r

LU

'

TI

NG

THE

MACHINE

IS

NORMALLY

SUPPLIED

COVERED

IN

PLASTI C

SH

EET WI

TH

SUNDR

Y

lTEMS

PACKED

IN

BOXES

AND

STRAPPED

TO

THE MACHINE FRAME. BEFORE

LIFTING

TO

WORK

POSITI

ON

REMO

VE SH

EET

I

NG

AND

ALL

BOXES

ALOKG

WITH

ANY

LOOSE ITEM

S.

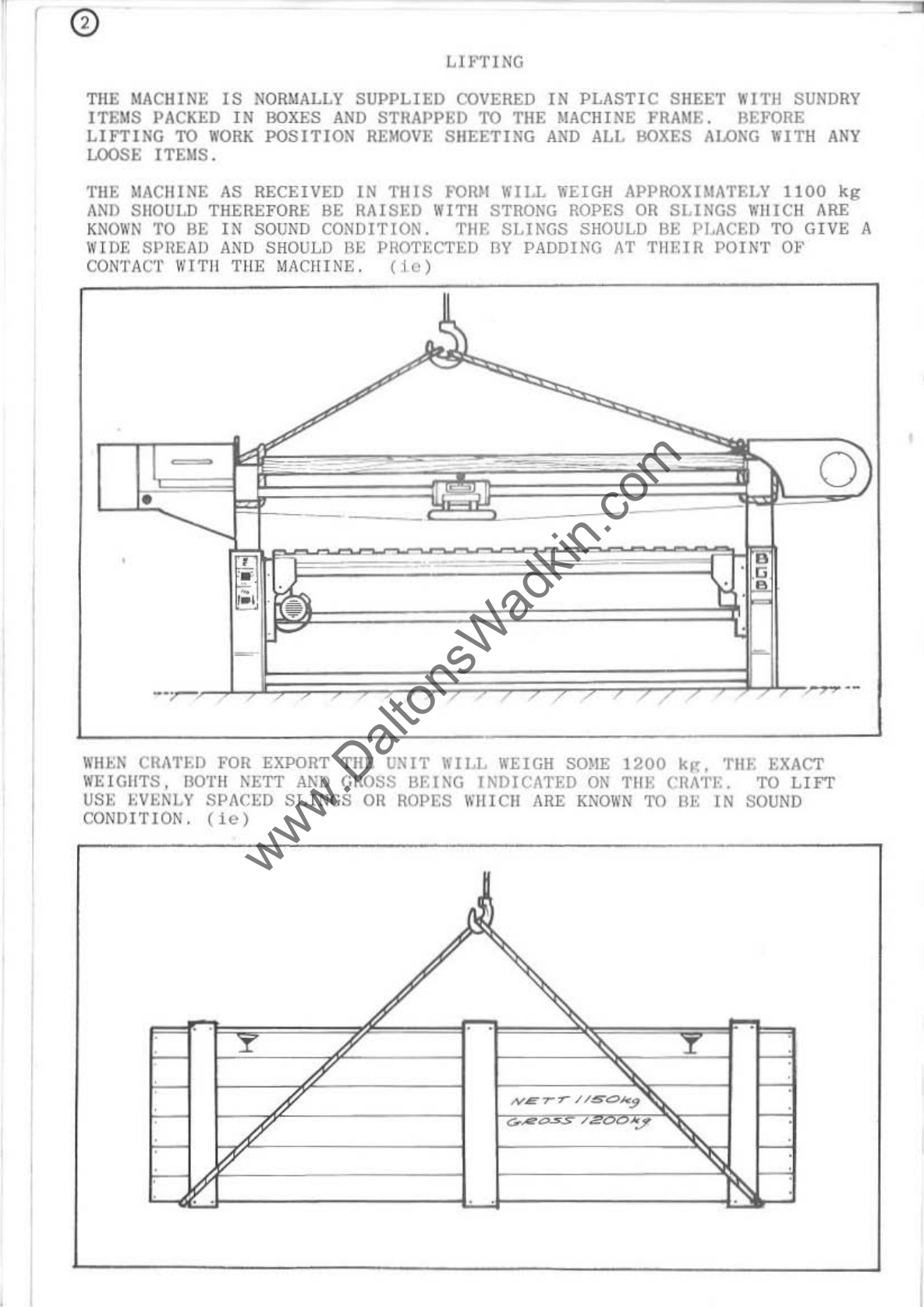

TilE

)!ACIIINE

AS

RECEIVED IN

TillS

FOIUl WIl.L WEIGH APPROXIMATELY 11

00

kg

ANI) SIlOULD THEREFORE BE

RAISED

lUTE! STRONG ROPES OR

SLINGS

WIIICH ARE

KN

OWN

TO BE

IN

SOUND

CONDITION.

