Water Tec WS1TA User manual

Water Tec of Tucson

• Water Tec of Tucson • www.water-tec.com •

• 4601 S. 3RD Avenue • Tucson, AZ 85714 • (520) 790-1512 • Fax (520) 745-0549 •

WS1TA

Twin‐AlternangWatersoener

MAINCOMPONENTS

YourwatertreatmentsystemisaTwin‐Altpointofentry(POE)systemcomposedoffourcomponents:

A.Thecontrolvalveandcomputerassembly

Thefiberglasstankassembly'sincludingthewatertreatmentmedium

Thebrinetankassemblyincludingsafetyfloat.

Eachoftheseassemblieshasaspecificfunconasdescribedbelow:

ControlValveAssembly…Automacallymonitorswaterusagepaerns,iniatesregeneraonandmovesthevalve

throughthestepsofregeneraon.

MediaTankAssembly…Afiberglassvessels,whichcontainsthewatersoeningmedia,intheproperdiameteranddepth

ofthemediaandevenlydistributesthefeedwaterthroughoutthemediatankassembly.

BrineTankAssembly…Apolyethylenevessel,whichisusedtodissolvesaltandtoholdtheproperamountofbrineforthe

nextregeneraon.Abrinevalvekeepsthecontrolvalvefromdrawingairintothesystem.

STEPSOFOPERATION

Service…Hardwaterflowsdownwardthroughthewatersoeningresinwherethehardnessminerals,calciumandmagnesium,as

wellasdissolvediron,areremovedfromthewaterandarecollectedontheresin.Theamountofresinandthesaltdosage

givesresinacertaincapacityforhardnessandironremoval.

Backwash1…Duringthecyclethewaterflowsupwardthroughtheresinbedandwashescollectedsedimentorotherforeignma‐

terialtothedrain.

BrineandRinse…Thebrinesoluonisdrawnfromthebrinetankandslowlyflowsdownwardthroughtheresincollecngthehard‐

nessandironasitgoes.Thebrinecarriesthehardnessandironwithitandrinsesthemtothedrain.

Backwash2…Sameasbackwash1abovebutofslightlyshorterduraon.

FastRinse…Waterflowsdownwardthroughtheresinandtothedraincarryingwithittheremainingtracesofbrine.

BrineTankRefill…Apredeterminedvolumeofwaterflowsintothebrinetankanddissolvesacalculatedamountofsaltcreang

brineforthenextgeneraon.ThisoccursattheonsetofthenextServicecycle.Besurethatthereisalwaysun‐dissolved

saltremaining.Sincethefrequencyofregeneraonisreasonablyconsistent,aregularaddionofsaltshouldbesched‐

uled.Approximately6"‐8"ofsaltmustbeinbrinetank.Insomecasestheinstallaontechnicianmaydecideapre‐brine

refillmaybeappropriate.Ifsobrinerefillwilloccur2hourspriortoregeneraonandwillresultinminimalwaterinthe

brinetankassemblyduringserviceposion.

