SNIJDERS SCIENTIFIC B.V.

ISO9001 certified by Lloyd’s

Economic Premium ECP01E, March ‘06 Page 3 of 22 Subject to change

USER- & TECHNICAL MANUAL ECONOMIC PREMIUM, MODEL ECP01E

1. IN GENERAL ...........................................................................................................................4

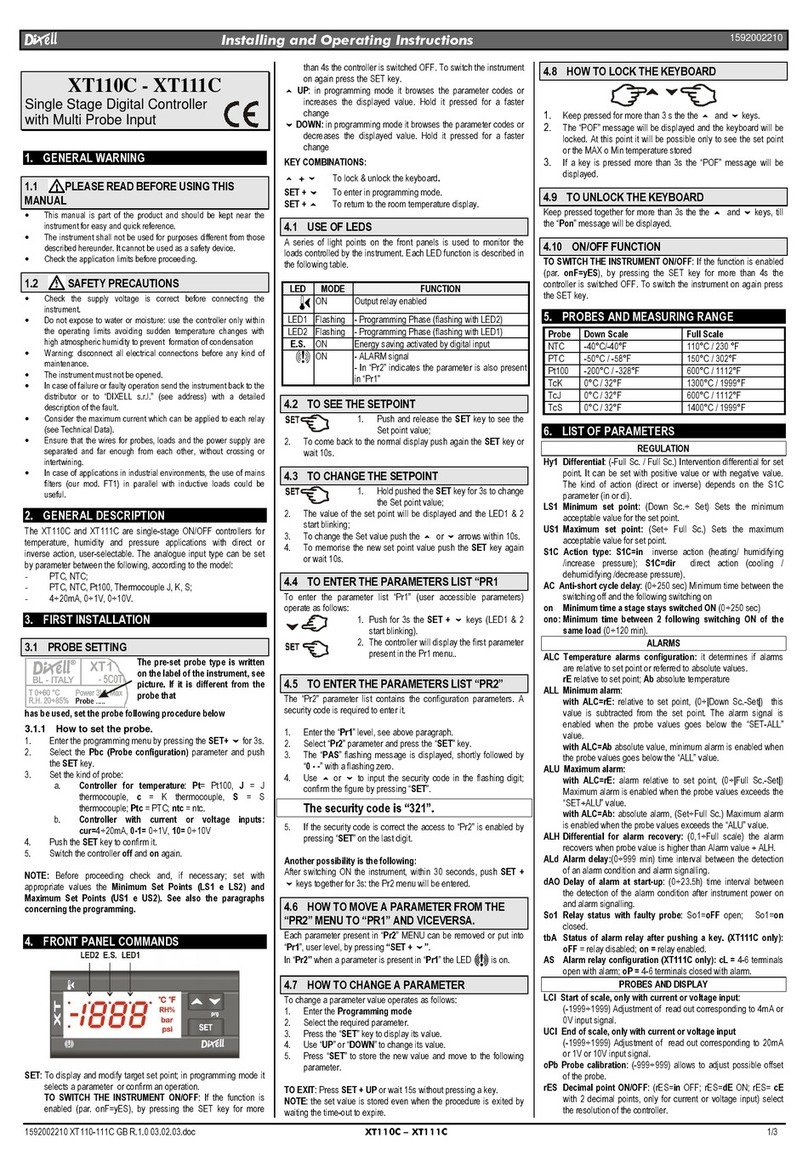

2. SPECIFICATIONS ..................................................................................................................5

