Henkel BONDERITE E-CO Series User manual

E-CO Level Control,

120 VAC, One, Two, Three, and Four Points

Operating Manual

i

Table of Contents

1Please Observe the Following ........................................................................................................................ 1

1.1Emphasized Sections ................................................................................................................................ 1

1.2For Your Safety ........................................................................................................................................... 1

1.3Unpacking and Inspection ...................................................................................................................... 2

1.4Items supplied ............................................................................................................................................ 2

1.5Features ........................................................................................................................................................ 2

2Description .......................................................................................................................................................... 3

3Technical Data .................................................................................................................................................... 4

3.1 Utilities ................................................................................................................................................................. 4

3.2 E-CO Level Control Unit Overall & Mounting Dimensions ................................................................ 4

3.3 General Arrangement .................................................................................................................................... 5

4Installation ........................................................................................................................................................... 6

4.1Electrical ........................................................................................................................................................7

4.2Air Probe ...................................................................................................................................................... 8

4.2Solenoid Valves .......................................................................................................................................... 9

5Operation ............................................................................................................................................................ 10

5.1 Indicator Light – color and function ......................................................................................................... 10

5.2 Adjusting Master Air Pressure Switch ...................................................................................................... 10

5.3 Adjusting Regulator Pressure on Master Level Control ..................................................................... 11

5.3 Adjusting Flow Regulator ............................................................................................................................ 11

5.4 Adjusting Air Differential Pressure Switch for Level ............................................................................ 13

5.5 One Point Level Control for Low Level Shut-Off for Drums, Totes, or Day Tanks .................... 14

6Troubleshooting ............................................................................................................................................... 15

7Care and Maintenance ................................................................................................................................... 16

ii

7.1 Master Air Pressure Switch .......................................................................................................................... 16

7.2 Master Air Pressure Regulator/Filter ........................................................................................................ 17

7.3 Flow Regulator ................................................................................................................................................ 17

7.4 Differential Pressure Switch ........................................................................................................................ 18

8Accessories and Spare Parts ......................................................................................................................... 19

9Diagrams ............................................................................................................................................................ 20

9.12251341 REV - E-CO Level MSTR 1 PT - electrical ......................................................................... 20

9.22250048 REV - E-CO Level STD 1 PT - electrical ........................................................................... 20

9.32251340 REV - E-CO Level MSTR 2 PT - electrical ........................................................................ 21

9.42251339 REV - E-CO Level STD 2 PT - electrical ........................................................................... 22

9.58907225 Master Level Control Three Point - electrical ............................................................... 23

9.68907224 Standard Level Control Three Point - electrical .......................................................... 24

9.78907227 Master Level Control Four Point - electrical ................................................................. 25

9.88907226 Standard Level Control Four Point - electrical ............................................................. 26

9.9Level Control Standard and Master Installation Drawing 8907228 ......................................... 27

10Warranty ............................................................................................................................................................. 28

1

1 Please Observe the Following

1.1 Emphasized Sections

Warning!

Refers to safety regulations and requires safety measures that protect the operator or

other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not

damaged.

Notice:

A notice gives recommendations for better handling of the unit during operation or

adjustment as well as for service activities.

1.2 For Your Safety

For safe and successful operation of the unit, read these instructions completely. If

the instructions are not observed, the manufacturer can assume no responsibility.

Do not expose the connecting cable to heat, oil, or sharp edges.

Make sure the Unit is securely mounted in an operator accessible area.

Use only original equipment replacement parts.

Do not operate the Unit if it has damage.

Always disconnect the power supply before servicing the unit.

Observe general safety regulations for the handling of chemicals such as Bonderite®

products. Observe the manufacturer’s instructions as stated in the Safety Data Sheet.

While under warranty, the unit may be repaired only by an authorized Henkel

service representative.

2

1.3 Unpacking and Inspection

Carefully unpack the Bonderite® E-CO Level Control and examine the items contained in

the carton. Inspect the unit for any damage that might have occurred in transit. If such

damage has occurred, notify the carrier immediately. Claims for damage must be made

by the consignee to the carrier and should be reported to the manufacturer.

1.4 Items supplied

1.4.1 E-CO Level Control

1.4.2 Equipment Manual, 8905238

1.4.3 Standard & Master Level Control Installation drawing 8907228

1.5 Features

1.5.1 E-CO Level Control MSTR – Master Level Control has air filter/regulator

1.5.2 E-CO Level Control MSTR – Master Level Control has master pressure

switch for 8 to 25 psig.

