Watlow Electric EZ-ZONE PM User manual

0600-0059-0000 Rev. M Made in the U.S.A.

April 2013

User’s Guide

EZ-ZONE®PM

Integrated Controller Models

1241 Bundy Boulevard., Winona, Minnesota USA 55987

Phone: +1 (507) 454-5300, Fax: +1 (507) 452-4507 http://www.watlow.com

TOTAL

3 Year Warranty

CUSTOMER

SATISFACTION

Registered Company

Winona, Minnesota USA

ISO 9001

Safety Information

We use note, caution and warning symbols through-

out this book to draw your attention to important

operational and safety information.

A “NOTE” marks a short message to alert you to

an important detail.

A “CAUTION” safety alert appears with informa-

tion that is important for protecting your equip-

ment and performance. Be especially careful to

read and follow all cautions that apply to your

application.

A “WARNING” safety alert appears with infor-

mation that is important for protecting you,

others and equipment from damage. Pay very

close attention to all warnings that apply to your

application.

The electrical hazard symbol, Ó(a lightning bolt

in a triangle) precedes an electric shock hazard

CAUTION or WARNING safety statement.

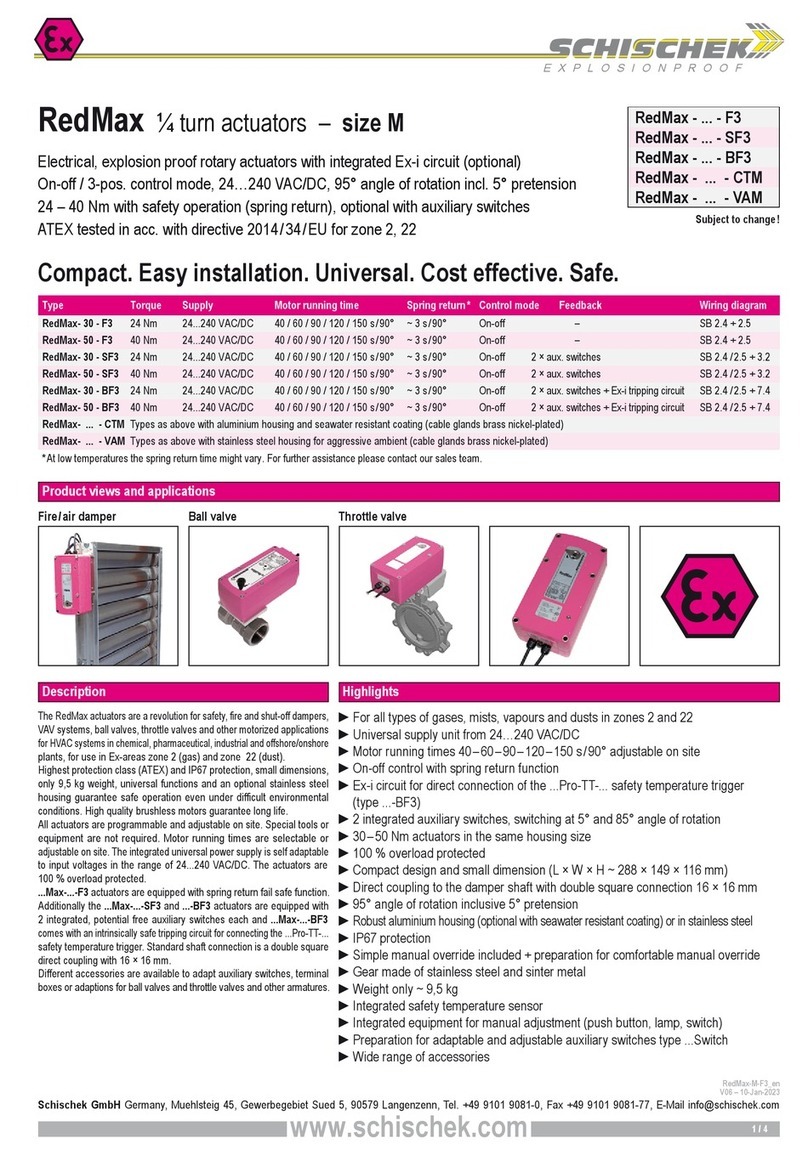

Symbol Explanation

CAUTION – Warning or Hazard

that needs further explanation

than label on unit can provide.

Consult User's Guide for further

information.

ESD Sensitive product, use proper

grounding and handling tech-

niques when installing or servic-

ing product.

Unit protected by double/rein-

forced insulation for shock hazard

prevention.

Do not throw in trash, use proper

recycling techniques or consult

manufacturer for proper disposal.

