WATSON INDUSTRIES SPS-P230 User manual

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

1

STABILIZED PAN AND TILT PLATFORM SYSTEM

OWNER'S MANUAL

PART NUMBER: SPS-P230

WATSON INDUSTRIES, INC.

3035 MELBY STREET

EAU CLAIRE, WI 54703

Phone: (715) 839-0628

FAX: (715) 839-8248

email: support@watson-gyro.com

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

2

Table Of Contents

Introduction................................................................................................................... 3

Product Description...................................................................................................... 3

Servo System .................................................................................................................................................................4

Joystick Controller.........................................................................................................................................................5

Operation ...................................................................................................................... 5

Start-Up..........................................................................................................................................................................5

Time Constant................................................................................................................................................................5

Pointing Angle...............................................................................................................................................................6

Inertial Mode..............................................................................................................................................................6

Position Mode............................................................................................................................................................7

Error Correction.............................................................................................................................................................7

Centrifugal Force:......................................................................................................................................................7

Delta Velocity (Acceleration):...................................................................................................................................7

Safety Features...............................................................................................................................................................7

Over-current detection:..............................................................................................................................................7

Electronic limit stop:..................................................................................................................................................8

Mechanical limit stop:................................................................................................................................................8

Reverse power connection:........................................................................................................................................8

Installation .................................................................................................................... 8

Mounting:.......................................................................................................................................................................8

Servo System: ............................................................................................................................................................8

User Payload:...........................................................................................................................................................10

Environment: ...............................................................................................................................................................11

Connections: ................................................................................................................................................................11

Power:..........................................................................................................................................................................11

Specifications.............................................................................................................. 12

RS-232 Output Format ............................................................................................... 13

Joystick Controller...................................................................................................... 14

Joystick ........................................................................................................................................................................14

Power Button ...............................................................................................................................................................14

Position Mode Button..................................................................................................................................................14

Home Button................................................................................................................................................................15

Rate Bias Button..........................................................................................................................................................15

Joystick Controller Pinout............................................................................................................................................15

Servo System Pinout....................................................................................................................................................16

RS-232 Input Commands ........................................................................................... 16

Warning ...................................................................................................................... 17

Appendix A................................................................................................................. 19

Appendix B................................................................................................................. 22

Activating Command Mode (Double Spacebar Mode)................................................................................................22

Determining Output Channels .....................................................................................................................................22

Setting Output Channels ..............................................................................................................................................23

Adjust Time Constant ..................................................................................................................................................23

Set Joystick Tilt Axis Parameters ................................................................................................................................24

Set Joystick Pan Axis Parameters................................................................................................................................25

Set New Home Position...............................................................................................................................................26

Set Baud Rate...............................................................................................................................................................27

Watson Industries prides itself on solving customer problems and serving their needs in a timely fashion. This manual

is intended to facilitate this goal and to provide written information about your product. We ask that you carefully read

this manual. Becoming familiar with the manual will help you understand the product’s capabilities and limitations, as

well as provide you with a basic understanding of its operation. If, after reading the manual, you require further

assistance, do not hesitate to call Watson Industries with your questions and comments.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

3

CAUTION!

Watson Sensors are rugged devices that have been used successfully in a number of harsh

environments. The components have been qualified to withstand a mechanical shock of 200g 's or

greater, and most enclosures provide an added level of protection. However, dropping a sensor

from waist height onto a hard floor can cause a shock level of 600g's. At this level, damage is

likely to occur.

Introduction

This manual is intended to help in understanding the installation and operation requirements of the

Watson Stabilized Pan & Tilt Platform System. This platform employs gyros to stabilize the

platform to allow devices to be accurately positioned on target irrespective of the motion of the

vehicle on which it is mounted. Details of the operation and adjustments are provided to allow the

owner to obtain optimum performance from this product.

Watson Industries has many years of experience developing stabilized platform sensor packages for

camera and antenna applications. Now we have taken the next step and are offering a complete

system.

Watson Industries also provides custom systems for special requirements. Our system design is

modular and configurable for economical and quick adaptation to a wide variety of hardware

configurations. Watson Industries’ excellent product support and applications engineering goes

along with every product.

