with an EPA-certified engine.

Additional information can be found in the engine

manufacturer‘s notes.

Engine exhaust, some of its constitvents, and certain vehicle

components contain or emit chemicals known to the State of

California to cause cancer and birth defects or other reproduc-

tive harm.

WARNING

Caution

This engine is an EPA engine.

Adjusting the engine speed will interfere with EPA certification and

the emissions.

Only authorized personnel can make adjustments to this engine.

Please contact you nearest engine dealer or your Wacker Dealer for more

information.

T00940GB.fm 4

Vorwort.fm 5

Foreword

1. Foreword

For your own safety and protection from bodily injuries, carefully read,

understand and follow the safety instructions in this manual.

Please operate and maintain your Wacker machine in accordance with

the instructions in this manual. Your Wacker machine will reward your

attention by giving trouble-free operation and a high degree of

availability.

Replace faulty or defective components Immediately.

All rights, especially the right for copying and distribution are reserved

Copyright 2007 by Wacker Construction Equipment AG

No part of this publication may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express permission in writing from Wacker Construction Equipment AG.

Any type or manner of reproduction, distribution or storage on data

carriers or storage mediums not authorized by Wacker represents an

infringement of valid copyrights and will be prosecuted. We expressly

reserve the right to make technical modifications - even without due

notice - which aim at improving our machines or increasing their safety

standards.

Table Of Contents

6

1. Foreword 5

2. Safety instruction 8

2.1 General instructions ..............................................................................8

2.2 Operation ...............................................................................................8

2.3 Safety checks ......................................................................................10

2.4 Maintenance ........................................................................................10

2.5 Transport .............................................................................................11

2.6 Maintenance checks ............................................................................11

3. Technical Data 12

4. Description 14

4.1 Applications .........................................................................................14

4.2 Dimensions ..........................................................................................14

4.3 Max. admissible inclination ..................................................................15

4.4 Description of function .........................................................................15

5. Transport to work site /Recommendations on compaction 17

5.1 Transport to work site ..........................................................................17

5.2 Recommendations on compaction ......................................................18

6. Operating instructions 19

6.1 Diesel fuel ............................................................................................19

6.2 Dry-type air filter ..................................................................................19

6.3 Air cleaner – inspecting the service indicator ......................................20

6.4 Starting the engine ..............................................................................20

6.5 Switching off the engine ......................................................................21

6.6 Short-term operation interruption ........................................................21

6.7 End of compaction operation ...............................................................21

7. Maintenance 22

7.1 Maintenance schedule ........................................................................22

7.2 Engine oil .............................................................................................23

7.3 Hydraulic control ..................................................................................25

7.4 Exciter .................................................................................................26

7.5 Exciter V-belt .......................................................................................27

Table Of Contents

7

8. Malfunction 28

8.1 Reverse speed too low ........................................................................28

8.2 Forward speed too low ........................................................................28

8.3 No advance .........................................................................................28

8.4 Loss of hydraulic oil .............................................................................28

8.5 Engine does not start ..........................................................................29

8.6 No vibration, even though engine is running .......................................29

9. Lables 30

EC - Conformity Certificate 31

DIN EN ISO 9001 Certificate 33

Safety instruction

SV00069GB.fm 8

2. Safety instruction

for the use of vibratory plates with combustion engines

2.1 General instructions

2.1.1 Vibratory plates may only be operated by persons who

∗are at least 18 years of age

∗are physically and mentally fit for this job

∗have been instructed in guiding vibratory plates and proved their ability

for the job to the employer

∗may be expected to carry out the job they are charged with carefully.

The persons must be assigned the job of guiding vibratory plates by

the employer.

2.1.2 Vibratory plates may only be used for compaction jobs. Both the

manufacturer’s operating instructions and these safety instructions

have to be observed.

2.1.3 The persons charged with the operation of vibratory plates have to be

made familiar with the necessary safety measures relating to the

machine. In case of extraordinary uses the employer shall give the

necessary additional instructions.

2.1.4 This machine generates noise that exceeds the country-specific

permissible noise levels (individual rating level). It may therefore be

necessary to wear ear protection

2.2 Operation

2.2.1 Only use original spare parts. Modifications to this machine, including

the adjustment of the maximum engine speed set by the manufacturer,

are subject to the express approval of Wacker. In case of

nonobservance all liabilities shall be refused.

2.2.2 The function of operation levers or elements is not to be influenced or

rendered ineffective.