1.5.3 Air differential flow regulator

1.5.4 differential pressure switch(s)

1.5.5 Circuit Breaker, internal, 5 Ampere

1.5.6 Indicator lamps

3

2 Description

The Bonderite® E-CO Level Controls are used to maintain liquid levels in operating chemical

tanks. Working on factory air supply, these controls offer a fail-save technique of solution

level control accurate within +/- ¼ inch.

Each level control can be supplied in multi-point configurations for customized

applications.

The system is not affected by agitation in the tanks or by corrosive action of the

contents. No ball floats, needle valves or hazardous electrodes are utilized. Only

the chemically resistant air probe is in direct contact with the process solution.

Batch operation may be accomplished by utilizing the “High-Low” option. A

measured amount of liquid may be added, and chemical additions and/or agitation

then provided. After chemical reaction, the vessel may then be emptied and the

process repeated.

Automatic tank heater and pump protection may also be controlled by the “High-

Low” option.

Common Uses:

o Water Tank Level

o Liquid Process Tank Level

o E-Coat Paint Tank Level

o Dilution of Liquids by Volume

o Sump Pump Operation

o Emergency Low Level Alarm

o Chemical Bulk Tank and Day Tank

o Dirty Screen Alarm

Benefits:

o Provides reliable, accurate, simple and safe liquid level control.

o Eliminates Operator errors that result in dangerous and costly low levels or

unnecessary overflows that often result in lost production.

o Assures an adequate and consistent concentration of operating chemicals

when used as part of a Henkel Automatic Process Control System, aiding in

uniform quality of coating and treatment.

o Saves in unnecessary use of water and excess manpower usage to perform

the consistent checking and adjusting of solution levels.

The level is maintained by detecting slight variations in air pressure due to changes in the

liquid level surrounding an immersed air probe. Immersion depth is typically a minimum

4

of 6” vertical immersion into the process solution. A properly mounted level control is

affected little by wave motion and maintains liquid levels within ¼” at a depth of 1.5 to 5

inches. It is operated by purging a low volume of air (≈ 0.8 cu ft/hr). Clean plant air range

of 30 to 150 psi must be supplied to the master pressure regulator of the system. A low air

pressure switch, filter regulator, pressure regulator and gauge are incorporated into the

master level control assembly. Each master assembly includes a circuit breaker, master

pressure switch, and at least one point of level control. A shutdown or loss of sufficient

plant air will cause an automatic shutdown of the Henkel Level Control System electrical

circuit. The loss of plant air may easily be alarmed by a warning signal which can be

supplied as an option.

The electrical and pneumatic components are housed in an enclosure. Each level control

uses at least one flow control to limit the air volume used and a micro switch to sense the

set-point and operate the load circuits.

3 Technical Data

3.1 Utilities

Operating voltage : 110…120 VAC 50/60 Hz

Air Supply to Master : 30…150 psig, clean shop air

Air Flow Regulation : 0.9…2.1 SCFH

3.2 E-CO Level Control Unit Overall & Mounting Dimensions

Level Control Part Number Overall

W x H x D

Mounting

W x H Mounting Hole

E-CO Level MSTR 1 PT 2251341 11.7 x 14.8 x 7.0 6.5 x 10.75 0.31 x 0.94 slot

E-CO Level STD 1 PT 2250048 9.1 x 14.8 x 7.0 6.5 x 10.75 0.31 x 0.94 slot

E-CO Level MSTR 2 PT 2251340 13.6 x 16.8 x 7.0 8.5 x 12.75 0.31 x 0.94 slot

E-CO Level STD 2 PT 2251339 9.1 x 14.8 x 7.0 6.5 x 10.75 0.31 x 0.94 slot

Master Level Control 3 PT 8907225 17.5 x 20.8 x 7.0 12.5 x 16.75 0.31 x 0.94 slot

Standard Level Control 3 PT 8907224 15.1 x 20.8 x 7.0 12.5 x 16.75 0.31 x 0.94 slot

Master level Control 4 PT 8907227 17.5 x 20.8 x 7.0 12.5 x 16.75 0.31 x 0.94 slot

Standard level Control 4 PT 8907226 15.1 x 20.8 x 7.0 12.5 x 16.75 0.31 x 0.94 slot

5

3.3 General Arrangement

Depicted is a four-point master level control

unit to show the general arrangement of the

level control system features. Configurations

and numbers of components will vary based

on level controller model.

