Water-Loo ABM 300 Series Manual

ABM Chilled Beam modules

Sizes 1200 - 3000

Operating and Maintenance

Instructions

2

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

ABM Active Chilled Beams

Installation

General Information

Foreword

These instructions are given as a guide to good

practice in the installation, start-up, operation, and

maintenance by the user, of Waterloo ABM 300 Active

Chilled Beams.

8QLW,GHQWL¿FDWLRQ

Units arrive on site with an unit model size, coil type,

SUHVHQFH LGHQWL¿FDWLRQ VWLFNHU ZLWK RI DQ HOHFWULF

heater, unit handing pictograms, which clearly

indicates important information such as the customer

order number, job name, unit model size, coil type,

unit handling etc.

5HFRPPHQGHG$LUDQG:DWHU4XDOLW\

To maintain unit performances, ensure that the air

HQWHULQJWKHXQLWLVRIVXI¿FLHQWTXDOLW\Table 1).

:DWHU4XDOLW\5HFRPPHQGDWLRQVIRU:DWHU

Coils

At installation and then yearly, the manufacturer

recommends having water analyzed for bacteria

IHUUREDFWHULD EDFWHULD JHQHUDWLQJ +2S and

reducing sulfates) and also a chemical analysis, to

avoid corrosion and scaling. The water circuit must

LQFOXGH ZDWHU WUHDWPHQW GHYLFHV ¿OWHUV DGGLWLYHV

intermediate exchangers, purges, vents, isolating

valves, etc, depending on the results of these analyses.

The results of the analyses must correspond to values

LQWKHTable 2).

'XFW,QOHW&RQGLWLRQV

As with all types of ATD, the duct inlet conditions are

very important to the correct function and operation of

WKLVSURGXFW%HVWSUDFWLFHSURFHGXUHVDQGWHFKQLTXHV

should always be followed.

,W VKRXOG EH QRWHG WKDW LQVXI¿FLHQW FRQVLGHUDWLRQ RI

duct entry conditions can result in:

Poor velocity distribution

Excessive turbulence

Unpredictable throw

%UHDNGRZQRIFHLOLQJDWWDFKPHQW

+LJKQRLVHOHYHOV

'LI¿FXOWEDODQFLQJSURFHGXUHV

Table 1- Air Quality Recommendations

Table 2- Water Quality Recommendations

Air Quality Recommendations

SO2<0.02 ppm

+2S <0.02 ppm

NO <1.00 ppm

NO2<1.00 ppm

1+3<6.00 ppm

N2O <0.25 ppm

Water Quality Recommendations

Total hardness in

French degrees 7+

Chloride [C L-] < 10 mg/l

Sulfate [SO42-] < 30 mg/l

Nitrate [NO3-] = 0 mg/l

Dissolved iron < 0.5 mg/l

Dissolved oxygen 4 < [O2] < 9 mg/l

Carbon dioxide [CO2] < 30 mg/l

Resistance 2000<Resistance<5000 cm

S+ S+

3

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

ABM Active Chilled Beams

Overall Dimensions (mm)

Sizes

Wis the nominal Width 300.

L LVWKHQRPLQDO/HQJWK

C LVWKHQRPLQDO+HLJKWIRUøand 230 for 100 ø.

Handling the Unit

:$51,1*

Wear protection gloves when handling the unit. When removing the unit from its pallet, do not handle it by

