TRC PRO 10 SPORT Installation guide

ASSEMBLY

INSTRU

TION

MANUAL

.

FOR

PRO

10

SPORT

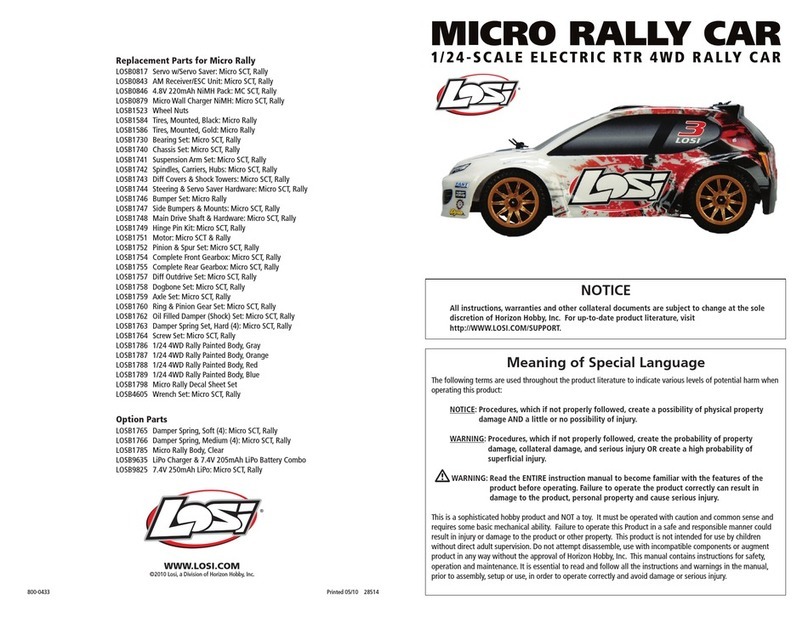

Pictured with optional bumper & side wing.

•

TO

BE

USED

WITH

STEP-BY-STEP

PICTORIAL

REFERENCE

THEPR

0

-10

1988

ROAR

NATIONAL

CHAMPION

I

Congratulations!

You have

now

joined

the wonderful world

of

RIC

racing.

Many

hours

of

fun

are

ahead

of

you. The

PR0-1

0

SPORT

you

have purchased

is

based

on

the nationalwinning

design

of

the

PR0-10

ELITE,

one

of

the top

1110th

scale T-bar

oval

and

on

road

cars

in

the world.

Two

of

the

most

successful radio controlled

car

manufacturers in the world,Co

mposite

c

raft

and

TRC

ha

ve

joined

forces

and

have

in

troduced

an

entry level racing machine

at

an

entry levelprice

without sacrificing race performance. The

PR0-

10

SPORT

can take

you

from the beginning

all

the

way

to the top.

As

you

r skill level increases, t

he

PR0-1

0

SPORT

can

be

up-dated to improved perform-

ance

and

will

be

readyto handleanything

you

can

give it. The

PR0-1

0 series

of

cars are still the

most simple cars to b

uild

and

maintain

on

the

circuit. Precision molded

and

machined compo-

nents make the

PR0-10

SPORT

a snap to

put

together,

but

you

still

need

to

read

and

follow the

instructions. Theywill

give

you

tips

in

the assem-

bly

process

that

w

ill

help

you

when

it

is

time to

race.

TAKE

YOUR TIME I

How

careful

you

assemble the

car

now

is

going

to determine

how

well

it

performs

on

the track. Don't

be

in a hurry.

You won't win anything

for

the fastest chassis

assembly.

••••••••••••••••••••••

•

AS

S

EMBL

Y TIPS

FROM

•

• •

• THE

FACTORY

•

•• •• • •••• •••• ••••• • •••

Before

you

get

started, here

are

some

suggestions

and

tips

that

w

ill

make the assembly

of

your

kita little easier.

Glance

through

the instructions

and

picturesoncebefore

you

startto assemble the kit.

This will help

get

you

familiarized with the

assemblysteps

and

the p

ic

tures.

2

To help eliminateconfusion,

only

open the

partsbags when they are calledfor in the instruc-

tions. Otherwise

you

might

mix

up

small parts

which willmake the assemblymuch more difficult.

When

you

empty

the parts bags, use a

paper

plate

or

a

small

containerto empty

it

in.

This

will

keep

parts from rolling

off

t

he

table

and

being

lost foreve

r.