1. Indicator lights (lined up vertically)

2. Master Pressure Regulator (Master Level

Controllers ONLY)

3. Flow Regulator

4. Differential Pressure Switch

5. Master Pressure Switch (Master Level

Controllers ONLY)

6. Circuit Breaker & Electrical Terminal Blocks

1

2

3

4

5

6

6

4 Installation

Before using the equipment for the first time check it carefully for signs of external

damage. If any shipping damage is found DO NOT USE THE EQUIPMENT – return it to your

supplier immediately.

A simple Henkel Level Control System would consist of a Master Level Control Assembly

(required) on the first process tank, with each subsequent tank utilizing a Standard Level

Control Assembly. Each tank would require its own individual normally closed water

solenoid valve.

With the use of multiple standard level control units; the master level control should

be centrally located between standard units to minimize regulated supply air tubing

length.

Installation of the level control system should be arranged by the purchaser and generally

involves the following:

1. Mount the level control assembly.

2. Plumb the solenoid valve (available from Henkel Corporation) to desired water

supply line.

3. Install the immersion air probe, typically 1” pipe (supplied by others).

4. Install plant air shut-off valve and connect plant air to the Master Level Control.

5. Install ¼” tubing, (supplied by others) from Master Control Regulator to all other

Standard Level Controllers.

6. Install ¼” tubing (supplied by others) to all immersion probes.

7. Connect 120 VAC power to the Master Level Control and to downstream Standard

Level Controllers.

8. Electrically connect the solenoid valve(s) to respective level controllers.

Refer to the installation drawing at the end of section 10 of this manual for further

installation details of the Level Control system.

Use with Henkel Automatic Process Control Systems.

If the Master Level Controller is being used in conjunction with a Henkel Automatic

Control System, the power to the Master and Standard Level Controllers may be

7

supplied from the Automatic Control System Panel. Since all Henkel Automatic

Control Systems are custom designed to meet specific customer needs, terminal

wiring will vary. Please consult the system print package supplied to your company.

4.1 Electrical

Input Power Wiring

Wiring the Level Control units must be performed by qualified personal.

Refer to the level control wiring diagrams in Section 10 of this manual for wiring

connections of the Level Control model to be installed.

The 120 VAC line, neutral, and ground wires are connected to the Master Level Control

L1, N, and Ground terminals respectively. Power to the Standard Level Controls is

supplied from the Master Level Control by “daisy chaining” and wiring the downstream

controllers in parallel to terminals 2 and N in the Master Level Control.

Load Wiring

Each level control units have 1 to 4 pressure switches to control separate loads.

Terminal connections vary based on the unit being wired:

The single point controllers, the first “Load” (e.g. solenoid valve) is connected to

terminals 4 and N.

The two and three point level controllers; the first “Load” is connected to terminals 6

and N, the second “Load” is connected to terminals 4 and N, and the third

“Load” is connected to terminals 7 and N.

The four point level controllers; the first “Load” is connected to terminals 10 and N, the

second “Load” is connected to terminals 6 and N, the third “Load” is connected

to terminals 4 and N, and the forth “Load” is connected to terminals 7 and N.

