Watkiss Automation Plockmatic PowerSquare 224 Operation instructions

Plockmatic PowerSquare™ 224

Service Training Workbook

Right to Left Version

Issue 1, November 2014, edited January 2017

Doc. No.x05082

Name: ............................................................................

© Watkiss Automation Limited 2019

All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as

allowed under the copyright laws.

Warranty

The information contained in this document is subject to change without notice. Watkiss Automation

Limited makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose.

Watkiss Automation Limited shall not be liable for errors contained herein or for incidental or conse-

quential damage in connection with the furnishing, performance or use of this material.

iPlockmatic PowerSquare™ 224 - Service Training Workbook

CONTENTS

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Conventions in this workbook . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Adobe Reader and Adobe Acrobat Instructions . . . . . . . . . . . . . . 2

1.3 Illustrated Parts Catalogues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Paper Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Paper Enters the System via the Connecting Bridge . . . . . . . . . . 7

3.2 The Gathering Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 The Shuttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 The Stitch Head and Clincher . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 The Stitch Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Fold and Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7 Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 Outfeed and Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 User Interface (GUI) - Operator Menu . . . . . . . . . . . . . . 12

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Power save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 The Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 GUI buttons and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Advanced Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Paper quality and machine performance. . . . . . . . . . . . . . . . . . . 16

5.2 Paper Path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Clear paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Book Quality and Machine Specifications . . . . . . . . . . . . . . . . . . 17

6 User Interface - Service Overview . . . . . . . . . . . . . . . . . 18

7 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

continued . . .

Plockmatic PowerSquare™ 224, Service Training Workbook.

R2L. Issue 1, Nov 2014 edited Jan 2017.

ii Plockmatic PowerSquare™ 224 - Service Training Workbook

8 Machine Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.2 Connecting Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.3 Gathering Area Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8.4 Shuttle - Book Gathering and Pick-up . . . . . . . . . . . . . . . . . . . . . 21

8.5 Shuttle - Book Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.6 Stitcher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.7 Fold and Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.8 Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.9 Outfeed and Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

8.10 Machine Cycle Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

9 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.1 Operator Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.2 Technical Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.3 Care Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10 Power and Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.1 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10.2 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.3 Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.4 DFA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

11 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11.1 Software System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11.2 Software download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

11.3 Web-browser Based Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 36

12 Replace Trimmer Blade (optional - time permitting) . . 37

13 PSQ Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

14 Product Updates and Technical Bulletins . . . . . . . . . . 37

15 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 38

16 Quality Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

17 PSQ Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 43

18 Glossary of booklet making terms . . . . . . . . . . . . . . . . 49

Introduction

Plockmatic PowerSquare™ 224 - Service Training Workbook 1

1. Introduction

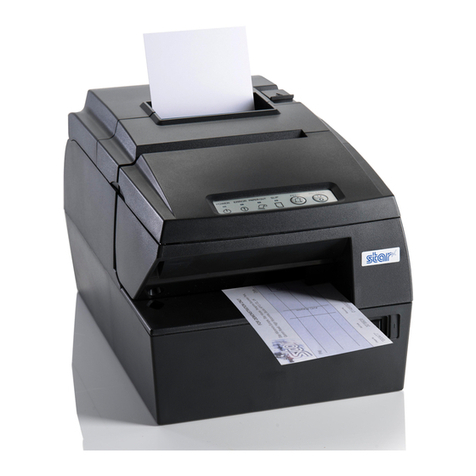

The Plockmatic PowerSquare™ 224 is an innovative, complete book making

system for digital print applications. In a single machine it combines the four

processes of stitching, folding, spine forming and trimming to produce

SquareBack™ books up to 224 pages thick. It features fully automatic setting

for different book size and pagination, including variable stitch leg length for

varying book thickness.

The maximum book thickness, of 10.4mm (208 pages/80gsm, 224 pages/

70gsm), is double that of alternative conventional booklet-making machines, so

it is ideally suited to higher paginations or to thicker stocks. This makes the

PowerSquare 224 a fast and cost effective alternative to perfect binding or tape

binding. Since it will also produce books from only a few sheets, it provides a

single book-making solution for documents from 8 through to 224 pages.

Digital print applications frequently use heavier stocks and need the flexibility to

produce a wider range of finished books from a single process, with little or no

operator intervention - the new PowerSquare 224 is a perfect match.

