G:\INSTRUCT\MERCHANT\MAXIPUMPS\MPEP3000 MPEP5000 Hydrojet Instructions 06-05-2019.docx

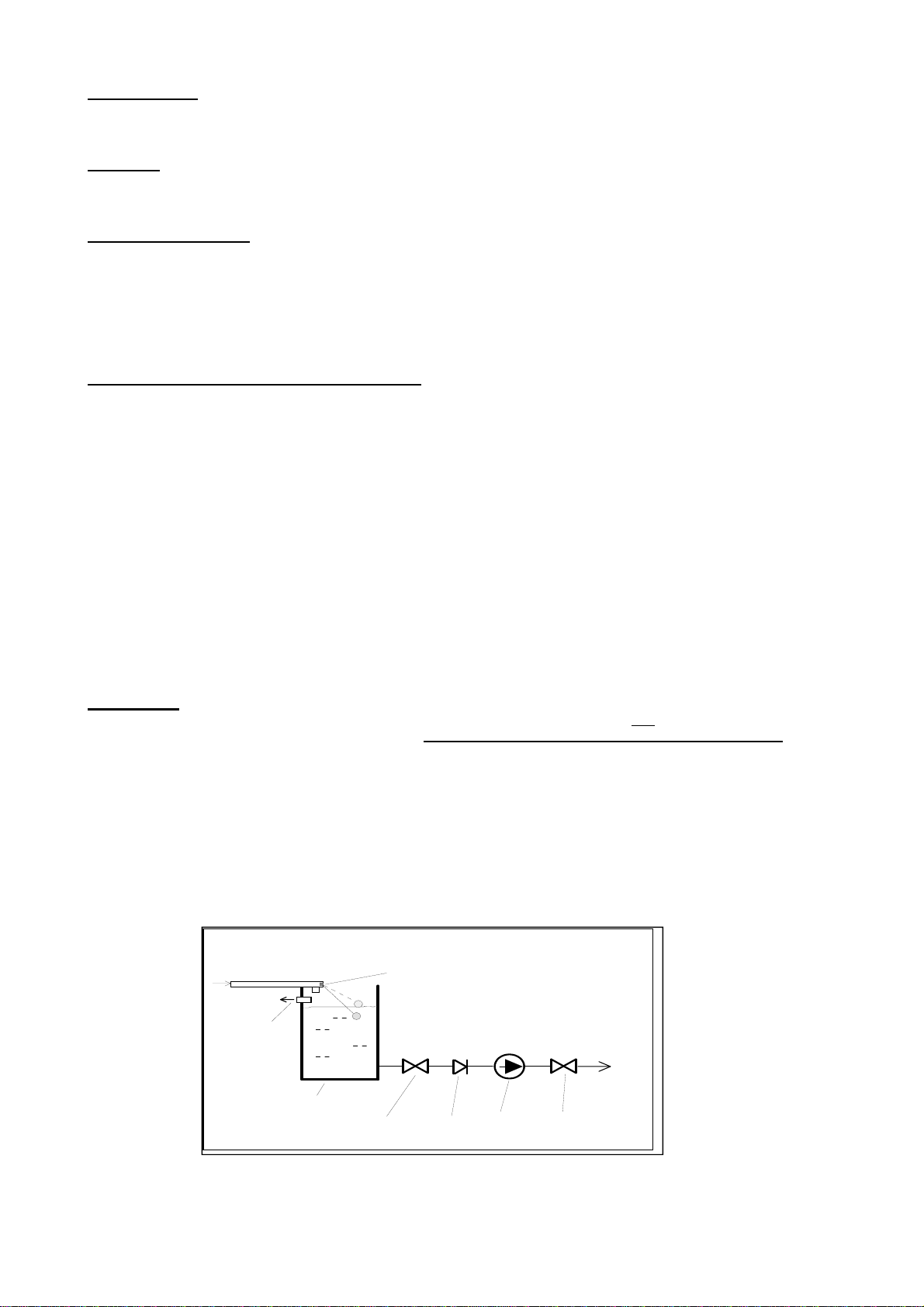

OPTIONAL PRESSURE TANK.