8

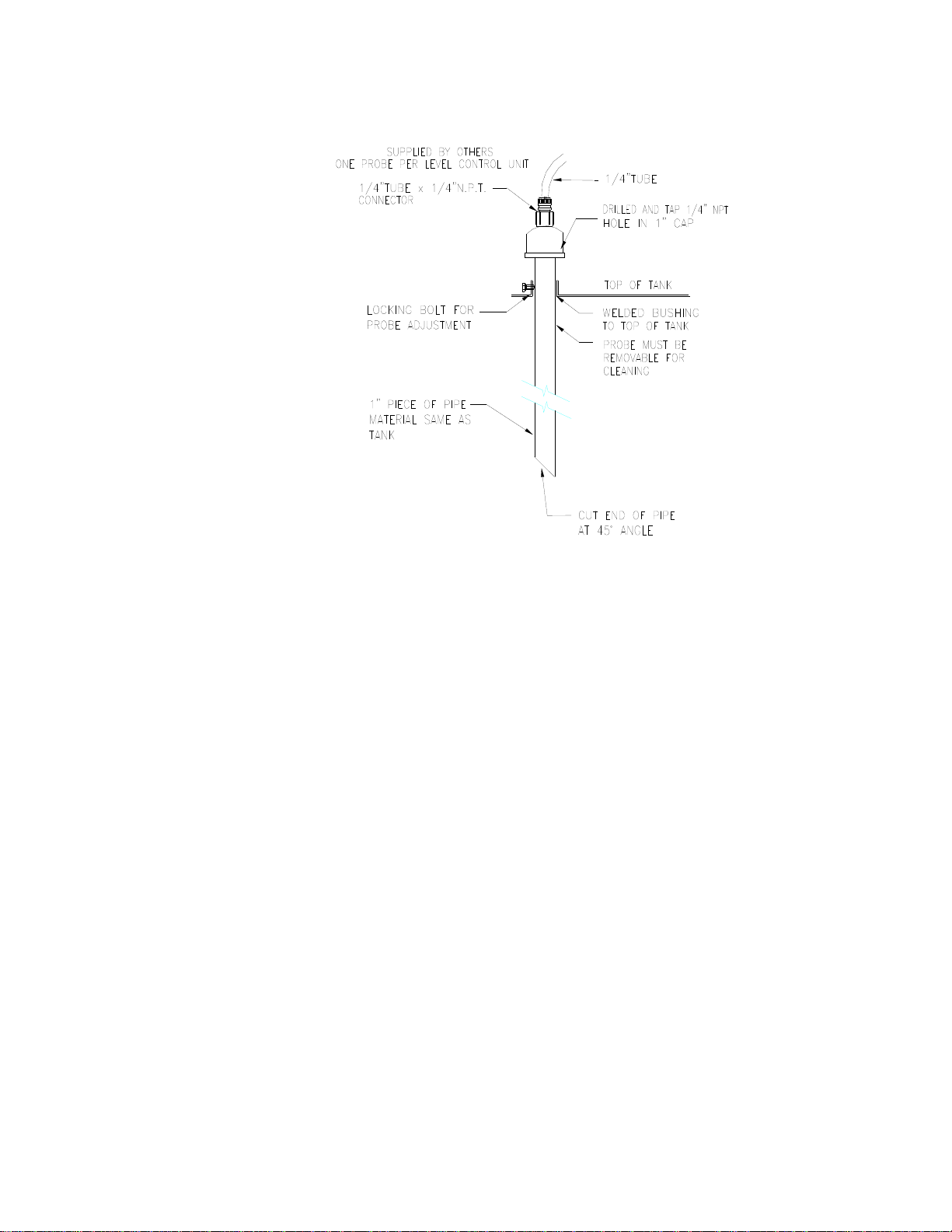

4.2 Air Probe

Supplier

The immersion air probe, is to be supplied by the customer or installation

contractor.

Diameter and Length

The immersion probe shall be at a minimum 1” NPT pipe and be of sufficient

length to extend 6” below the minimum liquid level test point.

Material

The probes should be the same material as the treatment tanks.

Mounting

The air probes may enter from the top or side of the process tank. If

entering from the side the top of the probe should be 6” below that

minimum desired liquid level of the process tank. Installation should ensure

that the probes remain firmly in place and be removable for cleaning if

needed. Ensure that no overhead interferences are present so the probes

may be fully removed vertically.

If the process tank accumulates sludge, the tip of the immersion probe must

be at least 2” above the maximum expected sludge level.

Tubing Runs and Fittings

Tubing (¼ “) is to be run by the installer from each controller to the

respective level control immersion air probe. The tubing shall not be longer

than 15 feet and must not have more than (4) four 90-degree bends. Each

probe must be equipped with a ¼” compression tube fitting for attaching

the tube from the level controller. Tubing is typically copper or

polyethylene. The fittings should be brass or polypropylene when used in

corrosive atmospheres.

9

Level Control Probe Details

4.2 Solenoid Valves

Solenoid valves are electrically activated by the Henkel Level Control installed at

each tank to maintain the desired level. A “Y” strainer shall be installed in the

upstream side of the solenoid valve, and the discharge of the valve should not

protrude below the liquid level of the tank. Valve construction should always be

governed by the liquid passing through it. City water uses brass, De-ionized water

or acidic material requires stainless steel or plastic.

