Water Furnace Aurora User manual

Integrated Aurora Controls for Versatec 700 Indoor DOAS Applications

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC

700 INDOOR DOAS APPLICATIONS

ICM2701EW 01/22

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Table of Contents

Table of Contents

Overview & Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Aurora Energy Controls Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Control Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Configuration Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sensor Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Overview & Features

BACnet

ModBus

Stand-alone

BAS

Rnet

Modbus

Modbus

Modbus

AURORA SYSTEM

AURORA PREMIUM

ECONOMIZER & SENSORS

AURORA TOUCH HMI

AURORA

ENERGY

SENSORS

Ethernet

Integrated Controls Platform

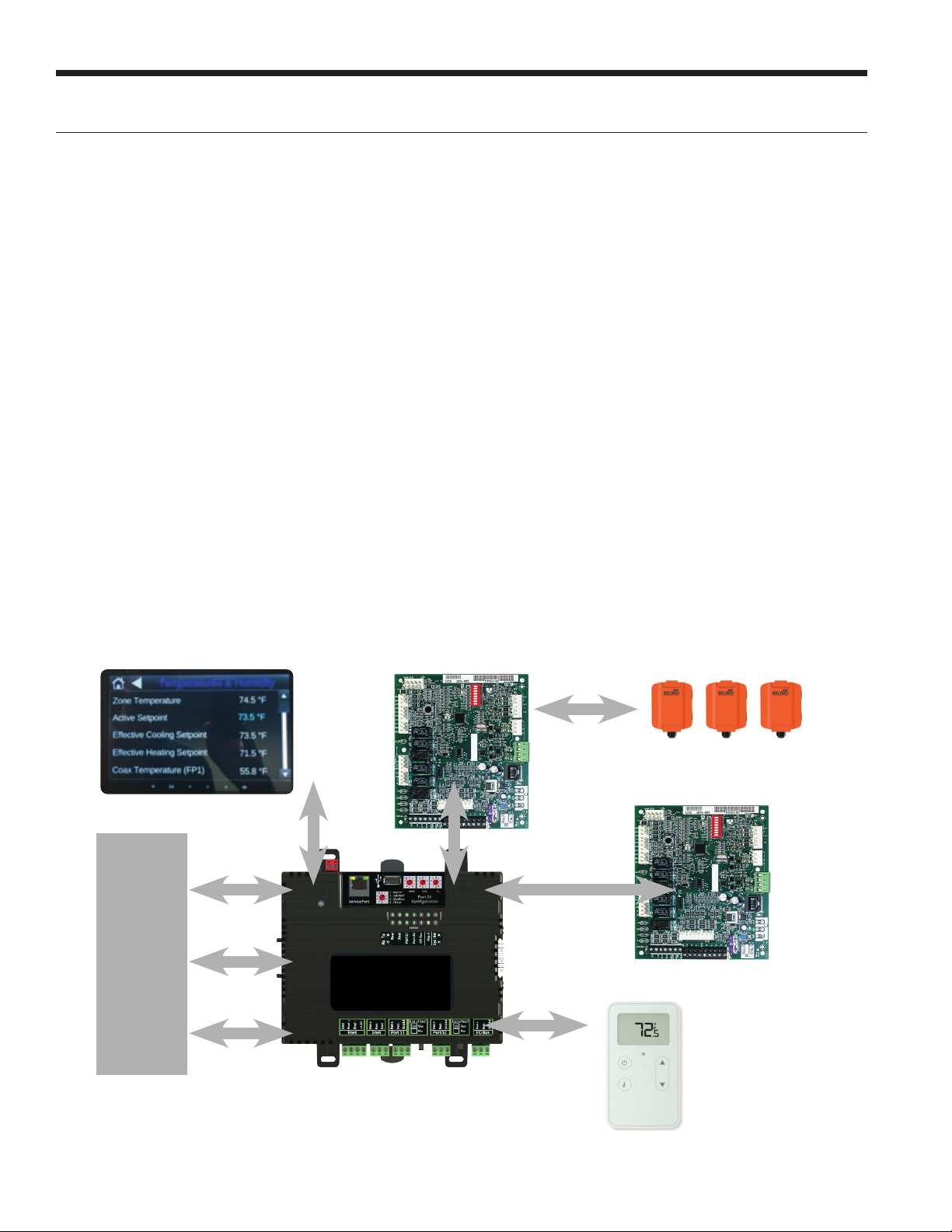

The Versatec DOAS unit operates on the Aurora Controls Network (ACN) which brings together different technologies

such as variable speed compressors, direct drive ECM plenum fans, electronic expansion valves, CFM control, and total

energy recovery to provide a complete DOAS unit. The Versatec DOAS control platform consists of the Aurora System

controller, Aurora Energy Control (AEC), and Aurora Premium. The AEC is a complete microprocessor which functions

as the state engine management of the air-to-air energy recovery equipment. It controls the operation of the energy

wheel, bypass dampers, exhaust blowers, and reads any sensors that are enabled on the energy recovery unit. It also

provide safety features of the energy recovery unit. The Aurora Heat Pump control provides state engine management

for the variable speed heat pump system. It will communicate to the supply blower, inverter board, and other communi-

cating devices or sensors that are enabled on the heat pump. The Aurora DOAS controller is the application controller

that provides all the decision making for the DOAS unit, provides setpoints and overrides to the heat pump and energy

recovery units.

• Simplified diagnostics for the DOAS system with

intuitive large touch screen display with the Aurora

Touch Tablet2

• All sensors communicate over modbus and are

reportable to the BAS

• Full Integration with Aurora Controls Network

• Hot gas modulating reheat with head pressure control

• Preheat output signal with configurable outdoor air

temperature limits

• Economizer operation with factory installed outdoor

air and exhaust air bypass dampers.

• Intelligent sensors at each station on the air-to-air

energy recovery device.

• CFM control

• Advanced Dehumidification

• Multi-Zone VAV

• Single Zone VAV

• CAV

• Demand controlled ventilation

• Drybulb/Enthalpy controlled economizer operation

• Supply Air Temperature Reset

• Remote Supply Air Temperature Reset

• Aurora DOAS Controller Secondary Operation

• Building Pressure Control

• BACnet MS/TP and IP capable

• Network controlled CFM

5

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

DOAS Applications

100% Outdoor Air

The Versatec DOAS unit is designed to fit a

range of variable air volume (VAV) applica-

tions such as single-zone VAV, multi-zone VAV,

and constant air volume (CAV).