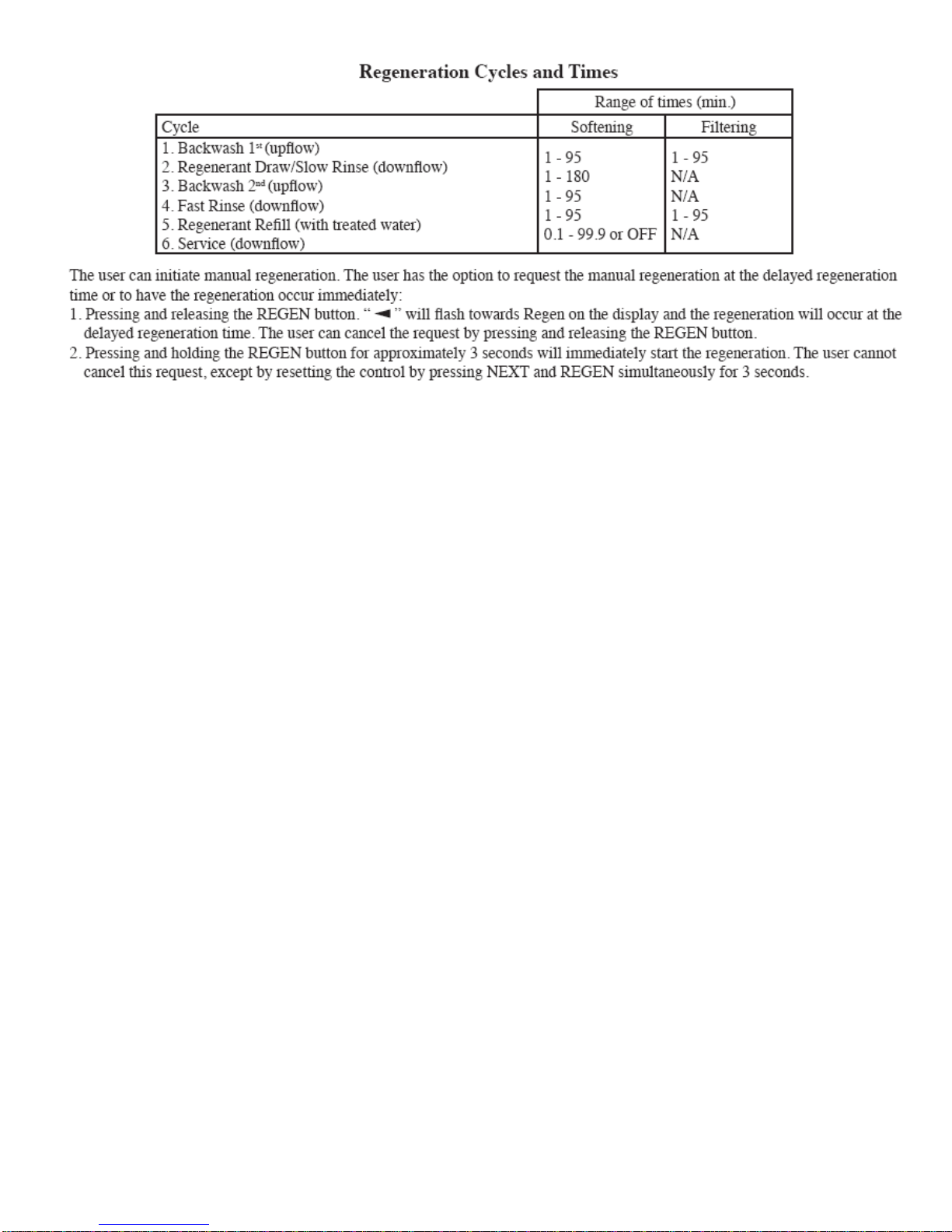

TotalRegeneraonTime(Backwash1throughFastRinse)canbeanywherebetween57and107minutesdependingonseng

madeforcertainwatercondions.

GENERALCAREANDMAINTENANCEINFORMATION

Thefollowingguidelinesarerecommendedforyoutoobtainmaximumefficiencyfromyourwatertreatmentsystem:

ControlValve…Trytokeepfreeofdirtanddebrisbothonvalvebodyandundercover.Nolubricaonisrequired.

BrineTank…Amajorcleaningisrecommendedeverytwoyears.Thisintervalmayneedtobeadjusteddependingonthe

amountofinsolublematerialinthesaltbeingused.

Allowsaltleveltobecomeverylowsothereisliletoremove.Scoopoutun‐dissolvedsalt.

Disconnectandremovebrinevalve.Thereisnopressureorsucononthislineexceptduringaregeneraon.

Removeinternalpartsofbrinetank,ifany.

Cleanbrinetankinteriorwithamildcleaningagent(dishsoap)andrinsethoroughly.

