3) Insert - do not glue - Turntable Pin* (10)

through Frame and clip to Deck (11). Glue Front

(12) and Rear (13) Counterweight together and

to mounting points on Deck.

4) Carefully remove sprue from center of Track

(2x 14) and turn inside out. Carefully thread

center guides over Sprocket and Idler, resting on

the upper carrier rollers and bottom rollers

molded on Drive Frames

Do Not Glue

13

12

11

14

14

10

Do Not Glue

20 21

22

19

18

17

16

15

27

24

25

23

26

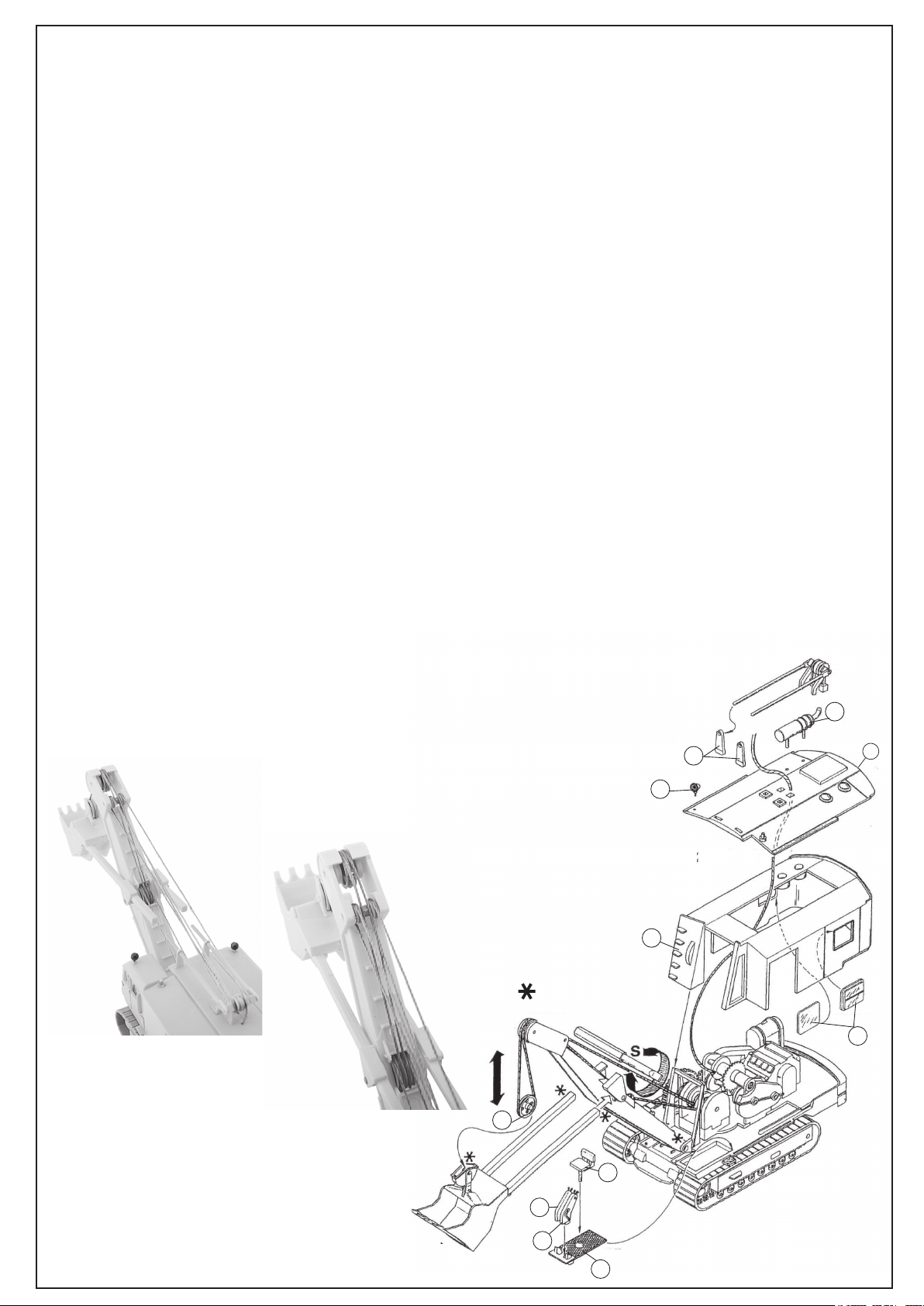

Machinery House Interior Assembly

PLEASE NOTE: All Winding Drums are designed to be moving parts.

1) Note raised area on front of Floor (15); insert - do not glue - Cable Drums*

(17) into openings in Right (16) and Left (18) Cable Sideframes; glue Side-

frames to Floor as shown.

2) Glue Boom Sideframe (19) to inset area on Floor as shown. Glue parts #20,

#21 & #22 as shown to build the Boom Drum; insert - do not glue - completed

Drum into openings in Boom Sideframe.

3) Glue Pinion Gear (23) to mounting point on Boom Sideframe. Insert - do not

glue - Gear Pin (24) through Gear and Drum Sideframe as shown.

4) Glue Left (25) and Right (26) Transmission Covers to Sideframes. Insert

open areas on Mounting Frame (27) into openings on Frame and glue in place.

1

2

3

6

9

87

7

89

4

6

5

Underframe Assembly

1) Glue Turntable (1) to Upper Frame (2)

and glue completed assembly to Lower

Frame (3).

2) Track Frames - Make 2: Insert - do not

glue - pins on Idlers* (2x 6; one each

side) into openings on rear of Right (4)

and Left (5) Track Frames. Glue Drive

Wheel Mounts (2x 7: one each left and

right) to raised area on front of Frame.

Push - do not glue - Shafts* (2x 9)

through Drive Wheels* (2x 8) and into

openings in Mounts. Glue completed

Drive Frames to left and right as shown.

Do Not Glue