When

you

are putting screws into plastic

pieces, be sure that

you

do

not

over

tighten them.

This

could

result in t

he

threads in theplasticstrip-

ping. Tighten the screws untilt

hey

are snug.

Check

all

the

hol

es

in t

he

nylon pieces.

Some

of

the holesare

no

t tapped. You should

tap

these holes with the correctsize tapbeforeputting

a

screw

in

the piece.

All

molded

nylon pieces will have a small

amount

of

flashing. Before

you

assemble these

pieces

it

is

a

good

idea to remove

it

with a hob

by

knife. In the instructions, certain parts are

referred to as left

and

right. Imagine yourself sit-

ting in a full size

car

in

the driver's seat. The

driver's side

is

what will

be

referred to

as

t

he

le

ft

side. The passengerside w

ill

be

referred

to

as

the

right side. Please keep this in

mind

while

you

are

assembling

your

car.

The step numbers

in

this manual corre-

spond

to t

he

pictur

es

in

the

pic

torial assembly

manual. Use both

for

the assemblyof this kit.

Due

to COMPOSITECRAFT & TRC's

on-going development program, certain parts in

the pictorial assembly

manual

may

be

different

from the actual

parts

in

the k

it.

/

'

Item

s

required

to

c

omplete

this

c

ar

1-

Two

channelradio system

1-

Speed

controldevice

1 -6

or

7 cellbattery

pack

-saddle type

1-

05

electric

motor

1 -

111

Oth

scale

body

(

if

not

included)

1 -Servo

saver

1 -Batterychargingsystem

/

'

/

15138

#5562

15140

15142

15144

15156

#5502

#5523

#5574

15476

15560

15166

15424

15428

#5502

#5506

#5540

15561

#5590

#5316

#5318

115320

#5322

#5328

Tools

and

supplies

needed

to

build

this

kit

#2

phillips screwdriver-large I Hobbyknife

SmallpliersI Needle nosepliersI Medium file

Shock

oil

I

20

-

25

Weight 1Silicone lube

_/

"'\

OPTIONAL TOOLS

N

ut

driversetI Dremel Tool

4-40tap, 8-32 tap

_/

•••••••••••••••••

:PRO

-10

SPORT

:

:

KIT

CONTENTS :

•••••••••••••••••

(

sAG#

1 FOR

PR0-10

SPORT)

MOLDED

NYLON

FRONT

CROSS

BAR...................1

1

11

6"

A

LLEN

WRENCH

....

..

....................................... 1

KING

PINS

FOR

NYLON

FRONT

CROSS

BAR

.......2

2

DEGREE

CASTER

SHIMS

.....................................2

118"

STEERING

BLOCKS

..........................................2

.022FRONTSUSPENSION

SPRINGS

.....................2

114"

X.060

STEEL

WASHER

....................................2

4-40X

114

"

STEEL

FLATHEAD

SCREWS

................2

8-32X

112"

ALUMINUM

FLATHEAD

SCREWS

......

...

2

118

" X

114

"

STEEL

WASHER

................................

...

..

2

118

" X5116"

FLANGED

OILITE

BUSHINGS

....

...

....

..

.4

1/8"

E-CLIP .........

..

............

..

...

..

................................

10

(

sAG#

1A FOR

PR0-10

SPORT )

SERVO

MOUNTI

NG

KIT

.........................................

..

1

3"

MOLDED

NYLONBODYPOST............................2

BODY

POST

COLLAR................................................2

4-40X

114

"

STEEL

FLATHEAD

SCREW...................2

4-40X

112

"

STEEL

FLATHEAD

SCREW......

...

..

........2

4-40 X

118

" SETSCREW...........................................2

.

050"

STEEL

ALLEN

WRENCH

................................. 1

STEERING

LINKAGEKIT...

..

.............

..

...................... 1

(s

AG#

2 FOR

PR0-10

SPORT )

SUPPORTPLATE PIVOT

BALL

& SOCKETSET.....1

FIBERGLASS

REAR

T-BAR

......................................1

TOP

MOTOR

BLOCK

BRACE

...............................

....

1

NYLON

MOTOR

BLOCKSET................................... 1

RIDEHEIGHT

ADJUSTOR

SET................................ 1

•

3

#5502 4-40X 11

4"

STEEL

FLATHEAD

SCREW

................... 1

#5514 5-40X 11

4"

STEEL

SOCKET

HEAD

CAP

SCREW

...