Enclosure made of Polycarbonate

material. Use proper recycling

techniques or consult manufac-

turer for proper disposal.

Unit can be powered with either

alternating current (ac) voltage or

direct current (dc) voltage.

Unit is a Listed device per Un-

derwriters Laboratories®. It has

been evaluated to United States

and Canadian requirements for

Process Control Equipment. UL

61010 and CSA C22.2 No. 61010.

File E185611 QUYX, QUYX7.

See: www.ul.com

Unit is a Listed device per Un-

derwriters Laboratories®. It has

been evaluated to United States

and Canadian requirements for

Hazardous Locations Class 1

Division II Groups A, B, C and

D. ANSI/ISA 12.12.01-2007. File

E184390 QUZW, QUZW7. See:

www.ul.com

Unit is compliant with European

Union directives. See Declaration

of Conformity for further details

on Directives and Standards used

for Compliance.

Unit has been reviewed and ap-

proved by Factory Mutual as a

Temperature Limit Device per FM

Class 3545 standard. See: www.

fmglobal.com

Unit has been reviewed and ap-

proved by CSA International for

use as Temperature Indicating-

Regulating Equipment per CSA

C22.2 No. 24. See: www.csa-inter-

national.org

Unit has been reviewed and ap-

proved by ODVA for compliance

with DeviceNet communications

protocol. See: www.odva.org

Unit has been reviewed and ap-

proved by ODVA for compliance

with Ethernet/IP communications

protocol. See: www.odva.org

Warranty

The EZ-ZONE®PM is manufactured by ISO

9001-registered processes and is backed by a three-

year warranty to the first purchaser for use, provid-

ing that the units have not been misapplied. Since

Watlow has no control over their use, and some-

times misuse, we cannot guarantee against failure.

Watlow’s obligations hereunder, at Watlow’s option,

are limited to replacement, repair or refund of pur-

chase price, and parts which upon examination prove

to be defective within the warranty period specified.

This warranty does not apply to damage resulting

from transportation, alteration, misuse or abuse. The

purchaser must use Watlow parts to maintain all

listed ratings.

Technical Assistance

If you encounter a problem with your Watlow control-

ler, review your configuration information to verify

that your selections are consistent with your applica-

tion: inputs, outputs, alarms, limits, etc. If the prob-

lem persists, you can get technical assistance from

your local Watlow representative (see back cover), by

e-mailing your questions to wintechsupport@watlow.

com or by dialing +1 (507) 494-5656 between 7 a.m.

and 5 p.m., Central Standard Time (CST). Ask for for

an Applications Engineer. Please have the following

information available when calling:

• Complete model number

• All configuration information

• User's Guide

• Factory Page

Return Material Authorization (RMA)

1. Call Watlow Customer Service, (507) 454-5300, for a

Return Material Authorization (RMA) number before

returning any item for repair. If you do not know why

the product failed, contact an Application Engineer or

Product Manager. All RMA’s require:

• Ship-to address

• Bill-to address

• Contact name

• Phone number

• Method of return shipment

• Your P.O. number

• Detailed description of the problem

• Any special instructions

• Name and phone number of person returning the

product.

2. Prior approval and an RMA number from the Customer

Service Department is required when returning any

product for credit, repair or evaluation. Make sure the

RMA number is on the outside of the carton and on all

paperwork returned. Ship on a Freight Prepaid basis.

3. After we receive your return, we will examine it and try

to verify the reason for returning it.

4. In cases of manufacturing defect, we will enter a repair

order, replacement order or issue credit for material

returned. In cases of customer misuse, we will provide

repair costs and request a purchase order to proceed

with the repair work.

5. To return products that are not defective, goods must

be in new condition, in the original boxes and they must

be returned within 120 days of receipt. A 20 percent

restocking charge is applied for all returned stock con-

trols and accessories.

6. If the unit is not repairable, you will receive a letter of

explanation. and be given the option to have the unit

returned to you at your expense or to have us scrap the

unit.

7. Watlow reserves the right to charge for no trouble found

(NTF) returns.

The EZ-ZONE PM User's Guide is copyrighted by Watlow

Electric, Inc., © April 2013 with all rights reserved.