2.2.3 During operation the operator may not leave the control elements.

2.2.4 The operator has to stop the engine of the vibratory plate before going

on breaks. The machine has to be placed such that it cannot turn over.

Safety instruction

SV00069GB.fm 9

2.2.5 Stop engine before filling fuel tank. When refilling fuel tank, do not

allow fuel to come into contact with the hot part of the engine or spill

onto the ground.

2.2.6 Do not smoke or handle open fire near this machine.

2.2.7 The tank lid must fit tightly. Shut fuel cock if available when stopping

the engine. For long distance transports of machines operated by fuel

or fuel- mixtures, the fuel tank has to be drained completely.

Leaky fuel tanks may cause explosions and must therefore be

replaced immediatelly.

2.2.8 Do not operate this machine in areas where explosions may occur.

2.2.9 Make sure that sufficient fresh air is available when operating vibratory

plates equipped with combustion engines in enclosed areas, tunnels,

galleries and deep trenches.

2.2.10 During operation keep your hands, feet and clothes away from the

moving parts of the vibraton plate. Wear safety shoes, and eye

protection glasses in case of trench operation where falling sand

stones maybe ejected.

2.2.11 When working near the edges of breaks, pits, slopes, trenches and

platforms, vibratory plates are to be operated such that there is no

danger of their turning over or dropping in.

2.2.12 Make sure the soil or subsoil to be compacted has a high enough load

carrying capacity.

2.2.13 Use appropriate protective clothing while working or while carrying out

maintenance work.

2.2.14 When traveling backwards the operator has to guide the vibration plate

laterally by its guide handle so that he will not be squeezed between

the handle and a possible obstacle. Special care is required when work

ing on uneven ground or when compacting coarse material. Make sure

of a firm stand when operating the machine under such conditons.

2.2.15 Vibratory plates are to be guided such that hand injuries caused by

solid objects are avoided.

2.2.16 Vibratory plates have to be guided such that their stability is

guaranteed.

2.2.17 Machines with integrated transport trolley may not be parked or stored

on the trolley. This device has only been designed to transport the

machine.

Safety instruction

SV00069GB.fm 10

2.3 Safety checks

2.3.1 Vibratory plates may only be operated with all safety devices installed.

2.3.2 Before starting operation, the operator has to check that all control and

safety devices function properly.

2.3.3 If defects in the safety equipment or other defects are detected which

impair the safe operation of the internal vibrator, the supervisor is to be

notified without delay.

2.3.4 The machine must to be switched off immediately in case of defects

jeopardizing the operational safety of the equipment.

2.3.5 Process materials and operating fuels must be stowed away in

receptacles or containers marked according to the respective

manufacturers specifications.

2.4 Maintenance

2.4.1 Only use original spare parts. Modifications to this machine including

the adjustment of the maximum speed set by the manufacturer are

subject to the express approval of WACKER. In case of

nonobservance all liabilities shall be refused.

2.4.2 All drive units have to be switched off before carrying out maintenance

jobs. Deviations from this are only allowed if the maintenance or jobs

require a running engine.

2.4.3 When working on vibratory plates equipped with electric starter,

disconnect battery before carrying out maintenance or repair jobs on

the electric parts of the machine.

2.4.4 Remove pressure from hydraulic lines before working on them.

Caution: take care when removing hydraulic lines, for the oil may be

very hot (up. over 80° C). Precautions are to be taken to prevent oil

from splashing into the operator’s eyes.

2.4.5 All safety devices must be reinstalled properly immediately after

maintenance and repair jobs have been completed.

2.4.6 Do not hose down the machine with water after each use to avoid

possible malfunctions. Do not use high pressure washers nor chemical

products.

Safety instruction

SV00069GB.fm 11

2.5 Transport

2.5.1 During transport, loading and unloading of vibration plates by means

of lifting devices, appropriate slinging means or hooks have to be used

on the lifting points provided for this purpose on the vibratory plate.

2.5.2 The load-carrying capacity of the loading ramps has to be sufficient

and the ramps have to be secure such that they cannot turn over. Make

sure that no one be endangered by machines turning over by slipping

or by moving machine parts.

2.5.3 When being transported on vehicles, precautions have to be taken that

vibration plates do not slip or turn over.

2.6 Maintenance checks

2.6.1 According to the conditions and frequency of use, vibratory plates have

to be checked for safe operation at least once a year by skilled

technicians, such as those found at WACKER-service depots and

have to be repaired if necessary.

