EN-RATIOfresh-250-400_TI-MA-0809-11214900 7

Standby Temperature Control

The RATIOfresh freshwater station is also equipped with a

standby temperature control in addition to the circulation

function. The control activates the primary pump and sup-

plies the station with hot water to maintain the preset

standby temperature at the primary flow outlet port re-

gardless of a withdrawal of hot water.

This function serves to preheat the plate heat exchanger;

this means that hot water is thus much more quickly avail-

able at the desired nominal temperature in case water is

withdrawn. This function also protects from frost if the

standby temperature is set to a lower value of 10 °C. The

standby temperature control is only activated if the cylin-

der temperature is sufficiently high.

2.3 Standards and Guidelines

The following standards and guidelines must be observed

and complied with when installing hydraulics and/or per-

forming electrical wiring: IEC 364 or CENELEC HD 384,

DIN VDE 0100 and IEC-Report 664, DIN VDE 0110 and na-

tional accident prevention rules and regulations, as well as

VDE 0100, VDE 0160 (EN 50178), VDE 0113 (EN 60204),

and local rules and specifications of your energy provider

or utility company.

Specifications outlined by DVGW W551 concerning pro-

tection from the Legionella pneumophila bacteria must be

observed for multi-family home installations. A circulation

must be operated between hot water heater and tapping

point for potable water volumes greater than 3 liters. The

hot water outlet temperature of the RATIOfresh station

must always be set to ≥60 °C.

2.4 Installation Recommendations

The tank must be installed in a frost-free room with short

lines to the consumer.

De-energize the control unit as outlined by the manual be-

fore working on the pump or the control unit. Controller

and pump carry electricity even if the controller switches

the pump off!