Single-Zone VAV

Single-zone VAV systems have typically been

used in larger zones with higher populated areas

with variable cooling loads such as churches,

meeting rooms, gymnasiums, etc. Single-zone

VAV combines aspects of multi-zone VAV and

constant air volume (CAV) applications to serve a single-

zone/space by using temperature setpoints to enable cooling/heating/dehumidification

mode. This application does not contain VAV boxes and the supply blower will operate to maintain the space temperature

in the zone.

Multi-Zone VAV

For multi-zone applications, the controller is configured to control the supply fan to maintain a duct static pressure setpoint.

The variable speed compressor will operate to either a leaving air temperature or evaporator coil temperature in cases where

the unit is equipped with modulating hot gas reheat. In cases with modulating hot gas reheat, the reheat valve will operate

off of a PID that controls to a leaving air temperature setpoint.

Multi-zone VAV units can be applied in a variety of ways such as operating off of BACnet from a BAS controller or stand-alone

operation with or without a thermostat

Constant Air Volume (CAV)

By adjusting the duct static pressure setpoint in the Aurora Premium control to constant, it can turn the VAV controller into

a CAV control application. With the exception of the blower modulation, the system will control the compressor to a leaving

air temperature and operate with all of the same input configuration points.

Model Shown: DAS360

Multi-zone VAV application for office building

6

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

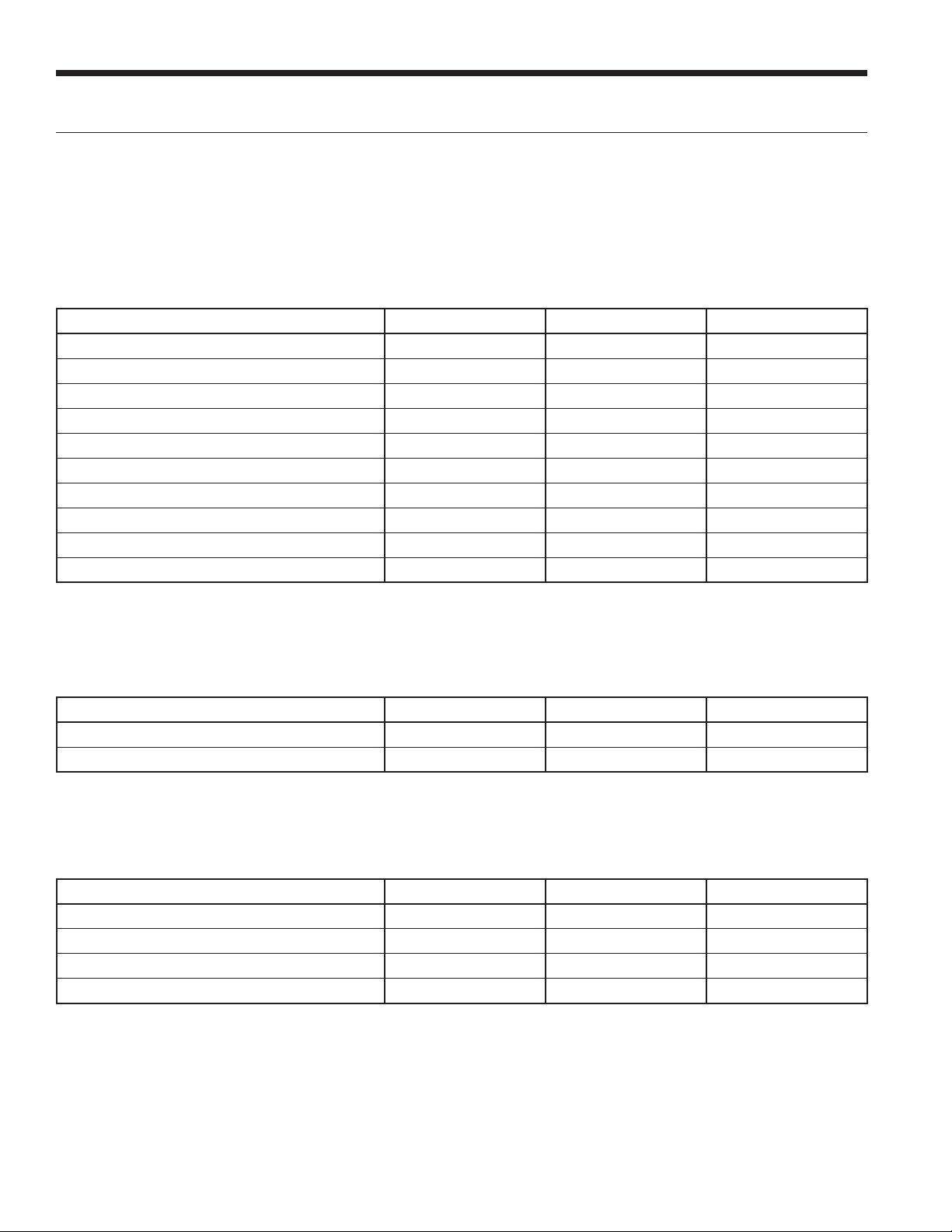

Each Versatec DOAS unit comes with optional controls packages that are included in the energy recovery device which is

represented by the Aurora Energy Controls. These packages are detailed below. Airside economizer functionality can be

added to any of the packages below by adding air bypass dampers.

Aurora Base Energy (“N”)

The Aurora Base Energy is the standard controls package that includes the necessary sensors on the energy recovery

device for DOAS operation. These sensors are listed below.

Aurora Advanced Energy (“P”)

The Aurora Advanced Energy adds additional features to the Aurora Base Energy as described below.

Aurora Premium Energy (“Q”)

The Aurora Premium adds more sensors to the Aurora Advanced as described below.

Aurora Energy Control Packages

Description Type ERW FAV

Outdoor Air Enthalpy Sensor AEC/Modbus X

Return Air Enthalpy Sensor AEC/Modbus X

Entering Wheel Temperature AEC/Analog X

Leaving Wheel Temperature AEC/Analog X

Building Static Pressure Variable BAS Network variable

Demand Controlled Ventilation BAS Network variable

Supply Blower CFM Measurement X

Exhaust Blower CFM Measurement X

Preheat Output Signal AEC/24 VAC

Supply Air Temperature Sensor Field Installed RNet

Description Type ERW FAV

Exhaust Air Enthalpy Sensor AEC/Modbus X

Optical Wheel Rotation Sensor AEC/Analog X

Description Type ERW FAV

Exhaust Filter Differential Pressure AEC/Modbus X

CO2 Return Air Sensor AEC/Modbus X

Wheel Differential Pressure AEC/Modbus X

Supply Filter Differential Pressure AEC/Modbus X

7

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Safety Features

The following safety features are provided to protect the

energy recovery device, wiring, and other components from

damage caused by operation outside of design conditions.