4

8-32X

318"

STEEL

SOCKET

HEAD

SCREWS

.........

2

15523 8-32X

112"

ALUMINUM

FLATHEAD

SCREWS

.......

.4

#5574

118"

X 114"

STEEL

WASHER

.....................................1

(

sAG#

3 FORPRO -10SPORT )

#5314

MO

LDED

NYLON

T-BAR

SUPPORT

PLATE

............ 1

#5334

REAR

DAMPENER

KIT........................................

.....

1

15426

#5428

#5523

#5340

#5342

#5510

#5540

#5553

#5512

ANTENNA

MOUNT...........

..

...

....................................1

4"

NYLON

BODY

POSTS

..........................................2

BODYPOST

COLLARS

............................................2

8-32X

112"

ALUMINUM

FLATHEAD

SCREW

........... 1

REAR

SUSPENSION

SPRINGS

...............................2

NYLON

SPRING

LOCATORS

...................................2

4-40X 11

4"

STEEL

FLATHEAD

SCREW...................1

4-40X 1"

STEEL

FLATHEAD

SCREW

......................2

4

·40

X

118"

STEEL

SETSCREW..............................2

4-40

STEEL

LOCKNUT............................................2

5-40X

318"

STEEL

FLATHEAD

SCREWS

................4

(_sAG#

4 FOR PR0-10SPORT)

#676 120

TOOTH

SPUR

GEAR

......................................... 1

#5558

8-32

NYLON

LOCKNUT........................................... 1

#5663

STEEL

DIFFAXLE .................................................... 1

#5667

MOLDED

NYLON

DIFF

HUB

..................................... 1

#5669

MOLDED

NYLON

WHEEL

HUB

................................1

#5677

THRUST

BEARING

SET...........................................1

#5678 CONE WASHER ........................................................ 1

#5566 3/32" ALLEN

WRENCH

.........................

..

..................1

#5685 AXLE

SPACER

SET..................................................1

#5546 10-32 X

114"

STEEL

SET

SCREW

............................2

#5674 DIFF DRIVERINGS.........................

....

......................2

#5690 114" X

318"

NYLON

DIFF

BUSHINGS

........................2

#5478

114"

X

318"

FLANGED

OILITE

BUSHINGS

................2

#5516 5-40 X

318"

STEEL

SOCKET

HEAD

CAP

SCREW

...

8

#5672

STANDARD

DIFF

BALLS

..........................................8

Checkthe contents

of

each bagwith the list above.

These bags have been checked at the factory, but it

is

possible that a part

may

be

missing. For missing parts call

704

-

982

-0507. Make sure you use part numbers when

ordering.

ONE

FINAL NQTE I

Assemblystep numbers correspond

to

the

picturenumbers. Complete eachstepbeforegoing

on

to

the next.

NOW

LET'S

GETSTABTED

I

STEP# 1

We

will needto do a slight amount

of

chassisprepbefore we startthe assembly.

Locate the chassis,

and

you will notice that

on

one

side the holes in the chassis are countersunk for screw

heads. This is the bottom

of

the chassis. On the top

of

the

chassis

we

want to file the batteryslots

at

a slightangle so

the batteries will not

be

sitting

on

a sharpcornerthat could

cut the protective heat shrink

on

them

and

cause them to

short out. Lightly file both the front

and

back

of

all

the

batteryslots so the cells willhavea flat spotto sit

in.

Before

you do this, itmight

be

a

good

idea to spreadsome newspa-

per

out

to

catch the filings. You will also use strapping tape

to

holdthe batteries in the chassis. You will needto file the

sections

of

the chassis that the tape goes around.

If

these

placesare leftsharp, theywill

cut

the tape

and

the batteries

willfallout. Just round

off

these edges.

When you are finished, wash

off

the chassis with

water

and

dry

it

off

witha

paper

towel.Then make sure you

wash your hands with soap

and

water. Clean up the dust

anddispose.

You

are

now

finished with step #1. Put a check

mark in the box

to

show that this step

is

complete. After

you've completed each step from nowon, check

off

its box

soyou know which part

of

the assemblyyou are on in case

of

an

interruption. You won't miss anysteps this

way.

PR0-10

SPORT

FRONT

END

ASSEMBLY

STEP#

2 Open bag #1

and

empty the

contents.

For

the time being do not open bag #1A. Locate

thefrontnyloncross

bar

.Checkoverthe beamto makesure

all the flashing,

if

any, is removed around the holes.