SLSHVVSLJRWVYDOYHVRUIUHVKDLULQOHW7DNHSUHFDXWLRQWRQRWGDPDJHWKHXQLW

6LGH(QWU\/+ 6LGH(QWU\5+

Top EntryEnd Entry

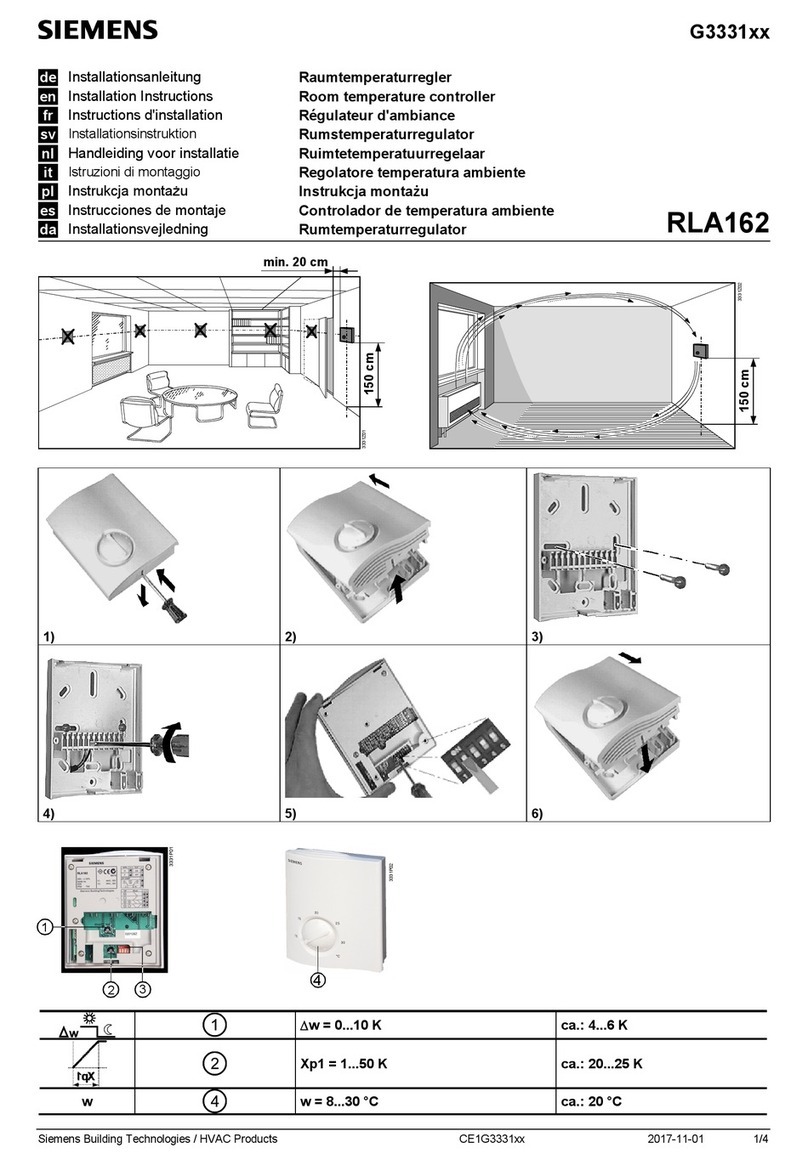

Figure 1- Overall Dimensions

Overall Length = L - 5mm

Overall width = L - 5mm

+HLJKWµ&¶

106

)LJXUH3RVVLEOHDLULQWDNHSRVLWLRQV

4

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

Figure 3

ABM Active Chilled Beams

0RXQWLQJWKH8QLW

:DWHUORR$%0¶VDUHSURYLGHGZLWKPRXQWLQJDSHUWXUHV

as part of their construction. They should be supported

independantly from the underside of the ceiling on

6mm threaded rods.

Two potential installation methods are described.

Method 1LVLIWKHURGVDUHSHUPHQDQWO\¿WWHGWRWKH

supporting ceiling.

Method 2 is if the rods are de-mountable from the

supporting ceiling.

Method 1

Measure the distance from the underside of the

supporting ceiling to the mounting point height on the

EHDP)LJXUH&XWWKHURGVWRWKHUHTXLUHGOHQJWK

allowing 50mm for the bolt to attach to. Include extra

IRUDQ\UHTXLUHGDGMXVWPHQW

Secure the rods to the underside of the solid ceiling,

at the mounting points shown on the next page,

depending on the unit size.

Offer the beam up to the ceiling, sliding the supporting

rods through mounting holes on the beam. Secure

with bolts underneath.

Method 2

Measure the distance from the underside of the

supporting ceiling to the mounting point height on the

EHDP)LJXUH&XWWKHURGVWRWKHUHTXLUHGOHQJWK

allowing 50mm for the bolt to attach to. Include extra

IRUDQ\UHTXLUHGDGMXVWPHQW

On top of the measured distance for adjustment, push

the threaded rods through the mounting points on the

beam, secure with bolts undernath and then offer the

unit up to the supporting ceiling.

With the unit now hanging from the supporting ceiling,

adjust the bolts on the threaded rods to ensure the

EHDP IDFH LV FRPSOHWHO\ ÀXVK ZLWK WKH IDOVH FHLOLQJ

that the beam is to be incorporated into.

Note: ,IKDQJLQJEUDFNHWVKDYHEHHQVXSSOLHGFKRRVH

evenly spaced mounting points along the length of the

EHDP7DEOH).

+DQJLQJEUDFNHWPRXQWLQJSRVLWLRQV

Nom

unit

length

Coil

length Plenum

length Qty of

EUDFNHWV

Mounting positions on

plenum

Length

AB C D

1200 1004

4

100 n/a

n/a

900

1500

1500 1270 1294 1190

1570 1594 6 1490

2400 2170 2194 1100 2090

3000 2770 2794 1724 2690

A

B

C

D

Table 3

5

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

Figure 4

Figure 5

Figure 6

ABM Active Chilled Beams

&OLSWKHKDQJLQJEUDFNHWWRWKHKDQJLQJUDLO)LJXUH

)LJXUH). Offer the beam up to the rod suspended

IURPWKHFHLOOLQJDQGVHFXUHZLWKEROWV)LJXUH)

'XFWZRUN&RQQHFWLRQ

Ducts must be connected to spigots by means of duct

WDSH7KH\PXVWQHYHUEHVFUHZHG0DNHVXUHWKDWWKH

entire spigot surface area is covered. Push the duct as

far as possible onto the spigot towards the unit to get

the best air tightness.

Circular connection ø 100mm

2400 3000

Circular connection ø 125mm

ø 100

ø 125

+DQJLQJ

point rail

Clip

EUDFNHW

to unit

6

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

ABM Active Chilled Beams

:DWHU&RQQHFWLRQ

:DWHUORR $%0 VHULHV FKLOOHG EHDPV DUH ¿WWHG

with 15mm diameter copper water connections as

standard.

These connections are always laid out in the same

RUGHUDVLOOXVWUDWHGLQWKH)LJXUH).

Inlet and outlet water connections

CAUTION! The use of untreated or improperly treated

ZDWHULQWKLVHTXLSPHQWPD\UHVXOWLQVFDOLQJVOLPH

HURVLRQRUFRUURVLRQ7KHVHUYLFHVRIDTXDOL¿HGZDWHU

treatment specialist should be engaged to determine

what treatment, if any, is advisable. Waterloo will not

accept any ability in regards of damage due to the use

of untreated or improperly treated water.

6WDWLF3UHVVXUH0HDVXUHPHQW

A static pressure measurement point is provided in

the end plate of the plenum for the measurement of

positive differential pressure relative to atmosphere.