Product Description

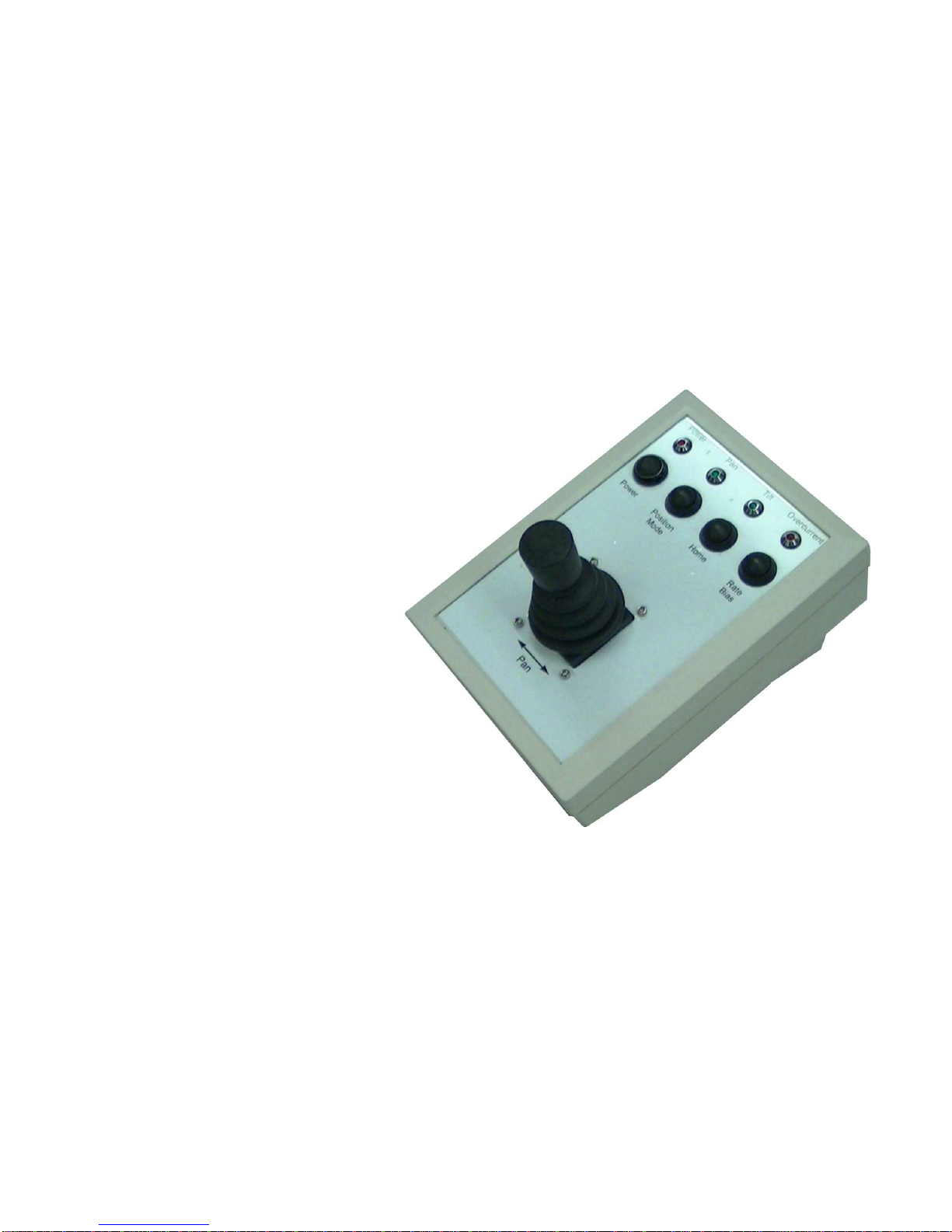

Watson Industries SPS-P230 Stabilized Pan & Tilt Platform System consists of two components.

The first component is the Servo System and the second component is the Joystick Controller.

These components are connected together by a 5-meter Interface Cable.

Power

Tilt

Pan

owerPosition

Mode

Overcurrent

Pan

Bias

Rate

Home

Tilt

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

4

Y

Servo System

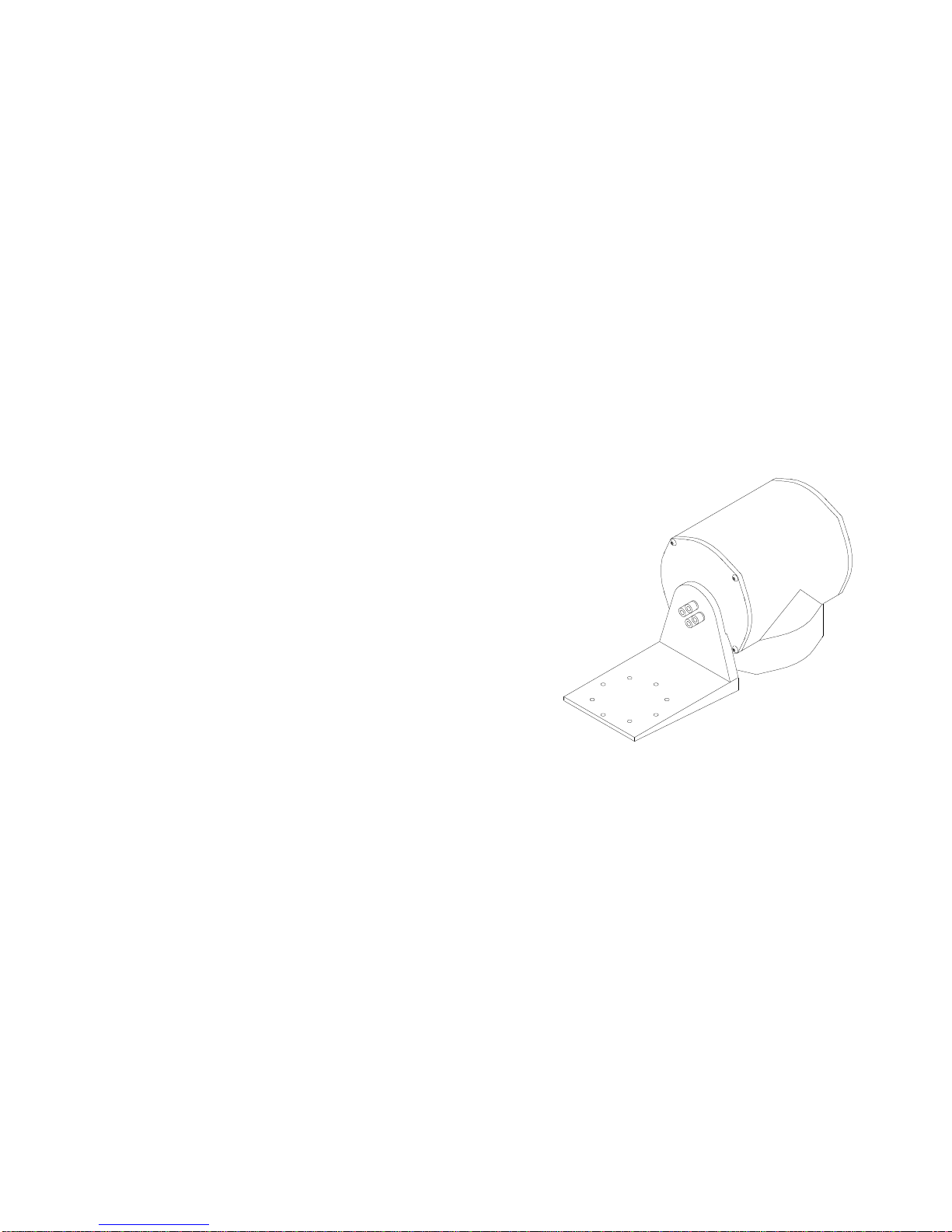

The Servo System is built around a rugged pan and tilt mechanism. This is a high-resolution digital

system that uses high quality, wide bandwidth, low noise, and solid-state gyros. The whole system

is user configurable to adapt to a wide range of payloads and requirements.