1.1 Conventions in this workbook

The PowerSquare 224 is referred to by its 3-letter code of PSQ.

this is an instruction or task that the trainer will do

this is a task that the student will do

This workbook refers to the following PowerSquare 224 Service Manual:

• Issue 1b, October 2016, Part No. 969-292

Offline PowerSquare

Online PowerSquare

Introduction

2Plockmatic PowerSquare™ 224 - Service Training Workbook

1.2 Adobe Reader and Adobe Acrobat Instructions

If you use Adobe Reader or Adobe Acrobat to read this manual, we recommend

you follow these instructions:

Make sure all the navigation buttons are visible

Adobe Reader and Adobe Acrobat include navigation buttons to help you move

around the file. When certain versions of Adobe Reader and Adobe Acrobat are

first installed, some of the navigation buttons are hidden.

Make sure all buttons are visible, as shown below:

Procedure:

1. Right-click on one of the arrows on the Navigation Toolbar.

2. Click on ‘Show page navigation tools’.

3. From the list, select the buttons you want to display.

Button Function

Click to go to first page in the document

Click to go to the previous page in the document

Click to go to the next page in the document

Click to go to last page in the document

Shows the current page number. To move to a certain

page, type the page number and press Enter.

Click to go to the previous view or the next view.

You can use these buttons to re-trace your steps.

FIGURE 1. The Navigation Toolbar, Adobe Acrobat Reader DC

Introduction

Plockmatic PowerSquare™ 224 - Service Training Workbook 3

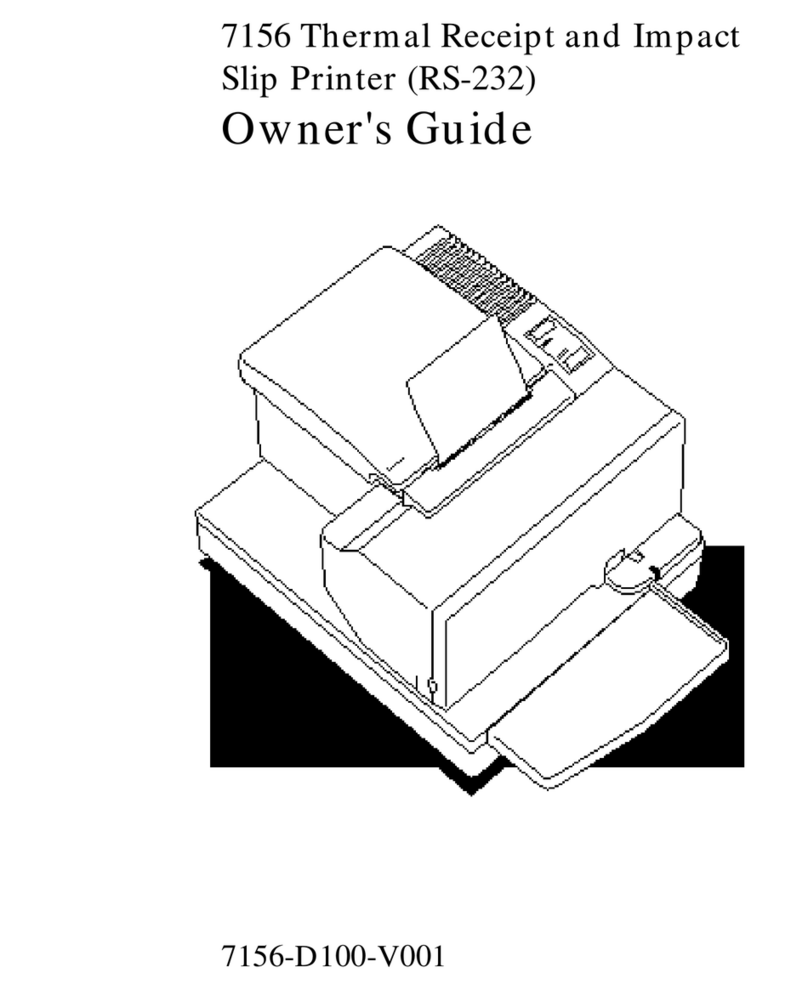

1.3 Illustrated Parts Catalogues

The Plockmatic PowerSquare™ 224 is made from these modules:

The Illustrated Parts Catalogues for the PSQ are separate documents available

in electronic form.

Part-number information for these modules is found in the related Illustrated

Parts Catalogues (IPC). The modules are split into assemblies. Each assembly

is shown as an exploded diagram. See FIGURE 2.