10

5 Operation

5.1 Indicator Light – color and function

Indicator lights table below provides the list of which level control units have the

indicator light. The list is in order of how the indicator lights appear on the level

control panel. Top of the list is top of the panel; bottom of the list is bottom of the

panel. List also shows the which level control units have the indicator light. Only

master level control units have the Master Air Level pressure switch and indicator

light. Standard level control units do not have this feature.

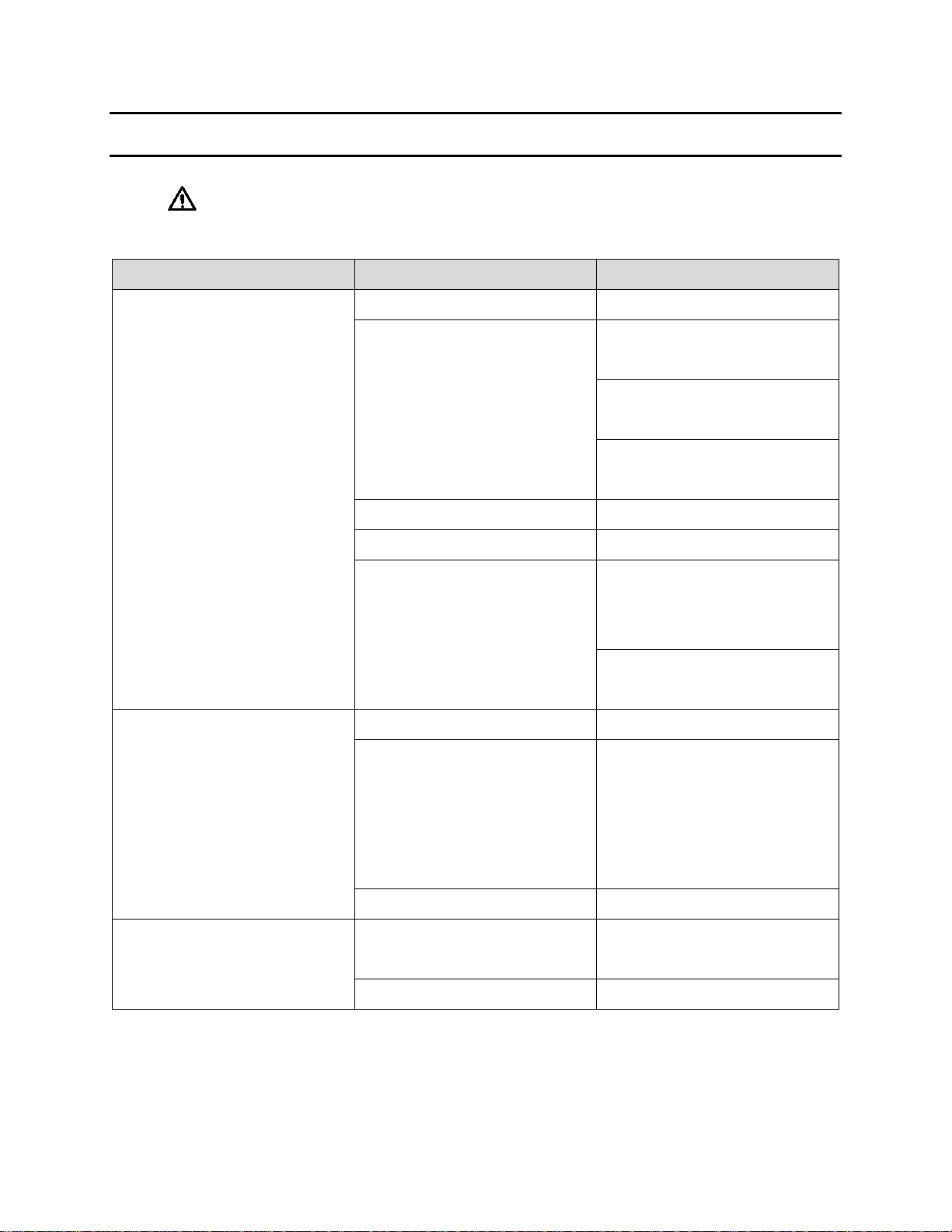

Indicator Label Indicator

Color Indicator ON when 1 PT

Level

2 PT

Level

3 PT

Level

4 PT

Level

Mater Air Low Red no or low air out of

regulator X* X* X* X*

High Level

Alarm Red high level condition X X

Operating Level Green at operating level X X X X

Control Point Amber filling X X X X

Low Level Alarm Red low level condition X X X

Pump Shut

Down Red

pump (or heater)

shut down – server

low level condition

X

* only Master Level Control units have a Master Air Low indicator and internal

pressure switch. Standard Level Controls do not have the Master Air Low

indicator.