Figure 1 Two-axis gyro Stabilized Platform installation

Each axis uses a servomotor, which drives the platform through an anti-backlash gear, a precision

potentiometer for positional measurements, and a pair of limit stops. The anti-backlash gear

minimizes the backlash from platform motions to less than 10 Arc Seconds. Furthermore, Watson

Industries has installed two gyros and a triaxial accelerometer that are used to calculate corrective

commands to the drive motors.

The two gyros are rugged vibrating-structure gyroscopes, whose angular rate signals are converted

from analog to 16-bit digital form. The effects of temperature variation on the DC bias of the gyros

are digitally corrected.

The micro controller assesses the desired motion of the platform based on joystick commands

received through the RS-422 serial link from the Joystick Controller. It then compares this desired

motion against the real motion of the platform, sensed by the gyros and accelerometers, developing

a rate error value. A servo-control system uses the angular rate and integral of the angular rate to

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

5

derive a motor voltage that drives the error to zero. In other words, the servo-control system

ensures that the motion of the platform matches that of the joystick commands.

The servo driver module in the mount enclosure accepts commands from the micro controller in

digital form, converts them to pulse-width modulation using two full-bridge switching motor

drivers and then applies the modulated signal to the two motors.

The platform is carefully designed to be rugged and reliable. Particular attention has been paid to

minimizing the effects of noise at every point in the system. This ensures that full advantage can

be taken of the low noise performance of the gyroscopes a highly stable platform.

Joystick Controller

The Joystick Controller has a joystick, four buttons, four led indicator lights and three connectors.

The joystick controls the positioning of the SPS-P230 payload. The joystick itself is used to pan

and tilt the payload. The indicator lights and buttons that are used to inform the operator or to

control the operation of the SPS-P230 in different ways.

Operation

Start-Up

The system is automatic. Once power is applied, the stabilized platform system will drive to its

preset home position with any errors corrected by using a short time constant. The time constant of

the corrections is increased in increments until it reaches the full operational time constant. The

initialization mode has a 10 second duration. Please allow a 30 second warm-up before operating

the unit.

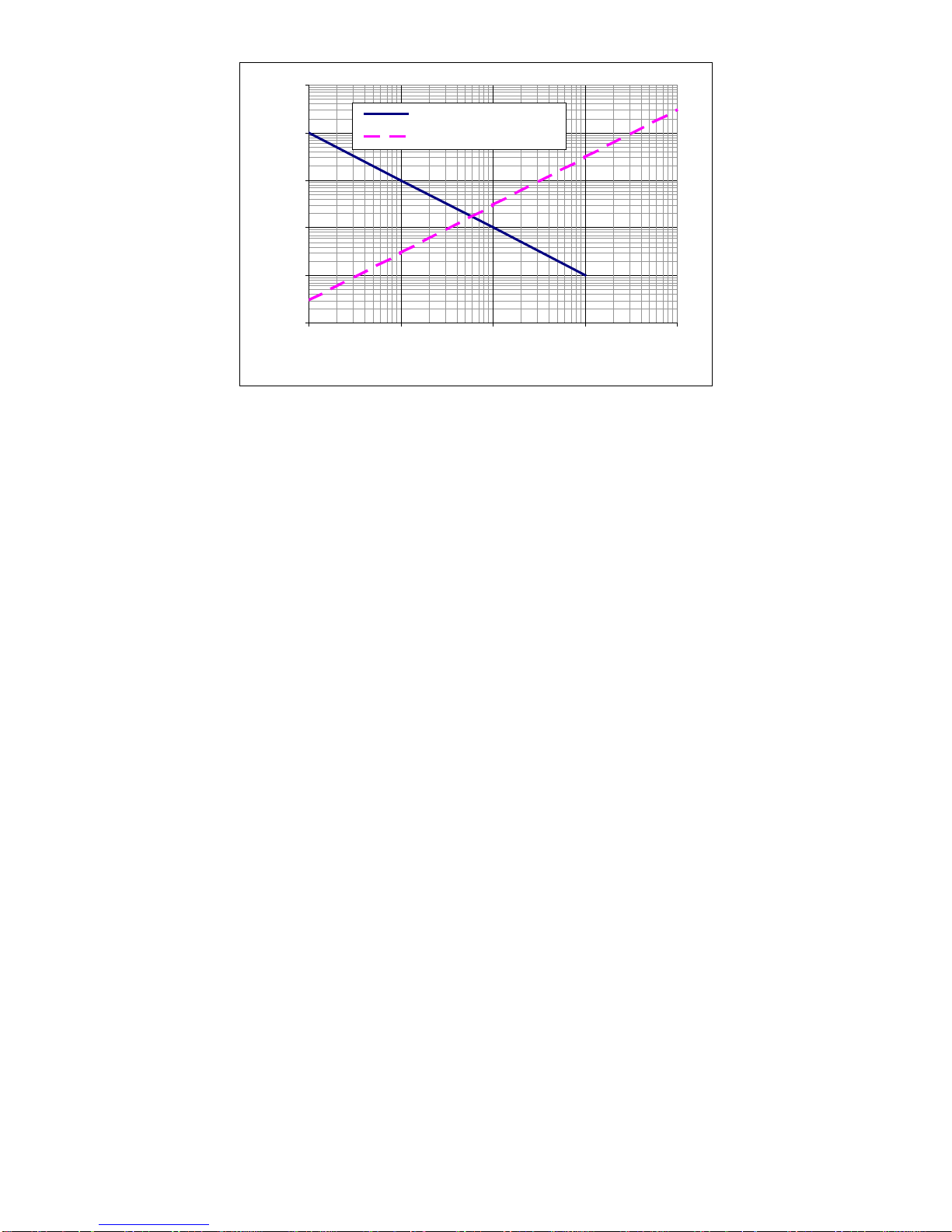

Time Constant

The operational time constant of error correction is chosen for the predicted influences on the

accuracy of the system. Chief among the sources of error are the dynamics of the vehicle and the

drift tendencies of the gyroscopes.