The measurement can be used for the indication

of operating differential pressure in accordance

with the published data during the installation

and commissioning phases as well as for periodic

monitoring )LJXUHDQG).

Figure 7

)LJXUH6WDWLFSUHVVXUHPHDVXUHPHQWSRLQW

ZLWKFDS¿WWHG

Figure 9 When static pressure measurement

is not in use replace cap

WARM

WATER

IN

COLD

WATER

OUT

COLD

WATER

IN

WARM

WATER

OUT

7

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

ABM Active Chilled Beams

&KLOOHG%HDP&RPPLVVLRQLQJ*XLGH

,WLVUHFRPPHQGHGWKDWWKHPDLQVXSSO\DQGUHWXUQSLSHZRUNWRHLWKHUFKLOOHGFHLOLQJHOHPHQWVRUFKLOOHGEHDPV

is designed in accordance with current CIBSE guidelines.

7KH V\VWHP VKRXOG PDLQWDLQ D SRVLWLYH SUHVVXUH DW DOO WLPHV WKURXJKRXW WKH FRPSOHWH SLSHZRUN V\VWHP DQG

should be designed to facilitate ease of balancing and speedy purging of any air contained within the system.

$GHTXDWHSURYLVLRQVKRXOGEHPDGHIRUGUDLQLQJDQGEDFNÀXVKLQJRQERWKPDLQDQGVXEFLUFXLWV7KHIROORZLQJ

guidelines should be considered.

a). As chilled ceiling elements and chilled beam systems can contain a substantial amount of horizontal small

ERUHSLSHZRUNLWLVHVVHQWLDOWKDWWKHV\VWHPLVSURSHUO\FOHDQVHGRIDQ\RQVLWHGHEULVRUFRQWDPLQDWLRQIURP

VROGHULQJRUZHOGLQJSURFHVVHV7KLVVKRXOGEHGRQHE\GUDLQLQJDQGEDFNÀXVKLQJRIWKHFRPSOHWHV\VWHP

b). The heat transfer in a water to air heat exchanger such as a chilled ceiling or beam is not linearly proportional

WRWKHZDWHUÀRZUDWH,WLVHVVHQWLDOWKDWZDWHUÀRZUDWHVDUHDFFXUDWHO\PDLQWDLQHGWRHQVXUHFRUUHFWRXWSXW

¿JXUHVWKHXVHRIFRUUHFWFRPPLVVLRQLQJYDOYHVZLWKPHDVXULQJIDFLOLW\DUHSODFHGRQPDLQULVHUVDQGVHFRQGDU\

EUDQFKHVDVDPLQLPXPUHTXLUHPHQW

F:DWHUTXDOLW\VKRXOGEHRIPDLQVGULQNLQJZDWHUGRVHGZLWKDVXLWDEOHLQKLELWRUDQGLQFRPLQJPDLQVVKRXOG

EHVL]HGWRSURYLGHVXLWDEOHÀRZUDWHVWRHQVXUHDQDGHTXDWHVXSSO\ZKHQWKHSLSHZRUNLVÀXVKHGFOHDQHG

6\VWHPSUHVVXUHDWWKH KLJKHVW SRLQWRIWKH SULPDU\ SLSHZRUNVKRXOG EH DWOHDVW %DUWRPDLQWDLQ VXLWDEOH

ÀXVKLQJYROXPHVGXULQJFOHDQVLQJ

d).'XHWRWKHXVHRIVPDOOERUHSLSHZRUNRIPPRUOHVVLQWKHKRUL]RQWDOSODQHLWUHFRPPHQGHGWKDWWKH

FRQQHFWLRQVWRWKHPDLQVXSSO\DQGUHWXUQKHDGHUVDUHWDNHQIURPWKHWRSRIWKHSULPDU\ÀRZDQGUHWXUQFLUFXLW

or at an angle of not less than 45oWKLVVKRXOGHQVXUHWKDWWKHLQJUHVVRIFRQWDPLQDQWVGRHVQRWWDNHSODFH

e). Primary chilled water branch circuits should be designed to use the reverse return principle to ensure that

the pressure drop to the secondary chilled element circuits are of similar rating. Air release devices on the

VHFRQGDU\FKLOOHGZDWHUV\VWHPVHUYLQJHOHPHQWVRUFRPELQDWLRQFKLOOHGEHDPVDUHQRWQRUPDOO\UHTXLUHGDVWKH

ZDWHUYHORFLWLHVZLWKLQWKHFLUFXLWVKRXOGKDYHEHHQVHOHFWHGWRPDLQWDLQDWXUEXOHQWÀRZFKDUDFWHULVWLFZKLFK

HQVXUHVVWDWHGRXWSXWDQGDVVLVWVLQWKHVHOIEDODQFLQJRIWKHFLUFXLW+RZHYHUPDLQFKLOOHGZDWHUFLUFXLWVVKRXOG

be provided with manual air venting at the end of each horizontal run and at the top of any circuit high point to

DYRLGDQ\DLUSRFNHWVIRUPLQJZKLFKPD\EHGLI¿FXOWRULPSRVVLEOHWRUHPRYH

f).,WLVDOVRUHFRPPHQGHGWKDWWKHYHORFLW\RIWKHÀXVKLQJZDWHUVKRXOGEHRIVXI¿FLHQWYHORFLW\WRSLFNXSDQG

FDUU\V\VWHPFRQWDPLQDQWVDQGGHEULVLQWKHÀXVKLQJSURFHVVW\SLFDOO\IRUPPSLSHVDWOHDVWPVHF#

0.20 l/sec) this should provide the minimum criteria to remove small steel or copper particles.

