A supply of dry, clean and uncontaminated compressed air must be provided. Dirty and moist

air leads to a premature deterioration of the ball bearings. The turbine needs a drive pressure

of 2.2 bar for operation. Lubricate the instrument before using it for the rst time.

The instrument must be coupled to a 2-hole Borden hose. Verify the connection of the ducts

of the instrument with those of the tubing, join them on and screw the xing nut by using

only ngers.

• Do not use an unqualified bur.

• Diamond bur shafts should follow the demands of ISO standard diameter of 1.59 - 1.60mm.

• Do not use a bent, damaged, or a short handle bur.

Bur Specications

For LED - The air ows into the built-in micro-generator, converting the kinetic energy into

electrical energy for LED lights. The discharge of airow through the motor gives the

high-speed rotation cutting eect.

For Non LED -The discharge of airow through the motor gives the high speed rotation

cutting eect.

• Operating pressure: 0.25MPa - 0.3MPa (0.3MPa

preferred ).

• Rotation Speed: 350,000 rpm for Super torque

head & 280,000 rpm for standard head.

• Borden 2-hole connection

• Air consumption: 55L/min

• Noise ≤ 60db

• Operating pressure: 0.18MPa - 0.25MPa.

• Rotation Speed: 350,000rpm for Super torque

head & 280,000rpm for standard head.

• Borden 2-hole connection

• Air consumption: 34-37Nl/min

• Noise ≤ 60db

Technical data (For LED) Technical data (For Non - LED)

Operation Principle

Introduction

OPERATION MANUAL

Dear dentist, thanks for choosing our handpiece. We hope that you will be benetted greatly

with this new, economical and high-quality product. Please observe the following notes to

assure continuous trouble-free and safe product operation. In case of any problems related to

the product, please consult our local customer assistance.

1. Dental Airotor Handpiece - 1 piece

2. Cap wrench - 1 piece

3. Operation manual

4. Chuck - ( if screw - type chuck )

Package Content ( For Non - LED )

1. E- generator integrated LED dental handpiece - 1 piece

2. Cap wrench - 1 piece

3. Operation manual

4. Chuck - ( if screw - type chuck )

Package Content ( For LED )

Connection of Units

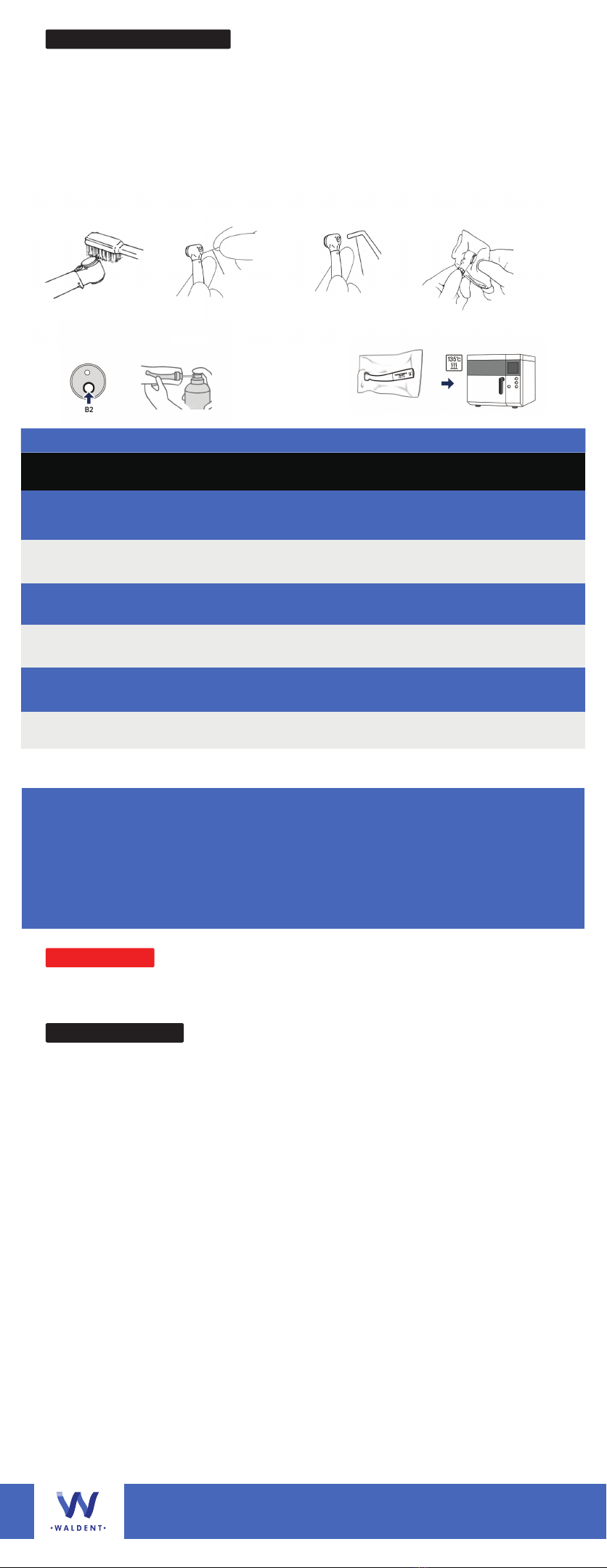

Screw type chuck (conventional chuck)

Bur removal: Mount the chuck wrench with the knurled knob pulled out. Push the knob into the head and make a ¼

turn in the counter- clockwise direction. Bur is ready to be removed (do not turn the knob more than a ¼ turn).

Bur mounting: To mount a bur, turn the knob in the clockwise direction with the knob pushed into the head.

Push type chuck

Bur removal: Press the push button in the head cap with tip of thumb to click, and remove the bur.

Bur mounting: Insert the bur into the head until it stops (1-2mm deep approx). Press the push button and further insert

the bur all the way into the head until it stops.

Cautions

Mounting and Dismounting burs

• Do not run the handpiece with the bur not fully inserted; bearings may fail prematurely due to poor bur concentricity

and resultant vibration.

• Never run a handpiece without a bur.

Cautions

• In case of cutting procedures having heavy vibrations such as in crown removal, there may be a case where it

becomes difficult to remove the bur. In such a case, pull out the bur with pliers while pushing the push button with

the wrench.

Cautions

• Do not exceed the recommended airpressure. This is important to prevent higher

speed which could causes breaking of the bur and premature bearing failure.

Airotor

Dental High Speed Air Turbine

Push - Type Chuck Screw - Type Chuck

Hold down the push

button.

Insert the bur

TM