Fuse – A 3 amp automotive type plug-in fuse provides

protection against short circuit or overload conditions.

Over/under voltage – An over/under voltage condition

exists when the control voltage is outside the range of 18

VAC to 30 VAC.

Low OAT shutdown – Low OAT shutdown will de-activate

all outputs based on a the Low OAT threshold temperature.

This is a configured setting to prevent operation in

undesirable conditions.

8

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Layout - Aurora Premium (ERW Cabinet)

Layout - Aurora System Controller & AEC (ERW Cabinet)

Aurora Touch HMI

Aurora Energy Control (AEC)Aurora System Controller & AEC (ERW

Cabinet)

9

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Layout - Aurora Premium (FAV Heat Pump Controls)

CC2

Factory

Fault

ALG

ALM

LS

ES

ACC c

Status

AuroraTM Base

Control

RV – K1

CC2

CC – K2

CC Hi – K3

Fan – K4

Alarm – K5

Acc – K6

ACC no

ACC nc

O/B

C

R

LO

G

Y1

Y2

W

DH

3A-Fuse

O/B

C

R

LO

G

Y1

Y2

W

DH

LO

G

HI

CCG

CC

FG

F

R

HP

HP

LP

FP2

FP2

FP1

REV

REV

CFM

PWM

ECM PWM

Factory

Factory Fan Connection

RR

CC

C

C

R

(-)

(+)

RS 485

EH2

C

EH1

C

CO

(+)

(-)

R

C

RS485

Exp Factory

Com1

Com2

Config

G

G

G

YR

SW1 Test

FP1 – 15oF/30oF

JW2 - Alarm

P11

P5

P2 P1

P8

P7

P9

P6

P3

SW2

P13

P4 FP2 – 15oF/30oF

RV – B/O

ACC

– Dip

1

ACC

– Dip

2

CC – Dual/Single

L – Pulse/Continuous

Reheat/Normal

Factory Use

Field ConnectionsField Connections

C

LP

FP1

F

CC

G

Y1

1

2

3

4

5

6

7

8

Off On

N/A

RS485 NET

EH1

LED 1

LED 3

LED 2

LED 5

LED 4

SCT SUC P

HW

HW

MOTOR

RS485

P7

ZONE

P9

ABC

STEPPER ANA SPR DH DIV

NO

COM

K6

NO

COM

K5

C

R

L1

L1

L2

L2

P12 P10 P5 P11

C

R

(-)

(+)

C

R

(-)

(+)

C

R

(-)

(+)

P4 P2

K1

K2K3

HA2 HA1 SGI LOOP PWM VS SLO SLI

P3

V+

C

R

TX

RX

+5

P14

LLT

P1 LATFLOWLWTEWT

CT2

4 3

CT2

4 3

CT1

2 1

CT1

2 1

Status

G

DISCH

P16

P17 P18 P15

(Aurora Expansion Board)

AXB™

See Figure 1 for

DHW wiring.

SW1

Modbus Add. ID

Future Use

1

2

3

4

5

ONOFF

Future Use

Acc 2 – Dip 4

Acc 2 – Dip 5

P8 P6

ABC Control Board Layout AXB Control Board Layout

Compressor Drive

CC2

EH1

Fac t ory

Faul t

ALG

ALM

LS

ES

ACC c

Status

AURORA BASE

CONTROL™

RV – K1

CC2

CC – K2

CC Hi – K3

Fan – K4

Alarm – K5

Acc – K6

ACC no

ACC nc

O/B

C

R

LO

G

Y1

Y2

W

DH

3A-Fuse

O/B

C

R

LO

G

Y1

Y2

W

DH

LO

G

HI

CCG

CC

FG

F

R

HP

HP

LP

FP2

FP2

FP1

REV

REV

CFM

PWM

ECM PWM

Fac t ory

Factory Fan Connection

RR

CC

C

RS 485

EH2

C

EH1

C

CO

(+)

(-)

R

C

RS485 Exp Fac t ory

Com1

Com2

Config

G

G

G

YR

SW1 Test

FP1 – 15oF/30oF

JW2 -

Alarm

P11

P5

P2 P1

P8

P7

P9

P6

P3

SW2

P13

P4 FP2 – 15oF/30oF

RV – B/O

ACC – Dip 4

ACC – Dip 5

CC – Dual/Single

L – Pulse/Continuous

Reheat/Normal

Factory Use

Fi eld ConnectionsFi eld Connections

C

LP

FP1

F

CC

G

Y1

1

2

3

4

5

6

7

8

Of f On

N/A

RS485 NET

LED3

LED2LED1

11111

33322

222

444

KM7

KM4 KM5 KM6 KM1

KM2

KM9

EEV/Power Supply Board Layout

10

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Physical Data

Serial Number

If you need the Aurora System controller (LS-CPU) serial number when troubleshooting, the number is on:

• a sticker on the back of the main translator board

• a Module Status report (modstat) from WebCTRL , or thru the Aurora Touch Interface by accessing the “Module Setup”

menu.

FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

CAUTION: Changes or modifications not expressly approved by the responsible party for compliance could void the

user’s authority to operate the equipment.

CE Compliance

The Aurora UPC conforms to the following standards. A full Declaration of Conformity is available on request.

Electromagnetic Emissions: EN55022: 1994 Class A Electromagnetic Compatibility:

Immunity for Commercial Environments EN61000-6-1: 2007 Electrostatic Discharge: EN61000-4-2: 2008

Radiated Electromagnetic Field: EN61000-4-3: 2010 Electronic Fast Transient/

Burst Requirements: EN6100-4-4: 2004

Surge Immunity: EN6100-4-5: 2005 Immunity to Conductive Disturbance:

EN6100-4-6: 2008 Power Frequency Magnetic Field Immunity:

EN6100-4-8: 2009 Immunity to Voltage Dips and Variations

EN6100-4-11: 2004 European Low Voltage Directive

Restriction of the Use of Certain Hazardous Substances (RoHS)

BACnet Compliance

BACnet® is a registered trademark of ASHRAE. ASHRAE does not endorse, approve or test products for compliance with

ASHRAE standards. Compliance of listed products to requirements of ASHRAE Standard 135 is the responsibility of the

BACnet manufacturers Association (BMA). BTL certification is pending.

BTL® is a registered trademark of the BMA.

11

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Control Inputs

Direct AEC Inputs:

Leaving Wheel Temperature – The Leaving Wheel Tem-

perature sensor will be a 10kΩNTC thermistor connected to

the FP1 input on the AEC control.