EZ-ZONE PM is covered by U.S. Patent Numbers:

6005577; D553095; D553096; D553097; D560175; D55766;

and OTHER PATENTS PENDING

Watlow EZ-ZONE®PM Integrated Controller • 1 • Table of Contents

TC Table of Contents

Chapter 1: Overview .....................................4

Standard Features and Benefits ...............................4

Optional Features and Benefits ................................ 5

A Conceptual View of the PM .................................6

Getting Started Quickly....................................7

Chapter 2: Install and Wire................................16

Dimensions..............................................16

Installation.........................................20

Wiring..................................................22

Network Status .....................................36

Module Status ......................................36

Activity Status ......................................36

Link Status ........................................36

Network Status .....................................38

Module Status ......................................38

Chapter 3: Keys and Displays ..............................42

Attention Codes ..........................................43

Chapter 4: Home Page...................................45

Chapter 5: Operations Page ...............................52

Analog Input Menu ........................................ 54

Linearization Menu ........................................54

Process Value Menu.......................................55

Digital Input/Output Menu ..................................56

Limit Menu ..............................................57

Monitor Menu............................................57

Control Loop Menu........................................58

Alarm Menu .............................................61

Current Menu ............................................62

Math Menu ..............................................63

Special Output Function Menu ...............................64

Profile Status Menu .......................................65

Watlow EZ-ZONE®PM Integrated Controller • 2 • Table of Contents

TC Table of Contents (cont.)

Chapter 6: Setup Page ...................................67

Analog Input Menu ........................................ 69

Linearization Menu ........................................71

Process Value Menu.......................................74

Digital Input / Output Menu .................................75

Limit Menu ..............................................79

Control Loop Menu........................................80

Output Menu.............................................85

Alarm Menu .............................................88

Current Menu ............................................91

Math Menu ..............................................92

Special Output Function Menu ...............................93

Function Key.............................................94

Global Menu .............................................95

Communications Menu.....................................98

Real Time Clock Menu ....................................102

Chapter 7: Profiling Page ................................103

Profile Setup............................................103

Starting a Profile.........................................104

Profiling Menu ..........................................107

Chapter 8: Factory Page.................................113

Custom ...............................................114

Lock Menu .............................................114

Unlock Menu ...........................................116

Diagnostics Menu........................................116

Calibration Menu ........................................118

Chapter 9: Features....................................119

Changing PM Integrated Model Number to PM Express ..........121

Tuning the PID Parameters.................................123

Inputs .................................................125

Outputs................................................128

Resetting a Tripped Limit .................................. 130

Control Methods.........................................131

Alarms ................................................136

Watlow EZ-ZONE®PM Integrated Controller • 3 • Table of Contents

Current Sensing .........................................138

Open Loop Detection .....................................138

Programming the EZ Key/s.................................138

Using Lockout and Password Security........................139

Using Lockout Method 1 (Read and Set Lock).................. 139

Using Lockout Method 2 (Password Enable) ...................140

Modbus - Using Programmable Memory Blocks ................ 142

CIP - Communications Capabilities ..........................142

CIP Implicit Assemblies .................................143

Compact Assembly Class ................................ 143

Modifying Implicit Assembly Members .....................143

Profibus DP - (Decentralized Peripherals) .....................144

Software Configuration....................................144

Searching Network for Devices. . . . . . . . . . . . . . . . . . . . . . . . 145

Available Network Devices Displayed...................145

Chapter 10: Applications ................................148

Example 1: Single Loop Control .......................148

Example 2: Sensor Backup...........................148

Example 3: Square Root.............................149

Example 4: Ratio...................................149

Example 5: Differential ..............................150

Example 6: Cascade ................................150

Example 7: Wet Bulb / Dry Bulb .......................152

Example 8: Vaisala .................................152

Example 9: Motorized Valve Control ....................153

Chapter 11: Appendix ..................................154

Troubleshooting Alarms, Errors and Control Issues..............154

Modbus - Programmable Memory Blocks .....................158

CIP Implicit Assembly Structures............................160

Compact Class Assembly Structure ..........................161

Specications .....................................168

Ordering Information for PM Integrated Controller Models ........171

Index..................................................172

How to Reach Us ........................................178

TC Table of Contents (cont.)

Watlow EZ-ZONE®PM Integrated Controller •4 • Chapter 1 Overview

Chapter 1: Overview

1

The EZ-ZONE®PM takes the pain out of solving your thermal loop requirements.

Watlow’s EZ-ZONE PM controllers offer options to reduce system complexity and the cost of control-loop

ownership. You can order the EZ-ZONE PM as a PID controller or an over-under limit controller, or you can

combine both functions in the PM Integrated Limit Controller. You now have the option to integrate a high-

amperage power controller output, an over-under limit controller and a high-performance PID controller all in

space-saving, panel-mount packages. You can also select from a number of serial communications options to

help you manage system performance.

It just got a whole lot easier to solve the thermal requirements of your system. Because the EZ-ZONE PM

controllers are highly scalable, you only pay for what you need. So if you are looking for a PID controller, an

over-under limit controller or an integrated controller, the EZ-ZONE PM is the answer.