TilE

SL

f

KGS

SHOULD BE PI..ACED TO

GIVE

A

WID

E SPltEAO

AND

SHOULD

BE

PROTECTED

BV

PADDING

AT

THEIR

POINT Ot'

CONTACT WITH T

HE

MACHINE .

Uc)

o

WHEN

CRATW

FOR EXPORT

TilE

UNIT

WILL

WEIGH SOME

1200

k~.

TilE

EXACT

W

EIGHTS,

30TH

NETT

AND

GIlOSS

BEING

INDICATED

ON

TlU; CHA1'E. TO

LIFT

USI::

EVENLY SPACED

SLINGS

OH

ROPES

\I

'

HIel!

ARE

KNOWN

TO

BE

IN

SOUN

D

CONDI

TI

ON.

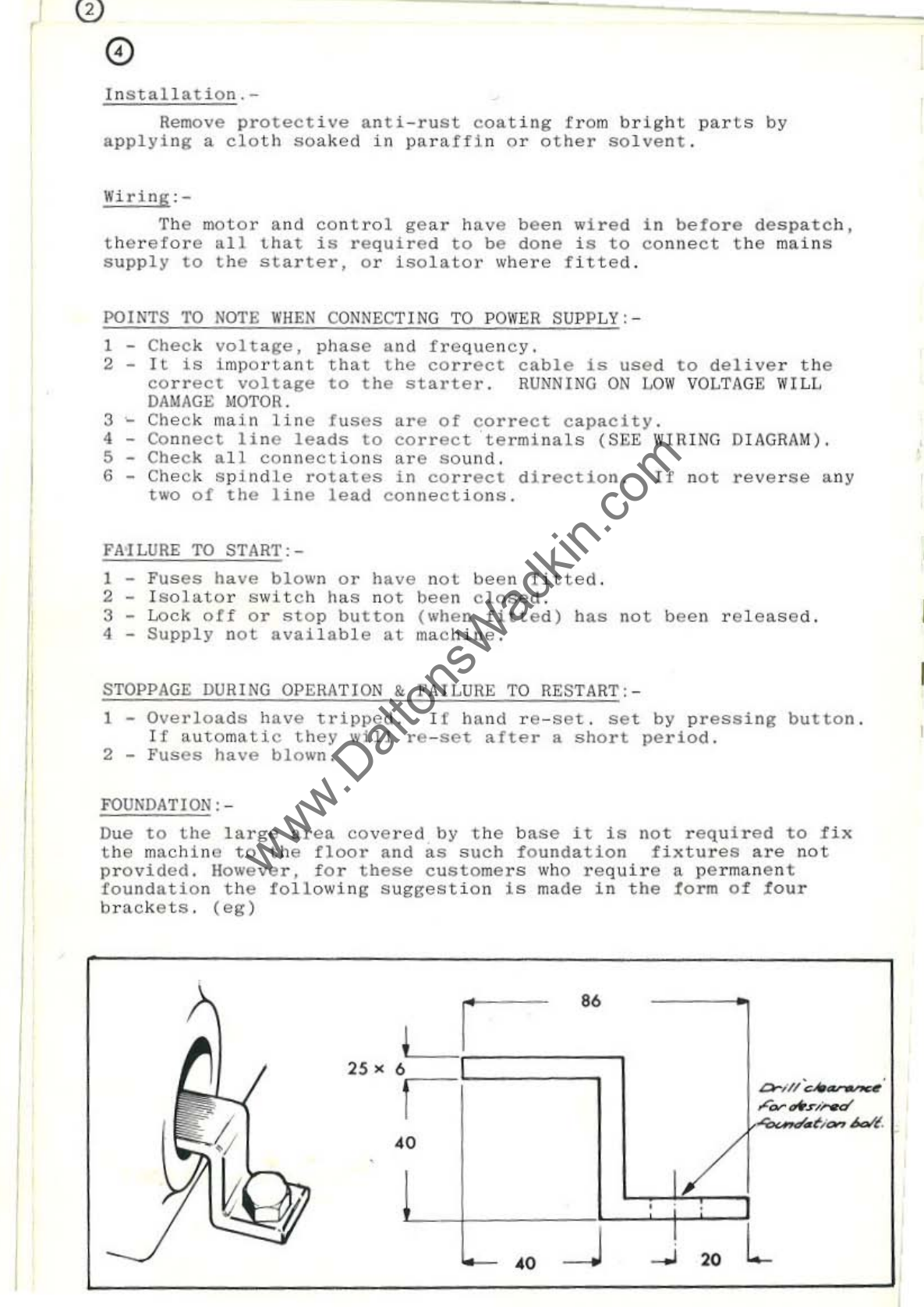

(ie)