Vehicle dynamics are characterized as being violent when they exist for a short time and gentle

when they are sustained over a long period. They are derivative in nature. In contrast, gyroscopes

have little error in the short term, but these errors grow rapidly as they accumulate in the system.

They are integral in nature. The time constant must be chosen to match the circumstances such that

the least error is likely as shown in example the below:

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

6

0.01

0.1

1

10

100

1000

1 10 100 1000 10000

Seconds

Error (Degrees)

Dynamic Disturbances

Sensor Drift

Figure 2 Errors versus Time Constant

The correction time constant for this system is adjustable based on the conditions detected by the

system. When increasing errors are detected, the time constant is made longer so that the gyros are

in more control of the angles. This is done on the assumption that short-term errors are more likely

to be caused by vehicle dynamics.

The dynamics of aircraft, ships, or land vehicles all have individual patterns and intensities.

Sometimes, only experience will expose the best time constant setting for the lowest error. This is

why the time constants are settable by the user through the RS-232 connection of the Joystick

Controller. Please consult with Watson Industries before altering the time constants of the unit.

Pointing Angle

In initialization, the unit will drive to a preset “Home” pointing angle based on the potentiometer

reading for each axis. After initialization, the unit can be commanded to return to this pointing

angle by pressing the Home Button on the Joystick Controller. The stable platform will hold this

angle until any joystick motion is detected. Full ranges of offsets to this starting point (within

mechanical limits) are settable by the user through a RS-232 connection of the Joystick Controller

(See Appendix B - Set New Home Position Section).

Inertial Mode

In this mode, the unit will stabilize both the pan and tilt axis of the platform. In “I” mode, the pan

and tilt axis will compensate so that the platform can stay pointed at a specific location regardless

of the motions of the vehicle on which it is mounted. Any joystick commands to move the platform

are relative to its stabilized position. Inertial mode is the default mode at startup for the platform.

When the platform is operating in inertial mode, the LED on the position mode button will not be

illuminated. The user can toggle between Inertial Mode and Position mode by pressing the Position

Mode button on the Joystick Controller.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

7

Position Mode

Position or “P” mode is a relative positioning mode. It uses the rate gyros to detect motion on the

pan axis and hold the platform in the last commanded position relative to the vehicle. The tilt axis

operates differently. In Position mode, as well as Inertial Mode, the tilt axis stays stabilized and

will maintain an inertial position irrespective of vehicle motions. Position Mode is activated by

pressing the Position Mode button on the Joystick Controller. When the platform is operating in

position mode, the LED on the position mode button will be illuminated.

Error Correction

Short-term disturbances will not affect the stable mount system, but as these errors become longer

term, joystick commands will become necessary to correct them. Two common sources of long-

term errors for the “P” mode are discussed below.

Centrifugal Force:

The centrifugal force from turns at a significant speed could pull the pointing angle into error over

time, depending on the pointing angle. If this is a problem, setting the system time constant to a

higher time interval may help.

Delta Velocity (Acceleration):

The compensation for forward acceleration is the same as the centrifugal force compensation.

Safety Features

Over-current detection:

There is current sensing for each axis of this system that is connected to the micro controller. If

sustained excessive motor current is detected (i.e. greater than one amp on either axis), the system

will reduce the drive circuit gain by a factor of 4 to reduce the drive current. The gain will be held

low for 2 seconds after the current is below the limit. Since the components of the system are

balanced, the only regular cause of sustained over current is driving against resistance such as an

obstruction. Such a load on the system could cause the motor to burn out and this must be

Vehicle Motion

Vehicle Motion

Position Mode

Inertial Mode

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

8

prevented. If an obstruction causes an over current state, the obstruction should be identified and

removed. If an overcurrent state is detected, the overcurrent LED on the Joystick Controller will be

illuminated.

Electronic limit stop:

The system tracks the orientation of the mount by reading the potentiometer outputs and will

prevent driving past a preset angle value held in the micro controller’s non-volatile memory.

Driving the mount away from this limit is not inhibited.

Mechanical limit stop:

This is a mechanical limit adjusted to keep the mount from colliding with its structure. It uses

micro switches to turn off the ability to drive further into the stop by interrupting one side of the

motor driver. This is a last line of defense from a system failure, as it is fully independent from the

other safety systems. Driving the mount away from this limit is not inhibited.

Reverse power connection:

Power is diode protected from voltage polarity reversal. Recovery is immediate and without

damage.

Installation

The servo system is mounted with careful alignment and

bolted together. Additionally, the payload (supplied

separately) must be attached to the SPS. The steps for

this process are described below and should be read and

understood before any installation or assembly begins.

WARNING – Do not apply power until the installation

is complete!

Mounting:

Servo System:

The servo system is the part of the SPS that will

stabilize the payload. The servo system consists of the

main servo housing and the payload-mounting arm. The main servo housing has a circular plate

with four M6 threaded holes and four #12 or M6 clearance holes for mounting. Several steps

should be followed for a proper installation of the servo system:

1. The servo system is heavy and must be supported during installation to its mounting place.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

9

2. Adjust the position of the mounting ring of the servo system so that the paint mark on the

mounting ring will line up in line with the center position of the intended field of view. The

stop pin on the servo system also needs to be aligned fore of the center position of intended

field of view.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

10

3. Loosely attach the servo system to the mounting position using four mounting bolts,

washers and possibly nuts. Use bolts that do not protrude beyond the mounting ring.

4. Once the servo system is aligned, secure the four mounting bolts.

User Payload:

Once the servo system is correctly installed, a payload may be installed on the arm of the servo

system. The SPS has no counterweight and is limited by this load imbalance to a 99 lb (45 Kg)

payload. WARNING – Do not apply power until the installation is complete!

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

11

Environment:

This product has been surface treated for resistance to salt air and precipitation. This resistance is

limited however, and the system should be kept clean and should be inspected for signs of

corrosion damage regularly.

As in all moving mechanisms there is concern about ice interfering with operation. The system has

internal protection against damage from stalling the motors, but performance may be reduced.

The system should be considered fragile:

DO NOT APPLY LOADS OR FORCES TO THE PAYLOAD.