Standard Features and Benefits

Advanced PID Control Algorithm

• TRU-TUNE+

®

Adaptive tune provides tighter control for demanding applications.

• Auto Tune for fast, efficient start ups

EZ-ZONE configuration communications and software

• Saves time and improves the reliability of controller set up

FM Approved Over-under Limit with Auxiliary Outputs

• Increases user and equipment safety for over-under temperature conditions

• To meet agency requirements, output 4 is the fixed limit output. Other outputs can be configured to mirror

the limit output (4).

Parameter Save & Restore Memory

• Reduces service calls and down time

Agency approvals: UL Listed, CSA, CE, RoHS, W.E.E.E. FM, SEMI F47-0200, Class 1, Div 2 rating

on selected models

• Assures prompt product acceptance

• Reduces end product documentation costs

EZ-Key/s

• Programmable EZ-Key enables simple one-touch operation of repetitive user activities

Programmable Menu System

• Reduces set up time and increases operator efficiency

Three-year warranty

• DemonstratesWatlow’sreliabilityandproductsupport

Touch-safe Package

• IP2X increased safety for installers and operators

P3T Armor Sealing System

• NEMA 4X and IP66 offers water and dust resistance, can be cleaned and washed down (indoor use only)

• Backed up by UL 50 independent certification to NEMA 4X specification

Removable cage clamp wiring connectors

• Reliable wiring, reduced service calls

• Simplified installation

Watlow EZ-ZONE®PM Integrated Controller •5 • Chapter 1 Overview

Heat-Cool Operation

• Provides application flexibility with accurate temperature and process control

Optional Features and Benefits

High-amperage Power Control Output

• Drives 15 amp resistive loads directly

• Reduces component count

• Saves panel space and simplifies wiring

• Reduces the cost of ownership

Integrated PID and Limit Controller

• Reduces wiring time and termination complexity compared to connecting discrete products

• Decreases required panel space

• Lowers installation costs

• Increases user ad equipment safety for over/under temperature conditions

Current Monitoring

• Detects heater current flow and provides alarm indication of a failed output device or heater load

Serial Communications Capabilities

• Provides a wide range of protocol choices including Modbus

®

RTU, EtherNet/IPTM, PCCC (Programmable

Controller Communications Commands),

DeviceNet

TM, Modbus

®

TCP, and Profibus DP

• Supports network connectivity to a PC or PLC

Dual Channel Controller

• For selected models provides two PID controllers in one space saving package

Enhanced Control Capabilities

• Easily handle complex process problems such as cascade, ratio, differential, square-root, motorized valve

control without slidewire feedback, wet-bulb/dry-bulb and compressor control

Full-featured Alarms

• Improves operator recognition of system faults

• Control of auxiliary devices

Ten Point Linearization Curve

• Improves sensor accuracy

Remote Set Point Operation

• Supports efficient set point manipulation via a master control or PLC

Retransmit Output

• Supports industry needs for product process recording

Profile Capability

• Preprogrammed process control

• Ramp and soak programming with four files and 40 total steps

Watlow EZ-ZONE®PM Integrated Controller •6 • Chapter 1 Overview

A Conceptual View of the PM

The flexibility of the PM’s software and hardware allows a large range of configurations. Acquiring a better

understanding of the controller’s overall functionality and capabilities while at the same time planning out

how the controller can be used will deliver maximum effectiveness in your application.

It is useful to think of the controller in terms of functions; there are internal and external functions. An

input and an output would be considered external functions where the PID calculation or a logic function

would be an internal function. Information flows from an input function to an internal function to an output

function when the controller is properly configured. A single PM controller can carry out several functions

at the same time, for instance closed-loop control, monitoring for several different alarm situations, perform-

ing logical operations and operating switched devices, such as lights and motors. Each process needs to be

thought out carefully and the controller’s various functions set up properly.

Input Functions

The inputs provide the information that any given programmed procedure can act upon. In a simple form,

this information may come from an operator pushing a button or as part of a more complex procedure it may

represent a remote set point being received from another controller.

Each analog input typically uses a thermocouple, thermistor or RTD to read the temperature of some-

thing. It can also read volts, current or resistance, allowing it to use various devices to read humidity, air

pressure, operator inputs and others values. The settings in the Analog Input Menu (Setup Page) for each

analog input must be configured to match the device connected to that input.

Each digital input reads whether a device is active or inactive. A PM with digital input-output (DIO) hard-

ware can include up to eight DIO each of which can be used as either an input or an output. Each DIO must

be configured to function as either an input or output with the Direction parameter in the Digital Input/Out-

put Menu (Setup Page).

