TABLE OF CONTENTS

Thank you for choosing a Walchem E Series metering pump. This instruction manual deals with the correct

installation, operation, programming maintenance, andtroubleshooting proceduresfor the EHE Series metering

pumps. Please read through it carefully to ensure the optimum performance, safety and service of your pump.

1.0 INTRODUCTION ............................................................................................................. 1

1.1 Safety and Caution Notes ............................................................................................ 1

1.2 Principle of Operation................................................................................................... 1

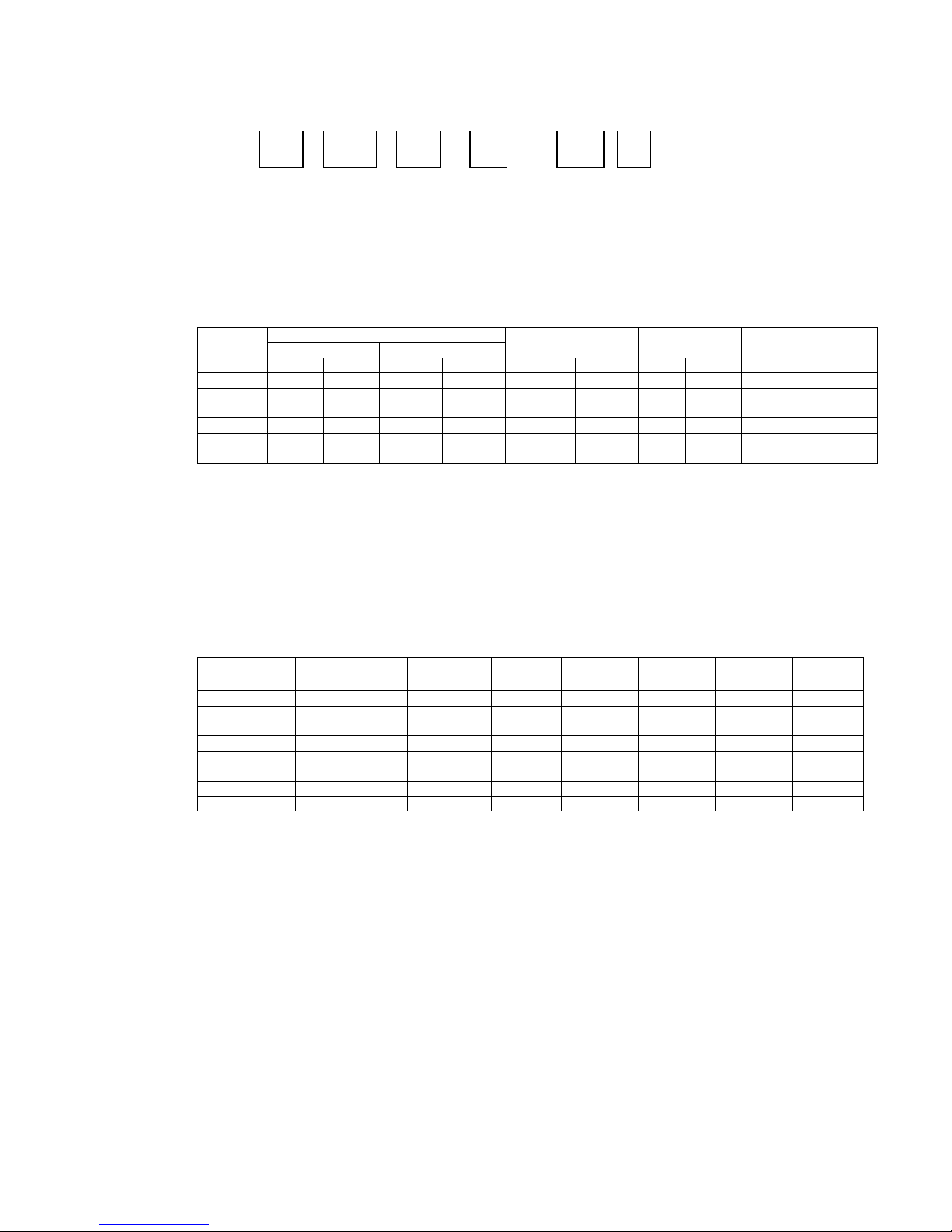

1.3 Specifications............................................................................................................... 2