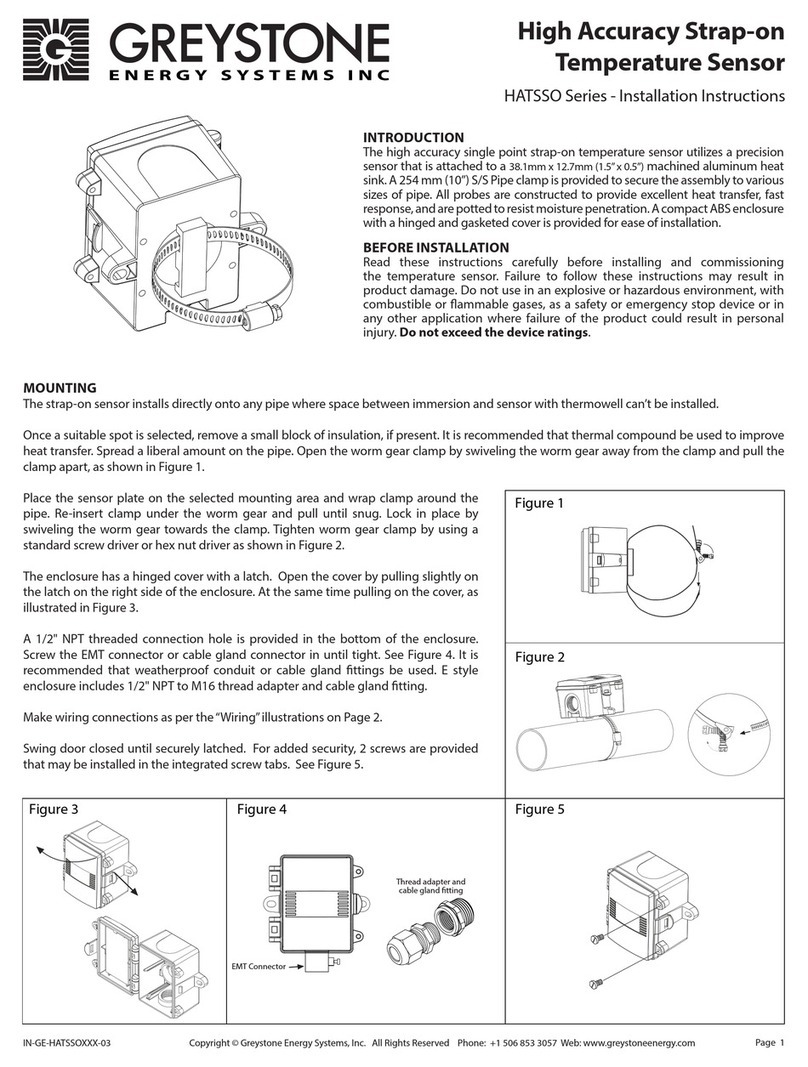

3. INSTALLATION .....................................................................................................................6

4. USER INSTRUCTIONS .......................................................................................................... 7

4.1. D

ESCRIPTION

IMAGO

500

CONTROLLER

..................................................................................... 7

4.2. C

ONTROL

....................................................................................................................................... 8

4.3. D

ISPLAY

........................................................................................................................................ 8

4.4. S

ET TIME

....................................................................................................................................... 9

4.5. B

ASIC MODE

.................................................................................................................................. 9

5. MANUAL MODE...................................................................................................................10

5.1. C

HANGING TEMPERATURE

,

HUMIDITY OR LIGHTCONTACTS

....................................................... 11

6. PROGRAM MODE................................................................................................................12

6.1. P

ROGRAM EDITOR

....................................................................................................................... 12

6.2. P

ROGRAM NAME

.......................................................................................................................... 14

6.3. P

ROGRAM WITH RAMFUNCTION

.................................................................................................. 14

6.4. S

TARTING THE PROGRAM WITH TIME INPUT

................................................................................ 17

6.5. A

LARMFUNCTIONS

...................................................................................................................... 17

7. MAINTENANCE....................................................................................................................18

7.1.

W

ARNINGS

.................................................................................................................................. 18

7.2.

U

SE OF WATER FOR THE HUMIDIFICATION

.................................................................................. 19

8. TROUBLESHOOTING.........................................................................................................20

9. PARTSLIST ............................................................................................................................21

10. APPENDIX..................................................................................................................................

-

Electrical Diagrams Economic Premium.

-

Cooling Diagram Economic Premium.

-

Testform.

-

Stek-Control-Certificate.