The Function or EZ Key on the front panel of the PM also operates as a digital input by toggling the func-

tion assigned to it in the Digital Input Function parameter in the Function Key Menu (Setup Page).

Internal Functions

Functions use input signals to calculate a value. A function may be as simple as reading a digital input to set

a state to true or false, or reading a temperature to set an alarm state to on or off. Or, it could compare the

temperature of a process to the set point and calculate the optimal power for a heater.

To set up an internal function, it’s important to tell it what source, or instance, to use. For example, an

alarm may be set to respond to either analog input 1 or 2 (instance 1 or 2, respectively).

Output Functions

Outputs can perform various functions or actions in response to information provided by a function, such as

operating a heater, driving a compressor, turning a light on or off, unlocking a door etc...

Assign an output to a Function in the Output Menu or Digital Input/Output Menu. Then select which in-

stance of that function will drive the selected output. For example, you might assign an output to respond to

alarm 4 (instance 4) or to retransmit the value of analog input 2 (instance 2).

You can assign more than one output to respond to a single instance of a function. For example, alarm 2

could be used to trigger a light connected to output 1 and a siren connected to digital output 5.

Input Events and Output Events

Input and output events are internal states that are used exclusively by profiles. The source of an event in-

put can come from a real-world digital input or an output from another function. Likewise, event outputs may

control a physical output such as an output function block or be used as an input to another function.

Watlow EZ-ZONE®PM Integrated Controller •7 • Chapter 1 Overview

Getting Started Quickly

The PM control has a page and menu structure that is listed below along with a brief description of its pur-

pose.

Setup Page

Push and hold the up and down keys (¿ ¯)

for 6 seconds to enter. (See the Setup Page

for further information)

Once received, a user would want to setup their control prior

to operation. As an example, define the input type and set

the output cycle time.

Operations Page

Push and hold the up and down keys (¿ ¯)

for 3 seconds to enter. (See the Operations

Page for further information)

After setting up the control to reflect your equipment, the

Operations Page would be used to monitor or change run-

time settings. As an example, the user may want to see how

much time is left in a profile step or perhaps change the

limit high set point.

Factory Page

Push and hold the Infinity and the green Ad-

vance keys (ˆ

‰

) for 6 seconds to enter. (See

the Factory Page for further information)

For the most part the Factory Page has no bearing on the

control when running. A user may want to enable password

protection, view the control part number or perhaps create a

custom Home Page.

Home Page

The control is at the Home Page when ini-

tially powered up.

Pushing the green Advance key

‰

will allow the user to see

and change such parameters as the control mode, enable au-

totune and idle set point to name a few.

Profile Page

Push and hold the the green Advance key

‰

for 6 seconds to enter. (See the Profile Page

for further information)

If equipped with this feature a user would want to go here

to configure a profile.

The default PM loop configuration out of the box is shown below:

• Analog Input functions set to thermocouple, type J

•Heat algorithm set for PID, Cool set to off

•Output 1 set to Heat

•Control mode set to Auto

•Set point set to 75 °F

If you are using the input type shown above, simply connect your input and output devices to the control.

Power up the control and push the up arrow ¿ on the face of the control to change the set point from the

default value of 75 °F to the desired value. As the Set Point increases above the Process Value, output 1 will

come on and it will now begin driving your output device. The PV function as shown in the graphic below is

only available with PM4/8/9 models.

Note:

The output cycle time will have a bearing on the life of mechanical relay outputs and can be different based

on the type of output ordered. The output cycle time can be changed in the Setup Page under the Output

Menu.

EZ-ZONE PM Default Configuration

Heat

Thermocouple Type J

Analog Input 1

PID

Controller

Heat

Loop 1

Input Sensor

Output

Function

Input

Function

Output 1

Process

Value

(PV)

Function

Off

Watlow EZ-ZONE®PM Integrated Controller •8 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/16 DIN System Diagram

With a Current Transformer, Without Communications Card (Slot B)

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

EZ Key

Programmable Event

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Current

Transformer

Board

(optional)

Slot B

Input

Functions

Output

Functions

- None

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+

®

disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

Output Status

5

1

3

2

4

Indicates Zone

Address

Indicates I/O

Status

Zone

Address

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Analog Input 2

Current Transformer

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slot A

(Optional)

Input Sensor

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, event

Modbus

Address

1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Current

Transformer

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

Output 3

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

6

Current Monitoring

• detects heater current flow

• provides an alarm indication of a failed-load issue.