Connections:

This product has two components. The Servo System and the Joystick Controller Box. First

connect the Servo System and Joystick Controller box together using the 5 meter Interface Cable

The 7 pin connector end of the Interface Cable is attached to the Joystick Controller box and the 8

pin connector end is connected to the Servo System. Make sure the power switch is in the off

position (up – non depressed position). Now the power connection is attached to the Joystick

Controller Box. The mating connector is included. Be sure to use the proper gauge wire for this

connection as the unit can draw up to 6 Amps of current @ 28 VDC. See Joystick Controller

Pinout Section.

The Power Switch on the Joystick Controller Box switches on power to the entire system.

Power:

This unit has an internal regulator to allow operation over a moderate voltage input range. Best

operation is obtained at 28 VDC level, although operation is fully satisfactory down to 18 VDC and

up to 30 VDC. The peak current is about 6 amperes. Internal capacitors are provided to remove a

reasonable level of power line noise, however, capacitors should be added for long power line

wiring or if noise is induced from other loads on the circuit.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

12

Specifications

Platform

Range: Pan ±170° (Electronic) ±175° (Mechanical)

Range: Tilt ±90° (Electronic) ±95° (Mechanical)

Slew Rate: Bank, Elevation ±45°/sec

Tilt Accuracy: Static ±1.5°

Tilt Accuracy: Dynamic ±3.0°

Noise: 0.1° rms

Stability: ±1.5° Over 20 minutes

Environmental

Temperature: Operating -20°C to +50°C

Temperature: Storage -50°C to +80°C

Vibration: Operating 0.5 g rms 100 Hz to 1 KHz

Vibration: Survival 2 g rms 100 Hz to 1 KHz

Electrical

Startup Time: Operational 10 seconds

Startup Time: Full Performance 90 seconds

Input Power: 18 to 30 VDC

Input Current: 2A @ 28VDC 6A Peak

Physical

Size: Including Mounting Flanges 6.7"W x 15.8"L x 9.2"H 17.0 x 40.1 x 23.4 (cm)

Weight: 28lb (12.7Kg) Not including payload

Connection: RS-232 9 pin female "D" subminiature On joystick controller

Connection: Power MS3112E-8-4P (4 pin male) On joystick controller

Connection: Interface MS3102A-16S-1S (7 pin female)

MS3102A-20-7P (8 pin male) On joystick controller

On servo controller

Interface Cable: 5 meter MS3106A-16S-1P 7 pin male end

mates to joystick controller MS3106A-20-7S 8 pin female end

mates to servo system

Capacity: 45 Kg

Base Mounting Holes: Qty 8 (4 x M6 threaded; 4 x #12

M6 clearance) 4" dia. bolt circle

Payload Mounting Holes: Qty 8 #12 (M6 clearance) 4" dia. bolt circle

• Specifications are subject to change without notice.

• This product may be subject to export restrictions. Export Classification ECCN EAR99.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

13

RS-232 Output Format

The nominal RS-232 output consists of a string of decimal ASCII characters sent asynchronously at

regular intervals at about 10 strings per second. The string is set to be sent at 9600 baud with eight

data bits, one stop bit, no parity, and no handshaking. The factory settings for the contents of the

string is formed as follows:

1. A six character string representing the tilt angle starting with a space, then a “+” or a “-“,

followed by two digits, a decimal point, and one digit for up to ±89.9 degrees.

2. A six character string representing the pan angle starting with a space, then a “+” or a “-“,

followed by three digits, a decimal point, and one digit for up to ±179.9 degrees.

3. A six character string representing the tilt axis angular rate starting with a space, then a “+”

or a “-“, followed by two digits, a decimal point and one digit for up to ±99.9

degrees/second.

4. A six character string representing the pan axis angular rate starting with a space, then a “+”

or a “-“, followed by two digits, a decimal point and one digit for up to ±99.9

degrees/second.

5. A five character string representing the power supply voltage starting with a space,

followed by two digits,

a decimal point, and one digit for up to 35.0 VDC.

6. .A six character string representing the tilt axis motor current starting with a space, then a

“+” or a “-“, followed by one digit, a decimal point and two digits for up to ±9.99 Amps.

7. A six character string representing the pan axis motor current starting with a space, then a

“+” or a “-“, followed by one digit, a decimal point and two digits for up to ±9.99 Amp.

8. A four character string representing the Status Bits starting with a space, followed by three

ASCII characters representing Octal digits.

9. A seven character string representing the Flag Bits starting with a space, followed by two

ASCII characters (Flag Bits1) representing Octal digits, a space, followed by three ASCII

characters (Flag Bits2) representing Octal digits.

10. The string is terminated by a carriage return. There will then be a short interval with no data

transmission before the next string begins.

Example:

+02.5

-001.5 +02.5 -05.0 24.5 +0.25 -0.22 064 04 000 <CR>

Tilt

Angle

(1)

Pan.

Angle

(2)

Tilt

Rate

(3

Pan

Rate

(4)

Power

Supply

Voltage

(5)

Tilt

Current

(6)

Pan

Current

(7)

Status

Bits

(8)

Flag

Bits

(9)

(10)

↑

↑

↑

↑

↑

↑

↑

↑

space space space

space space space space space

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

14

The output message and baud rate can be configured by the user. See Appendix B for more

information.

A text header is sent by the SPS during initialization that identifies the unit by part number and

serial number and gives the date of last calibration. Additionally, a line of text characters that

identifies the data channel columns is sent if the serial output is set to ASCII decimal. This header

message can be suppressed or restored by sending a “*” command from the interfacing computer.

This change can also be made the default by sending a quote (“) command.

Data transmission sent by the SPS-P230 can also be suppressed or restored by sending a “+”

command from the interfacing computer. This change can be made the default setting by sending a

quote (“) command.

Joystick Controller

The Joystick Controller has a

joystick, four buttons, four led

indicator lights and three

connectors. These items are

explained below.

Joystick

The joystick positions the SPS-P230

payload. A left or right movement

of the joystick controls the pan

motion of the payload while an up

or down movement controls the tilt.