g).7KHÀXVKLQJSURFHVVVKRXOGEHFDUULHGE\WKHIRUZDUGÀXVKEDFNZDUGÀXVKPHWKRGDVWKLVSURYLGHVDPRUH

UHOLDEOHZD\RIUHPRYLQJV\VWHPFRQWDPLQDWLRQWKDQE\IRUZDUGÀXVKLQJDORQH

h).$VPRVWFKLOOHGFHLOLQJDQGEHDPFKLOOHGZDWHUFLUFXLWVFRQWDLQDKLJKSURSRUWLRQRIÀH[LEOHVWDLQOHVVVWHHO

braided hoses these should be of not less than 12 strand stainless steel over braiding and manufactured in

WKHUPRSODVWLFWR17.JUDGHZKLFKVKRXOGDYRLGNLQNLQJDQGVXEVHTXHQWORVVRIÀRZUDWHDQGRXWSXW+RVHV

VKRXOGEHRIVXI¿FLHQWOHQJWKWRDOORZIRUQDWXUDOEHQGVDQGDQ\WHQGHQF\WRIRUPKLJKSRLQWVWKDWPD\DOORZ

DLUWRFROOHFWDQGUHGXFHÀRZVKRXOGEHDYRLGHG:KHQXVLQJSXVK¿WÀH[LEOHFRQQHFWRUVLWLVDGYLVDEOHQRWWR

exceed 15 bar test pressures.

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

ABM Active Chilled Beams

7R REWDLQ PD[LPXP UHOLELOLW\ ÀH[LEOH KRVHV VKRXOG

QRWEHÀH[HGEH\RQGWKHPLQLPXPEHQGUDGLXVDQG

sharp bends or tortional twisting should be avoided.

The following formulae should be used:

Where:

R = Minimum bend radius

M = Movement

Ⱥ

/ 0LQLPXP$FWLYHOHQJWKZLWKRXWHQG¿WWLQJV

For vertically hung loop with vertical travel,

Inside Dia 6 10 15 20

X = 56 75 100 125

/ ;Ⱥ502)

:DWHUORR$%0XQLWVVKRXOGEHVHOHFWHGWRPHHWWKHGHVLJQVSHFL¿FDWLRQIRUWKHSURMHFWLQTXHVWLRQ(DFKXQLW

should be individually selected, and will be supplied with an reference label to ensure that the installer locates

it correctly , and it performs to the design characteristics.

All Beams supplied should match with a technical submittal issued prior to delivery, giving the design

FKDUDFWHULVWLFV$Q\GLVFUHSDQFLHVVKRXOGEHPDGHNQRZQWR:DWHUORRZLWKLQZHHNRIGHOLYHU\

(QVXUHWKHDLUÀRZOHYHOWRWKHEHDPLVFRUUHFWWRPDLQWDLQWKHFRUUHFWQRLVHDQGGXW\OHYHODQGWKHZDWHUÀRZ

rate is correct to ensure the coil pressure and duty are also in line with design parameters.

7KHIROORZLQJ¿YHSDJHVJLYHVHOHFWLRQH[DPSOHVIRUYDULRXVURRPFRQGLWLRQVKHDWLQJDQGFRROLQJGXWLHVZDWHU

ÀRZUDWHVDQGDLUÀRZUDWHV:KLOVWWKHVHPD\QRWUHODWHH[DFWO\WR\RXUUHTXLUHPHQWVLWVKRXOGJLYHDJRRG

LQGLFDWLRQ RI UHTXLUHG SHUIRUPDQFH DQG DOORZ FRUUHFW XQLW VHOHFWLRQ ,I \RXU UHTXLUHPHQWV DUH QRW LQ GLUHFW

accordance with the data provided, use the Waterloo Selection program to generate a complete technical

submittal.

+RVH'HVLJQ,QVWDOODWLRQ5HFRPPHQGDWLRQV

&KLOOHG%HDP2SHUDWLQJ3DUDPHWHUV

)LJXUH+RVH'HVLJQ,QVWDOODWLRQ

Recommendations

&KLOOHG%HDP&RPPLVVLRQLQJ*XLGH

i).:DWHU7UHDWPHQW2QFHDFORVHGV\VWHPLVFRUUHFWO\FOHDQHGE\EDFNÀXVKLQJDQGWKH¿QDOZDWHUFKDUJHLV

LQVLWXH WKHUHVKRXOG EHYHU\OLWWOHPDNHXS UHTXLUHGWR UHVWRUHZDWHUORVW E\DQ\OHDNDJHIURPYDOYHVWHPV

SDFNLQJ RU SXPS VHDOV HWF 7KH GLVVROYHG VROLGV LQ WKH V\VWHP ZDWHU GR QRW FRQFHQWUDWH VLQFH WKHUH LV QR

HYDSRUDWLRQIURPWKHV\VWHP$Q\OHDNDJHIURPWKHV\VWHPLVUHSODFHGGLUHFWO\E\PDNHXSZDWHUFRQWDLQLQJ

the same amount of dissolved solids. Therefore unless the incoming charge water is exceptionally hard then

SUHWUHDWPHQWWRUHPRYHVFDOHIRUPLQJHOHPHQWVZLWKLQWKHFKLOOHGV\VWHPVKRXOGEHXQQHFHVVDU\+RZHYHULWLV

recommended that the incoming water charge is tested by an accredited N.A.M.A.S. laboratory and any dosing