Entering Wheel Temperature – The Entering Wheel Tem-

perature sensor will be a 10kΩNTC thermistor connected to

the FP2 input on the AEC control.

Optical Wheel Sensor – The Optical Wheel Sensor input

will be connected to the LPS input on the AEC control.

Shutdown – The Shutdown input will be a grounded signal

connected to the ES input on the AEC control. The opera-

tion of the Shutdown input will depend on the position of

AEC DIP switch SW6.

Supply Dirty Filter Switch – The Supply Dirty Filter Switch

(SDFS) input will be a 24 VAC input signal connected to

the W input on the AEC control. This switch is optional and

available upon request.

Exhaust Dirty Filter Switch – The Exhaust Dirty Filter

Switch (EDFS) input will be a 24 VAC input signal con-

nected to the DH input on the AEC control. This switch is

optional and available upon request.

Modbus Sensor Inputs:

For all Modbus devices, the device must be “added” to

the AEC Modbus slave device list for the AEC to attempt

communications with the device.

Outdoor Air Sensor – The Outdoor Air Sensor can provide

temperature, humidity, and enthalpy values.

Return Air Sensor – The Return Air Sensor can provide

temperature, humidity, and enthalpy values.

Exhaust Air Sensor – The Exhaust Air Sensor can provide

temperature, humidity, and enthalpy values. The Exhaust

Air Sensor is an optional sensor.

CO2 Return Air Sensor – The CO2 Return Air Sensor can

provide temperature, humidity, enthalpy, and CO2 values.

The optional CO2 Return Air Sensor replaces the standard

Return Air Sensor when present.

Exhaust Blower Differential Pressure –The Exhaust Blower

Differential Pressure Sensor can provide differential

pressure and volumetric flow values.

Building Differential Pressure – The Building Differential

Pressure Sensor can provide a signed differential pressure

value. The Building Differential Pressure Sensor is an

optional sensor.

Wheel Differential Pressure – The Wheel Differential

Pressure Sensor can provide a signed differential pressure

value. The Wheel Differential Pressure Sensor is an optional

sensor.

Supply Filter Differential Pressure – The Supply Filter

Differential Sensor can provide a signed differential

pressure value. The Supply Filter Differential Pressure

Sensor is an optional sensor.

Exhaust Filter Differential Pressure – The Exhaust

Filter Differential Pressure Sensor can provide a signed

differential pressure value. The Exhaust Filter Differential

Pressure Sensor is an optional sensor.

AEC Control DIP Switch Inputs

SW1 – System Configuration SW1 Future use

SW2 – System Configuration SW2 Future use

SW3 – Conditioning Inputs SW3 Future use

SW4 – ACC Relay Operation SW4 On = Track Blower,

SW4 Off = Track Wheel

SW5 – ACC Relay Operation SW5 Future Use

SW6 – Shutdown SW6 On = Emergency

Shutdown, SW6 Off =

Shutdown with Exhaust

SW7 – Alarm Output SW7 On = Continuous,

SW7 Off = Pulsed

SW8 – Future SW8 Future Use

All control system input values may be read from sensors physically connected to the control system, either communicating

or discrete, or they may be alternatively supplied via Modbus from a BAS controller or other appropriate Modbus master

controller.

12

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Control Outputs

Discrete AEC Outputs:

Outdoor Air Damper – The Outdoor Air Damper output

will be a 24 VAC output signal connected to the RV output

on the AEC control.

Energy Recovery Wheel – The Energy Recovery Wheel

output will be a 24 VAC output signal connected to the F

output on the AEC control.

External Preheat – The External Preheat output will be a 24

VAC output signal connected to the CC output on the AEC

control.

Alarm Relay Output – The Alarm Relay output will be a 24

VAC or dry contact output connected to the ALM output of

the AEC control.

Lockout Output – The Lockout Output will be a nominal 24

VDC output signal connected to the LO output of the AEC.

The operation of the output will depend on the setting of

AEC DIP switch SW7.

Modbus Controlled Outputs:

For all Modbus devices, the device must be “added” to

the AEC Modbus slave device list for the AEC to attempt

communications with the device.

Exhaust Blower – The Exhaust Blower is a Modbus

controlled output for an ECM plenum blower. The AEC may

control either one or two exhaust blowers. If the system

has two exhaust blowers, they will always be operated at

the same speed.

Supply Air Bypass Damper – The optional Supply Air

Bypass Damper is a Modbus controlled output for a

modulating actuator. The AEC may control either one or

two supply air bypass dampers. If the system has two

supply air bypass dampers, both actuators will always be

operated to the same position.

Exhaust Air Bypass Damper – The optional Exhaust

Air Bypass Damper is a Modbus controlled output for a

modulating actuator. The AEC may control either one or

two exhaust air bypass dampers. If the system has two

exhaust air bypass dampers, both actuators will always be

operated to the same position.

13

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Configuration Settings

Configuration setting values will be stored in non-volatile

memory and may be adjusted using an Aurora Touch HMI

or through the BAS interface.

Neutral Air Target SAT (NeutTgt)

The Neutral Air Target SAT is the system target SAT with

no active heating or cooling demand. The NeutTgt value

will be in the range of 45°F to 75°F, with a default value of

65°F.

Heating Air Target SAT (HeatTgt)

The Heating Air Target SAT is the target SAT with active

heating demand. The HeatTgt value will be in the range of

65°F to 85°F, with a default value of 80°F.

Cooling Air Target SAT (CoolTgt)

The Cooling Air Target SAT is the target SAT with active

cooling demand. The CoolTgt value will be in the range of

45°F to 65°F, with a default value of 50°F.

Target Supply Air Humidity (SAHtgt)

The Target Supply Air Humidity is the target value for the

supply air relative humidity. The SAHtgt value will be in the

range of 50% to 75% RH, with a default value of 60% RH.

Deadband Temperature Value (DBT)

The Deadband Temperature Value is the temperature

hysteresis value for operational condition activation /

deactivation. The DBT value will be in the range of 0.5°F to

5.0°F with a default value of 2.0°F.

Deadband Humidity Value (DBH)

The Deadband Humidity Value is the humidity hysteresis

value for operational condition activation / deactivation.

The DBH value will be in the range of 1% to 5% with a

default value of 2%.

Deadband Enthalpy Value (DBE)

The Deadband Enthalpy Value is the enthalpy hysteresis

value for operational condition activation / deactivation.

The DBE value will be in the range of 0.1 BTU/lb. to 1.0

BTU/lb., with a default value of 0.3 BTU/lb.