Replacebrinevalveandinternalparts.

Pourfivegallonsofwater(soenedifavailable)intothetank(Addonlytwogallonsifpre‐brinerefilloponisused).

Addsalt.

Replacecover.

Allowtwohoursforconcentratedbrinetobemadebeforenextregeneraon.

Itisrecommendedthat…amanuallyiniatedregeneraonshouldbestartednow.SeeManualRegeneraon.

GENERALINSTALLATION&SERVICECAUTIONS

The control valve, fittings, and/or bypass are designed to accommodate minor plumbing misalignments they are not de-

signed to support the weight of a system or the plumbing.

DonotuseVaseline,oils,otherhydrocarbonlubricants,orsiliconesprayanywhere.Donotusesiliconeonredorclearlip

seals.

Donotusepipedopeorothersealantonthreads.Teflontapemustbeusedonthethreadsofthe1"NPTelbow,its¼"

NPTconnecons,andonthethreadsforthedrainlineconnecon.Teflontapeisnotusedonthenutconneconsorcaps

becauseo‐ringsealsareused.Thenutsandcapsaredesignedtobeunscrewedorghtenedbyhandorwiththespecial

plascServiceWrench,CLV‐V3193(modelswithClackcontrolvalves).Ifnecessary,plierscanbeusedtounscrewthenut

orcap.Donotuseapipewrenchtoghtennutsorcaps.Donotplacescrewdriverinslots,oncaps,and/ortapwitha

hammer.

SITEREQUIREMENTS

‐WaterPressure,20‐125psi‐Currentdrawis0.25amperes

‐WaterTemperature,40º‐110ºF‐A15.powercordisfurnished

‐Thetankshouldbeonafirmlevelsurface ‐Theplug‐intransformerisfordrylocaons

‐Electrical:Usea115/120V,60Hzuninterruptedonly.

outlet.‐Baeriesarenotused.

Thedistancebetweenthedrainandthewatercondionershouldbeasshortaspossible.

Sincesaltmustbeperiodicallyaddedtothebrinetank,thetankshouldbelocatedwhereitiseasilyaccessible.

Donotinstallanywatercondionerwithlessthan10feetofpipingbetweenitsoutletandtheinletofawaterheater.

Donotlocateunitwhereitoritsconnecons(includingthedrainandoverflowlines)willbesubjectedtotemperaturesatorbelow

34ºF.

Theuseofresincleanerinanunventedenclosureisnotrecommended.

Donotinstallequipmentinlocaonsthatwouldreceiverainrun‐offfromroof.

