G:\INSTRUCT\MULTISAN PRO\Multisan Pro Instructions 251119.docx Page 9

10. GENERAL INSTALLATION ASPECTS AND ELECTRICAL DATA

10.1 General

1. Where a permit is required, it is required that the unit should be installed by a registered plumber and the power supply should

be connected by a registered electrician. It is the responsibility of the installer to obtain all the necessary permits and consents.

Ensure full compliance with all applicable local regulations. The owner or owner's agent must ensure that the MULTISAN-PRO is

compatible with the existing or proposed plumbing system design.

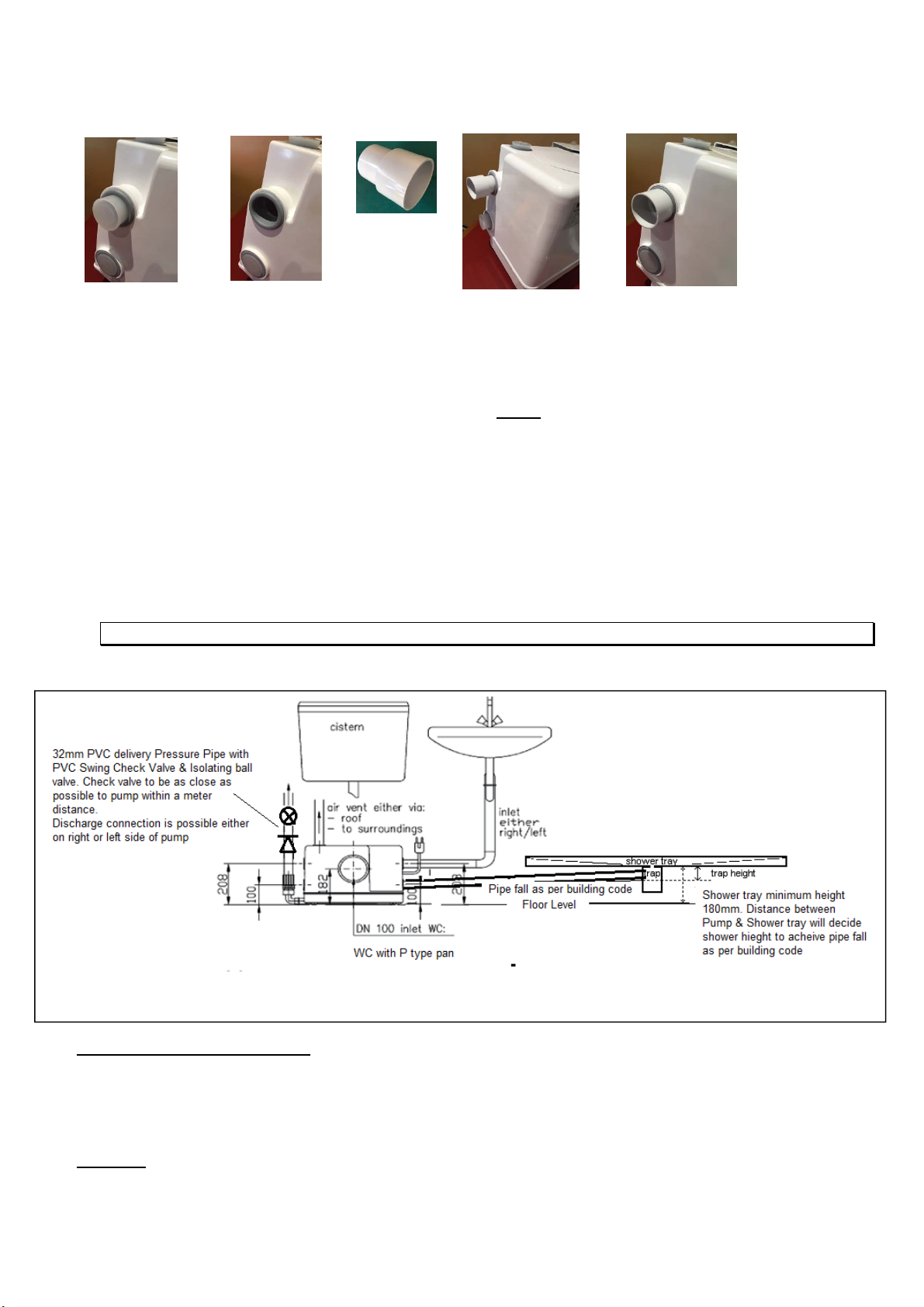

2. The installation of the unit and non-return and isolating valve must comply with the following conditions:

- They are easily accessible for servicing;