If you are operating the pump at low flows (less than 0.4 L/min – MPEP3000, MPEP5000, HJ60, HJ100, HJ140)

we recommend a pressure tank be installed. Install the tank on a tee of from the discharge pipe before the first

tap. Tank air charge pressure: The flexible membrane inside the tank separates the air and water within the tank

and so prevents the water absorbing the air (water logging).The tank charge pressure is 195 kPa (28 psi ).

The tank air charge pressure must be checked with the water pressure relieved, follow the procedure carefully.

An initial easy check you can do is; After the pump has stopped, open a tap, you should get at least a cup of water

before the pump starts, if you do the tank pressure is OK and does not need checking.

Checking and replenishing the tank air charge. Procedure:-

Every 3 months the tank air charge pressure must be checked, and if necessary replenished as follows:-

1. Release all water pressure from the tank by; switching off the power to the pump, and turn on any tap to release

water pressure from the system. In flooded suction situations close the tank isolating valve.

2. Apply a car tyre or similar type pressure gauge to the air valve on the tank to check the pressure.

3. If necessary; drain, or replenish tank air charge pressure using a suitable car tyre pump or compressor to the

correct pressure. DO NOT over pressurise the tank.

4. Close the tap, open the tank isolating valve, switch on the pump.

SAFETY

Turn power off and pull out the plug at the wall, before attempting any servicing.

Keep hands clear of the pump whilst it is operating.

Note that the pump may start without warning due to water demand or the internal thermal overload resetting.

Do not charge the pressure tank above 200 kPa.

Do not run the pump dry.

Read and follow all instructions.