Watlow EZ-ZONE®PM Integrated Controller •9 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/16 DIN System Diagram

With Auxillary Input, Without Communications Card (Slot B)

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

EZ Key

Programmable Event

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Auxillary

Input

(optional)

Slot B

Input

Functions

Output

Functions

- None

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+

®

disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

Output Status

5

1

3

2

4

Indicates Zone

Address

Indicates I/O

Status

Zone

Address

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slots A

(Optional)

Input Sensor

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, event

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

Output 3

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Analog Input 2

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Input Sensor

6

Remote Set Point Operation

• Supports efficient set point manipulation from a remote device, such as a master control or PLC.

Watlow EZ-ZONE®PM Integrated Controller •10 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/16 DIN With Limit, System Diagram

Without Communications Card (Slot B)

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

EZ Key

Programmable Event

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Limit Controller

Board

(optional)

Slot B

Input

Functions

Output

Functions

- None

- Limit reset

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+®disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

Output Status

5

1

3

2

4

Indicates Zone

Address

Indicates I/O

Status

Zone

Address

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slots A

(Optional)

Input Sensor

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, retransmit,

duplex or event

Limit

off, heat, cool

alarm, event

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

Output 3

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 4

5A mechanical relay (form A)

Analog Input 2

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Input Sensor

If Limit, this output must

be Limit

6

Integrated PID and Limit Controller

• Reduces wiring time and termination complexity compared to connecting separate products

• Reduces panel space

• Reduces installation costs

• Increases dependability with backup control sensor operation

• Increases user and equipment safety for over-under temperature conditions

Watlow EZ-ZONE®PM Integrated Controller •11 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/16 DIN System Diagram

with Expanded Communications (Slot B)

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

EZ Key

Programmable Event

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Digital Input (or Output) 5 & 6

(optional) none, switch, volts dc

Input

Functions

Output

Functions

- None

- Idle set point

- Tune

- Alarm clear, request

- Force alarm

- Silence alarm

- Manual/auto mode

- Control outputs off

- Remote set point

enable

- Lock keypad

- TRU-TUNE+®disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

Output Status

5

1

3

2

4

Indicates Zone

Address

Indicates I/O

Status

Zone

Address

Analog Input 1

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slot A

(Optional)

Input Sensor

off, heat, cool

alarm, retransmit,

duplex, event

off, heat, cool

alarm, event

off, heat, cool

alarm, event

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

Communications

EIA 232/485 Modbus RTU/TCP,

EtherNet/IP, DeviceNet, Profibus

Modbus Address

1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Communications

Board

Slot B

6

Serial Communication Capabilities

• Supports network connectivity to a PC or PLC

• Available in a wide range of protocol choices, including Modbus RTU, EtherNet/IP™, Modbus TCP

Watlow EZ-ZONE®PM Integrated Controller •12 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/8 and 1/4 DIN System Diagram

Without 6 Digital I/O (slot D), Without Communications (slot E)

EZ-ZONE PM Integrated 8th DIN System Diagram

Without 6-digital I/O (slot D), Without Comms Card (slot E)

Input

Function

Output

Function

If limit, this output

must be limit

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Output 1

none, switched dc/open collector,

5A mechanical relay (form C),

process, or 0.5A SSR (form A)

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slots A

(Optional)

100 to 240Vac

20 to 28 Vac or 12 to 40Vdc

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Input Sensor

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

off, heat, cool,

retransmit, alarm,

duplex or event

off, heat, cool,

alarm, event or

limit

Output Status

LEDs

5

6

1

3

2

4

Zone

Address

LEDs

Channel

Indicates Zone

Address & Channel

Indicates I/O

Status

off, heat, cool,

alarm, or event

8

7

PID Controller,

Limit, or Current

Transformer Sense

(CT)

Slots B

(Optional)

Analog Input 2

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Input Sensor

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Output 3

none, switched dc/open collector,

5A mechanical relay (form C),

process, or 0.5A SSR (form A)

off, heat, cool,

retransmit, alarm,

duplex or event

off, heat, cool,

alarm or event

Power Supply

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

Digital Input (or Output) 5 & 6 (optional)

Programmable Functions

EZ Key 1 & 2

Programmable Functions

Digital Output (or Input) 5 & 6

(optional) none, switched dc

- None

- Limit reset

- Idle set point

- Tune

- Alarm clear, request

- Silence alarm

- Manual/auto mode

- Control mode

- Remote set point

enable

- Lock keypad

- Force alarm

- TRU-TUNE+

®disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

- Math

Watlow EZ-ZONE®PM Integrated Controller •13 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/8 and 1/4 DIN System Diagram

With 6 Digital I/O (slot D), Without Communications (slot E)

Input

Function

Output

Function

off, heat, cool

alarm, retransmit,

duplex or event

EZ-ZONE PM Integrated 8th DIN System Diagram

With 6-digital I/O (slot D), Without Comms Card (slot E)