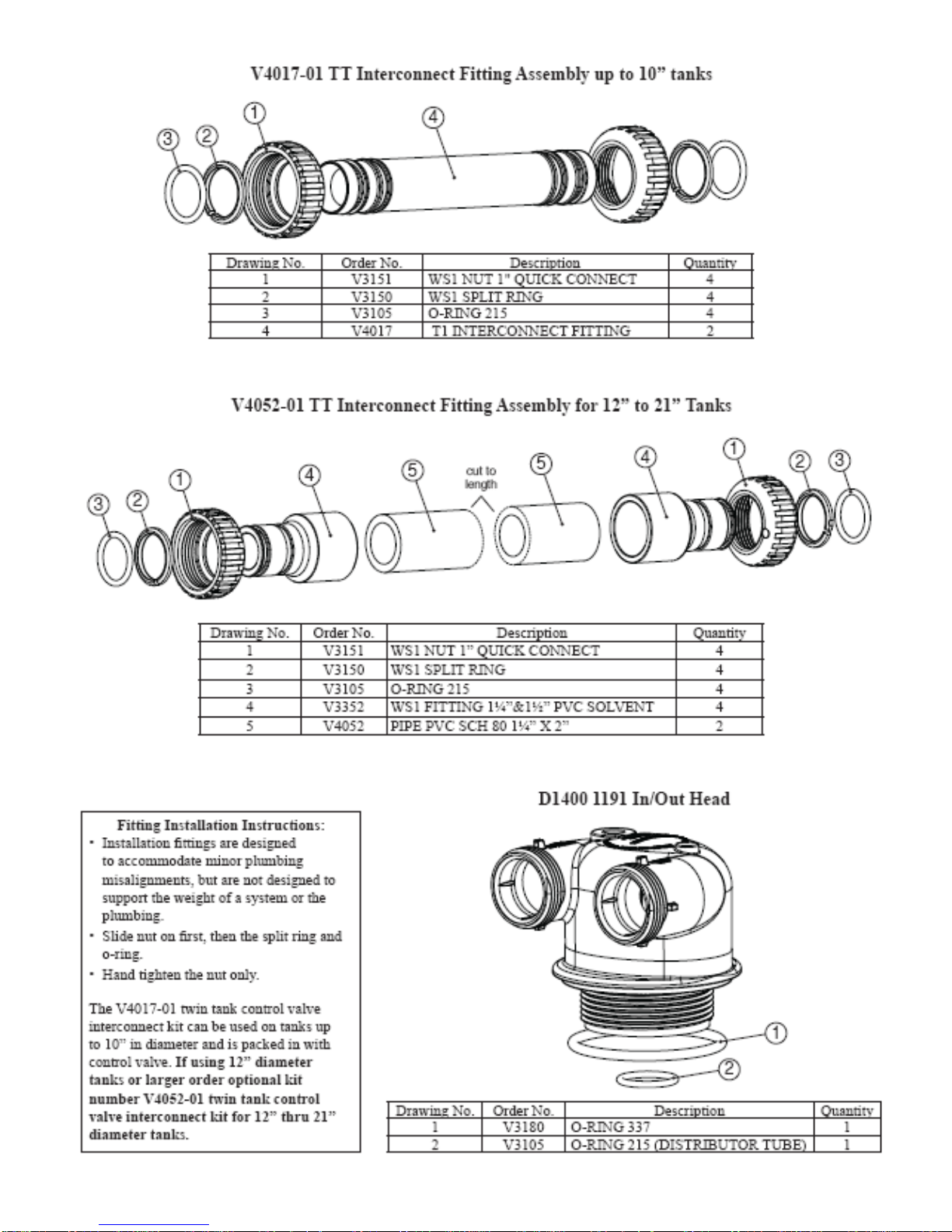

INLET/OUTLETPLUMBING:Connecttoasupplylinedownstreamofoutdoorspigots.Installaninletshutoffvalveandplumbtothe

unitsbypassvalveinletlocatedattherightrearasyoufacetheunit.Whenassemblingtheinstallaon‐fingpackage(inlet

andoutlet),connectthefingtotheplumbingsystemfirstandthenaachthenut,splitringandO‐ring.Heatfromsoldering

orsolventcementswilldamagethenut,splitringorO‐ring.Solderjointsshouldbecoolandsolventcementsshouldbeset

beforeinstallingthenut,splitringandO‐ring.Avoidgengsolderflux,primer,andsolventcementonanypartoftheo‐rings,

splitrings,bypassvalve,orcontrolvalve.Ifthebuilding’selectricalsystemisgroundedtotheplumbinginstallacopper‐

groundingstrapfromtheinlettotheoutletpipe.Plumbingmustbedoneinaccordancewithallapplicablelocalcodes.