The

caster

on

this front

end

is 0 degrees. This means the king

pins will

be

straight up

and

down. You need

to

run a small

amount

of

caster

in

the front end, so locate the two caster

shims. These are molded

at

2 degrees each. Fasten the

frontbeam

to

the chassiswith the castershims betweenthe

chassis

and

the frontbeam.

Use

an 8-32x

112"

screw in the

front

and

a 4-40x

114"

screwin the rear

of

the beamblock.

Tighten

all

screwscompletely.

STEP#

3 Locate the two front steering

blocks

and

remove any flashing from around the holes

with a hobby knife.

STEP#

4 Locate the two front kingpins.

You

will notice that they have a groove in each end. These

groovesarefor

thee

-clips. Putonee-clip

on

one

end

of

each

kingpin.

STEP# 5 Next,

put

a king pin

in

the bottom

arm on the front cross

bar

so it sticks through about

118".

Now slide a steering block

on

the king pin

as

shown

and

push the king

pin

up until

it

reaches the top

of

the steering

4

block

and

sticks throughabouta

1116".

There is nota leftor

a right

on

the steeringblocks. Theyarethe same. Nowputa

spring

on

the king

pin

on

top

of

the steeringblock, then a

thick washer

and

push the king

pin

through the top

of

the

axle beam. Put an e-clip in the top groove

to

hold the

assembly inplace.

STEP#

6 Open

bag

#1A. Findthe frontbody

posts. Fasten them to the chassis using the 4-40 x 1/2"

screws. Holdthepostswithplierswhiletighteningthescrews.

Make sure you do notovertighten the screws

and

strip out

the threads. Put the body

post

collars

on

the posts just

underthelastset

of

hood

pin

holes

and

lockinplacewiththe

4-40 x

118"

set screws. These will

be

adjusted laterto the

body.

STEP#

7 Putthe seNomountingpostsin the

chassis

as

shownusinga 4-40x

114"

screw.

For

now,

put

the

seNo mounting face plates on the posts with the

#2

X

318"

selftap screws so theydo

not

get

lost These will

hold

the

steeringseNo in placelater.

PR0-10

SPORT

REAR

T-SAR

ASSEMBLY

STEP#

8 Open bag

#2

and

locate the steel

pivotball

and

the

114"

steelwasher. Fasten thepivotballto

the t-bar in the middle hole with the washer in between the

pivot ballandthe t-bar

as

shown using a 4-40x

114"

screw.

It would

be

a good idea

to

lock lite this screw.

Do

not use

pliers to holdthe ball while tightening the screw.

STEP#

9 Find the pivot ball nylon socket.

Using a lightoil, coatthe inside

of

the socketthatsnapsonto

thepivotball

as

well

as

the pivotball. Snapthepivotsocket

onto the pivotball. Move it around.

It

willprobablybe a little

tight. Afterthe

car

hasbeenruna few times itwillloosen

up.

STEP#

10 Next, findthetworearmotorblocks.

Fasten them to the rear t-bar using four 8-32 x

112"

aluminumflatheadscrews. Note:bothmotorblocks are the

sameshape. The

only

difference is in the holes for the ride

height adjustors. Be sure to

put

the blocks on the t-bar so

the rideheightadjustors will

be

on theoutside

of

theblocks.

Not

on

the inside.

STEP#

11

Now

find the ride height adjustor

set. You will notice that there are three different offsets in

them. This gives you the option

of

five different rear axle

heights, depending

on

how they are placed in the motor

blocks. Most

of

the racers run the axlein the middle setting,

butyou can referto the section

on

RIDE HEIGHTSET

UP.

When you have chosen the

set

you are goingto use, install

them in the motorblocks

as

shown. Be sure to trim

off

any

flashing that might

be

presentaroundthe edges.

STEP#

12 Next, fasten the

motor

blockbrace

to

the motorblocks, using four 5-40 x

114"

capscrews and

the 8-32 X 318" screws.

Put

the brace on so that the TRC

logo

is

facing

up

andto the rear

of

the t-

bar

as

shown_

PR0-10

SPORT

SUPPORT

PLATE

ASSEMBLY

STEP#

13 Open bag

#3

and

find the t-bar

supportplate. Usingfour5-40x

318"

flatheadscrew

s,

fasten

thesupportplateto thechassis asshow

n.

