5

Assembly of Roof, Sides and Ends

9. Offer up eaves gutter to bolts and, taking care to push

fully home, tighten securely both roof end glazing bars.

10.Repeat instructions 8 and 9 for other side.

11.Turn completed assembly over.

NOTE: It would be most advisable to

obtain assistance in carrying out

instruction 11 – particularly with larger

buildings.

THE SIDES

12.Identify Side and Corner Glazing Bars (Nos. 2 and 8,

ID Chart) and lay out roughly in position. Thread PVC

Glazing Strip into the grooves provided in all glazing

bars. Fit PVC strip only to the inside grooves of corner

glazing bars.

NOTE: If fitting a partition or extension

read in conjunction with pages 11.

13.Loosely fit nuts and bolts in all remaining holes in the

roof assembly taking care that square bolt heads face

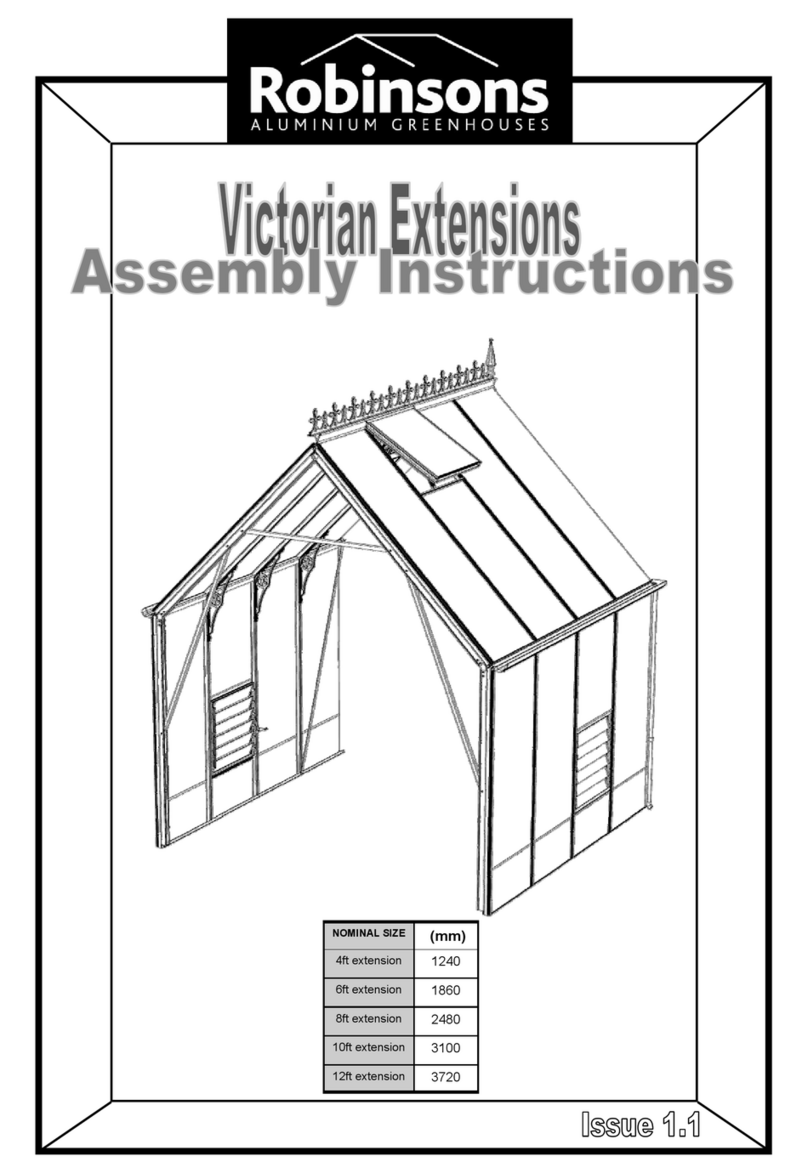

outward. Fit long bolts (No. 9, ID Chart) in the end

holes of each eaves gutter and in the bottom hole of

each roof end glazing bar. A strengthening brace will

be fitted to the long bolts at a later stage.

14.Liftingonesideoftheroofassemblyonly,slideacentre

intermediateglazingbarontothepreviouslyfittedbolt

in the eaves gutter. Tighten nut securely.

15.Fit remainderofintermediateglazingbarstothe same

side.

16.Slide corner glazing bars (No. 8, ID Chart) onto the

bolts previously fitted in end of gutter and bottom of

roof end glazing bar.

17.If fitting a louvre, slide two short bolts up each

adjoiningsideglazing bars and securewith nuts.Then

slide long bolts up each of the side glazing bars

(including corners) and lock temporarily in position.

18.Identify side base rail (No.10, ID Chart), place in

position,then attach using bolts temporarily locked in

glazing bars.

19.Liftothersideofgreenhouse,fitcentreglazingbarand

proceed as for previous side until complete.

20. Fit two diagonal braces to each side as shown on page

1. The long bolts at the top of the corner glazing bar

and at the bottom of the glazing bars will be long

enough to accommodate the brace. The sides are now

complete.

PLAIN END AND DOOR END

21.Identify end gable base rail. (No. 11, ID Chart) and

loosely fit long bolt to end holes

22.Fit corner glazing bars onto gable base rail (door end)

as shown and secure.

23.Identifyplainendgablebaserail(No.11,IDChart)and,

remembering to slide an additional short bolt into

corner(Gableend side)glazingbars(Royale &Rosette

only) for fitting plain end purlin at later stage. Repeat

procedure as for door end base rail.

24.Identify plain end glazing bars (door end glazing bars

are the same) and slide up onto bolts in roof end

glazingbarsandapexplateasappropriate.ForRegent

models no centre glazing bar is fitted.

25.Slide a short bolt approximately 1/2 way up each bar

and temporarily lock in position (Royale & Rosette

only).

lift

Locate bolt

heads into corner

glazing bar

Gable end

glazing bar

Side rail

Gable end base rail