The joystick is also used to correct

any rate bias in the system, which is

discussed later. When the joystick

is commanding the SPS-P230 to

move in the pan axis, the green pan

indicator light will be illuminated.

Similarly, when the system is

moving in the tilt axis, the green tilt

indicator light will be illuminated.

Power Button

The power button turns the SPS-P230 on and off. When the system is powered on, the power

indicator light will be illuminated.

Position Mode Button

This button toggles the sensor between position mode and inertial modes of operation. When the

platform is operating in position mode, the LED on the position mode button will be illuminated.

For more information on these to modes, see the Pointing Angle section earlier in this manual.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

15

Home Button

Pressing the home button will command the SPS-P230 to return the payload to a predetermined

Home position. The platform will stay at this position regardless of vehicle motion. Any joystick

input will exit the home position. The home position is set through the SPS-P230 menu system. See

Appendix B for more information.

Note: When the SPS-P230 is first powered on, it will go to the home position.

Rate Bias Button

The rate bias button allows the user to eliminate any rate bias motion from the platform using

joystick inputs. Pressing this button toggles the sensor between normal operation and a special rate

bias adjustment mode. When the SPS-P230 is in rate bias adjustment mode, the LED on the rate

bias button will be illuminated. When in this mode, joystick motions are added to the system as

bias adjustments. Moving the joystick in the pan axis will adjust pan rate bias, while joystick tilt

motions will adjust tilt rate bias.