STEP#

14 Fasten the reardamperpostto the

t-bar support pla

te

as

shown using a 4-40 x 1

12

" screw.

Make sure you do

not

overtighten the screw. Also

be

sure

the holes

in

the posts are facing the front

and

rear

of

the

chassis. N

ot

side to side.

STEP#

15 Next, locate the

rear

damper

pushrod

and

install it in the rear motor block brace as

show

n.

STEP#

16

pushrodasshow

n.

Slide a

set

collarandspring on the

STEP#

17 Next, slide the t-

bar

assembly into

position underthe t-b

ar

supportplate that

is

on the chassis,

andslide the push rod into the middle hole

of

the damper

post.

STEP#

18 Next, slide the nylon pivotsocket

into the large hole in the nylont-barsupportplate.

STEP#

19 Now, using a 8-32x 112"aluminum

screw, fasten the front

of

the t-bar to the front hole

in

the

t-

bar

supportplate

and

lock into place usingan 8-32 nylon

lock nut.

STEP#

20

Slide anotherspring

and

set

collar

on thepush rodasshown. Using a 4-40set screw, tighten

the setcollar

on

the

pus

h rod to

hold

the assembly

in

place.

This will beadjustedlater.

STEP#

21 In each hole next to the pivot ball

in the t-bar, placea 4-40 x 1" screw.

STEP#

22 Put a rear suspension spring

over

eachscrewon top

of

thet-barsupportplate. Ontop

of

each

spr

ing, place a nylonspring locatoras show

n.

STEP#

23

Lockthis assemblyintoplace with

a 4-40 lock

nut

on each screw. Tighten the nuts until they

compress the springsapproximately25%

STEP#

24

Next, fasten the antennamount

on

the chassisusing a 4-40 x 114" screw.

5

STEP#

25

Next, fasten the

4"

bodyposts

to

the chassisusinga 4-40x

112"

screw. Make sureyou

do

not

over

tighten the screw

in

the

body

post. Put the bodypost

collarson the bodyposts

jus

t underthe lastset

of

hood

pin

holes

and

lockintoplacewitha 4-40x 1/8"setscrew. These

will

be

adjustedlaterto the body.

STEP#

26

Take a break. Go and

get

a cold

drink andsitback

and

tellyourseffwhatagreatjobyou have

done so far.

(DIFFERENTIAL ASSEMBLY )

STEP#

27

Locate bag #5 and empty into a

container. There are many small parts that will roll off a

table in this bag. Find the diffaxle. Slip one

of

thediffdrive

rings onto the hubonthe axleasshow

n.

Many racersuse a

drop

of

superglue, like

ZAP

or

HOT

STUFFtoholdthedrive

ring inplaceon the hub.

STEP#

28

Now locate the spur

gear

.

You

will

notice t

hat

the

gear

has two sets

of

holes

in

it. We will be

using the outside set

of

holes. Push an

118

"diffballin each

of

theoutside eight holes. Now

put

a smalldab

of

diffgrease

on eachball.

STEP#

29 Now slide the spur

gear

onto

the

diff

ax

le topped with the second diffdrive ring.

If

you find

something to stand the

diff

axle

in

while building, it makes

assemblymuch easier.

STEP#

30

Next, push a nylon bushing into

each endof thediffhub. Besure

to

trimanyflashingoff

from

the edge

of

thebushings. Makesuretheyfit

all

the w

ay

down

in the hole. Put a drop

of

light

oil

inside each bushingand

slidethehub assemblyonthe axle.Lineupthe drive ringon

t

op

of

thegear with the

diff

hub. This drive ring

may

also be

superglued

to

the hub.

STEP#

31 Now

put

the thin thrust washer on

the axle, inside the

diff

hub, followed

by

the black thrust

bearing,andthen thethick thrustwasher. Next, putthesteel

cone washeronthe axle

(small

end

up)

andlastly the 8-32

nylon lock nut. Tighten the

nut

just enough

to

hold

all

the

partsinplace. We willadjustitlater. Onlyuse a nylon nuton

thediff axle.

STEP#

32 Put the two 11

4"

x

318"

flanged

bushingsin theride heightadjustorsin the motorblocks. Put

a drop

of

light oilinside each bushing.

STEP

#

33

Next, find the nylon axle spacers.

Take the

118"

spacer

and

s

li

de it

on

the di

ff

axle. Slide the

assemblythrough the bearin

gs

in the rear

pod

.