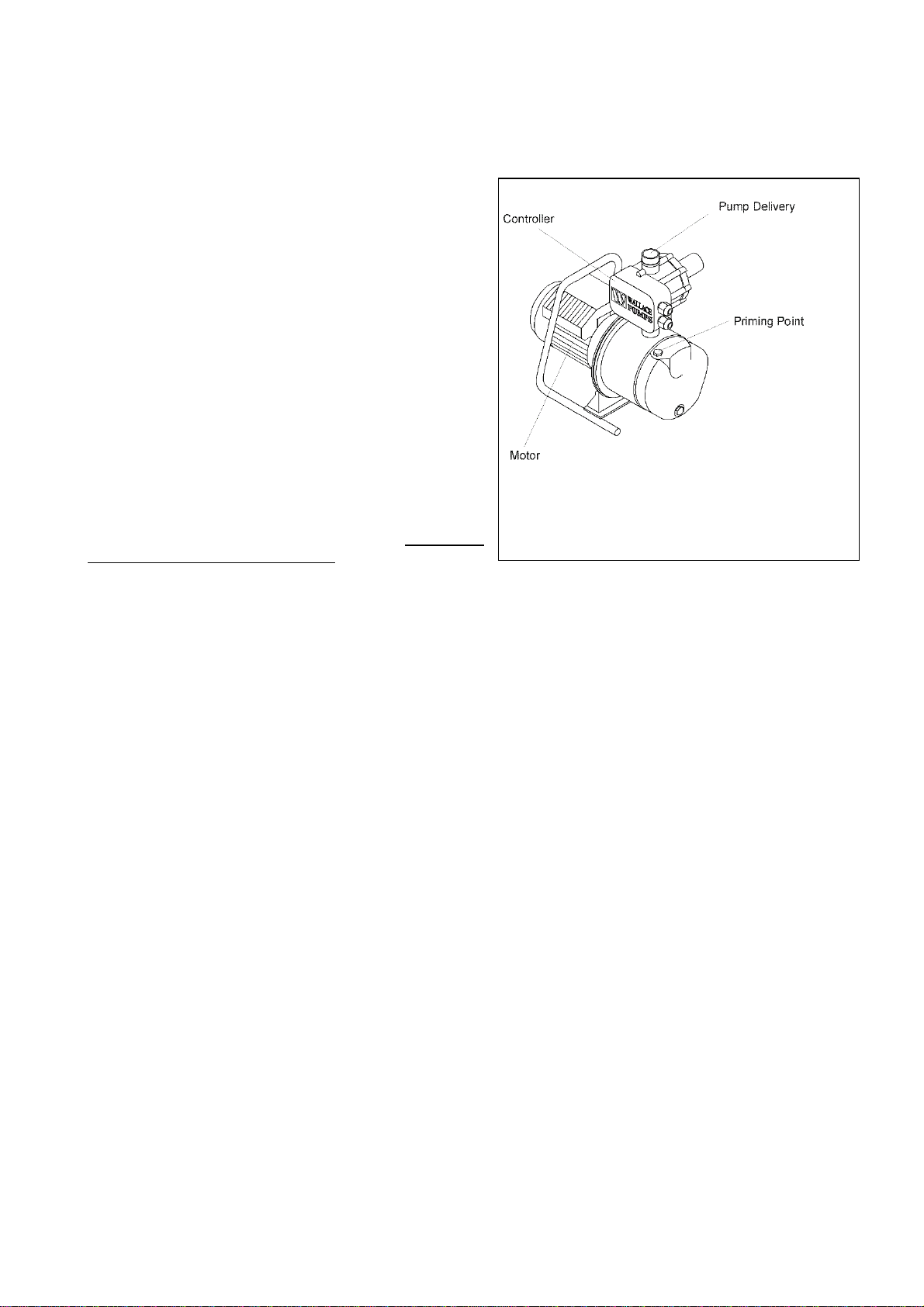

MPEP3000, MPEP5000, HJ60, HJ100, HJ140 WITH CONTROLLER

The controller may have three LED lights (certain models) which when lit, indicate the following functions:-

POWER ON ( green colour ) There is power to the controller

PUMP ON ( yellow colour ) The pump is operating

FAILURE ( red colour ) There is a system or pump fault. System faults may include: the pump is not

fully primed, there has been a run dry e, there is a suction or delivery pipe restriction.

When the pump is first turned on it may run for approximately 0 seconds and turn off, the failure LED will be lit. This

indicates that the pump is not fully primed and has been stopped by the controller as it has sensed a run dry

condition, repeat priming procedure, press the reset button to reset the controller. Repeat until the priming is

completed and pump runs and stops normally. The controller is not serviceable, it is protected by an anti tamper

seal, if broken the warranty is invalidated. As the motor and controller are electrical devices they may be damaged

in the event of a power failure or lightning strike, if this is a risk for your installation we recommend that a suitable

protection device be installed in the power supply to the pump.

If the controller has only a restart button and will not work, check the fault finding instructions.

RESET / RESTART button resets the pump after it has tripped due a fault such as loss of water supply. After

the fault has been rectified press the reset / restart button to start the pump. Do not press the reset button and

operate the pump for more than two times without checking and recifying the cause of the trip. Refer to fault

finding later in these instructions.

HJ60PT, HJ100PT Pressure Pumps with Pressure Switch

Thesepumps DO NOThave power,operation or faultdisplay. Always approach these pumps as being live electrical

equipment. Take care to turn off power if work is being attempted on pump motor or pressure switch.

FAULT FINDING MPEP3000, MPEP5000, HJ60, HJ100, HJ140:

Note: - Not all pumps have a pressure tank. If not, ignore pressure tank points.

Priming trouble: ( Red failure light if applicable, is lit )

DO NOT RUN THE PUMP DRY. Do not press reset button more than twice without checking pump has water in it

and remedying the fault.

1. Air leak in suction pipe system.

2. Foot valve not fully submerged. Or no water in the supply.

3. Suction lift too high, check pump level above the water supply to the pump.

4. Foot or check valve leaking, or jammed.

5. Suction valve is blocked, closed, leaking air or faulty.

Motor switching on and off when no water appears to be being used:

1. Leak / s in suction and / or delivery pipework.

2. Foot or check valve leaking, or not installed, or installed in the wrong place.

3. ( IF FITTED ) Pressure tank air charge pressure incorrect, too high or low. Refer to previous section.