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

PID Controller,

Limit, or

Current Trans-

former Sense

(CT)

Slots B

(Optional)

PID

Controller

(Optional -

Ramp/Soak max

4 files, 40 steps)

Slots A

(Optional)

Input Sensor

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Analog Input 2

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

6 - Digital

Inputs / Outputs

Slot D

(Optional)

Power Supply

100 to 240Vac

20 to 28 Vac or 12 to 40Vdc

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

Output Status

LEDs

5

6

1

3

2

4

Zone

Address

LEDs

Channel

Indicates Zone

Address & Channel

Indicates I/O

Status

8

7

Input Sensor

If limit, this output

must be limit

Output 1

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

off, heat, cool

alarm or event

Output 3

none, switched dc/open collector, 5A

mechanical relay (form C), process

(V, mA), or 0.5A SSR (form A)

off, heat, cool

alarm, event or limit

off, heat, cool

alarm, retransmit,

duplex or event

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

off, heat, cool

alarm or event

off, heat, cool

alarm or event

Digital Input (or Output) 7-12 (optional)

Programmable Functions

Digital Output (or Input) 7-12

(optional) none, switched dc

Digital Input (or Output) 5 & 6 (optional)

Programmable Functions

EZ Key 1 & 2

Programmable Functions

- None

- Limit reset

- Idle set point

- Tune

- Alarm clear, request

- Silence alarm

- Manual/auto mode

- Control mode

- Remote set point

enable

- Lock keypad

- Force alarm

- TRU-TUNE+®disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

- Math

Digital Output (or Input) 5 & 6

(optional) none, switched dc

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

Watlow EZ-ZONE®PM Integrated Controller •14 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/8 and 1/4 DIN with CT System Diagram

Without 6 Digital I/O (slot D), Without Communications (slot E)

EZ-ZONE PM Integrated 8th DIN with CT System Diagram

Without 6-digital I/O (slot D), Without Comms Card (slot E)

Input

Function

Output

Function

If limit, this output

must be limit

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Output 1

none, switched dc/open collector,

5A mechanical relay (form C),

process, or 0.5A SSR (form A)

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slots A

(Optional)

Power Supply

100 to 240Vac

20 to 28 Vac or 12 to 40Vdc

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Input Sensor

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

off, heat, cool,

retransmit, alarm,

duplex or event

off, heat, cool,

alarm, event or

limit

Output Status

LEDs

5

6

1

3

2

4

Zone

Address

LEDs

Channel

Indicates Zone

Address & Channel

Indicates I/O

Status

off, heat, cool,

alarm, or event

8

7

Current Transformer

Sense (CT)

Slots B

(Optional)

Analog Input 2

Current Transformer

Current

Transformer

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Output 3

none, switched dc/open collector,

5A mechanical relay (form C),

process, or 0.5A SSR (form A)

off, heat, cool,

retransmit, alarm,

duplex or event

off, heat, cool,

alarm or event

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

Digital Input (or Output) 5 & 6 (optional)

Programmable Functions

EZ Key 1 & 2

Programmable Functions

Digital Output (or Input) 5 & 6

(optional) none, switched dc

- None

- Idle set point

- Tune

- Alarm clear, request

- Silence alarm

- Manual/auto mode

- Control mode

- Remote set point

enable

- Lock keypad

- Force alarm

- TRU-TUNE+®disable

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

- Math

Watlow EZ-ZONE®PM Integrated Controller •15 • Chapter 1 Overview

EZ-ZONE®PM Integrated Model 1/8 and 1/4 DIN System Diagram

Without 6 Digital I/O (slot D), With Communications (slot E)

EZ-ZONE PM Integrated 8th DIN System Diagram

Without 6-digital I/O (slot D), With Comms Card (slot E)

Input

Function

Output

Function

If limit, this output

must be limit

Output 4

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Output 1

none, switched dc/open collector,

5A mechanical relay (form C),

process, or 0.5A SSR (form A)

Analog Input 1

none, Thermocouple, RTD (100Ω,

1kΩ), Thermistor 5kΩ, 10kΩ, 20kΩ,

40kΩ) Process (V, mV, mA) or 1k

Potentiometer

PID

Controller

(Optional -

Ramp/Soak max 4

files, 40 steps)

Slots A

(Optional)

Power Supply

100 to 240Vac

20 to 28 Vac or 12 to 40Vdc

Modbus

Address 1 - 247

Standard Bus

Zone Address

1 - 16

Supervisory &

Power Board

Slot C

Input Sensor

EIA-485 Communication

Standard Bus

(optional Modbus RTU)