Cold and Hot Water Line

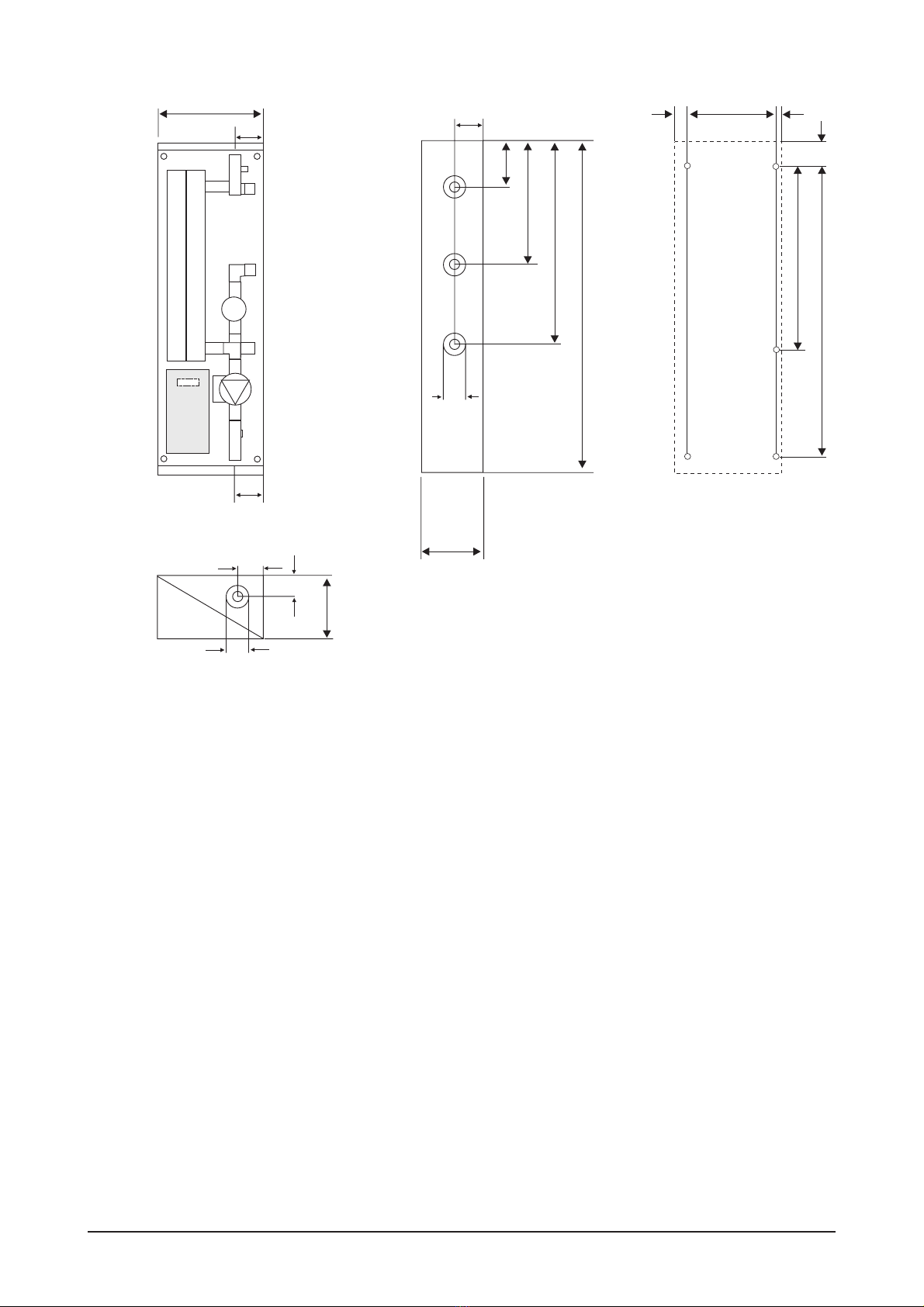

A safety valve (cf. fig. 5) is required in the cold water supply

line as specified by DIN 4753 T1. A min. thread diameter of

DN 15 must be selected for a heating output of max. 75 kW.

The safety valve can be omitted only if a type approved flow

monitor limits the water temperature to 95 °C. The valve

must be designed for a blowing-off pressure that corre-

sponds with the permissible working overpressure. In case

of 10 bar and higher waterline pressures, install a pressure

reducer behind the water meter. When heating the fresh-

water station without water tap,water is dripping out off the

safety valve. Use a siphon funnel to catch and dispose off

this water.

Do not install a shut-off between safety valve and freshwa-

ter station. A drain valve should be installed for mainte-

nance and service tasks. The functionality of the safety

valve must be checked regularly in accordance with DIN

4753. The exhaust vent may never be closed or restricted. A

corresponding water filter meeting current technology

standards is to be installed into the cold water supply line.

Connecting the Circulation

The freshwater station RATIOfresh is designed to be con-

nected to a circulation line.The circulation pump must be a

commercially available stepped wet pump. E-pumps or

pumps with integrated motor protection or ON/OFF

switching electronics may not be operated.

Connecting the Primary Circuit

The piping of the primary circuit should be as short as pos-

sible to achieve the rapid heating of the heat exchanger

when water is tapped. The max. permissible pressure loss

within the primary circuit may not be exceeded when lines

are longer.

A bleeder is to be installed at the highest point of the pri-

mary circuit. The primary flow should be withdrawn at the

hottest point of the buffer storage tank, and the primary re-

turn should be returned as close to the bottom of the buffer

storage tank as possible.

Gravity circulations may occur depending on the length,

design, and insulation state of the primary circuit. This con-

tinuously withdraws energy from the standby section of the

buffer cylinder.

A gravity brake with low admission pressure must be in-

stalled on-site in addition.

Thermal Disinfection / Protection from Legionella

Pneumophila Bacteria

Please note that the “Disinfection” function only can be

used as intended if the cylinder temperature sensor can

correctly measure the derivative temperature within the

connected auxiliary heating range. The sensor should thus

be attached 10 cm below the actual tapping point on the

buffer cylinder (on the tank wall as depicted in fig. 7).

Please also note that increased temperatures within the hot

water network and associated pipes pose a risk of scalding

injuries while the disinfection program is running!

Protection from Corrosion and Lime Buildup

All water-conducting parts are basically subject to corro-

sion and lime buildup, especially if temperatures exceed

60 °C and with aggressive water. Hot water temperatures

thus should never exceed 60 °C. Significant lime deposits

are not expected with carbonate hardness below approx.

10° dH and temperatures less than 60 °C. If your potable

water is harder than this, we recommend on-site lime

buildup reducing measures. If the plate heat exchanger

must be decalcified on a regular basis, irrigation cocks (fig.

6) should be installed during the system assembly.

The plate heat exchanger of your freshwater station is

made from copper soldered stainless steel plates. Steel

pipes may thus not be used in the flow direction (towards

the freshwater station) since copper is water soluble in

minute particles and causes pitting when deposited on

steel.

Water with low hydrocarbon content and high portion of

neutral salts (e.g. soft water containing chloride) can cause

dezincification of the installed brass elements.