Please also observe the corresponding rules and regulations valid in your

country.

Technical Data

TD00682GB.fm 12

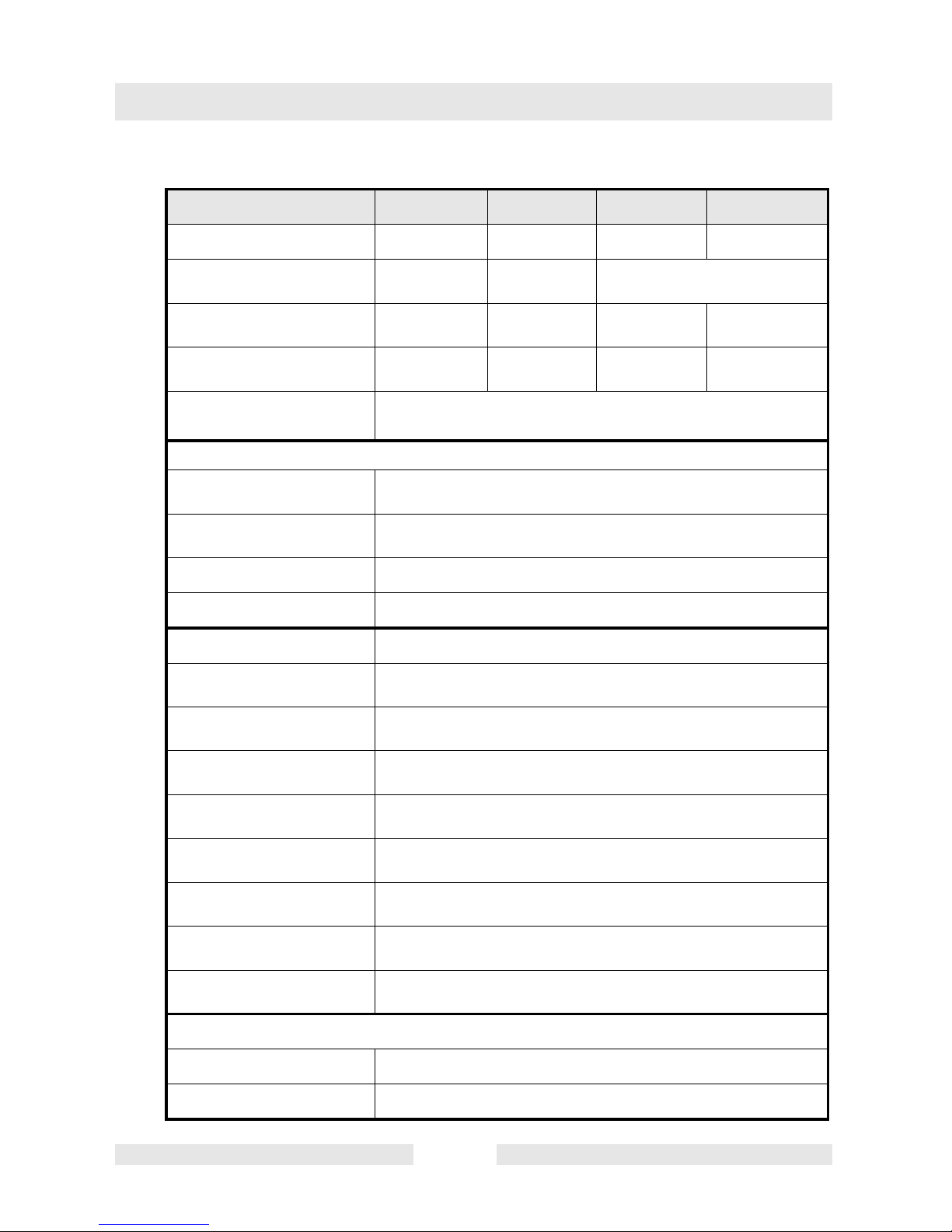

3. Technical Data

DPU 2540H DPU 2550H DPU2560H DPU 2560H-TS

Item no. 0610035 0610036 0610037 0610038

Operating weight kg: 160 166 171

Advance and reverse travel

m/min: 24 22 20 23

Compacted area m2/h: 576 660 720 828

Kraftübertragung From drive engine directly to exciter unit via centrifugal

clutch and V-belt

Exciter

Vibrations min-1 (Hz): ca. 5400 (90)