- Service fixtures and appliances located on the same floor level as the unit, each must have a waste trap installed.

- Pump is in a clean, dry, non-floodable position, protected from UV and on a permanently sturdy support;

- Design against overflow, flooding or unwarranted children interferences or excessive moisture;

- Protect from freezing of liquids in the unit and the pipework;

- The tank is installed with the screwed inspection lid on top;

- Install an individual special 40mm DWV pipe connection with “one way check valve” for the shower tray & bath

- All the requirements in these instructions are met.

3. Any modifications not described in this manual and without written authorisation by a Wallace representative will

nullify the Wallace Pumps warranty and durability compliance.

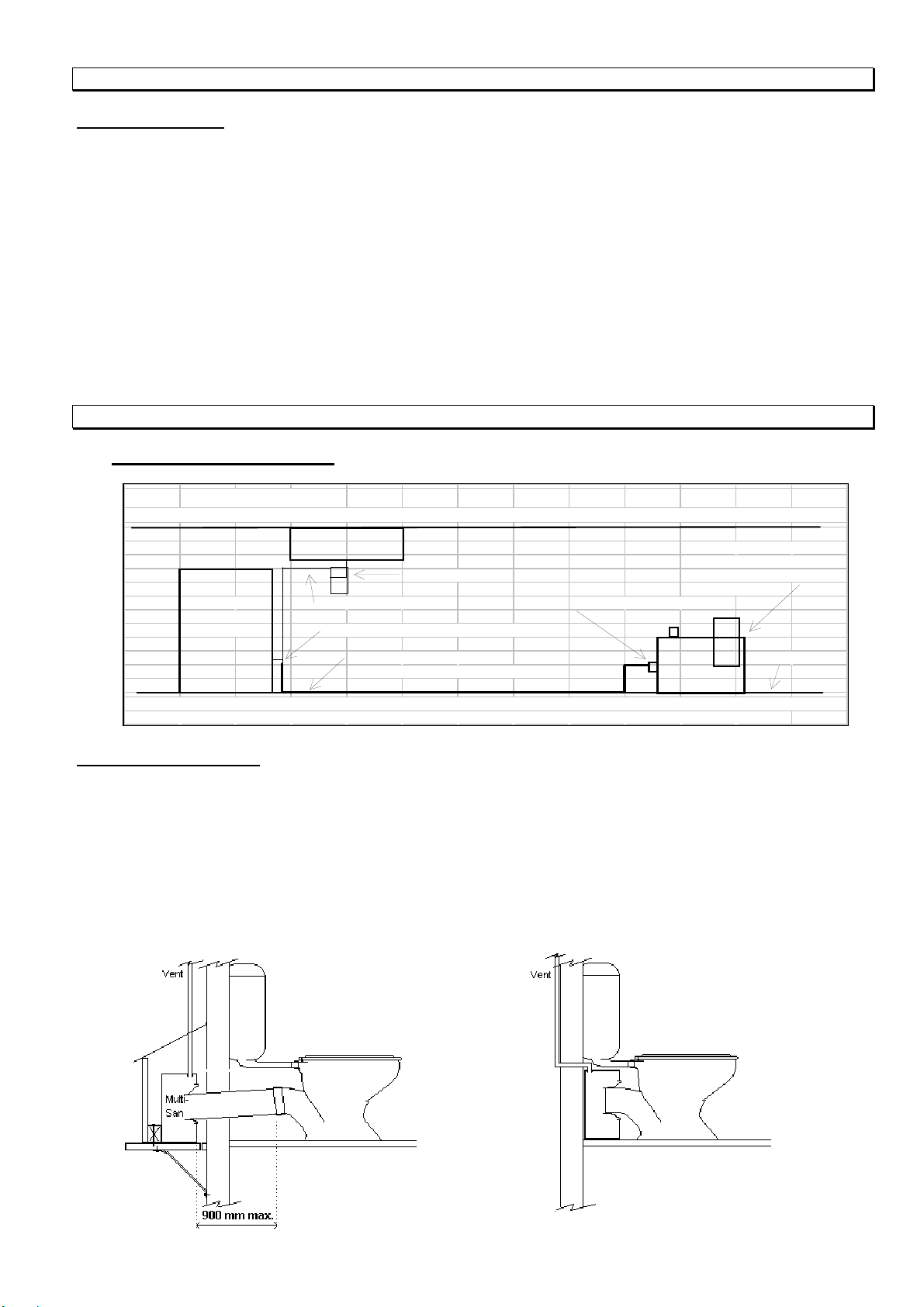

10.2 Plumbing

1. The connection to the soil and waste drain system must be carried out in accordance with the Building and Plumbing Code.

The connection of the unit's delivery pipe to a soil or waste pipe should be kept at least 0.5 metre distance from any other

connection. Also it must not be connected in a section of the pipe which runs the risk of being flooded creating a back pressure

down the pipework to the unit. The connection point is usually 600 mm above the lowest W.C. connection or the lowest gully trap.

The connection of the delivery from the unit to a soil or waste pipe should be a swept inspection bend in the direction of flow of

the soil or waste pipe.

2. Any horizontal section of the delivery pipework should always have a continuous rise towards the soil or waste pipe connection.

It should never be level or have a fall. The pipework must be securely strapped and isolated from the building structure to prevent

vibration and noise transmission.

3. Install only the supplied full flow non-clog swing check within one metre of the pump in a vertical position, below and close to

the supplied isolating ball valve.

5. All pumped appliances, such as washing machines and dishwashers, must discharge via an approved waste system which

includes an air gap and a trap.

6. Ensure that the 40 mm tank vent to outside (if required) is installed in the top of the unit and that it extends full-bore to the

external air (the minimum height must be 50mm above the overflow level of the highest fixture discharging into the WALLACE

MULTISAN-PRO) or terminated elsewhere as described in the current Building & Plumbing regulations. DO NOT use air

admittance e.g. a "Hunter Valve" venting devices as they do not let air out of the tank.

7. It is important from a health and safety reason and for the protection of property, that an overflow relief pipe is plumbed and

delivered to a safe and visible area in the event that the discharge flows into the MULTISAN-PRO exceed the pump hydraulic

performance capability or caused by a mechanical failure or a pipe blockage. Pumped appliances and water supply can also be

safeguarded as per Section 9.1.