Two-point level control unit can be reconfigured as a special for operations

requiring a “Control Point” and “High Level Alarm”. Inquire about this option

with your Henkel representative.

5.2 Adjusting Master Air Pressure Switch

The master air pressure switch changes state based on the set and reset point

adjustment. The pressure switch is adjustable from 8 to 25 psig. The set and reset

points have a fixed difference of 1.8 psig.

11

Adjustment of this pressure switch should be made with the power off and

appropriate lock-out tag-out measures.

The adjustment is made using the adjustment wheel located in the center of the

pressure switch. Approximate pressure setting can be determined by the markings

on the pressure switch calibration scale. Adjustment of the setting is made by

turning the wheel clockwise and counterclockwise.

A more accurate setting of the pressure switch can be made using a multi-meter.

Set the multi-meter to continuity or resistivity and connect the probes to

terminals 1 and 2 of the level control.

Adjust the indicator toward the pressure connection or beyond the desired

pressure set point by turn the adjustment wheel clockwise.

Start with the regulator adjusted to zero. Multi-meter should have

continuity or read 0 ohms.

Adjust the regulator until the pressure gauge reads the desired set point of

the pressure switch.

Turn the adjustment wheel counterclockwise until the switch actuates.

Multi-meter should not have continuity or read open circuit (infinite ohms).

Adjust the regulator to lower the pressure until the switch actuates on from

the decreasing pressure. Multi-meter should have continuity or read 0

ohms.

For a more precise pressure setting; increase and decrease pressure setting

to cycle the pressure switch a few times while making fine adjustments with

the pressure switch wheel.

5.3 Adjusting Regulator Pressure on Master Level Control

Each Master Level Control has a pressure regulator with filter mounted on the side

of the enclosure. A 0…30 psig gauge provides pressure reading of the regulator

outlet to the level controller flow regulators. Outlet pressure must be at least 5 psig

greater than the maximum downstream pressure from the flow regulator.