Centrifugal force kN: 25

Oil Fuchs Titan Unic 10W40 MC (SAE 10W40)

Oil quantity l: 0,6

Drive motor Air-cooled single-cylinder 4-cycle diesel engine with recoil starter

Piston displacement cm3:232

Engine speed (rpm) min-1:2800

Rated power (*) kW (PS): 3,1 (4,2)

Fuel Diesel

Fuel consumption l/h: 0,4

Tank capacity l: 3,0

Oil Fuchs Titan Unic 10W40 MC (SAE 10W40)

Oil quantity l: 0,9

Hydraulic control

Hydraulic oil Fuchs Renolin MR 520

Oil quantity 0,4

Technical Data

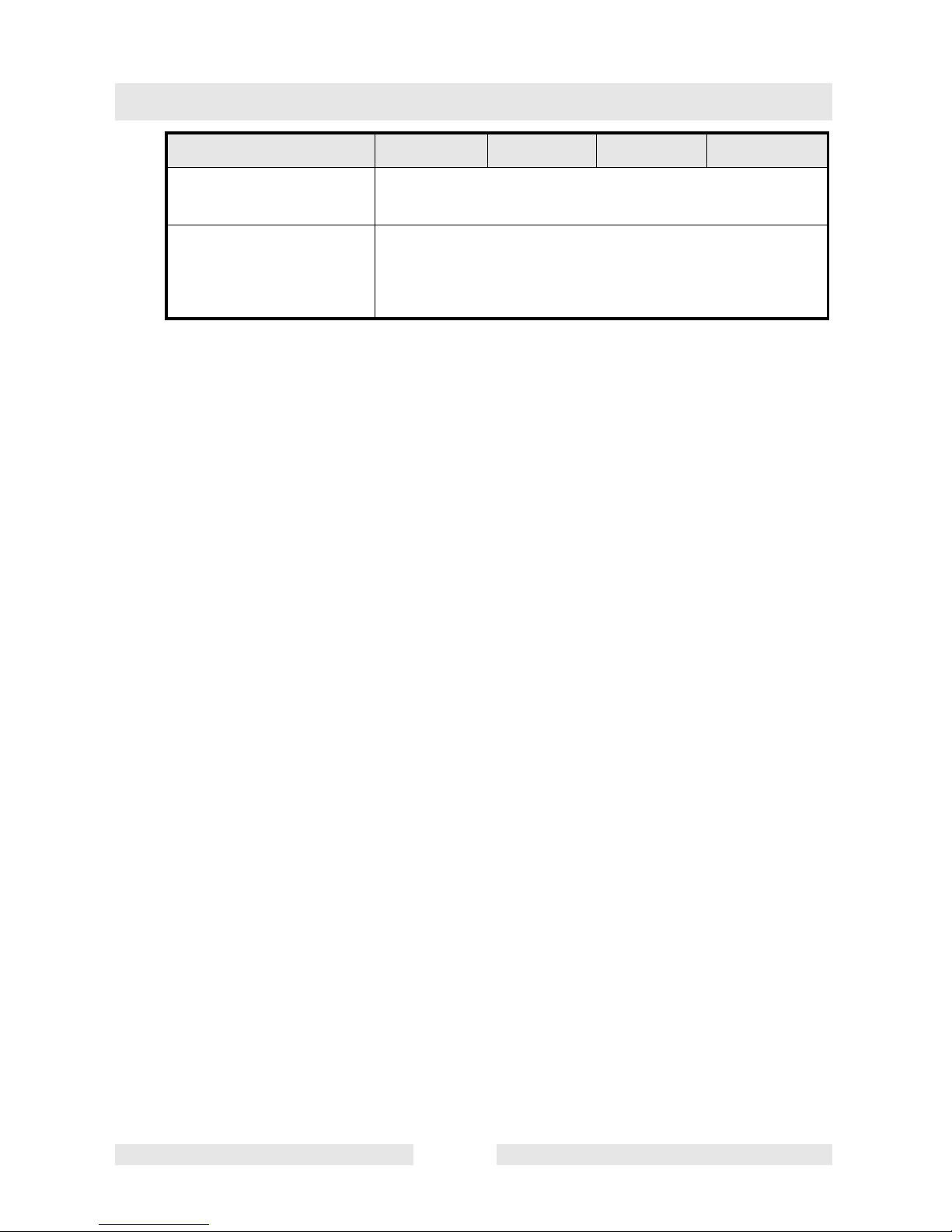

TD00682GB.fm 13

(*) In accordance with the installed useful outlet power according to Directive 2000/14/