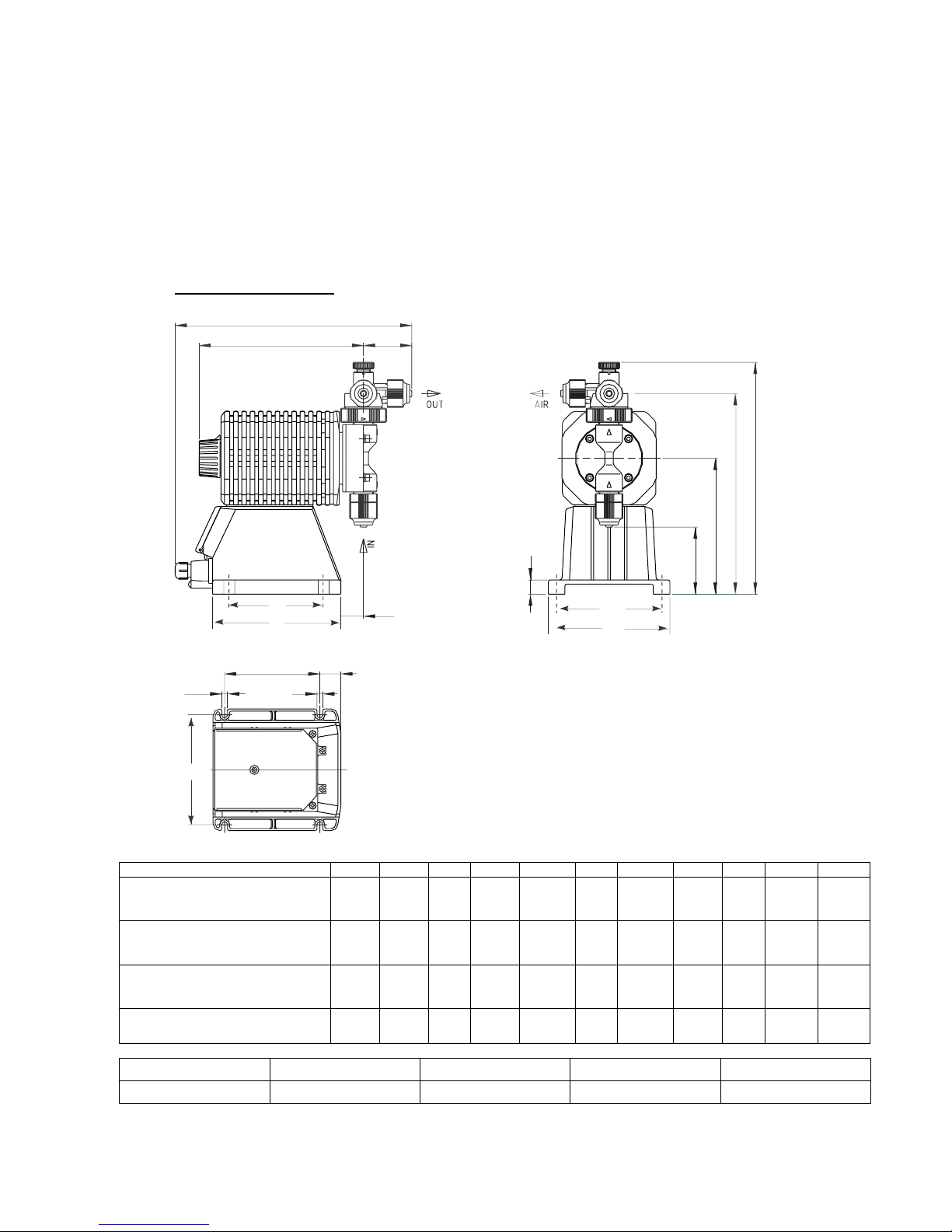

1.4 Dimensions.................................................................................................................. 3

2.0 INSTALLATION............................................................................................................... 5

2.1 Unpacking.................................................................................................................... 5

2.2 Location....................................................................................................................... 5