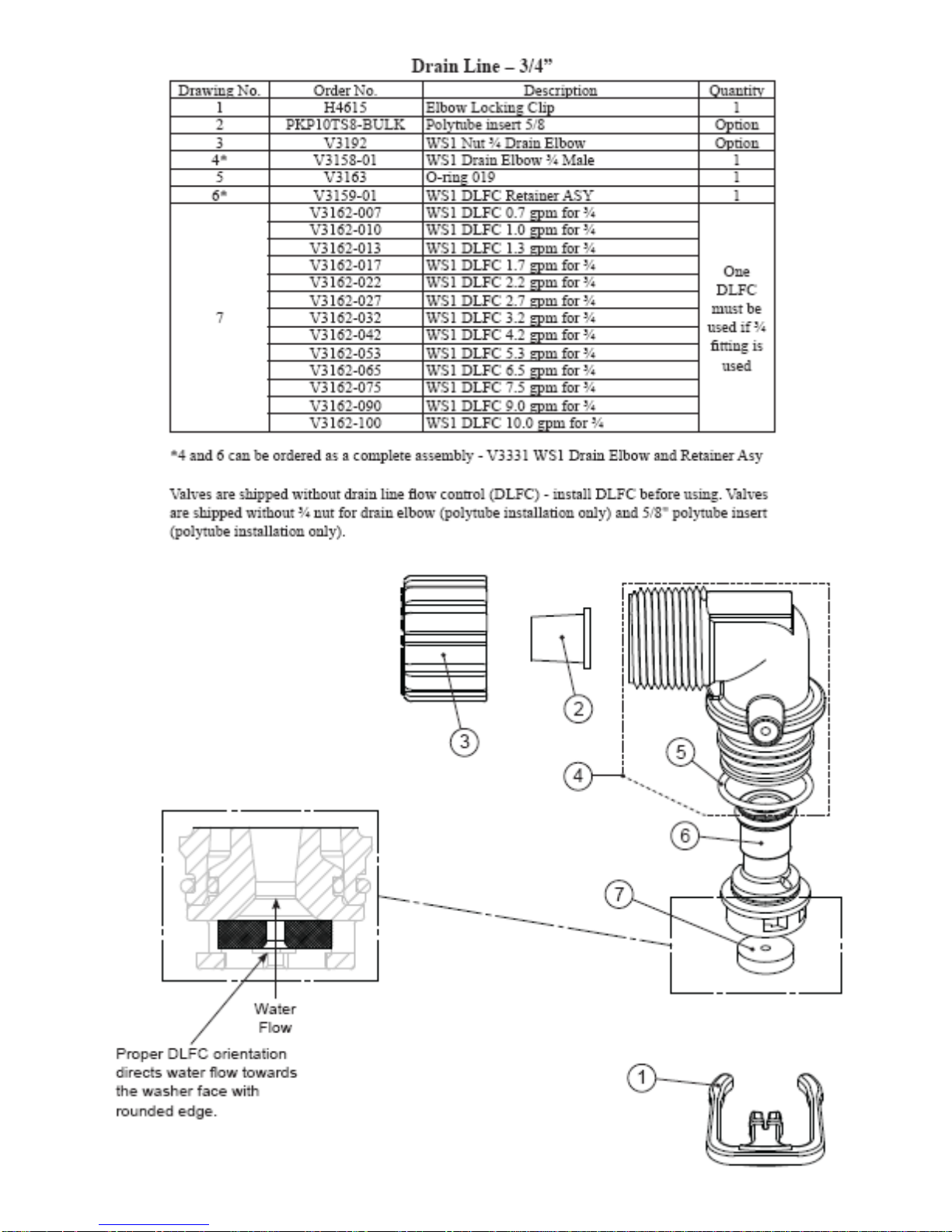

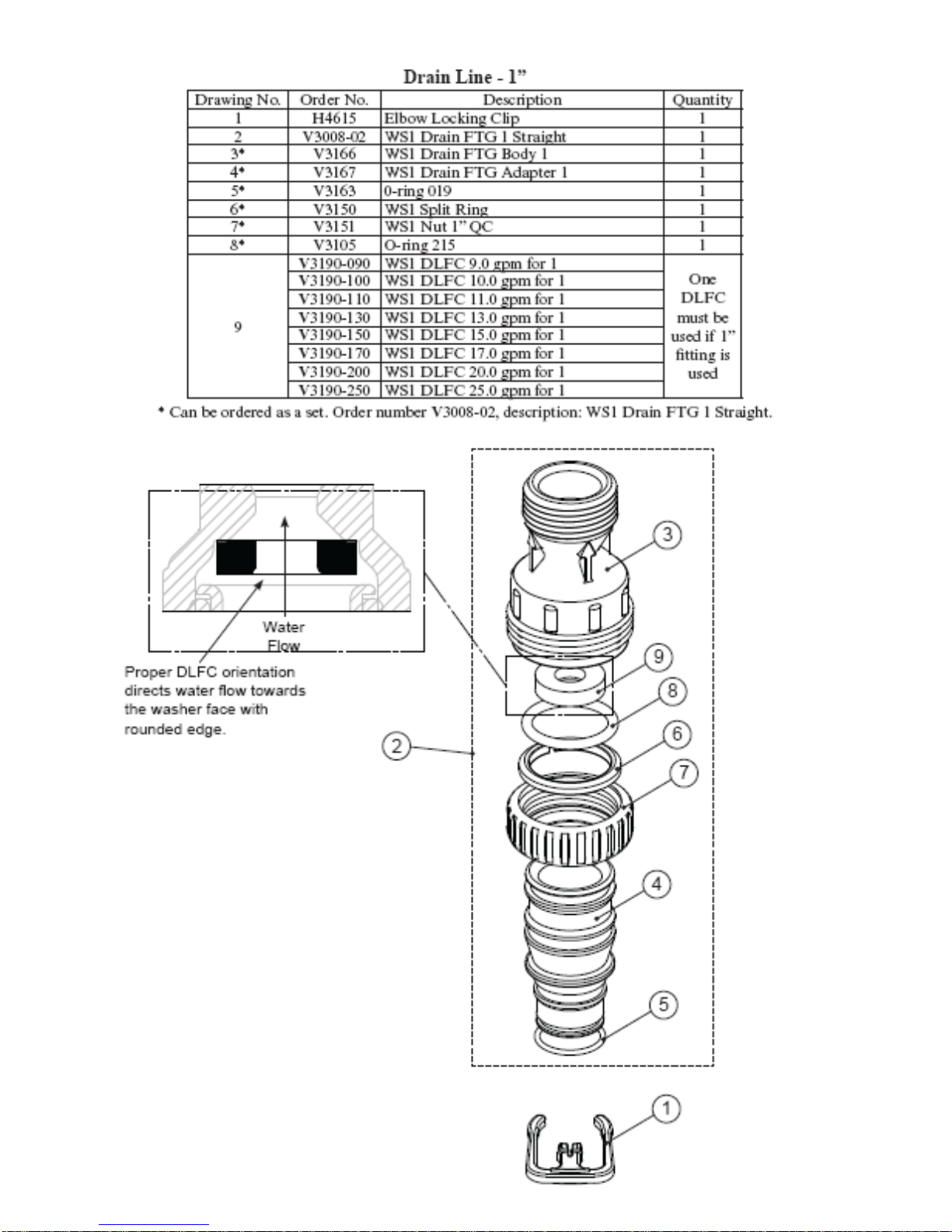

DRAINLINE:First,besurethatthedraincanhandlethebackwashflowofthesystem.Solderjointsnearthedrainmustbelocated

priortoconnecngthedrainlineflowcontrolfing.Leaveatleast6"betweenthedrainlineflowcontrolfingandsolder

joints.Failuretodosocouldcauseinteriordamagetotheflowcontrol.Installa3/8"‐1/2"I.D.flexibleplasctubetotheDrain

LineAssemblyordiscardthetubingnutandusethe¾"NPTfingforrigidpipe.Ifthebackwashrateisgreaterthan7gpm,

usea¾"drainline.Rundraintubetoitsdischargepointinaccordancewithplumbingcodes.Payspecialaenontocodesfor

airgapsandantsiphondevices.