EG

Special lubricating

grase LPA:94 dB(A)

The weighted effec-

tive acceleration

value, determined

according to

EN ISO 5349

m/s2:is 8,8

DPU 2540H DPU 2550H DPU2560H DPU 2560H-TS

Description

T00978GB.fm 14

4. Description

4.1 Applications

This vibratory plate is optimally suited for all types of soil compaction

applications in confined areas thanks to it’s narrow design and the

infinitely variable change of direction; application examples are e.g.

compaction in cable trenches, marginal strip compaction during

asphalt pavement patchwork as well as all those compaction jobs for

which the use of larger machines is not convenient.

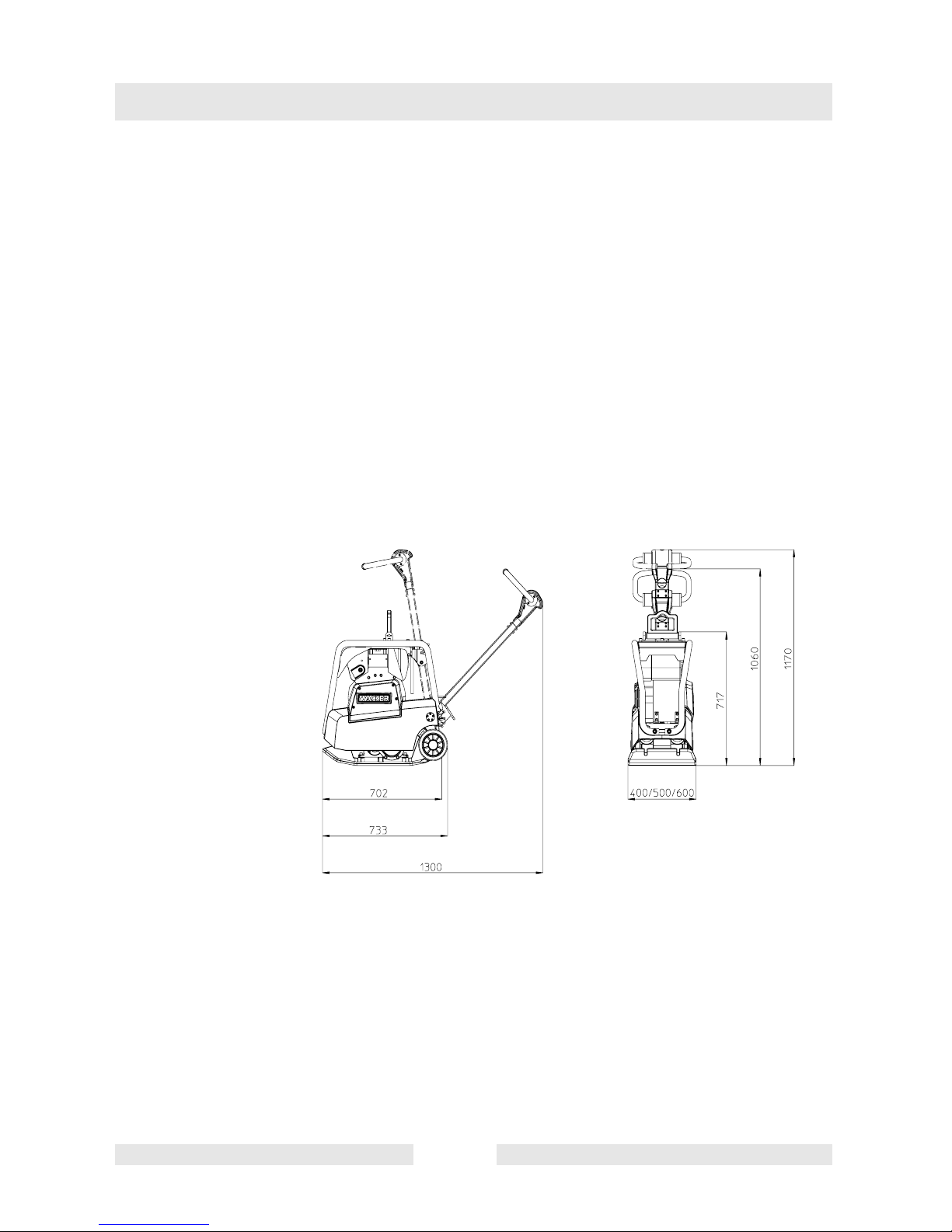

4.2 Dimensions

Description

T00978GB.fm 15

4.3 Max. admissible inclination

4.4 Description of function

4.4.1 The vibration required for compaction is produced by the exciter (5)

which is firmly joinded to the lower mass (4). This exciter (5) is

designed as a central vibrator with aligned vibrations. Such a principle

permits the direction of vibration to be changed by turning the eccentric

weights (13). In this way an infinitely variable transition between

vibration in forward motion, at standstill and in reverse motion is

possible.

