27-05-19 UNI-SAN Domestic Instructions Page 3

The UNI-SAN pump is designed for the disposal of waste water and any solids which can pass through a plumbing

trap and a waste strainer with a maximum of 10 mm diameter apertures. The unit is capable of pumping the effluent

from a kitchen waste unit, but it is neither a waste disposal macerator nor suitable for pumping raw sewage waste

from a toilet. For these other applications, contact Wallace Pumps or a Distributor for other options.

The WALLACE UNI-SAN collects the gravity fed waste liquid into its collection tank. When a set water level is

reached, the level switch inside the collection tank automatically activates the powerful quiet pump to deliver the

effluent under pressure to the desired location through a 25 mm internal diameter pipe. The discharge point will

usually be into a gulley trap or into a soil stack.

Due to the small pipe size and pump pressure, the delivery can be run virtually anywhere, in any direction,

- through walls,

- through ceiling spaces,

- under floors,

- around, under and over obstacles.

The unit enables the installation of a variety of equipment where this was previously impossible due to economic

constraints, physical limitations, or because there was no unit available with adequate performance or reliability.

The UNI-SAN has been developed to overcome these problems, including

- below sewer-line installations,

- where gravity fall is not possible,

- physical restrictions, e.g. concrete walls or concrete floors,

- where new pipes cannot be run under the floor, such as concrete floors,

- where large diameter 80 - 100 mm gravity lines are not appropriate for the location,

- and many other situations.

3. APPLICATIONS

The UNI-SAN range is made up of two models, and as the names suggest there is one for domestic applications

and one for commercial. Both units are the same dimensions and pumping performance, the major differences are

in the materials of construction, level control and motor switching design.

The UNI-SAN DOMESTIC is NOT to be used in commercial applications.

The UNI-SAN collects and automatically pumps away waste water from the following and many other sources :

- laundry tubs,

- domestic and commercial sinks with or without waste disposal units,

- domestic and commercial clothes washing machines,

- domestic and commercial dishwashing machines,

- bar facilities,

- bath, shower, vanity,

- air conditioning condensate,

- dehumidifier water,

- a floor waste gully trap plumbed according to AS3500 and Appendix C, Figure 7c.

PROVIDED THAT

- in a multi-storey construction, they are all located on the same floor level as the UNI-SAN,

- maximum temperatures in the collection tank are 60C continuous and 95C intermittent,

- no acids, solvents, paints, petroleum products, corrosive/abrasive liquids or excessive fats are discharged

into the unit

- and the volume of water discharged into the unit from fixtures and/or appliances operating at the same

time must not exceed pump output.

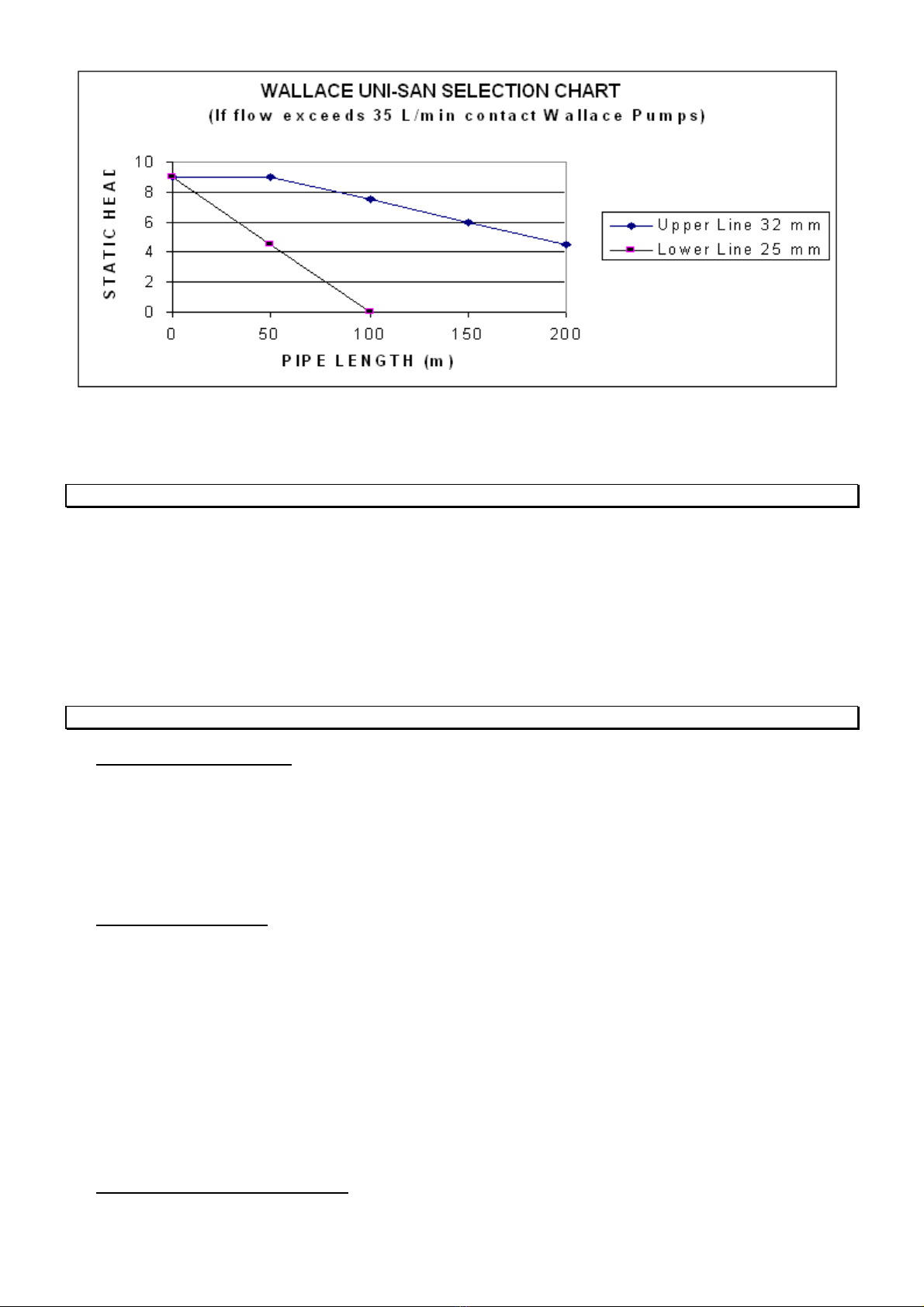

Contact our office for advice :

- for inflows higher than 35 litres per minute,

- for general commercial applications,

- where there is a high quantity of fats being discharged,

- for printing, photographic or similar trade processing waste.

Typical applications for the UNI-SAN DOMESTIC are :

- basement facilities

- relocated domestic amenities where gravity fall to existing sewer connections is not possible

- master bedroom en-suites without toilet ( Refer MULTI-SAN unit for toilet applications )

- executive bars and showers

- re-developed apartment blocks in inner cities enabling waste pipes in ceilings

Typical applications for the UNI-SAN COMMERCIAL are :

- arcade or retail developments including hair salons, cafeterias, delicatessens, etc.

- amenities in factories built on concrete floor slabs