PSQK - Complete M/C

- PBCK - Connecting Bridge

- - PBR5 - Rotator

- PRTP - Base Machine

- - PBRG - Gathering Module

- - PRSH - Shuttle

- - PSTI - Stitcher

- - PRFD - Folder

- - PFRM - Spine Former

--PSTP - Trim Stop

- - PTRM - Trimmer

- - POFD - Outfeed

- - PSTK - Stacker

PBS - PowerSquare Book Stacker (optional)

P2TK - PowerSquare 2-Knife Trimmer (optional)

Oct 2009 PSHU - FIG 16 - TAMPER GATE FRAME

10

2b

∗

2a

∗

REL 2.3 PSQ/0300 ONWARDS (Mod 39c)

1a 1b 1c 1d 1e 1f 1d

5d

5c

5b

6

7

2d 31g

4

9

13

8

11

12

order kit 940-127.

2c

5a

Prior to PSQ/0300, when

replacing these parts,

∗

∗

891-460

891-461

FIGURE 2. Extract from PSHU, Issue 3. Fig.16 - tamper gate frame

Additional information

Exploded diagram

Introduction

4Plockmatic PowerSquare™ 224 - Service Training Workbook

Every exploded diagram is followed by the related part number information. The

part number information is given for the top level assembly, sub-assemblies and

components where available. See FIGURE 3.

Part No.Item Description Qty. Fig.

FIG.16 - TAMPER GATE FRAME PSQ SHUTTLE -PSHU LAST EDIT:18 AUG 09

Fig16 891-648 P.ASSY, (PSQ) TAMPER-GATE FRAME 1

1 891-688 • P.ASSY, (PSQ) TAMPER-GATE TIE BAR 1

1a 180-418 • • SPRING, E-CLIP FOR 4mm GROOVE 6

1b 190-575 • • OILITE, 5ID x 8OD x12LG + MOS2 2

1c 180-078 • • SPRING, 18mm x 9mm Ext., Extra strong 2

1d 266-086 • • SHAFT,(PSQ) ACTIVE-GATE TOP HAT SPACER 2

1e 190-370 • • BEARING, ROLLER 12mmODx8mmIDx3.5mm LG 2

1f 266-087 • • SPACER, (PSQ) GATE 10.50ODX8IDX3LG 1

1g 266-095 • • SHAFT, (PSQ) ACTIVE-GATE TIE BAR 1

•

2 891-647 • P.ASSY, (PSQ) TAMPER PIVOT DRIVE SIDE 1

2a 100-334 • • SCREW, SKT HD CAP, M2.5x10mm STAINLESS 1

2b 160-202 • • WASHER, M2.5 FORM A BZP 1

2c 257-833 • • ST ST, (PSQ) PIVOT LOCATION PLATE 1

2d 266-088 • • SHAFT,(PSQ) ACTIVE-GATE PIVOT PIN 1

•

3 315-775 • PLASTIC,(PSQ) ACTIVE-GATE PIVOT BLOCK 1

4 891-645 • P.ASSY, (PSQ) TAMPER GATE BRACKET 1

5 891-646 • P.ASSY, (PSQ) TAMPER PIVOT PLATE 1

5a 266-088 • • SHAFT,(PSQ) ACTIVE-GATE PIVOT PIN 1

5b 257-833 • • ST ST, (PSQ) PIVOT LOCATION PLATE 1

5c 160-202 • • WASHER, M2.5 FORM A BZP 1

5d 100-334 • • SCREW, SKT HD CAP, M2.5x10mm STAINLESS 1

•

6 160-002 • WASHER, M3 FORM A BZP 2

7 100-326 • SCREW, SKT HD CAP, M3 x 10mm STAINLESS 2

8 165-001 • SHAKEPROOF WASHER, M4 INTERNAL BZP 2

FIGURE 3. Extract from PSHU, Issue 3. Fig.16. Part number information.