UHTXLUHPHQWVFDUULHGRXWE\DQDSSURYHGZDWHUWUHDWPHQWFRPSDQ\

9

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

PP+HDW([FKDQJHU

AIRSIDE DATA WATERSIDE DATA

Supply Air

Quantity

Primary

Static

Pressure

Loss

Cooling

Throw

+HDWLQJ

Throw

Sound

Level

LWA

6RXQG

power

G%

Air Cooling

capacity Room

WR$LU¨7

Water

Quantity

Cooling at Various Room

WRPHDQ:DWHU¨7

+HDWLQJDW9DULRXV5RRP

WRPHDQ:DWHU¨7

¨7 ¨7 Pressure

Loss

¨7 ¨7 ¨7 Pressure

Loss

¨7 ¨7

l/s m3/h Pa m G%$ Watts l/h l/s N3D Watts N3D Watts

Nozzle A - 20

5.6 20 64 0.7 21 54

90 0.025 0.9 201 217 266 2.6 517 775

120 0.033 1.4 229 303 3.9

150 0.042 2.1 252 272 333 5.7 644 966

6.9 25 107 1.2 1.3 22 66

90 0.025 0.9 263 346 2.6 572

120 0.033 1.4 301 325 3.9 653 979

150 0.042 2.1 332 359 5.7 716 1074

30 152 1.6 1.9 25 103

90 0.025 0.9 302 400 2.6 624 937

120 0.033 1.4 349 376 460 3.9 714 1070

150 0.042 2.1 415 506 5.7 1176

Nozzle B - 20

9.7 35 63 1.3 1.5 20 93 120

90 0.025 0.9 202 246 2.6

120 0.033 1.4 214 231 3.9 672

150 0.042 2.1 236 255 311 5.7 1107

11.1 40 1.5 21 107 137

90 0.025 0.9 237 256 312 2.6 656

120 0.033 1.4 272 294 360 3.9 751 1126

150 0.042 2.1 301 325 397 5.7 1239

13.9 50 130 2.0 2.3 24 133 171

90 0.025 0.9 316 341 416 2.6 1077

120 0.033 1.4 364 393 3.9 1235

150 0.042 2.1 402 435 533 5.7 907 1361

Nozzle C - 20

13.9 50 76 1.5 1.7 24 133 171

90 0.025 0.9 230 249 304 2.6 676 1015

120 0.033 1.4 265 350 3.9 774 1162

150 0.042 2.1 293 316 5.7 1279

16.7 60 112 2.1 160 205

90 0.025 0.9 311 2.6 721

120 0.033 1.4 332 359 3.9 1241

150 0.042 2.1 5.7 912

19.4 70 160 2.1 2.4 32 240

90 0.025 0.9 353 467 2.6 763 1145

120 0.033 1.4 409 442 539 3.9 1316

150 0.042 2.1 453 5.7 1452

22.2 204 2.4 2.7 36 213 274

90 0.025 0.9 415 2.6 1204

120 0.033 1.4 519 634 3.9 924

150 0.042 2.1 533 576 704 5.7 1021 1531

Selection Data

Chilled Beam Selection Parameters

ABM 300 1200mm

10

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

Unit Selection Data

ABM 300 1500mm

PP+HDW([FKDQJHU

AIRSIDE DATA WATERSIDE DATA

Supply Air

Quantity

Primary

Static

Pressure

Loss

Cooling

Throw

+HDWLQJ

Throw

Sound

Level

LWA

6RXQG

power

G%

Air Cooling

capacity Room

WR$LU¨7

Water

Quantity

Cooling at Various Room

WRPHDQ:DWHU¨7

+HDWLQJDW9DULRXV5RRP

WRPHDQ:DWHU¨7

¨7 ¨7 Pressure

Loss

¨7 ¨7 ¨7 Pressure

Loss

¨7 ¨7

l/s m3/h Pa m G%$ Watts l/h l/s N3D Watts N3D Watts

Nozzle A - 20

6.9 25 61 0.6 0.7 69

0.022 163 177 216 2.1 537

110 0.031 1.3 191 206 252 3.6 625 937

140 0.039 1.9 213 230 5.1 693 1039

30 1.0 1.1 19 103

0.022 249 269 327 2.1 604 907

110 0.031 1.3 291 314 3.6 705 1057

140 0.039 1.9 325 352 430 5.1 1175

9.7 35 119 1.3 1.5 20 96 120

0.022 321 346 423 2.1 666 999

110 0.031 1.3 377 407 3.6 779 1169

140 0.039 1.9 422 456 5.1 1302

Nozzle B - 20

11.1 40 53 1.1 1.3 19 110 137

0.022 177 192 235 2.1 591

110 0.031 1.3 209 226 276 3.6 1034

140 0.039 1.9 232 251 307 5.1 766 1149

13.9 50 1.5 1.7 20 137 171

0.022 332 2.1 673 1009

110 0.031 1.3 291 320 370 3.6

140 0.039 1.9 314 349 402 5.1 1315

16.7 60 122 2.1 24 164 205

0.022 310 335 410 2.1 745

110 0.031 1.3 397 3.6 1313

140 0.039 1.9 412 445 544 5.1 1467

Nozzle C - 20

19.4 70 76 1.6 1.9 27 192 240

0.022 247 266 325 2.1 707 1061

110 0.031 1.3 291 314 3.6 1244

140 0.039 1.9 326 351 430 5.1 925

22.2 103 2.1 31 219 274

0.022 304 329 402 2.1 759

110 0.031 1.3 361 390 476 3.6

140 0.039 1.9 405 437 534 5.1 996 1494