Supply Blower Target (SupBlwTgt)

The Supply Blower Target value is the target nominal

supply blower operating CFM value. The SupBlwTgt

value range and default value will be dependent on the

configuration. The actual operating target CFM may

vary from the nominal setting under certain operating

conditions such as DCV.

Supply Airflow Calculation Multiplier

(kSCFM)

The Supply Airflow Calculation Multiplier value is used to

calculate the airflow for the supply blower based upon

the measured values from the differential pressure sensor.

Appropriate ranges and default values for the kSCFM value

are shown in the BlowConfig table above.

DCV Enable (DCV)

The DCV Enable value is a Boolean control point to enable

or disable demand control ventilation operation. The

default state will be disabled.

CO2 Target for DCV (DCVlimit)

The CO2 Target for DCV is the target level for demand

control ventilation operation. The DCVlimit will be in the

range of 300 ppm to 1500ppm with a default value of 900

ppm.

DCV interval Time (DCVint)

The DCV Interval Time is the time period between potential

adjustments of the supply blower based on the current

CO2 value for demand control ventilation operation. The

DCVint value will be in the range of 15 seconds to 60

seconds, with a default value of 30 seconds. This value

will most likely not be exposed for field modification, but

adjustable for development.

Building Pressurization (BldPres)

The Building Pressurization value is a Boolean control point

to enable or disable building pressurization operation. The

default state will be disabled.

Building Pressurization Target (BPDP)

The Building Pressurization Target value is the target

differential pressure for building pressurization operation.

The BPDP value will be in the range of –0.20 inchWC to

0.20 inchWC with a default value of 0.01 inchWC.

Preheat Temperature Limit (PHtemp)

The Preheat Temp Limit is the activation temperature below

which preheat is activated. The PHtemp value will be in the

range of –25°F to 30°F with a default value of 20°F..

Minimum Ventilation Temperature

(MinVent)

The Minimum Ventilation Temperature is the minimum

allowed ventilation air temperature without the wheel

operating. The MinVent temperature limit will be in the

range of 35°F to 55°F with a default value of 45°F.

Maximum Ventilation Temperature

(MaxVent)

The Maximum Ventilation Temperature is the maximum

allowed ventilation air temperature without the wheel

operating. The MaxVent temperature limit will be in the

range of 75°F to 95°F, with a default value of 85°F.

Absolute Minimum OAT (MinOAT)

The Absolute Minimum OAT is the minimum outdoor

temperature for operation of the system with or without

pre or post heat. The MinOAT will be in the range of –40°F

to 20°F, with a default value of 15°F.

14

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

Configuration Settings cont.

Supply Filter Base DP (SFBaseDP)

The Supply Filter Base DP is the differential pressure

value of the Supply Filter Differential Pressure Sensor

with a clean filter. The value will be set at system start-up

by a technician with the system blower operating. The

SFBaseDP value will be in the range of 0.010 inchWC to

0.500 inchWC with a default value of 0.100 inchWC.

Exhaust Filter Base DP (EFBaseDP)

The Exhaust Filter Base DP is the differential pressure

value of the Exhaust Filter Differential Pressure Sensor

with a clean filter. The value will be set at system start-up

by a technician with the exhaust blower operating. The

EFBaseDP value will be in the range of 0.010 inchWC to

0.500 inchWC with a default value of 0.100 inchWC.

Wheel Base DP (WhBaseDP)

The Wheel Base DP is the differential pressure value of the

Wheel Differential Pressure Sensor with a clean wheel. The

value will be set at system start-up by a technician with the

system blowers operating. The WhBaseDP value will be in

the range of 0.010 inchWC to 1.000 inchWC with a default

value of 0.250 inchWC.

15

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

System Operation - System Operating Modes

Energy Recovery Cooling

In the energy recovery cooling mode, the bypass dampers

will be closed, the energy wheel will be active, and the

compressors will operate as needed to maintain supply air

conditions.

Economizer

In the economizer mode, the bypass dampers will be open,

the energy wheel will be de-activated, and the compressors

will operate as needed to maintain supply air conditions.

Economizer with Energy Recovery

In the economizer with energy recovery mode, the dampers

will modulate, the energy wheel will be active, and the

compressors will operate as needed to maintain supply air

conditions.

Energy Recovery Heating

In the energy recovery heating mode, the bypass dampers

will be closed, the energy wheel will be active, and the

compressors will operate as needed to maintain supply air

conditions.

Compressor Where Needed

Compressor Where Needed

Energy Recovery

Economizer

Economizer &

Energy Recovery

Energy

Recovery

Cooling Design

Dew Point

16

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

System Operation - Target Supply Air Temperature Determination

System Operation - System Blowers

Nominal Target Supply Air Temperature

The Target Supply Air Temperature value will be either

NeutTgt, HeatTgt, or CoolTgt. The Target Supply Air

Temperature value will be determined by either BAS

commands, or in stand-alone operation by physical inputs,

space temperature, or return air temperature.

Supply Blower

When the system is enabled and outdoor air damper is

open, the supply blower will be active. For systems with

multiple heat pumps, the number of blowers operating may

vary depending on airflow requirements. All operating

blowers will operate at the same speeds.

For CAV applications, the supply blower will be controlled

to maintain the target supply airflow. The target airflow

maybe adjusted from the nominal value for demand

controlled ventilation.

For multi-zone VAV applications, the supply blower will be

controlled to maintain the duct static pressure setpoint.

The supply blower may operate at a higher duct static

pressure for demand controlled ventilation.

For single zone VAV applications, the supply blower will be

controlled based on the system heating or cooling demand.

The supply blower may operate at a higher airflow for

demand controlled ventilation

Exhaust Blower

When the system is enabled and outdoor air damper is

open, the exhaust blower will be active. For systems with

multiple blowers, all blowers will operate at the same

speeds.

When configured for building pressurization, the exhaust

blower will operate to maintain the building pressure

setpoint.

When building pressurization is not selected, the exhaust

blower will operate to maintain the target exhaust blower

airflow. The target exhaust airflow maybe adjusted based

on supply blower operation.

Demand Controlled Ventilation

When enabled and active, demand controlled ventilation

will increase the supply blower airflow to maintain CO2

PPM setpoint. When using BAS or space sensor supplied

value, VOC maybe used in place of CO2.

Supply Air Temperature Reset

Supply Air Temperature Reset may adjust the target

supply air temperature from the nominal value. Supply Air

Temperature Reset maybe controlled space temperature,

return air temperature, or outdoor air temperature. Supply

Air Temperature Reset can be enabled for heating, cooling,

or both.

17

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

System Operation - Energy Recovery

Outdoor Air Damper

The Outdoor Air Damper output will always be activated

30 seconds prior to the supply blower to allow the damper

to open.