Top-level assembly

Sub assembly

Component level

Product Overview

Plockmatic PowerSquare™ 224 - Service Training Workbook 5

2. Product Overview

2.1 Paper Path

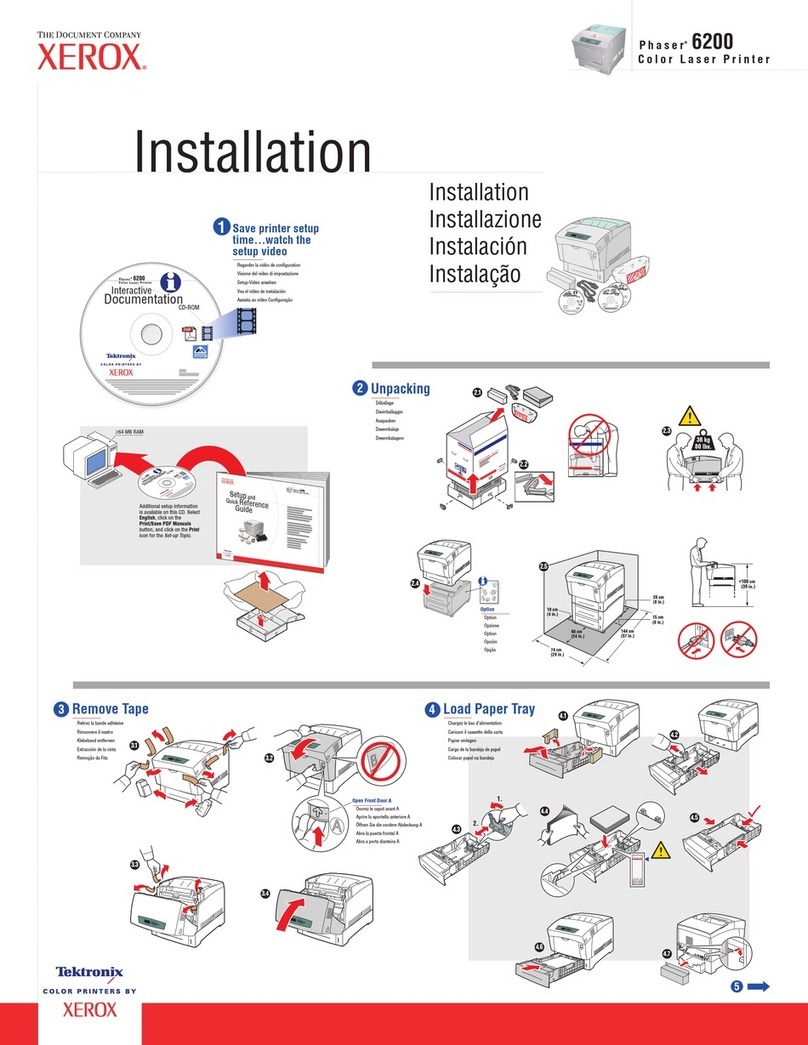

Stage Description Service Manual Reference

The sheets of paper leave the printer and

enter the infeed of the connecting bridge.

See Section 1.7.1.

The paper is rotated in the connecting

bridge if necessary.

See Section 1.7.1.

The sheets of paper are gathered into a set

in the gathering area. When a set is

complete it is collected by the shuttle.

See Section 1.7.2.

See Section 1.7.3.

The set is moved to the stitch head where

the set is stitched

See Section 1.7.4.

See Section 1.7.5.

The set is moved to the fold position where

the fold blade pushes the set into the spine

form clamp.

See Section 1.7.6.

FIGURE 4. Plan view of the Plockmatic PowerSquare 224 showing

Product Overview

6Plockmatic PowerSquare™ 224 - Service Training Workbook

Stage Description Service Manual Reference

The fold blade lifts and the form clamp

closes. The form roller creates the

SquareBack spine on the book.

See Section 1.7.6.

The book is moved to the trim stop and

clamped in position. The fore-edge of the

book is trimmed by the trimmer blade that

moves horizontally.

See Section 1.7.7.

The book is released and conveyed by the

outfeed mechanism to the stacker.

See Section 1.7.8.

The finished books are stacked neatly,

ready for the operator to remove.

See Section 1.7.8.

Figure 2:1. End view of the Plockmatic PowerSquare 224 showing

Description of Operation

Plockmatic PowerSquare™ 224 - Service Training Workbook 7

3. Description of Operation

After the PSQ is turned on, the operator configures the paper size and direction,

the set-thickness and the number of stitches. The PSQ is controlled by the

printer and by a system of internal sensors.

The PSQ includes these modules

• PSQK - Complete M/C

• PBCK - Bridge Covers

• PRTP - Base Machine

• PBR5 - Rotator

• PBRG - Gathering Area

• PRSH - Shuttle

• PSTI - Stitcher

• PRFD - Folder

• PFRM - Spine Former

• PSTP - Trim Stop

• PTRM - Trimmer

• POFD - Outfeed

• PSTK - Stacker

• PBS - PowerSquare Book Stacker (optional)

• P2T - PowerSquare 2-Knife Trimmer (optional)

Part-number information for these modules is found in the related Illustrated

Parts Catalogues (see Section 1.3).

3.1 Paper Enters the System via the Connecting Bridge

For additional information, see Section 1.7 in the PSQ Service Manual.