9.BRINETANKCONNECTION:Installa3/8"O.D.polyethylenetubefromtheRefillElbowtotheBrineValveinthebrinetank.

10.OVERFLOWLINECONNECTION:

ANOVERFLOWDRAINLINEISRECOMMENDEDANYWHEREABRINEOVERFLOWCOULDDAMAGEFURNISHINGSORTHEBUILD‐

INGSTRUCTURE.

Yoursoenerisequippedwithabrinetanksafetyfloat,whichgreatlyreducesthechanceofanaccidentalbrineoverflow.In

theeventofamalfuncon,anOVERFLOWLINECONNECTIONwilldirectthe“overflow”tothedraininsteadofspillingonthe

floor.Thisbarbtypefingshouldbeonthesideofthecabinetorthebrinetank.

To connect the overflow fitting, locate the hole inside of brine tank. Insert overflow fitting into tank and tighten with plastic

thumbnut from the inside. Attach a length of ½" I.D. tubing (not supplied) to the fitting and run to drain. Do not elevate overflow

line higher than 3" below bottom of overflow fitting. Do not connect this tube into the drain line of the control valve. Overflow

should be a direct, separate line from overflow fitting to drain, sewer, tub, or appropriate outdoor location. Allow an air gap as

per the drain line instructions.

IMPORTANT:

Never insert a drain line directly into a drain, sewer line, or trap. Always allow an air gap between the drain line and the

wastewater to prevent the possibility of sewage being back-siphoned into the water conditioner.

Brinetank

connecon

SecondTankAdaptor

Inter–connector

Inlet Outlet

Drain

***DonotremoveredclipsonBrineTankconneconorDrainconnecon,theseclipsareretainerclipsand

mustbeinstalledforproperoperaon.

InstallaonandStartup

1)Connectsecondtanktomaincontrolvalve.

