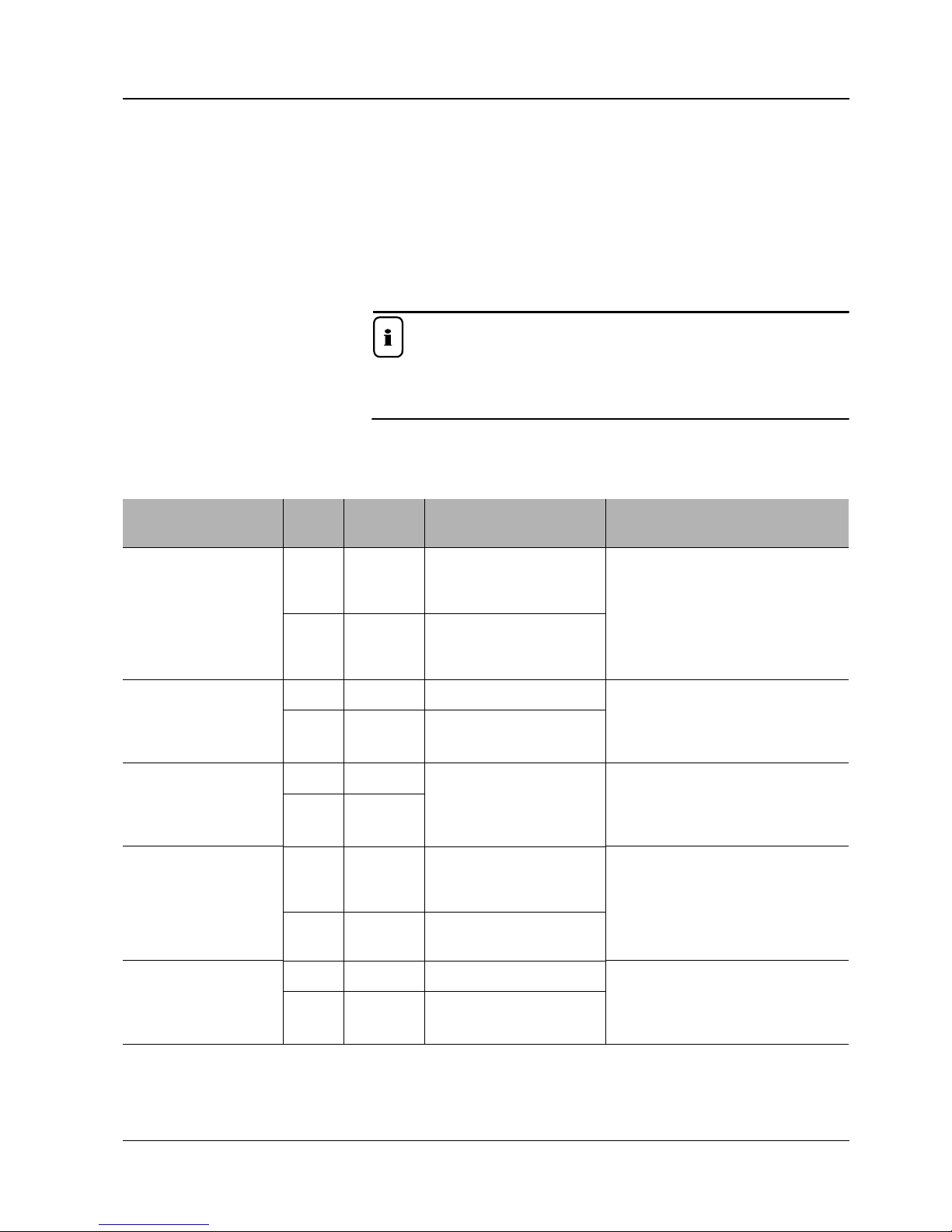

1-6 BA34603_04US–Edition2.1*34603_04b110.fm

Introduction

See“MerkblattfürAnbaugeräte“(leafletwithspecificinstructionsfor attachments)§30clauses10/11/12of theStVZOGermanroadtrafficregulationsforfurtherinformationonmountingattachments.

High-tilt bucket3, 4, 5 WL 750 1000156433

1000108803 1850 mm (72.83”) without teeth

1850 mm (72.83”) without teeth As standard bucket, with a 80 – 100 cm

higher dump height

(material density ≤p = 1.8 t/m³)

(material density ≤p = 112 lbs./cu. ft.)

WL 850 1000156433

1000154475 1850 mm (72.83”) without teeth

Heavy duty bucket with

hydraulic clamp3, 4, 5

WL 750 1000111090 1850 mm (72.83”) Picking up and transporting e.g. bulky recy-

cling material

(material density ≤p = 1.3 t/m³)

(material density ≤p= 81 lbs./cu. ft.)

WL 850 1000111053 2050 mm (80.70”)

Heavy duty forks with

hydraulic clamp

(silage bucket)3, 4 WL 750

WL 850 1000128262 1800 mm (70.86”)

Picking up and transporting e.g. bulky and

fibrous recycling material (e.g. grass,

manure, brushwood;

material density ≤p = 1.3 t/m³)

(material density ≤p= 81 lbs./cu. ft.)