When the print job starts, the printer sends a start signal to the PSQ. Paper

leaves the printer and enters the connecting bridge infeed. The paper is moved

through the connecting bridge by belts into the gathering area. When the page

is in portrait format, the paper can be rotated through 90° by the rotator in the

connecting bridge if necessary.

A3 (17 x 11") and A4 (11 x 8½") Landscape jobs move straight through the

bridge without rotation. The turning ball and sidelay are not in the paper path.

The bridge drive belt is parallel to the sidelay.

A4 (8½ x 11") Portrait jobs are rotated around the turning ball. The paper is

driven against the sidelay by the angled, bridge drive-belt. The sidelay makes

sure the paper aligns to the centre reference line of the bridge.

The bridge drive belts are driven by a brushless 3-phase electric motor via a

dedicated controller box in the connecting bridge.

The rotate axis in the connecting bridge is adjusted by a 24V DC electric motor.

Description of Operation

8Plockmatic PowerSquare™ 224 - Service Training Workbook

The PBR5 bridge does not have static elimination bars. Blue, non-conductive

belts and additional anti-static brushes remove the static charge on the paper.

An optical sensor in the bridge infeed sees that a piece of paper has entered the

system. Another optical sensor at the entry to the gathering area sees that the

paper has left the bridge. If the time between the operation of the sensors is

more than a calculated period, a paper jam is indicated. The PSQ sends an

error message to the printer. The print job and the PSQ stop.

3.2 The Gathering Area

When the paper is fed into the gathering area, the paper falls between the

endlays and sidelays. The endlays and sidelays are adjusted by the PSQ

according to the paper size selected. This adjustment is important and

necessary to the quality of the finished book. Adjustments to the sidelays and

endlays are made with two 24V DC electric motors.

The tamper fingers guide smaller sheets of paper to help them drop between

the sidelays and the endlays. The tamper fingers are positioned and operated

by a stepper motor. The lowest position for the tamper fingers is for the smallest

size of paper. The highest position for the tamper fingers is for A3-size (11 x 17")

paper.

An active gate in the sidelay closest to the stitch head jogs the incoming sheets

into a tidy set. When the set is complete, the active gate lifts away to let the set

move to the stitch position.

When a set is printed the printer sends an ‘end of set’ signal to the PSQ, which

starts the PSQ cycle of operation.

The tamper fingers drop and apply pressure to the top of the set, which

removes the air from between the pages. After a standard interval, the tamper

fingers lift and leave the set ready for collection by the shuttle. A rear tamper in

the gathering area prevents sheets from riding-up over the rear pick-up fingers.

3.3 The Shuttle

The set is collected by the shuttle and moved to the 1st stitch position. A cam

mechanism tightens the shuttle pick-up fingers on the set when the shuttle

moves towards the 1st stitch position. The increased hold makes sure the

pages remain in alignment when the set is stitched. The rear or large shuttle

pick-up fingers incorporate rollers to prevent toner deposition that could mark

the covers of the books.

The set is stitched, then moved by the shuttle to the next stitch position. This

process is repeated as necessary to a maximum of 6 stitches. When set to

AUTO, the PSQ automatically calculates the stitch positions. The user can

change the stitch pitch within certain limits. This function can be used to give a

clearance between the stitches and the print on the spine of the book.

Description of Operation

Plockmatic PowerSquare™ 224 - Service Training Workbook 9

The set is moved to the folding area when the set is stitched. When the shuttle

moves to the folding area, the pick-up fingers loosen on the book. The shuttle is

operated by a 230V AC electric motor through a linear transmission.

3.4 The Stitch Head and Clincher

The single stitch head is a custom version of the Deluxe G8 stitch head. The

stitch head is installed vertically and upside down. The stitch-wire is fed from a

15kg (33-lb) spool in the stitch-wire cabinet. The stitch-wire spool can supply a

maximum of 291,500 stitches. The stitch head and clincher are aligned to the

centre reference line of the PSQ. The book is moved to each stitch position by

the shuttle.

The size of stitch or ‘wire draw’ setting is calculated from the set-thickness input

by the operator. Adjustment is made to the ‘wire draw’ by the PSQ. This

automatic adjustment makes sure the correct size of stitch is formed for every

thickness of book. The operator does not need to adjust the stitch head.

The clincher is held in a frame above the stitch head. The PSQ uses a clincher

with moving points. The clincher forms a high quality stitch that lies flat against

the book.

Drive for the stitch head and clincher operation is transferred from the main

motor by a system of chains, shafts and clutches.