25.0 90 131 2.0 2.4 33 246

0.022 363 391 479 2.1 1210

110 0.031 1.3 430 465 3.6 950 1425

140 0.039 1.9 523 639 5.1 1063 1595

100 162 2.3 2.6 36 274 342

0.022 419 453 553 2.1 1276

110 0.031 1.3 499 539 3.6 1004 1507

140 0.039 1.9 562 607 742 5.1 1126

11

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

Unit Selection Data

$%0PP

PP+HDW([FKDQJHU

AIRSIDE DATA WATERSIDE DATA

Supply Air

Quantity

Primary

Static

Pressure

Loss

Cooling

Throw

+HDWLQJ

Throw

Sound

Level

LWA

6RXQG

power

G%

Air Cooling

capacity Room

WR$LU¨7

Water

Quantity

Cooling at Various Room

WRPHDQ:DWHU¨7

+HDWLQJDW9DULRXV5RRP

WRPHDQ:DWHU¨7

¨7 ¨7 Pressure

Loss

¨7 ¨7 ¨7 Pressure

Loss

¨7 ¨7

l/s m3/h Pa m G%$ Watts l/h l/s N3D Watts N3D Watts

Nozzle A - 20

30 53 0.6 0.7 103

70 0.019 0.6 161 174 212 1.9 563

100 1.3 194 210 256 3.9 674 1012

130 0.036 2.1 220 237 6.4 759 1139

9.7 35 77 0.9 1.0 20 96 120

70 0.019 0.6 276 299 365 1.9 620 930

100 1.3 335 361 442 3.9 745

130 0.036 2.1 379 410 502 6.4 1261

11.1 40 102 1.1 1.3 20 110 137

70 0.019 0.6 341 369 451 1.9 673 1009

100 1.3 415 449 3.9 1216

130 0.036 2.1 471 509 623 6.4 917 1375

Nozzle B - 20

13.9 50 53 1.1 1.3 21 137 171

70 0.019 0.6 211 279 1.9 626 939

100 1.3 242 277 307 3.9 753 1129

130 0.036 2.1 291 314 6.4 1274

16.7 60 77 1.4 1.7 25 164 205

70 0.019 0.6 317 375 1.9 693 1039

100 1.3 346 374 456 3.9 1254

130 0.036 2.1 394 425 520 6.4 946 1419

19.4 70 102 1.7 2.0 192 240

70 0.019 0.6 330 357 436 1.9 753 1130

100 1.3 403 435 532 3.9 912

130 0.036 2.1 460 497 607 6.4 1035 1552

Nozzle C - 20

22.2 67 1.5 1.7 31 219 274

70 0.019 0.6 237 256 313 1.9 705 1057

100 1.3 311 3.9 1277

130 0.036 2.1 329` 354 433 6.4 964 1446

25.0 90 1.7 1.9 34 246

70 0.019 0.6 291 314 1.9 1123

100 1.3 355 469 3.9 906 1359

130 0.036 2.1 405 536 6.4 1542

30.6 110 131 2.0 2.3 39 301 376

70 0.019 0.6 367 1.9 1240

100 1.3 447 590 3.9 1006 1509

130 0.036 2.1 503 544 667 6.4 1145 1717

36.1 130 2.4 43 356 445

70 0.019 0.6 419 453 565 1.9 1344

100 1.3 570 697 3.9 1095 1642

130 0.036 2.1 607 656 6.4 1250

12

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Unit Selection Data

ABM 300 2400mm

PP+HDW([FKDQJHU

AIRSIDE DATA WATERSIDE DATA

Supply Air

Quantity

Primary

Static

Pressure

Loss

Cooling

Throw

+HDWLQJ

Throw

Sound

Level

LWA

6RXQG

power

G%

Air Cooling

capacity Room

WR$LU¨7

Water

Quantity

Cooling at Various Room

WRPHDQ:DWHU¨7

+HDWLQJDW9DULRXV5RRP

WRPHDQ:DWHU¨7

¨7 ¨7 Pressure

Loss

¨7 ¨7 ¨7 Pressure

Loss

¨7 ¨7

l/s m3/h Pa m G%$ Watts l/h l/s N3D Watts N3D Watts

Nozzle A - 20

13.9 50 75 1.2 1.3 21 137 171

200 0.06 6.7 377 409 20.0 967 1450

250 0.07 469 551 30.0 1125

300 13.4 465 601 1247

16.7 60 109 1.6 1.9 22 164 205

200 0.06 6.7 426 463 543 20.0 1631

250 0.07 530 621 30.0 1269 1904

300 13.4 529 575 673 1409 2114

19.4 70 135 1.9 2.1 24 192 240

200 0.06 6.7 530 626 20.0 1199

250 0.07 606 713 30.0 1402 2103

300 13.4 604 656 771 1562 2344

Nozzle B - 20

22.2 1.3 1.5 24 219 274

200 0.06 6.7 505 551 675 20.0 1064 1596

250 0.07 596 650 796 30.0 1240

300 13.4 667 1379

25.0 90 106 1.5 27 246

200 0.06 6.7 631 20.0 1142 1713

250 0.07 744 931 30.0 1320

300 13.4 910 1043 1477 2216

100 131 2.0 29 274 342

200 0.06 6.7 675 737 20.0 1211

250 0.07 797 996 30.0 1417 2125

300 13.4 974 1115 1579

Nozzle C - 20

33.3 120 1.7 2.0 30 329 411

200 0.06 6.7 395 514 20.0 1176 1764