This process is hydraulically controlled with the operating control

handle (7) on the centre pole head (8).

Description

T00978GB.fm 16

4.4.2 The drive engine (1) is anchored to the upper mass (3) and drives the

exciter (5). The torque is transmitted by means of a friction connection

through the centrifugal clutch (9) and the exciter V-belt (10).

4.4.3 The centrifugal clutch (9) interrupts flow of power to the exciter (5) at

low engine speeds and thus permits perfect idling of the drive engine

(1). The speed of the drive engine (1) can be infinitely varied by way of

the throttle lever (6).

4.4.4 The upper (3) and lower (4) masses are connected to each other by 4

vibration-damping shock mounts (11). This damping system prevents

the very high frequencies from being transmitted to the upper mass (3).

As a result the functionability of the drive engine (1) is retained in spite

of the high compaction performance.

4.4.5 The drive engine (1) works according to the diesel principle, is

equipped with a recoil starter, draws in combustion air through a dry

type air cleaner (12) and is air-cooled.

Forwards Reverse

On the spot

Transport to work site /Recom-

T00979GB.fm17

5. Transport to work site /Recommendations on

compaction

5.1 Transport to work site

Conditions:

∗To transport the vibration plate, use only suitable lifting equipment with

a minimum load-bearing capacity of 200 kg.

∗Only attach suitable tackle at the central lifting point (15) provided.

∗Always tie down the vibratory plate by the protective frame (14) and

latch the center pole in place during transport of the vibratory plate on

the loading area of a transport vehicle.

The engine must be stopped when using the integrated transport

device. Lubrication of the engine is not guaranteed if the engine is

running when the plate is in transport position.This could lead to

serious engine damages.

Furthermore the danger exists that oil will spill out of the crankcase

breather.

Note: Also observe the regulations in the chapter “Safety instructions“.

Transport to work site /Recommendations on compaction

T00979GB.fm18

5.2 Recommendations on compaction

5.2.1 Ground conditions

The max. compaction depth depends on several factors relating to the

ground condition, such as moisture, grain distribution etc,

it is therefore not possible to specify exact values.

Recommendation: In each case determine the max. compaction

depth with compaction tests and soil samples.