2)ConnectBrineTank

3)ConnectDrain

4)Connectinlet&Outlet

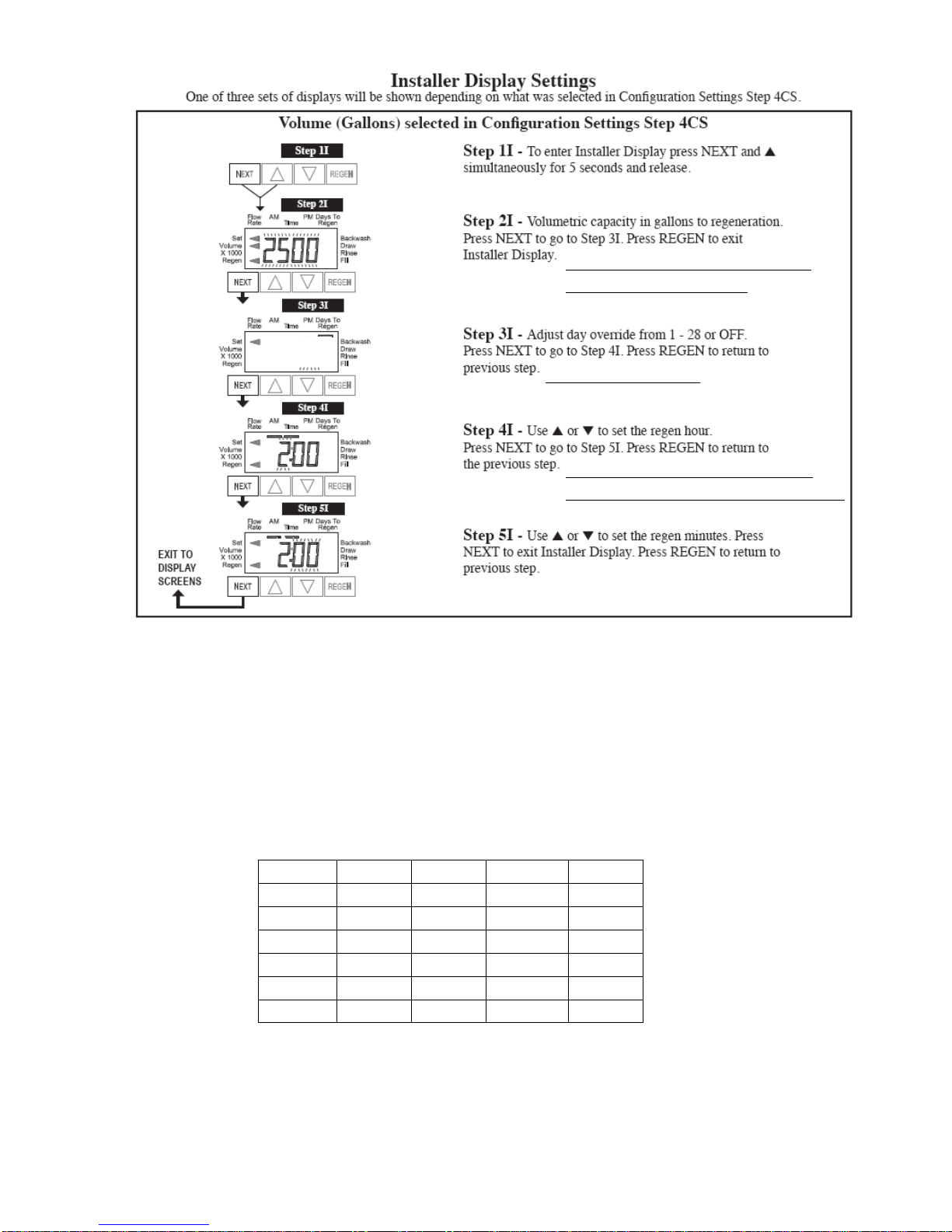

5)ProgramRegeneraonCapacityingallons(seenextpage)

**AllcontrolprogrammingwiththeexceponoftheRegenCapacityisdoneatthefactory.

6)PerformamanualBackwashandrinseCycleoneachtank.PressandholdREGENbuonfor5secondstostartare‐

generaonletthefirstbackwashcompleteandthenskiptheBrine&RinsecyclebypressingtheRegenbuonwhenmer

startscounngdown.AllowthenextcycletocompletethenskiptheFillCycleforthefirsttank.Repeatthesestepsforthesec‐

ondtank(DONOTskipthefillcycleonthesecondtank).

Thesystemisnowreadyforuse.

UsecalculaonBELOWtosetcapacity

usingthetestedHARDNESS.

**OFF**Factoryseng

**2:00AM**Theunitwillregenerate

whenthemeterreaches0**Factoryseng

Unitcapacity/hardness=VolumetricCapacity

UnitCapaciesbasedontanksize

OFF

TANKSIZECAPACITY TANKSIZECAPACITY

08X3512,000 12X5248,000

08X4018,000 13X5460,000

09X4824,000 14X6472,000

10X3524,000 16X6596,000

10X4430,000 18X65120,000

10X5436,000 21X62144,000

Table of contents

Popular Water Dispenser manuals by other brands

mysoda

mysoda Oasis Evo instruction manual

Water Care

Water Care CareSoft Series Installation instructions & owner's manual

Aquapure

Aquapure AP1610SS Installation and operating instructions

Proficook

Proficook PC-HWS 1145 instruction manual

Eco Pure

Eco Pure EP31 Installation and operation manual

Pure Water

Pure Water 200 Series owner's manual

Halsey Taylor

Halsey Taylor HCRF-ER owner's manual

Kenwood

Kenwood KTLD60X15 Installation instructions manual

SCHLIESSMANN

SCHLIESSMANN AQUA Compact User instructions

Permaflo

Permaflo Purity installation instructions

Wowtech

Wowtech OLK-W-01 Eco Laundry user manual

Hague

Hague HFFE-1054 Owner's manual and installation guide