The stitch head vertical-axis adjustment is made by a stepper motor. The set

thickness can also be automatically calculated from the thickness of the paper

and the number of sheets in a set. The stepper motor allows wire-draw and

stitch-head compression to change dynamically to match varying thickness jobs

without operator intervention.

3.5 The Stitch Process

The shuttle collects the set between the pick-up fingers and moves to the first

stitch position. When the book is stitched and moved to the next stitch-position,

the previous stitch moves across a stitch sensor. The stitch sensor detects the

steel of the stitch wire. If this sensor does not detect a stitch, a ‘missing stitch’

fault is indicated and production is stopped.

When the book is stitched correctly, the book is moved by the shuttle to the fold

position. If a book remains over the optical sensor next to the stitch head, a jam

is indicated and the PSQ is stopped.

If the stitch head jams, a stitch head jam sensor stops the machine. The stitch

head jam sensor is fitted next to the clincher cam and is connected to a PCB on

the stitcher PCB bracket.

Description of Operation

10 Plockmatic PowerSquare™ 224 - Service Training Workbook

3.6 Fold and Form

When the shuttle stops in the park position, the folder blade is operated. The

folder blade pushes against the centre line of the book - located by the stitches

- and folds the book in half. The folder blade pushes the book to a calculated

depth between a pair of feed-rollers and into the form clamp. On each face of

the form clamp there is a horizontal, polyurethane strip that gives a cushioned

grip. The polyurethane strip is important for thin books because the soft surface

prevents the stitch cutting through the front and back covers of the book.

Drive for the fold blade is transferred from the main motor by chain and clutch.

The drive is changed from rotary to linear movement by a crank and connecting

rod. Drive for the spine form clamp is provided by the main motor and

transferred to a drive shaft by a chain and clutch. Adjustment of the fold blade

position for sets of different thickness is made with a 24V DC motor.

The fold blade retracts and the clamp closes on the book. The form roller rolls

along the spine of the book to create the SquareBack book. The number of

spine forms and the pressure applied is calculated by the PSQ or can be

overridden on the touch screen by the operator.

The form roller is transported on a carriage that runs along the carriage guide.

The carriage drive is from the main electric motor by a clutch and chain system.

When the carriage reaches the end of the carriage guide, either the LH or RH

limit sensor is operated. If the carriage stops before either of the limit sensors is

reached, a jam is indicated. The form roller is turned by a gear wheel that

engages with a rack.

While the book is in the form clamp, a pair of lifters either side of the book, raise

the book clear of the shuttle. The shuttle can then return to the pick-up area to

collect the next book to be stitched.

When the spine is formed, the carriage stops at one end of the carriage guide

and the spine form clamp is released. A solenoid is operated that moves the

eject rollers into contact with the book. The eject rollers rotate and move the

book towards the trimmer infeed.

3.7 Trim

The book passes between two facing sets of conveyors in the trimmer infeed.

These conveyors move the book to the trim stop. The distance of the trim stop

from the trimmer blade is calculated by the PSQ according to the size of the job.

The PSQ applies an amount of trim according to the size of the paper. The

operator can change the amount of trim from the touch screen if necessary. The

trim clamp and trimmer blade move forwards in one action to hold and trim the

book. The trim clamp and trimmer blade then return to their start position.

Offcuts are pushed into the trim bin by flexible fingers on one of the trimmer

infeed conveyor shafts.

The trimmer uses a chevron blade to apply balanced cutting pressure across

the width of the book. The chevron blade decreases to the minimum any shear

forces. Drive for the trimmer blade and the trim clamp is transferred from the

Description of Operation

Plockmatic PowerSquare™ 224 - Service Training Workbook 11

main electric motor by a chain and clutch system. Rotary movement is changed

to linear movement with a crank mechanism.

3.8 Outfeed and Stacker

When the trim clamp is released, two solenoids move the trim stop from below

the book. The book is moved out of the trimmer by the book eject belt.

A conveyor moves the books from the PSQ and drops them on the catch tray.

An adjustable collection-table makes sure the finished books stack correctly.

There is an optical sensor in the outfeed to detect jams. This sensor prevents

the books on a full stacker from backing-up into the outfeed.