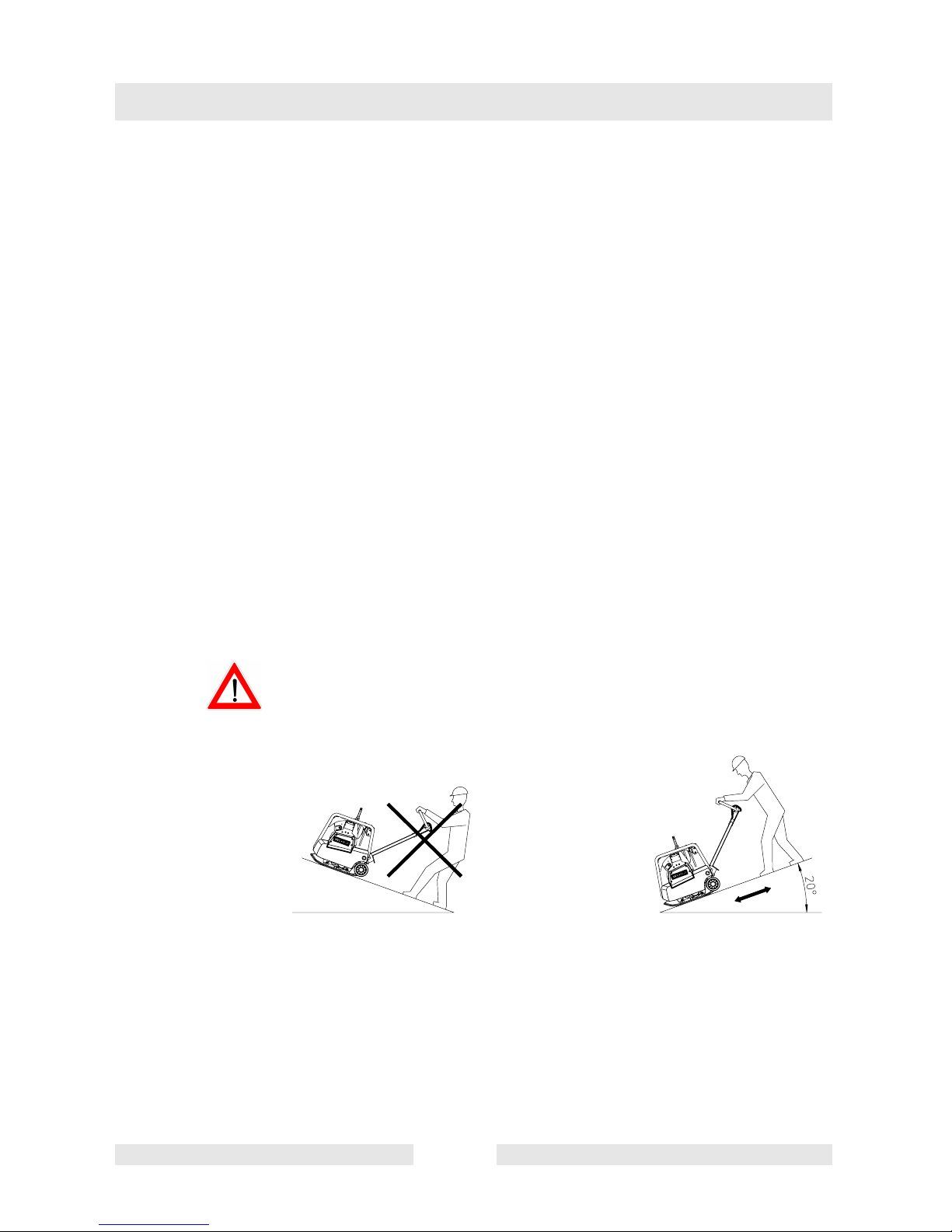

5.2.2 Compaction on slopes

The following points are to be observed when compacting on sloped

surfaces (slopes, embankments):

∗Only approach gradients from the bottom (a gradient which can be

easily overcome upwards, can also be compacted downwards without

any risk).

∗The operator must never stand in the direction of descent (see chapter

“safety instructions“).

∗The max. gradient of 20omust not be exceeded.

If this gradient were exceeded, this would result in a failure of the

engine lubrication system and thus inevitably lead to a breakdown of

important engine components.

Wrong! Right!

Operating instructions

T00980GB.fm 19

6. Operating instructions

6.1 Diesel fuel

Only use pure diesel fuel.Close fuel tank immediately. It is important to

maintain absolute cleanliness to avoid otherwise inevitable trouble

with the fuel injection system, and to avert a premature clogging up of

the fuel filter. Do not open the fuel line nor the fuel pump or any other

point of the fuel system to avoid danger of dirt contamination, not

even for bleeding of air. The fuel pump will bleed automatically. This

applies even should the fuel tank have run dry by mistake. In such a

case simply refill fuel tank.

6.2 Dry-type air filter

A loss of engine power with a simultaneous belching of smoke

indicates a plugged-up air filter. Remove filter cartridge and clean by

light tapping to dislodge dust from the paper element.

Clean filter housing! Use a clean rag, do not clean with compressed

air. While cleaning avoid by all means introducing dirt into the engine

intake port.

Operating instructions

T00980GB.fm 20

6.3 Air cleaner – inspecting the service indicator

Set the engine to full rpms for a short period of time. If the bellows is

drawn together during this time and the green field „1“ is covered, then

the air cleaner system is due for maintenance. Check the rubber

bellows repeatedly per day when working in dusty environments.

6.4 Starting the engine

∗Only start with the engine starting procedure once a sufficiently stable

position is assured.

∗Move throttle lever to start position.

∗Slowly pull out starter rope until the engine’s compression resistance

can be felt.

∗At this point let starter rope slowly return into starter housing.

∗Now start the engine. Pull out the rope (evenly, not by jerks as is usual

with gasoline engines) and turn the engine with ever increasing speed.

Use complete length of starter rope.

Table of contents

Other WACKER Group Power Tools manuals