Energy Recovery Wheel

The Energy Recovery Wheel output will operate based on

the current supply air target value and system temperature,

enthalpy, and humidity values. The energy wheel is active

any time the system is in the energy recovery cooling,

economizer with energy recovery, or energy recovery

heating mode.

Supply Bypass Damper

The optional Supply Bypass Damper is closed in the energy

recovery cooling or energy recovery heating mode. It will

be open in the economizer mode and modulate in the

economizer with energy recovery mode.

Exhaust Bypass Damper

The optional Exhaust Bypass Damper is closed in the

energy recovery cooling or energy recovery heating mode.

It will be open in the economizer mode and modulate in the

economizer with energy recovery mode.

Preheat

The Preheat output will operate based on the preheat

setting and OAT when the supply blower is active.

Accessory Output

The Accessory output (ACC) will operate as an accessory

relay tracking the operation of the either the exhaust

blower or energy wheel.

System Fault/Warning Conditions

For all fault conditions all control outputs except the ALM

and LO outputs will be deactivated. When a fault condition

is recognized except the Over/Under Voltage Fault, the

ALM and LO outputs will be activated immediately and

remain active until the fault is no longer active.

For all Warning conditions the system in general will

continue to operate, although some functions will no longer

be fully operational.

All fault and warning conditions can be reset by a fault

reset which is activated by either cycling power to the AEC,

setting the SysMode to Off, or via a Modbus fault reset

value. Some fault and most warning conditions are also

self-clearing conditions if the conditions for activating the

fault or warning are no longer present .blower or energy

wheel.

a. Energy Recovery Wheel Rotation Warning

An Energy Recovery Wheel Rotation Warning will

impact the operation of the bypass dampers and limit

the operation of the system.

If the Energy Recovery Wheel output is active and

wheel rotation is not detected an Energy Recovery

Wheel Rotation Warning condition. The control

logic will maintain the wheel output based on system

operating conditions, and if wheel rotation is once

again detected the Energy Recovery Wheel Rotation

Warning will be cleared and normal operation will

continue.

If an Energy Recovery Wheel Rotation Warning is

active the Supply Bypass Damper and the Exhaust

Bypass Damper will be opened, and the other control

outputs will continue operating normally.

b. Energy Recovery Wheel Rotation Fault

If the Energy Recovery Wheel output is active and

wheel rotation is not detected an Energy Recovery

Wheel Rotation Fault will be recognized.

If an Energy Recovery Wheel Rotation Fault is active, it

will remain active until a fault reset occurs.

c. Entering Wheel Temperature Sensor Warning

If the AEC control does not have a valid Entering

Wheel Temperature (EWhT) value an Entering Wheel

Temperature Sensor Warning will be recognized. The

warning condition will remain until a valid Entering

Wheel Temperature value is present, or a fault reset

occurs.

If an Entering Wheel Temperature Sensor Warning is

active, the current OAT value will be used in place of

EWhT for control logic.

d. Leaving Wheel Temperature Sensor Warning

If the AEC control does not have a valid Leaving

Wheel Temperature (LWhT) value a Leaving Wheel

Temperature Sensor Warning will be recognized. The

warning condition will remain until a valid Leaving

Wheel Temperature value is present, or a fault reset

occurs.

If a Leaving Wheel Temperature Sensor Warning is

active, there will not be modulation of the Supply

Bypass Damper to maintain the supply air temperature.

18

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

System Operation - Energy Recovery cont.

e. Over / Under Voltage Fault

An Over/Under Voltage Fault condition exists when

the control voltage is outside the nominal operating

range of 18VAC to 30VAC. For an Over/Under Voltage

Fault condition the LO output will be activated after

5 seconds, and the ALM output will be activated after

the fault condition has been active for 15 minutes. Both

outputs will be turned off as soon as the fault condition

is cleared.

f. Modbus Communication Fault

A Modbus Communications Fault will be recognized

when the AEC does not receive valid communications

from a critical slave device. Normal operation will

resume once communication has been restored and

the fault will be reset. Critical slave devices are any of

the following components:

1) Exhaust Blower or Blowers

2) Outdoor Air Sensor

g. Modbus Communication Warning

A Modbus Communications Warning will be recognized

when the AEC does not receive valid communications

from a non-critical slave device. The warning will reset

once proper communication has been restored. The

following non-critical sensors are listed below:

1) Return Air Sensor

2) Supply Air Sensor

3) Exhaust Air Sensor

4) Supply Bypass Damper or Dampers

5) Exhaust Bypass Damper or Dampers

6) Building Differential Pressure Sensor

7) Wheel Differential Pressure Sensor

8) Supply Filter Differential Pressure Sensor

9) Exhaust Filter Differential Pressure Sensor

10) Supply Blower Differential Pressure Sensor

11) Exhaust Blower Differential Pressure

Sensor

h. Exhaust Blower Fault

An Exhaust Blower Fault will occur if the AEC control

does not detect communication with the exhaust

blower. Normal operation will resume once the fault

condition is removed.

19

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

System Operation - Heat Pump

System Operation - Low OAT Shutdown

System Operation - Emergency Shutdown

System Operation - Shutdown with Exhaust

Compressor

The compressor will operate in the appropriate mode

and at the appropriate capacity to maintain the supply

air temperature setpoint when required and modulating

hot gas reheat is not active or present. If compressor is

operating in the cooling mode with modulating hot gas

reheat active, the compressor will operate to maintain the

appropriate target air coil temperature.

Modulating Gas Reheat

When cooling is active and dehumidification is required, the

modulating hot gas reheat valve will modulate to maintain

the supply air temperature setpoint. When enabled, head

pressure control will modulate the system water valve to

maintain a discharge temperature setpoint.

Waterside Economizer

When cooling is required, waterside economizer is

operated prior to mechanical cooling to maintain supply

air temperature setpoint when enabled and available.

If waterside economizer cannot maintain setpoint,

mechanical cooling will also be activated.

When Low OAT Shutdown is active all systems outputs will

be de-activated.

When Emergency shutdown is active all system outputs

will be de-activated.

When Shutdown with Exhaust is active the exhaust bypass

damper will be open, the exhaust blower will operate at the

target exhaust airflow, and all other system outputs will be

de-activated.

20

INTEGRATED COMMERCIAL AURORA CONTROLS FOR VERSATEC 700 INDOOR DOAS APPLICATIONS

System Operation - Standalone Control

Physical Input

When the system occupancy is set to occupied physical

thermostat inputs to the Aurora Energy Control may

operate the system. A “G” input will activate the system to

operate using the NeutTgt Target Supply Air Temperature

value. A “Y1” input will activate the system to operate

using the HeatTgt Target Supply Air Temperature value.