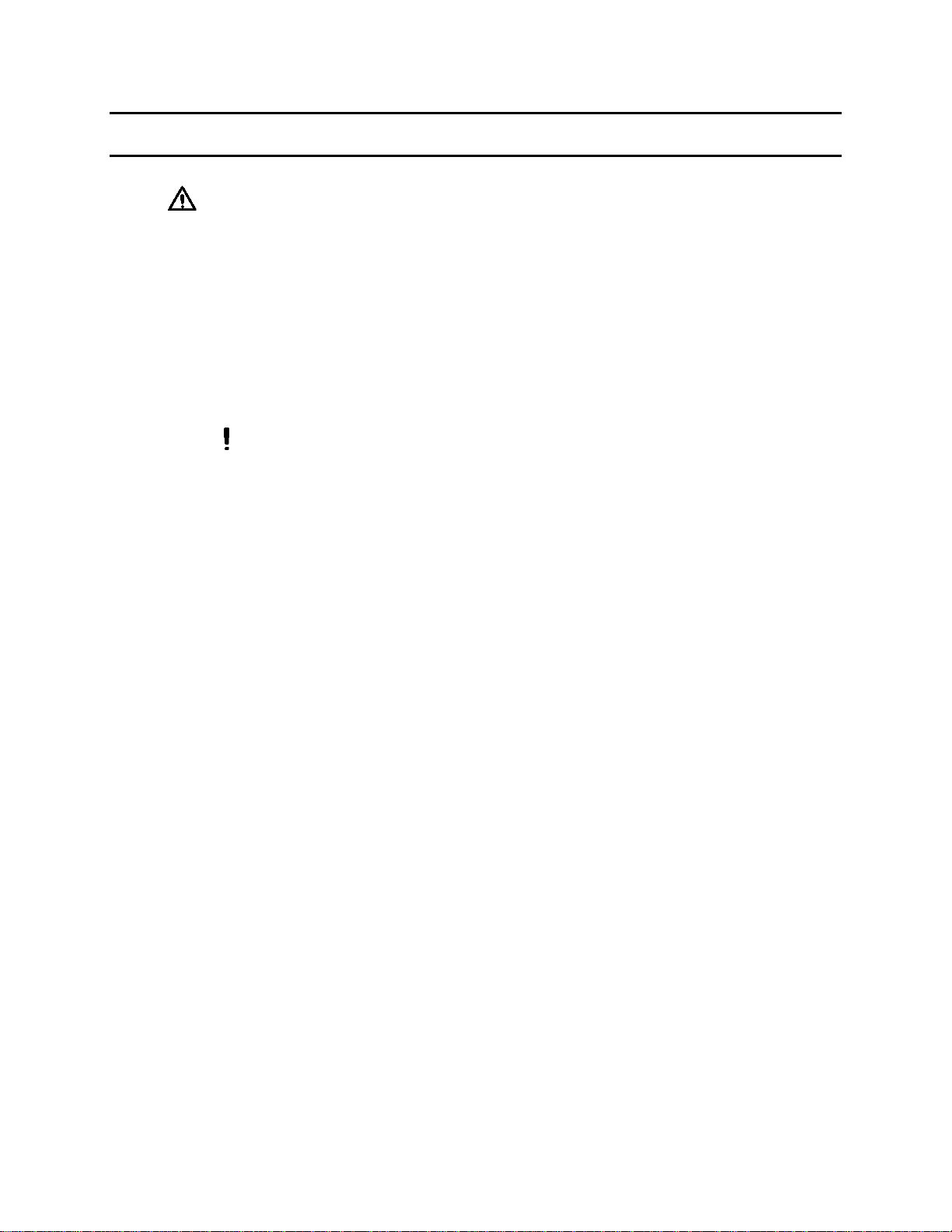

5.3 Adjusting Flow Regulator

With supply air pressure on adjust the needle valve to produce the desired bubble

rate. The bubble rate is dependent on the volume of air in the system and fluid

12

level responsiveness. The minimum flow rate of 0.9 SCFH (adjusting screw seated)

can be satisfactory.

If the process tank can have rapid level fluctuations and/or there is much air volume

in the system, the 0.9 SCFH may not have the desired speed of response. Increasing

the bubble rate produces quicker responsiveness to the process tank level changes.

When looking at the level control panel, the flow regulator adjusting screw is

located on the bottom of the flow regulator assembly closest to the outlet. Other

screw next to it is a cleaning wire, furthest from the outlet, is to the right of the

adjusting needle.

It may take a couple of adjustments when

setting the flow regulator to maintain a

minimal bubble rate with an acceptable

response to process tank level changes.

Supply pressure to the flow regulator

must be at least 5 psig greater than the

maximum downstream pressure.

Bubble Rate Adjusting Needle

Increase Counterclockwise

Decrease Clockwise

Adjustment Needle &

Cleaning wire

Bottom of flow regulator

Front of Level Control

Bottom of Level Control

13

5.4 Adjusting Air Differential Pressure Switch for Level

The Henkel Level Controllers have one to four internal differential pressure switches,

depending on model. Adjustment of the differential pressure switch set points are

done the same. Internal springs of the pressure switches may vary for different

process tank level depths.

Consult with Henkel prior to modifying the internal springs. Springs may

need to be replaced in one or more of the pressure switches to achieve

the low or high level operations as required.

Differential pressure switches are not preset for specific process tank level control.

The level settings must be performed on-site to ensure proper operation.

If present, remove the cover from the center of the differential pressure switch

diaphragm housing. Slotted 10-turn adjusting screw will be visible.

Clockwise rotation of the adjusting screw will increase the switch point; raise

the process tank level.

Counterclockwise rotation of the adjusting screw will decrease the switch

point; lower the process tank level.

Before adjusting the differential pressure switches; the level control air probe

must be installed and the bubble rate set.

The process tank should be filled and drained manually during the level set point

adjustment for each differential pressure switch. On recirculating tanks the settings

should be based on the level obtained when the pump is running. The minimum

level setting must be high enough to cover heating coils, and the maximum level

setting must be low enough to prevent overflow when the pump is stopped.

Start adjustments with the differential pressure switch with the lowest fluid

level setting. Work upward towards the pressure switch with the highest

fluid level setting.