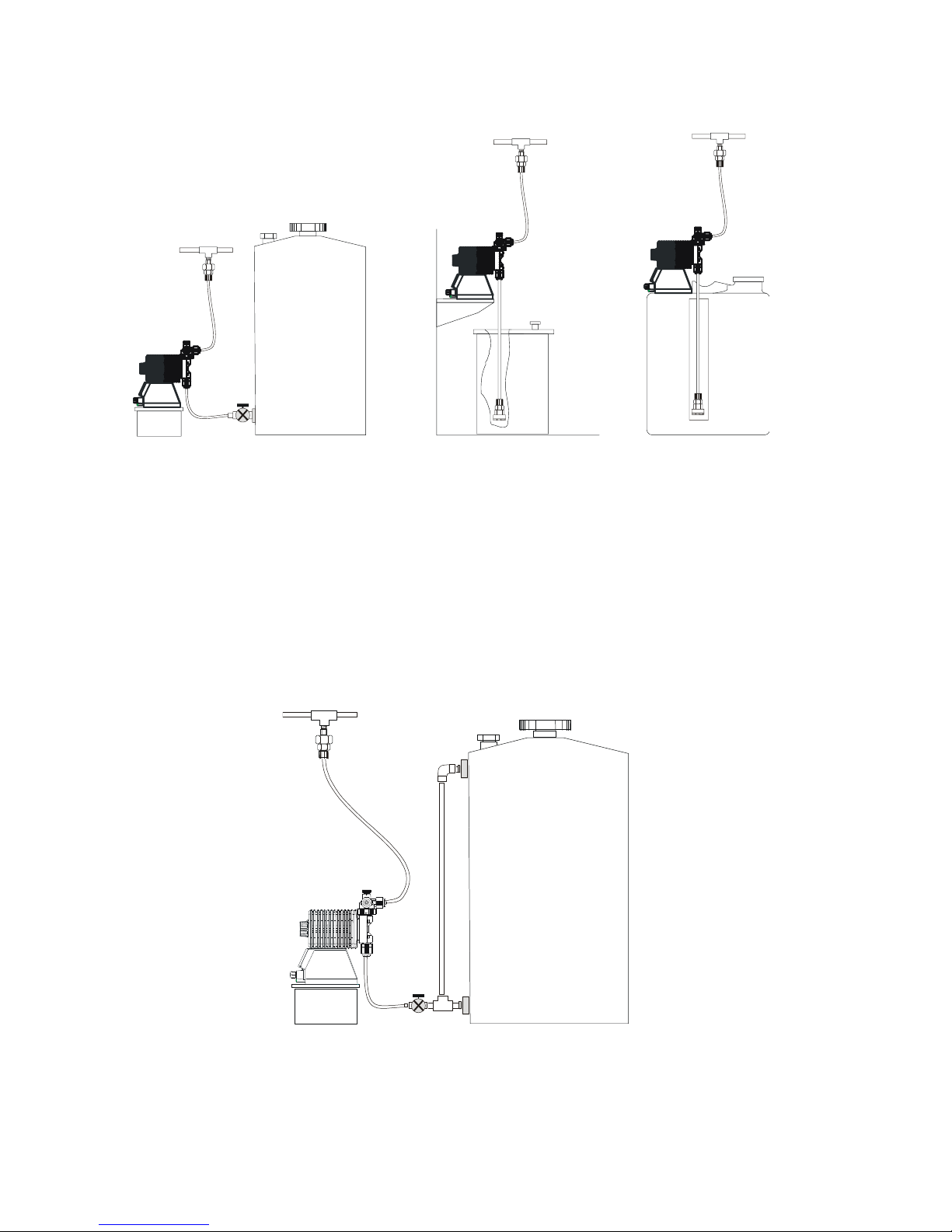

2.3 Supply Tubing.............................................................................................................. 7

2.4 Discharge Tubing......................................................................................................... 8

2.5 Installing Injection Check Valve.................................................................................... 8

2.6 Interlocking Pump ........................................................................................................ 9

2.7 Electrical ...................................................................................................................... 9

3.0OPERATION ................................................................................................................. 10

3.1 Priming....................................................................................................................... 10

3.2 Adjustment................................................................................................................. 10