User Interface (GUI) - Operator Menu

12 Plockmatic PowerSquare™ 224 - Service Training Workbook

4. User Interface (GUI) - Operator Menu

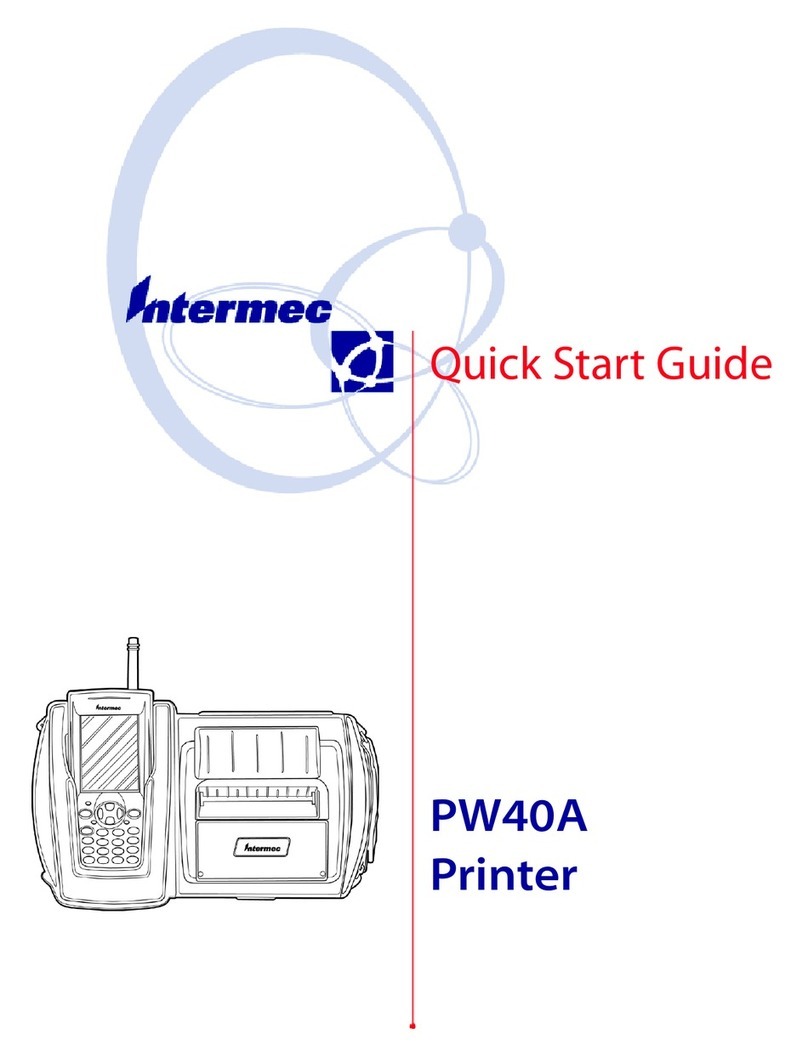

The user interface includes a colour touch screen and START/STOP buttons.

4.1 Introduction

Operate the touch screen with a fingertip. You can touch the screen with a blunt

item, for example a palm-top ‘wand’ or the blunt end of a pen. Do not use too

much force. A light touch is all that is needed.

CAUTION: Do not operate the touch screen with a sharp object or with too

much force. These actions can damage the touch screen.

If you hear a ‘beep’ when you operate the touch screen, the selected function is

not available. Some functions are not available when the machine is in

operation.

Some functions and buttons are only available at certain access levels.

4.2 Power save

The touch screen has a power-save function. After several minutes without use,

the brightness of the touch screen decreases. After several hours, the touch

screen turns off.

Touch the screen to restore the normal brightness. The touch screen takes two

or three minutes to reach full brightness.

FIGURE 3. The User Interface

START Button

STOP Button

Touch Screen

User Interface (GUI) - Operator Menu

Plockmatic PowerSquare™ 224 - Service Training Workbook 13

The Touch Screen

Window Tabs:

LOAD & SAVE

BASIC

ADVANCED

CONFIGURE

MENU

The MESSAGE LIST

shows errors and other

information.

The HELP button gives you

more information.

• Touch HELP, then touch

any button.

• Touch HELP, then touch

the message list.

STATUS

•GREEN = Ready or running.

• ORANGE - PLEASE WAIT

•ORANGE - ATTENTION = operator action needed.

•RED = Error condition.

JOB MIMIC

• paper size

• stitch pitch

• set thickness

•form

•trim

• side trim

Window Buttons

• Each Window tab

has its own group

of window buttons.

User Interface (GUI) - Operator Menu

14 Plockmatic PowerSquare™ 224 - Service Training Workbook

4.3 GUI buttons and options

Window Buttons

BASIC PAPER SIZE

PAGE DIRECTION

PRESETS

ROTATE

Enter the paper size

Portrait or Landscape

Standard paper sizes

On or Off

SET THICKNESS

AUTO

SHEET

THICKNESS

Either input the measured set thick-

ness or use AUTO

Auto calculates the set thickness

from the sheet thickness and sheet

count.