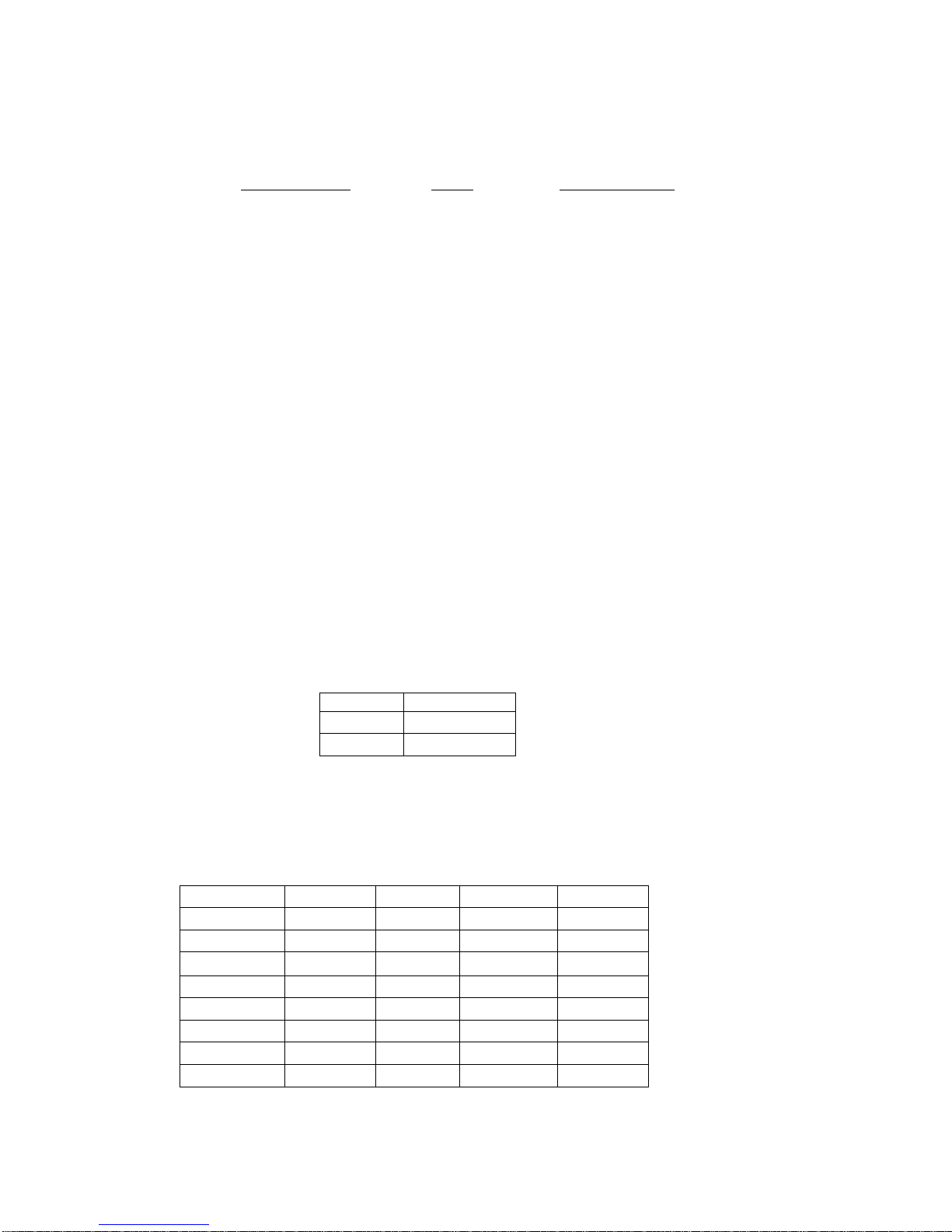

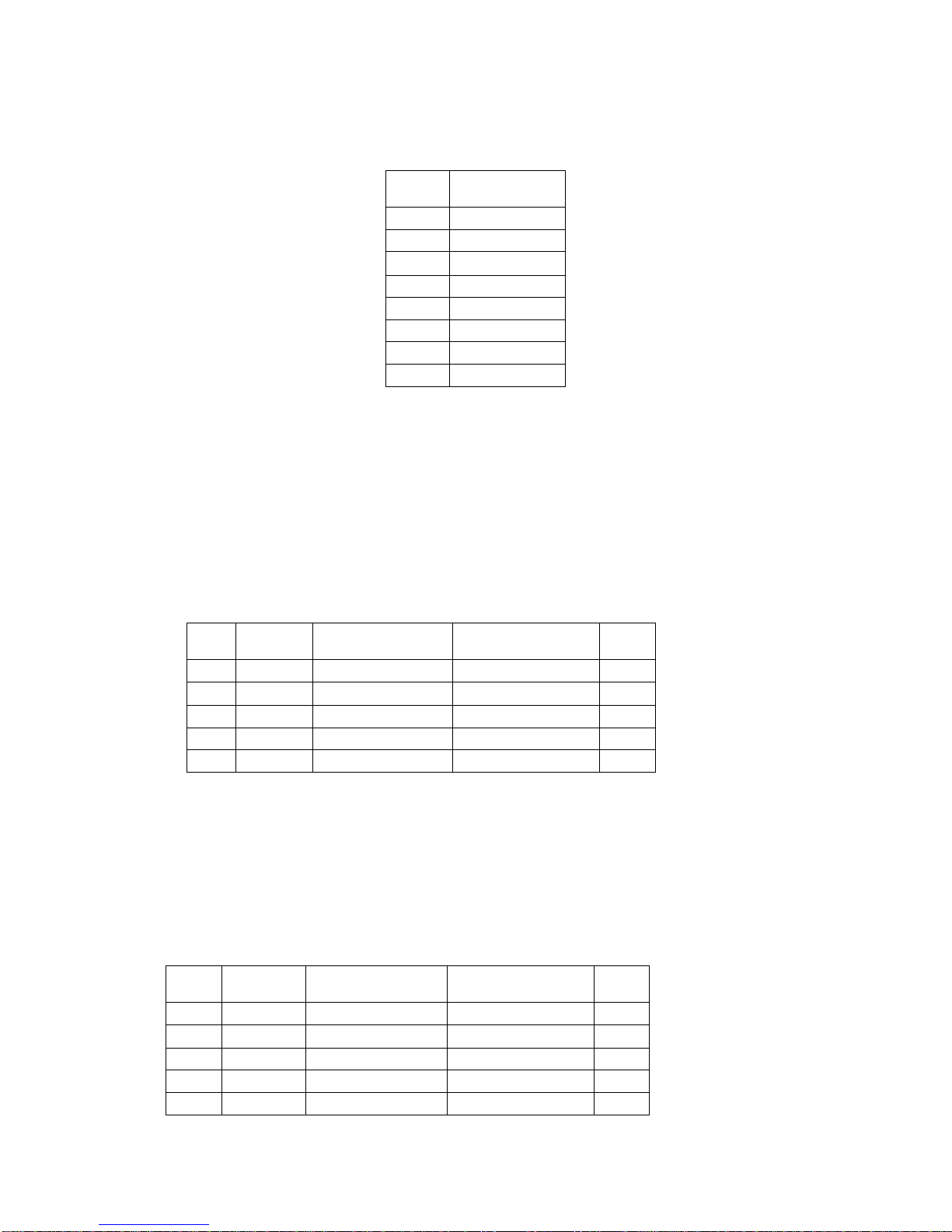

Joystick Controller Pinout

The joystick controller has three connectors mounted to the rear panel as shown below:

9 Pin Female D-Sub

RS-232 Interface MS3102A-16-1S

Interface to Platform MS3112E-8-4P

Power

Pin Description Pin

Description Pin

Description

1 N.C. A Power Ground A N.C.

2 RS-232 TXD B +28VDC Power B +28 VDC Power In

3 RS-232 RXD C RS-422 RX+ C N.C.

4 N.C. D RS-422 RX- D Power Ground

5 Signal Ground E Signal Ground

6 N.C. F RS-422 TX-

7 N.C. G RS-422 TX+

8 N.C.

9 N.C.

12345

69 8 7

A

B

C D

G

F

E

A

B C

D

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

16

Servo System Pinout

The Servo System has one connector:

Pin Function

A Power Return

B +28 Volt Power

C RS-422 TX+

D RS-422 TX-

E Signal Ground (connected internally to Power Return)

F RS-422 RX-

G RS-422 RX+

H Case Ground

RS-232 Input Commands

The RS-232 input commands are provided for the purpose of unit test and installation set-up.

These input commands use the same communication parameters that the output data uses (9600

baud ASCII nominal, or as reset in the units EEPROM). There are some commands intended for

the user while others are used at the factory for alignment and calibration.

An exclamation point “!” will reinitialize the unit just as re-powering the unit would. Furthermore,

the access to initialization is inhibited such that a spacebar command must be sent within 2.5

seconds of the “!” command for initialization to be engaged.

There are several interface commands: “:” will toggle the output to send a frame of data upon

receiving any non-command character and “+” will toggle the output for no output data. These

and other changes are made non-volatile (default) in the unit on EEPROM by keying in the quote

(“) character. Double spacebar at initialization is required for access to these commands.

Note that the “:” setting will cause the mechanical brake to be engaged between frames. This is not

intended to be an operational mode.

The “&” command calls a menu which allows any of several parameters to be set. These are the

system time constant, joystick/axis parameters, selection of data channels for serial output, listing

current serial channels and baud rate. Double spacebar at initialization is required for access to this

command. See Appendix B for more information.

The commands “~”, “@”, “#”, “$”, “(“, “)”, “{“, “}”, “|”, “<”, “>” and “?” are used by the Watson

factory to calibrate the unit and should be used only with the assistance of the factory. If an

undesired function is called, a “Q”, and sometimes the Escape or Delete key will interrupt the

command and return to operation with the least disturbance to the system. All other unspecified

characters such as carriage return, line feed and space are ignored by the system.

}

Transmit from SPS-P230

}

Receive to Joystick Controller

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

17

Warning

Rough handling or dropping of this unit is likely to cause damage.

Over-voltage and/or miswiring of this unit will cause damage.

This unit should be inspected regularly when exposed to

prolonged exposure to high humidity and/or salt air environments.

DISCLAIMER

The information contained in this manual is believed to be accurate and reliable; however, it is the

user’s responsibility to test and to determine whether a Watson Industries’ product is suitable for a

particular use. Suggestion of uses should not be taken as inducements to infringe upon any patents.

This product is not to be used as a primary instrument for life critical use.