An “O” input will activate the system to operate using the

CoolTgt Target Supply Air Temperature value. If the system

occupancy is unoccupied or both “Y1” and “O” are active,

the system will be off.

Temperature

The system uses the current occupancy status to determine

which set points (Occupied or Unoccupied) it should

control the system from. The effective heating and cooling

set points will reflect the occupancy status, occupancy

override, and any influence from the sensor’s warm/cool

adjustment.

The control temperature for standalone operation may be

either the space temperature, return air temperature, a BAS

supplied value, or the outdoor air temperature.

The system will be active when the occupancy status is

Occupied, and may be configured to be active during

Unoccupied, or only operate in the unoccupied mode when

a control temperature demand is present. If the system is

operating without an active control temperature demand in

the Occupied or Unoccupied mode, the system will use the

NeutTgt Target Supply Air Temperature value.

The current control temperature and effective heating and

cooling set points are used to control the Target Supply

Air Temperature value. If the current control temperature

and effective heating set point result in a heating demand,

the system will operate using the HeatTgt Target Supply

Air Temperature value. If the current control temperature

and effective cooling set point result in a cooling demand,

the system will operate using the CoolTgt Target Supply Air

Temperature value.

Scheduling & Occupancy

The system occupancy may be controlled externally

or using the internal scheduling capability of the

Aurora System controller. Whether internal or external

scheduling is selected, the system may be configured so

the unoccupied mode may be overridden by occupancy

sensors or by temporary overrides from zone sensors.

For external occupancy control the occupancy may be

set using a BACnet MSV to select between Occupied,

Unoccupied, Standby, or Temporary Occupied.

Alternatively, the MSV may be set to unoccupied and the

external occupancy controlled by a BACnet BV.

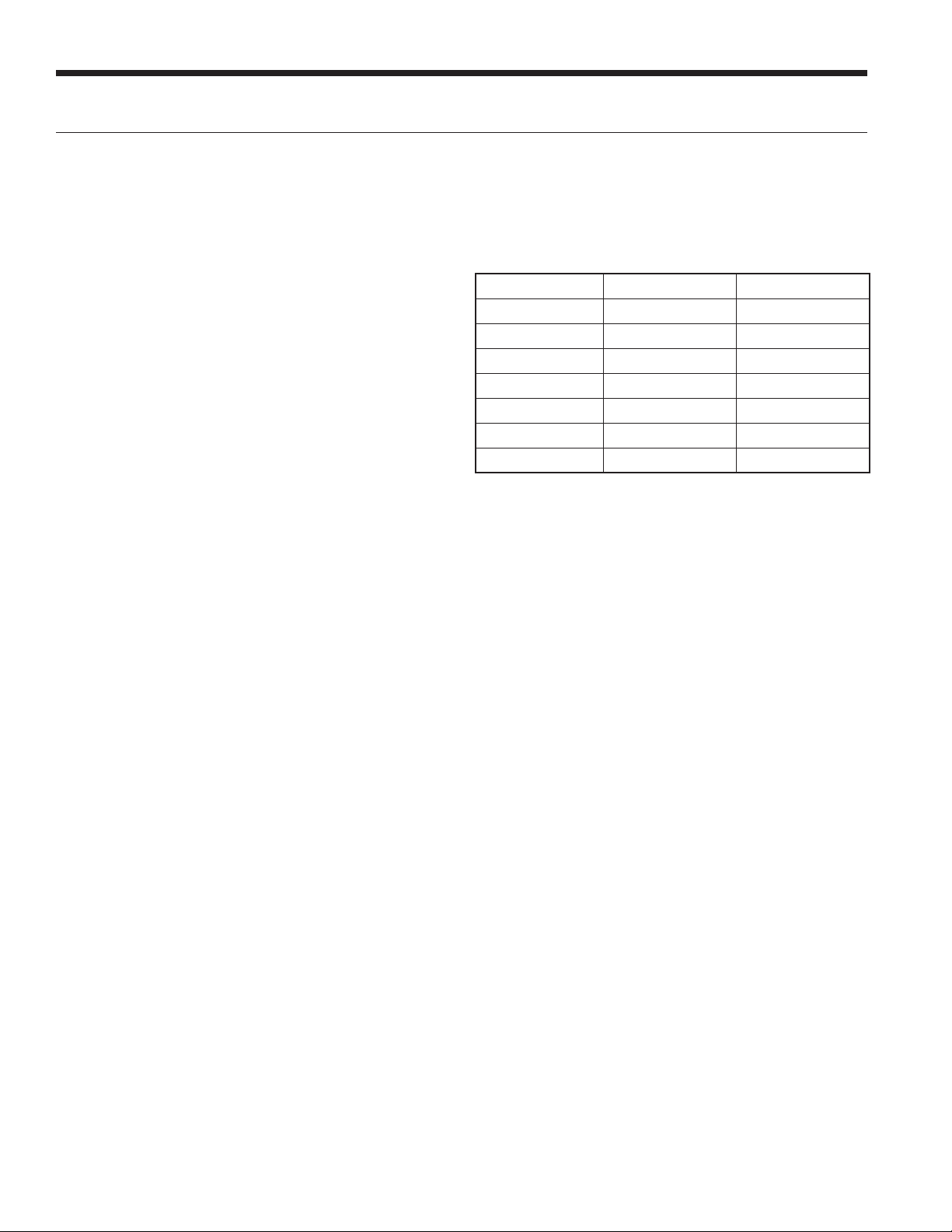

For internal occupancy control the Aurora System

controller has an internal occupancy schedule that will

allow the system to operate on its own if it has a valid

control temperature. The schedule can be edited with the

Aurora Touch HMI. See the table below for details on the

pre-programmed weekly schedule.

Occupancy Override

For systems with occupancy sensors enabled, the system

occupancy will be set to Occupied when the sensor is

active, regardless of the internal or external occupancy

control values.

For systems with Rnet zone temperature sensors that

incorporate an occupancy override button, the network

established unoccupied status may be temporarily

overridden for a period of 120 minutes. When the “Temp

Occ” button is pressed the Aurora System controller will

report the occupancy status as “Temp OCC” for the current

effective occupancy. Once the temporary occupancy timer

expires the unit will return to the unoccupied mode of

operation until the override button is pressed again.