Use SHEET THICKNESS to enter

the measured thickness of one sheet

of paper.

STITCHES

STITCH PITCH

AUTO

Number of stitches

Distance between stitches

Automatic stitch pitch setting

FORM

AUTO

NUMBER

PRESSURE

THRESHOLD

Automatic, according to thickness

Number of form roller actions

Pressure to make spine -9 to +9

Minimum thickness for square spine

TRIM

AUTO

Trimmed dimension of the book

Automatic, according to thickness

SIDE TRIM (where fitted)

AUTO

TRIM SIZE

TRIM OFFSET

Trimmed dimension of the book

Automatic, according to PAGE SIZE

Side-trim dimension can be changed

Trim can be biased to top or bottom

LOAD & SAVE SAVE

REPLACE

CANCEL

SAVE NEW

Save the job

Overwrite the existing job

Cancel the save

Save as a new job

JOB DETAILS List of the job settings

LOAD Load a job from memory

PADLOCK SYMBOL Supervisor use to lock/unlock a job

DELETE Delete a job

VIEW OF JOB LIST View A-Z, by use, by index

ADVANCED RE-REF Re-calibrate the machine axes

STITCHER UP Lift the stitch head for maintenance

PURGE SET

MAKE BOOK

Clear the set from the machine

User Interface (GUI) - Operator Menu

Plockmatic PowerSquare™ 224 - Service Training Workbook 15

Perform the following tasks:

Set the PSQ to make a preset size book:

A3 input size

Measure the paper from the ream

Enter the measured size into the touch screen

40 sheets (4mm thick)

2 stitches

Save as “A3 Test”

Set the PSQ to make a non-standard book:

A4 input size

Measure the paper from the ream

Enter the measured size into the touch screen

35 sheets (3.5mm thick)

3 stitches, with custom stitch pitch

4 forms, with +5 pressure

Trim to 130mm

Save as “A4 Test”

Re-reference all axes. Observe what happens on the message list.

Open the gathering area, then use HELP to find out about the error

message on the GUI message list.

CONFIGURE MACHINE OPTIONS

MEASUREMENT

STITCH SENSOR

PRESET PAPER

SIZES

SIDE TRIM (P2T)

PBS INSTALLED

Select mm or inches as units

Turn stitch sensor on or off

ISO ‘A’ sizes or US sizes

Touch to turn off communication to

the Side-Trimmer. Only do this if the

Side-Trimmer is disconnected.

Touch to turn off communication to

the Book Stacker. Only do this if the

Book Stacker is disconnected.

NETWORK SETTINGS (service function)

FORM SETUP (service function)

SHUTTLE (service function)

MENU ACCESS LEVEL Operator, Supervisor, Service

(Distributor & Factory)

CURRENT LANGUAGE

AXES Re-reference individual axes

BRIDGE Reference individual axes

COUNTERS

RESET

Book / Sheet / Stitch

Resets the operator count

Window Buttons

Advanced Operation

16 Plockmatic PowerSquare™ 224 - Service Training Workbook

5. Advanced Operation

5.1 Paper quality and machine performance

Careful measurement of the paper size and set thickness is important in order

to produce good quality books.

• To make an accurate book you must enter accurate paper dimensions into

the touch screen.

• Measure the size of the printed paper. The paper dimensions change due to

shrinkage when the paper is printed.

• If the book is made from several different types of paper, make sure the

different paper types are all the same size. If the size of the paper is different,

an accurate book cannot be made.

• The paper must be cut accurately. If the sheets are not cut squarely, an

accurate book cannot be made.

Perform the following tasks:

Load the saved “A3 Test” job.

A3 input size

Measure the paper from the stacker

Make the book

Delete the saved job.

Load the saved “A4 Test” job.

A3 input size

Measure the paper from the stacker

Make the book

Delete the saved job.

5.2 Paper Path

It is important that the alignment of the PSQ and the printer is correct. This can

change if either the PSQ or the printer is moved accidentally.

Curly paper can sometimes cause the set to remain in the stitch area, causing a

jam. Paper curl problems must be resolved at the printer by changing or turning

the paper or making adjustment to the printer.

5.3 Clear paper jams

The operator can clear most paper or book jams. These procedures are

described in the User Manual and include paper jams in the

• connecting bridge

• gathering area

• stitch area

• fold and form area

• trim area

Table of contents

Other Watkiss Automation Printer manuals