250 0.07 466 505 616 30.0 1356 2034

300 13.4 526 567 693 2277

140 113 1.9 2.2 35 479

200 0.06 6.7 497 526 643 20.0 1273 1909

250 0.07 620 759 30.0 1492

300 13.4 656 695 1665

44.4 160 146 2.1 2.4 37 547

200 0.06 6.7 592 629 690 20.0 1366 2049

250 0.07 699 742 30.0 1606

300 13.4 912 1793

50.0 2.3 2.7 41 616

200 0.06 6.7 709 794 917 20.0 1451 2176

250 0.07 937 30.0 1710 2565

300 13.4 941 1054 1217 1913

Operating and maintenance instructions

13

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Unit Selection Data

ABM 300 3000mm

PP+HDW([FKDQJHU

AIRSIDE DATA WATERSIDE DATA

Supply Air

Quantity

Primary

Static

Pressure

Loss

Cooling

Throw

+HDWLQJ

Throw

Sound

Level

LWA

6RXQG

power

G%

Air Cooling

capacity Room

WR$LU¨7

Water

Quantity

Cooling at Various Room

WRPHDQ:DWHU¨7

+HDWLQJDW9DULRXV5RRP

WRPHDQ:DWHU¨7

¨7 ¨7 Pressure

Loss

¨7 ¨7 ¨7 Pressure

Loss

¨7 ¨7

l/s m3/h Pa m G%$ Watts l/h l/s N3D Watts N3D Watts

Nozzle A - 20

16.7 60 73 1.0 1.1 19 164 205

0.05 455 497 19.1 1020 1530

250 0.069 11.6 531 33.9

320 17.7 751 53.3 1317 1975

19.4 70 104 1.3 1.5 21 192 240

0.05 530 576 677 19.1 1721

250 0.069 11.6 621 674 792 33.9 1340 2009

320 17.7 742 53.3 2232

22.2 134 1.6 24 219 274

0.05 604 656 774 19.1 1265

250 0.069 11.6 707 905 33.9 2220

320 17.7 996 53.3 1649 2474

Nozzle B - 20

25.0 90 64 1.1 1.3 22 246

0.05 555 617 707 19.1 1123

250 0.069 11.6 649 721 33.9 1309 1964

320 17.7 726 922 53.3 1455

30.6 110 91 1.5 1.7 27 301 376

0.05 633 706 19.1 1279

250 0.069 11.6 741 943 33.9 1495 2243

320 17.7 909 1037 53.3 1666 2499

36.1 130 131 2.1 33 356 445

0.05 696 776 19.1 1416 2123

250 0.069 11.6 779 992 33.9 1664 2497

320 17.7 1071 53.3

Nozzle C - 20

41.7 150 74 1.7 2.0 33 411 513

0.05 670 799 19.1 1343 2015

250 0.069 11.6 737 790 33.9 1575 2363

320 17.7 796 949 53.3 2636

47.2 170 94 2.0 2.3 36 465

0.05 751 19.1 1442 2163

250 0.069 11.6 33.9 1695 2542

320 17.7 915 53.3

190 119 2.2 2.5 39 520 650

0.05 993 19.1 1531 2297

250 0.069 11.6 933 999 1112 33.9

320 17.7 1023 1201 53.3 2020 3030

210 146 2.4 2.7 41 575 719

0.05 972 19.1 1617 2425

250 0.069 11.6 992 1049 1169 33.9

320 17.7 1051 1111 1239 53.3 2139 3209

Operating and maintenance instructions

14

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Operating and maintenance instructions

:DWHUORR$%0¶VDUHDLUWHUPLQDOGHYLFHVZLWKQRPRYLQJSDUWVZKLFKHVVHQWLDOO\UHTXLUHYHU\OLWWOHPDLQWHQDQFH

7KHIDFHSODWHKLQJHVGRZQVHHEHORZWRJDLQDFFHVVWRWKHFRROLQJKHDWLQJFRLOZKLFKVKRXOGEHYDFXXPHG

on an annual basis to ensure air has a free path through the exchanger for maximum performance. Please

HQVXUHWKDWZKHQYDFXXPLQJWKHFRLOFDUHLVWDNHQQRWWRGDPDJHWKHDOXPLQLXP¿QVDVWKLVZLOODIIHFWWKH

performance of the unit.

,IWKHXQLWEHFRPHVPDUNHGLWFDQEHFOHDQHGZLWKDFORWKZHWWHGZLWKGHWHUJHQWGLOXWHGZLWKZDWHU$WWKHVDPH

time the coil is being vacuumed, it is commonly good practice to ensure the air connection spigot is still secure.

&KLOOHGEHDP0DLQWHQDQFHDQG&OHDQLQJ

15

www.waterloo.co.uk Tel: +44 (0) 1622 711500

Waterloo Product Range

GRILLES

$FRPSOHWHUDQJHRISURGXFWVVXLWDEOHIRUDOOZDOOFHLOLQJDQGÀRRUDSSOLFDWLRQV

0RVWJULOOHVDUHPDGHIURPDOXPLQLXPDQGKDYHDUDQJHRI¿[HGRUPRYHDEOH

blades designed to give performance whilst remaining aesthetically pleasing

WRWKHH\H*ULOOHVDUHPDGHWRFXVWRPHUVSHFL¿HGVL]HVDQGFRORXUV330*

VWDQGDUGFRORXU330*ORVV:KLWH7KHUDQJHLVFRPSOHPHQWHGE\

the Aircell range of polymer Grilles.