14

Adjust the Level Set Point (General Procedure)

1. Turn the adjustment screw clockwise until seated.

2. Turn the adjustment screw counterclockwise 5 complete turns.

3. Fill tank to desired switch level (with recirculating pumps on, if present).

4. Turn adjustment screw slowly until the lamp changes state:

a. If indicator is ON turn the adjustment screw slowly clockwise.

b. If indicator is OFF turn the adjustment screw slowly counterclockwise.

The “Green” and “Amber” indicators are on the Control Point switch.

When one is ON the other is OFF. Adjusting the screw will toggle both

lights.

5. Turn adjustment screw slowly in the opposite direction to change the

indicator state back.

6. Perform number 4 and 5 a couple times stopping with the indicator just

turning OFF. For the Control Point switch, “Green” indicator will be ON and

“Amber” indicator will be OFF.

7. Check switch point by adjust the tank fluid level down and up to change

indicator state. Note tank levels at the indicator state changes.

8. For fine tuning switch point level, repeat steps 3 through 7.

9. Repeat process for next highest process tank level.

5.5 One Point Level Control for Low Level Shut-Off for Drums, Totes, or Day Tanks

One point level control can be used with drums, totes, or day tanks for low level

shutoff of mixers or pumps. The bottom of the probe should be located 1” up from

the bottom of the container. The level control adjustment screw should be turned

full counterclockwise.

Use tubing in place of the immersion air probe when inserting into drums due to

the small drum openings. The tubing needs to be securely fastened to the foot

valve assembly for the chemical feed pump prior to insertion.

15

6 Troubleshooting

Before proceeding with any repair or maintenance operation disconnect and turn off

electric and air supplies from the equipment, and discharge any stored energy.

Type of Malfunction Possible Causes Correction

No Bubbles Out of Air Probe

Main Air Supply Off Turn on Main Air Supply

Master Regulator pressure

output too low

Check filter bowl for fluid –

drain and clean

Check filter and clean if

necessary

Adjust Master Regulator

Pressure Higher

Air lines blocked Remove blockage

Air lines collapsed Replace air line

Flow regulator blocked

Verify Master Regulator

pressure setting –

adjust if needed

Clean needle passage of flow

regulator with cleaning wire

Indicators not turning ON

No Power Turn on power

Tripped Circuit Breaker

Inspect loads and wiring for

damage or short circuit –

repair or replace any failed

components before resetting

circuit breaker.

Blown Bulb Replace Bulb

Differential Pressure Switch

not switching

Set Point not set for proper

fluid level Adjust Set Point

Switch Failed Replace Switch

16

7 Care and Maintenance

Before proceeding with any repair or maintenance operation disconnect and turn off

electric and air supplies from the equipment, and discharge any stored energy.

7.1 Master Air Pressure Switch

Ensure proper operation of the pressure switch, periodically cycle the switch by

adjusting the air pressure.

Make sure pressure switch external surfaces are clean and free from foreign matter,

corrosion, or other contamination.

The master pressure switch is not a field repairable item. The entire pressure switch

must be replaced if damaged or not functioning.

Causes of improper operation

Incorrect electrical connection: check leads to switch. Be sure the leads are

properly connected. Switch is marked NO for normally open, NC for

normally closed, and C for common.

Faulty Control Circuit: check the electrical power supply to the switch.

Check for loose or blown fuses, open-circuited or grounded wires, loose

connections at switch. See nameplate for electrical rating and range.

Incorrect pressure: check pressure in system with suitable pressure gauge.

Pressure must be within the range specified on nameplate.

Incorrect Adjustment: check pressure scale to see approximate setting.

Refer to section on Set Point Adjustment of Fixed Deadband Pressure

switch.

External Leakage or Snap Switch Failure: Replace pressure switch, see

Ordering information.

Excessive Vibration or Surges Causing Switch to Operate Undesirably:

Check for pressure fluctuations in system and install pressure surge

suppressor. Check switch mounting and be sure there is no excessive

vibration.

If the operation of the pressure switch cannot be corrected by the above

means, it should be replaced.

This manual suits for next models

8

Table of contents

Other Henkel Control Unit manuals

Popular Control Unit manuals by other brands

M-system

M-system R3-PS3 instruction manual

swissflex

swissflex uni_75RF operating instructions

Audioplex

Audioplex MUSIC MASTER 1 installation manual

Texas Instruments

Texas Instruments ADC12DJ3200 user guide

Nice

Nice mindy TT1N Instructions and warnings for the fitter

TechNexion

TechNexion PICO-IMX8M product manual