Internal Schedule Occupied Times Unoccupied Times

Sunday Unscheduled Unscheduled

Monday 7:30am-5pm 5pm-7:30am

Tuesday 7:30am-5pm 5pm-7:30am

Wednesday 7:30am-5pm 5pm-7:30am

Thursday 7:30am-5pm 5pm-7:30am

Friday 7:30am-5pm 5pm-7:30am

Saturday Unscheduled Unscheduled

Table of contents

Popular Control Unit manuals by other brands

Accutrol

Accutrol AccuValve AVT4000 Series Installation & operation manual

INNO

INNO USB-CAN MODULE user manual

Dewetron

Dewetron DAQP-LV Technical reference manual

APARIAN

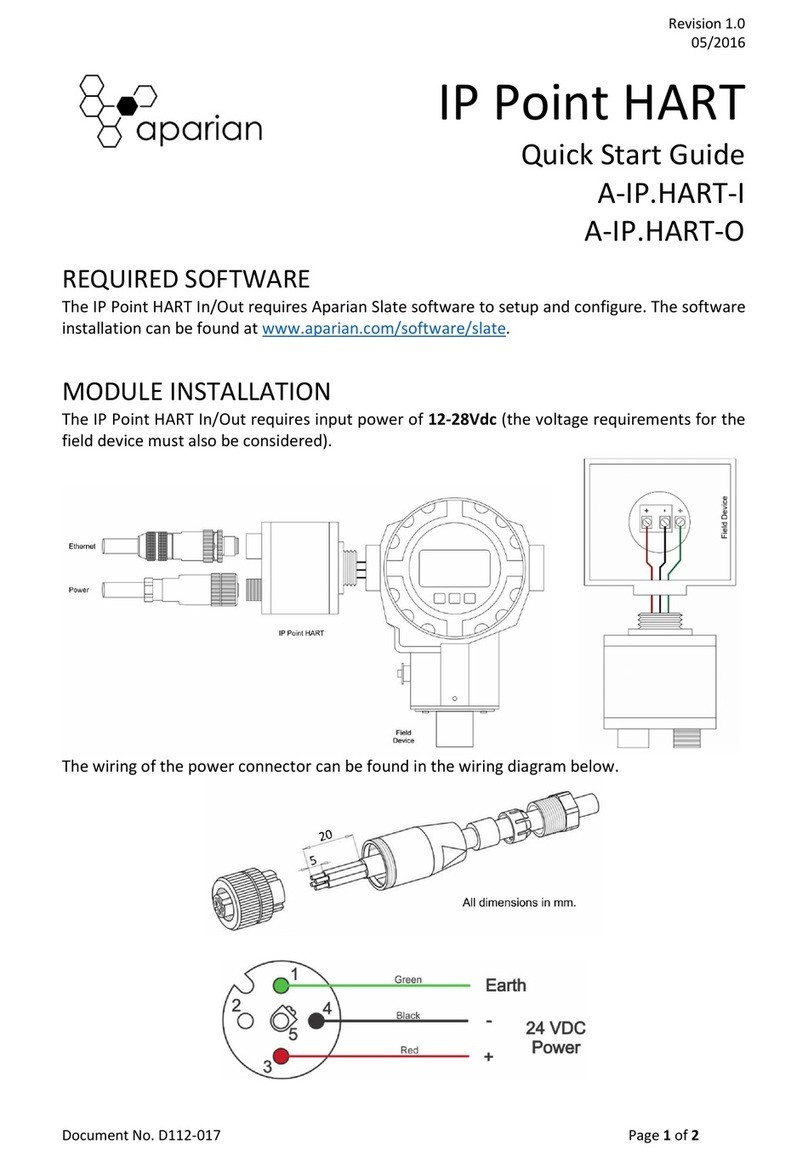

APARIAN IP Point HART quick start guide

Spirax Sarco

Spirax Sarco MSC-125 Installation and maintenance instructions

Hyperdyne Labs

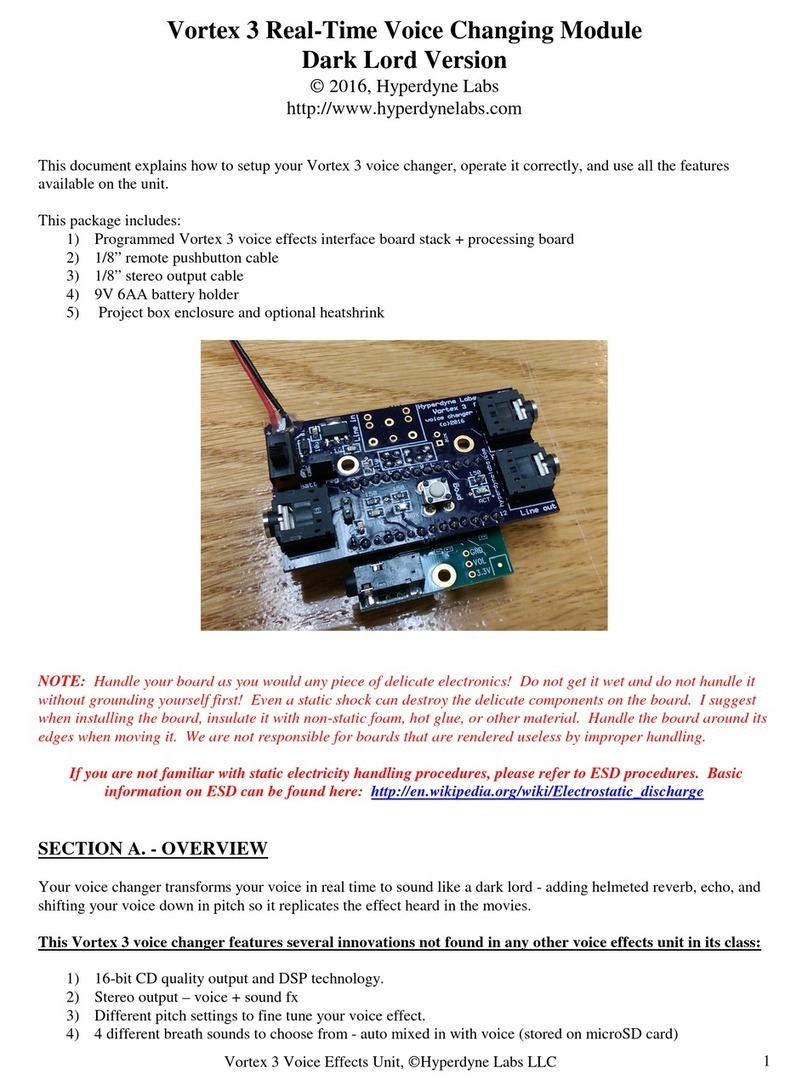

Hyperdyne Labs Vortex 3 Dark Lord manual