Pallet forks3, 4, 6 WL 750

WL 850 1000101820

1000101822 1000 mm (39.37”)

1200 mm (47.24”) Picking up and transporting

pallets

Palletforks withfoldable fork

arms3, 6, 7 WL 850 1000147393 1200 mm (47.24”) Picking up and transporting

pallets

Material pusher3, 4 WL 750

WL 850 1000050660 3000 mm (118.11”) For moving loose bulk material

Manure forks with grab WL 750

WL 850 1000178474 1800 mm (70.86”) Picking up and transporting e.g. grass,

manure, brushwood and straw

Hydraulic round bale clamp WL 750

WL 850 1000177701 800 – 1800 mm

(31.49 – 70.86”) Picking up and transporting round bales

Tree replanter3, 4 WL 750

346-02 1000100840 – Digging and transporting nursery trees

Front scarifier3, 4 WL 750

WL 850 1000100841 – Scarifying dense soil, loosening humus soil

Work platform8WL 750

WL 850 1000109953 – For repair, assembly, disassembly, mainte-

nance and inspection work above ground

Rotary broom WL 750

WL 850 1000139717 – Cleaning roads or facilities

Snow plow2, 3, 4, 9WL 750

WL 850 1000142915 – Winter service

1. Bucket with screwed-on exchangeable blade

2. Only in connection with additional lights order no. 1000105002 and mounting kit order no. 1000137629 when traveling on public roads

3. See the Operator's Manual of the attachment for putting the attachment into service and using it

4. Not certified for traveling on public roads (individual certification may be possible depending on your country's legislation)

5. Only in connection with restrictor unit order no. 1000114139

6. Only in connection with load diagrams for model WL 750 (order no. 1000138363) and for model WL 850 (order no. 1000143064)

7. Get informed on the legal regulations of your country which may require specific permits, certifications, registrations etc. for use on public roads!

8. Model WL 750: only in connection with assembly 1000169659

Model WL 850: only in connection with assembly 1000169660

9. Only in connection with rotating beacon order no. 1000133985

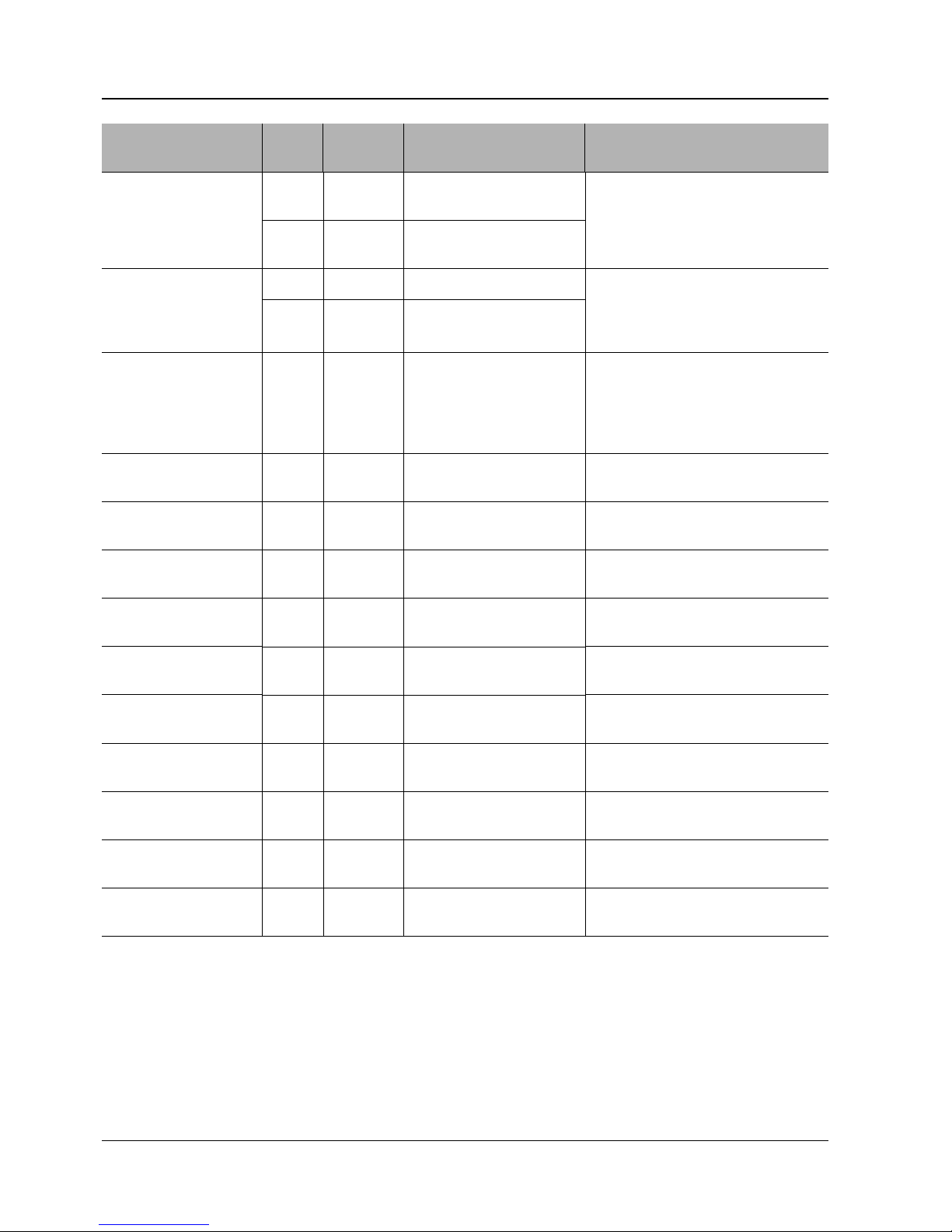

Description of

attachment

Wheel

loader

Part no.

(model) Dimensions Use