DIFFUSERS

Designed to be installed in various ceiling systems, we have a complete range

WRVXLWERWKSHUIRUPDQFHDQGDHVWKHWLFDOUHTXLUHPHQWV0RVWGLIIXVHUVDUHPDGH

from aluminium and can be ordered with or without plenum boxes for easy

GXFW ZRUN 'LIIXVHUV FDQ EH RUGHUHG LQ FXVWRPHU VSHFL¿HG FRORXUV 330*

VWDQGDUGFRORXULV330*ORVV:KLWH7KLVUDQJHLVFRPSOHPHQWHG

by the Aircell range of polymer Diffusers.

DISPLACEMENT

$IXOOUDQJHRIUHFHVVHGVHPLUHFHVVHGÀRRUZDOODQGFRUQHUXQLWVSURYLGLQJ

KLJK YHQWLODWLRQ HI¿FLHQF\ DQG H[FHOOHQW FRPIRUW 7KH YHU\ ORZ SUHVVXUH

LQYROYHGDOVRRIIHUTXLHWLQVWDOODWLRQV'LVSODFHPHQWXQLWVDUHDYDLODEOHDVZDOO

RUÀRRUPRXQWHGRULQGHHGLQWHJUDWHGZLWKLQWKHDUFKLWHFWXUDOGHVLJQ

EXTERNAL LOUVRES

$TXDOLW\UDQJHRISURGXFWVIRUH[WHUQDOZDOODSSOLFDWLRQV0DGHIURPDOXPLQLXP

with birdscreen or insect screen options. All louvres are made to customer

VSHFL¿HGVL]HVDQG330*FRORXUVVWDQGDUGFRORXULV330

AIR VOLUME CONTROL DAMPERS

Pressure independent Variable Air Volume and Constant Air Volume dampers

made from zintec plate. Most volume dampers are regulated with an electronic

PRWRUDQGVHQVRUVDQGDUHFDOLEUDWHGWRFXVWRPHUVSHFL¿FDWLRQVEHIRUHGHOLYHU\

7KH&RQVWDQW$LU9ROXPHGDPSHUUHTXLUHVQRSRZHUVRXUFHDVLWLVFRQWUROOHG

via a mechanical device and calibrated before delivery. All volume dampers can

EHRUGHUHGZLWKDVLQJOHRUGRXEOHLQVXODWLRQVNLQ

$&7,9($1'3$66,9(&+,//('%($06

7KH¿QHVWTXDOLW\UDQJHRIKLJKRXWSXWDFWLYHEHDPVXVHGIRUYHQWLODWHGKHDWLQJ

and cooling applications. These units have 4 pipe coils to allow heating and

cooling circuits to run simultaneously, giving constant and responsive control.

The design allows a large optimum capacity and also allows the customer to

specify the nozzle type and pitch for individual circumstances.

$FWLYHEHDPVDUHPDGHIURPVWHHOWRDODUJHUDQJHRIFXVWRPHUVSHFL¿HGVL]HV

DQGDVVXFKDUHVXLWDEOHIRUYDULRXVGLIIHUHQWFHLOLQJV\VWHPV6WDQGDUG¿QLVKLV

330KRZHYHURWKHU330*FRORXUVDUHDYDLODEOHRQUHTXHVW

VWDQGDUG

FRORXU

330

*ORVV

:KLWH

the Aircell ran

ge

of

pol

yme

rG

rilles.

e

Aircell

range

of

pol

yme

me

me

rG

r G

r G

r G

ril

ril

ril

ril

les

les

les

le

.

J

S

.

E

E

RS

t

l

k

¿HGVL]HVDQG

3

30

*

FRORXU

V

V

EXTERNAL LOUVRES

Waterloo Product Range

All products conform to the Terms and Conditions of Waterloo Air

3URGXFWVSOFDFRS\RIZKLFKDUHDYDLODEOHXSRQUHTXHVW'XHWRRXU

continuous research and development programme, Waterloo Air

Products plc reserve the right to alter products and prices without prior

QRWL¿FDWLRQ

Copyright Waterloo Air Products plc 2019

Waterloo declare that, at the time of print, all products are in

DFFRUGDQFHZLWKUHOHYDQWGLUHFWLYHVDVLGHQWL¿HGE\+(9$&

and other European Organisations and will display the

&(0DUNLQJZKHUHUHTXLUHG

Waterloo Air Products plc

+HDG2I¿FH

Mills Road, Aylesford,

Maidstone, Kent ME20 7NB

7HO

)D[

HPDLOVDOHV#ZDWHUORRFRXN

LQWHUQHWZZZZDWHUORRFRXN

1RUWKHUQ2I¿FH

+\GH3DUN+RXVH&DUWZULJKW6WUHHW

1HZWRQ+\GH6.(+

7HO

)D[

HPDLOVDOHV#ZDWHUORRFRXN

LQWHUQHWZZZZDWHUORRFRXN

April 2019

)0 EMS 590755

Table of contents

Popular Temperature Controllers manuals by other brands

Omega Engineering

Omega Engineering CNiTH-i32 quick start guide

Eurotherm

Eurotherm 3200 user guide

Elsner

Elsner Cala KNX T 101 CH Installation and adjustment

PKP

PKP TFK02 instruction manual

S+S Regeltechnik

S+S Regeltechnik HYGRASREG RH-30 Operating Instructions, Mounting & Installation

Ruby

Ruby ZEUS 7000 instruction manual