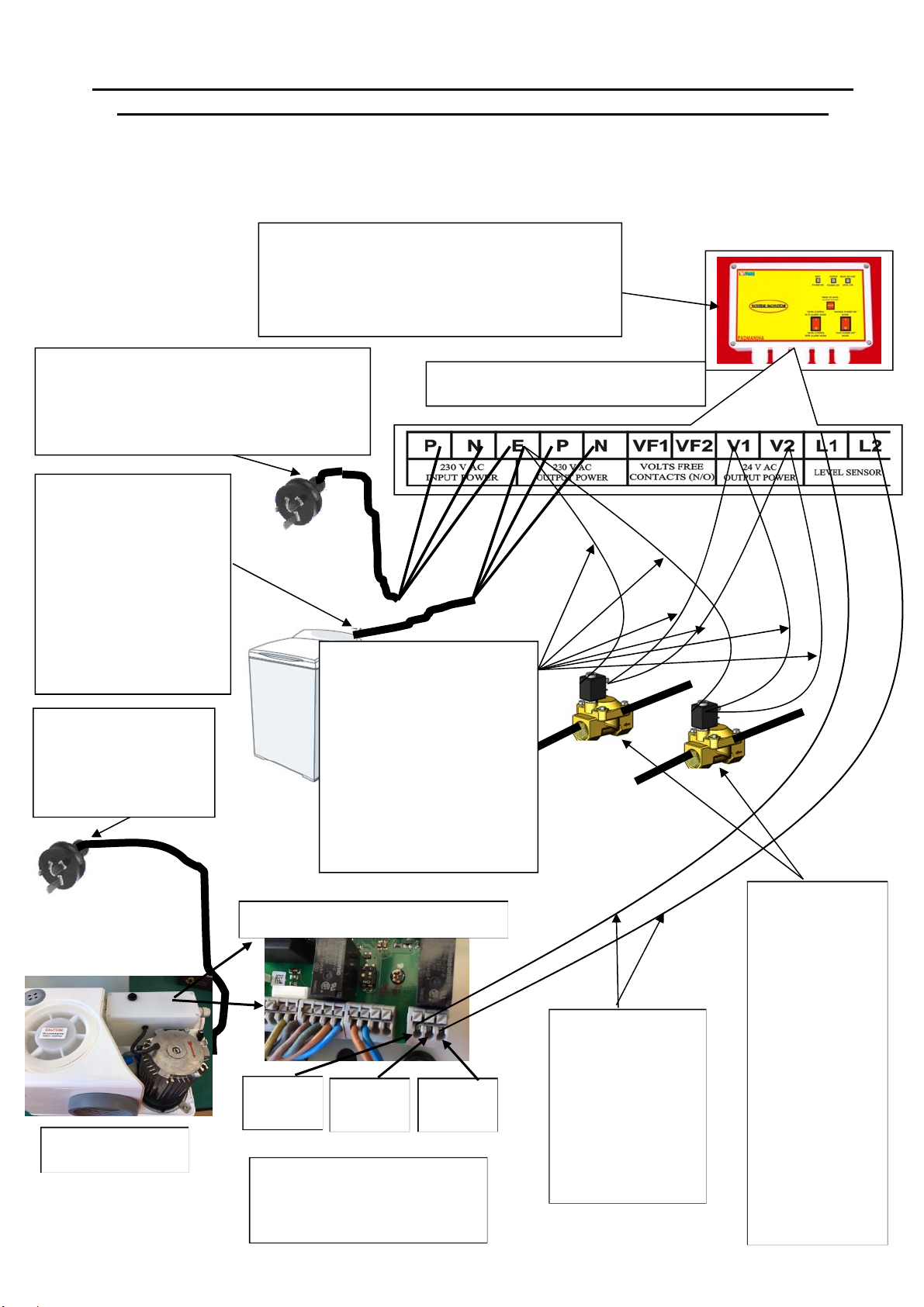

10.3 Electrical Connection

1. The WALLACE MULTISAN-PRO is fitted with a high quality 2900 rpm motor:

Nominal current : 2.5 amps

Motor input : 0.6 kW

Cable : 1.5 metres of 3 core - supplied with the unit

Cable Plug : Standard 3 pin domestic earthed - supplied with the unit

Supply : 1 phase 230 volts 50 Hz.

2. Overload protection (thermal / overload): the unit has a built-in automatic motor overload. In the event of an overload trip, the

pump will not restart automatically as it must be manually reset. Nevertheless always switch off the power in case the fault was

not an overload trip. Then determine and eliminate the cause of the overload. Press the reset button under a clear plastic bubble

to ensure pump operates.

3. Wiring connection: the electrical wiring connection type should preferably be the "Clipsal Permanent Connection Unit with

Neon" type, or PDL 253N, or similar. The permanent connection should be fixed in a position where it cannot be reached by a

person in a bath or shower or standing on a wet surface.

4. The unit requires a domestic 3 pin earthed single phase power supply. The appliance must not be connected to a conventional

plug, socket or adaptor when installed in a bathroom, unless properly protected by an approved earth leakage circuit breaker or

similar.

5. Refer Section 6 (Warning: for your safety) for additional electrical information.

Always refer to your local power supply authority for details of acceptable wiring, as their requirements over-ride the guidelines

above.