WARRANTY

Watson Industries, Inc. warrants, to the original purchaser, this product to be free from defective

material or workmanship for a period of two full years from the date of purchase. Watson

Industries’ liability under this warranty is limited to repairing or replacing, at Watson Industries’

sole discretion, the defective product when returned to the factory, shipping charges prepaid, within

two full years from the date of purchase. All sensors returned under warranty will be repaired (or

replaced at the sole option of Watson Industries) at no cost to the customer other than shipping

charge from customer to Watson Industries (plus any export and transportation charges outside the

United States). The warranty described in this paragraph shall be in lieu of any other warranty,

express or implied, including but not limited to any implied warranty of merchantability or fitness

for a particular purpose.

Excluded from any warranty given by Watson Industries are products that have been subject to

abuse, misuse, damage or accident; that have been connected, installed or adjusted contrary to the

instructions furnished by seller; or that have been repaired by persons not authorized by Watson

Industries.

Watson Industries reserves the right to discontinue models, to change specifications, price or

design of this product at any time without notice and without incurring any obligation whatsoever.

The purchaser agrees to assume all liabilities for any damages and/or bodily injury, which may

result from the use, or misuse, of this product by the purchaser, his employees or agents. The

purchaser further agrees that seller shall not be liable in any way for consequential damages

resulting from the use of this product.

No agent or representative of Watson Industries is authorized to assume, and Watson Industries

will not be bound by any other obligation or representation made in connection with the sale and/or

purchase of this product.

PRODUCT LIFE

The maximum expected life of this product, other than wear out, is 20 years from the date of

purchase. Watson Industries, Inc. recommends the replacement of any product that has exceeded

the product life expectation.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

18

Customer Service

All repairs, calibrations and upgrades are performed at the factory. Before returning any product,

please contact Watson Industries to obtain a Returned Material Authorization number (RMA).

Return Address & Contact Information

Watson Industries, Inc.

3035 Melby Street

Eau Claire, WI 54703

ATTN: Service Department

Returning the Product

Product shall be packaged making sure there is adequate packing around all sides. Correspondence shall

include:

• Customer’s Name and Address

• Contact Information

• Equipment Model Number

• Equipment Serial Number

• Description of Fault

It is the customer’s responsibility to pay all shipping charges from customer to Watson

Industries, including import and transportation charges.

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

19

Appendix A

The following outputs are available via the RS-232 serial link. Their full-scale ranges are listed for decimal format.

Inertial Output Label Decimal Range

Time TM 000.1 to 999.9 s

Tilt Angle TA ±89.9º

Pan Angle PA ±179.9º

X Accelerometer XA ±9.99 g

Y Accelerometer YA ±9.99 g

Z Accelerometer ZA ±9.99 g

Tilt Axis Angular Rate TR ±99.9 º/s

Pan Axis Angular Rate PR ±99.9 º/s

Power Supply Voltage PS 00.0 to 35.0 VDC

Tilt Potentiometer PT ±179.9º

Pan Potentiometer PP ±179.9º

Tilt Current TC ±9.99 Amps

Pan Current PC ±9.99 Amps

Tilt Joystick Rate TJ ±49.9 º/s

Pan Joystick Rate PJ ±49.9 º/s

Temperature TP -40º to 88ºC

Status Bits ST 3 ASCII chars representing

Octal digits

Flag Bits 1 F1 2 ASCII chars representing

Octal digits

Flag Bits 2 F2 3 ASCII chars representing

Octal digits

Status Bits:

The status bits provide operational information that is presented as two ASCII octal digits. The

first digit is made up of one bit as follows:

First Digit Mode

1 Position

0 Inertial

The Second digit is made from three bits as follows:

1) Initialization mode equals a value of 1 during start up.

2) Tilt Error Flag equals 1 when Tilt angle is in error

3) Pan Error Flag equals 1 when Pan Angle is in error

Second Digit Pan Error Tilt Error Initialization

7 Yes Yes Yes 4 + 2 + 1

6 Yes Yes No 4 + 2

5 Yes No Yes 4 + 1

“4” Pan Error

4 Yes No No 4

“2” Tilt Error

3 No Yes Yes

2 + 1 “1” In Initialization

2 No Yes No 2

1 No No Yes 1

0 No No No

Watson Industries, Inc. SPS-P230 Rev A 10/17/2017

20

The Third digit represents the current time constant as a power of two:

TC = 2

X

Seconds

The nominal time constant is 64 seconds which would display the octal value of X as “6”.

Third

Digit Time Constant

(seconds)

7 128

6 64

5 32

4 16

3 8

2 4

1 2

0 1

Flag Bits 1:

The flag bits present warning information. The first digit is made from three bits:

1) Pan angle negative stop limit equals a value of 1 when the Pan potentiometer reaches a

preset limit.

2) Pan angle positive stop limit equals a value of 2 when the Pan potentiometer reaches a

preset limit.

3) Pan axis active bit equals a value of 4 when the Pan axis is active.

First

Digit Pan Axis

Active Pan Angle Positive

Stop Limit Pan Angle Negative

Stop Limit

6 Yes Yes No 4 + 2

5 Yes No Yes 4 + 1

“4” Pan Axis Active

4 Yes No No 4

“2” Pan Positive Stop Limit

2 No Yes No 2

“1” Pan Negative Stop Limit

1 No No Yes 1

The second digit is made from three bits as follows:

1) Tilt angle negative stop limit equals a value of 1 when the Tilt potentiometer reaches a

preset limit.

2) Tilt angle positive stop limit equals a value of 2 when the Tilt potentiometer reaches a

preset limit.

3) Tilt Axis active bit equals a value of 4 when the Tilt axis is active.

First

Digit Tilt Axis

Active Tilt Angle Positive

Stop Limit Tilt Angle Negative

Stop Limit

6 Yes Yes No 4 + 2

5 Yes No Yes 4 + 1

“4” Tilt Axis Active

4 Yes No No 4

“2” Tilt Positive Stop Limit

2 No Yes No 2

“1” Tilt Negative Stop Limit

1 No No Yes 1

Table of contents

Other WATSON INDUSTRIES Industrial Equipment manuals