RUI, EZ-ZONE

Controllers, PLC, PC

or HMI

off, heat, cool,

retransmit, alarm,

duplex or event

off, heat, cool,

alarm, event or

limit

Output Status

LEDs

5

6

1

3

2

4

Zone

Address

LEDs

Channel

Indicates Zone

Address & Channel

Indicates I/O

Status

off, heat, cool,

alarm, or event

8

7

PID Controller,

Limit, or Current

Transformer Sense

(CT)

Slots B

(Optional)

Analog Input 2

none, CT, Thermocouple, RTD (100

Ω, 1kΩ), Thermistor 5kΩ, 10kΩ,

20kΩ, 40kΩ) Process (V, mV, mA)

or 1k Potentiometer

Input Sensor

Output 2

none, 15A NO-ARC, switched dc,

5A mechanical relay (form A), or

0.5A SSR (form A)

Output 3

none, switched dc/open collector,

5A mechanical relay (form C),

process, or 0.5A SSR (form A)

off, heat, cool,

retransmit, alarm,

duplex or event

off, heat, cool,

alarm or event

Communications

Board

Slots E

(Optional)

Communications

Modbus RTU/TCP, DeviceNet,

EtherNet/IP, Profibus

Note:

Number of inputs and outputs and various combinations of the same will vary

depending upon part number; see ordering matrix for more detail.

Digital Input (or Output) 5 & 6 (optional)

Programmable Functions

EZ Key 1 & 2

Programmable Functions

Digital Output (or Input) 5 & 6

(optional) none, switched dc

- None

- Limit reset

- Idle set point

- Tune, TRU-TUNE+

®

- Alarm clear, request

- Silence alarm

- Manual/auto mode

- Control mode

- Remote set point

enable

- Lock keypad

- Force alarm

- Loop & alarms off

- Profile disable

- Profile hold/resume

- Profile start

- Profile start/stop

- Restore user settings

- Event inputs

- Math

Watlow EZ-ZONE®PM Integrated Controller •16 • Chapter 2 Install and Wire

Chapter 2: Install and Wire

2

Dimensions

1/16 DIN (PM6)

L1

K1

J1

L2

K2

T1

S1

R1

L3

K3

J3

L4

K4

T2

S2

R2

98

99

CF

CD

CE

B5

D6

D5

15.8 mm

(0.62 in)

101.6 mm

(4.00 in) 53.3 mm

(2.10 in)

53.3 mm

(2.10 in)

51.2 mm

(2.02 in)

Side Front

Top Back

1/16 DIN (PM6) Recommended Panel Spacing

Recommended panel spacing

panel thickness 1.53 to 9.52 mm

(0.060 to 0.375)

44.96 to 45.47 mm

(1.77 to 1.79 inches)

44.96 to 45.47 mm

(1

.77 to 1.79 inches)

21.6 mm

(0.85 in)

minimum

21.6 mm

(0.85 in)

minimum

Watlow EZ-ZONE®PM Integrated Controller •17 • Chapter 2 Install and Wire

1/8 DIN (PM8) Vertical Dimensions

(3.95 in)

100.33 mm

(2.16 in)

54.8 mm

(2.10 in)

53.34 mm

(4.00 in)

101.60 mm

(0.62 in)

15.75 mm

(0.06 in)

1.52 mm

(0.40 in)

10.16 mm

(1.21 in)

30.73 mm

1/8 DIN (PM8) Vertical Recommended Panel Spacing

Panel thickness (0.060 in) 1.53 mm

to (0.375 in) 9.52 mm

21.6 mm

(0.85 in)

Minimum

21.6 mm

44.96 to 45.60 mm

(1.77 to 1.79 inches)

92.00 to 92.80 mm

(3.62 to 3.65 inches)

(0.85 in)

Minimum

Table of contents

Other Watlow Electric Controllers manuals

Popular Controllers manuals by other brands

LEGRAND

LEGRAND Wattstopper LMPL-101 installation instructions

ABB

ABB PSTX30 Spare part instruction

SCHUNK

SCHUNK SRU-plus Assembly guide

EWS

EWS EC3020 instruction manual

dixell

dixell XC660D Installing and operating instructions

Outback Power Systems

Outback Power Systems MX60 Installation, programming, and user's manual

Smarteh

Smarteh Longo LPC-2.A03 user manual

Dahua

Dahua DHI-ARC3008C user manual

Truma

Truma MonoControl CS Gastank Operating instructions & installation instructions

Lumiax

Lumiax Smart CC Series user manual

JLCooper Electronics

JLCooper Electronics TransportPro RS422 user manual

HTD

HTD MC-66 Multi-Zone owner's manual