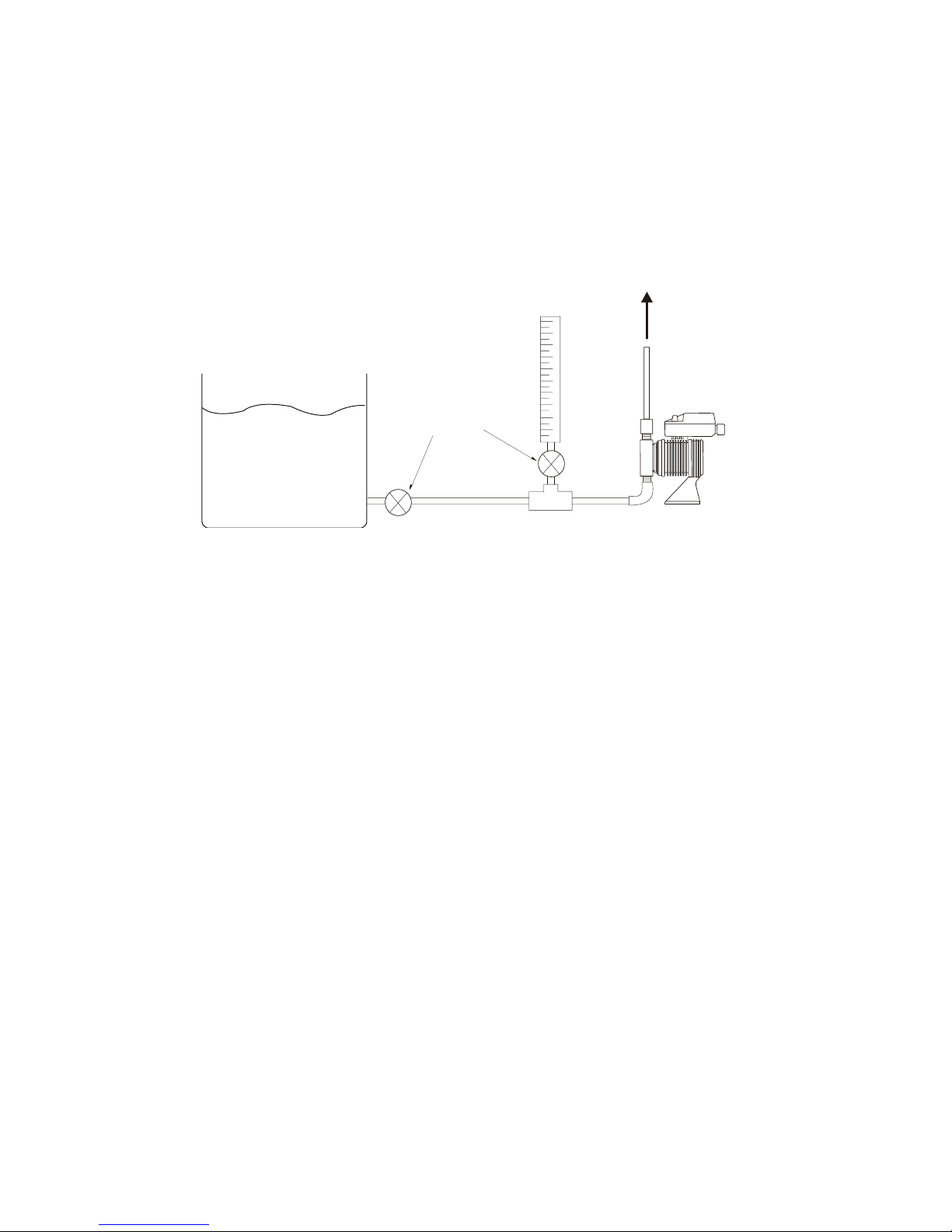

3.3 Calibration.................................................................................................................. 10

3.4 Control Unit Operation and Programming .................................................................. 10

3.5 Input Wiring and Connections .................................................................................... 21

3.6 AC Power Interruption................................................................................................ 22

4.0 MAINTENANCE ............................................................................................................ 23

4.1 Diaphragm Replacement............................................................................................ 23

4.2 Valve Replacement.................................................................................................... 23

4.3 Tubing........................................................................................................................ 23

5.0 EXPLODED VIEW AND PARTS GUIDE ....................................................................... 24

5.1 How to order parts for your metering pump................................................................ 24

5.2 Accessories (Not shown)............................................................................................ 24

5.3 EHE31, 36, 46 Liquid End Exploded View.................................................................. 25

5.4 EHE 56 Liquid End Exploded View............................................................................. 27

5.5 EHE 36-HV Liquid End Parts List............................................................................... 29

5.6 Drive Control Components......................................................................................... 30

5.7 Assembly Part Numbers............................................................................................. 30

5.8 Spare Parts Kit........................................................................................................... 31

6.0 TROUBLESHOOTING................................................................................................... 32

7.0 SERVICE POLICY......................................................................................................... 32