4

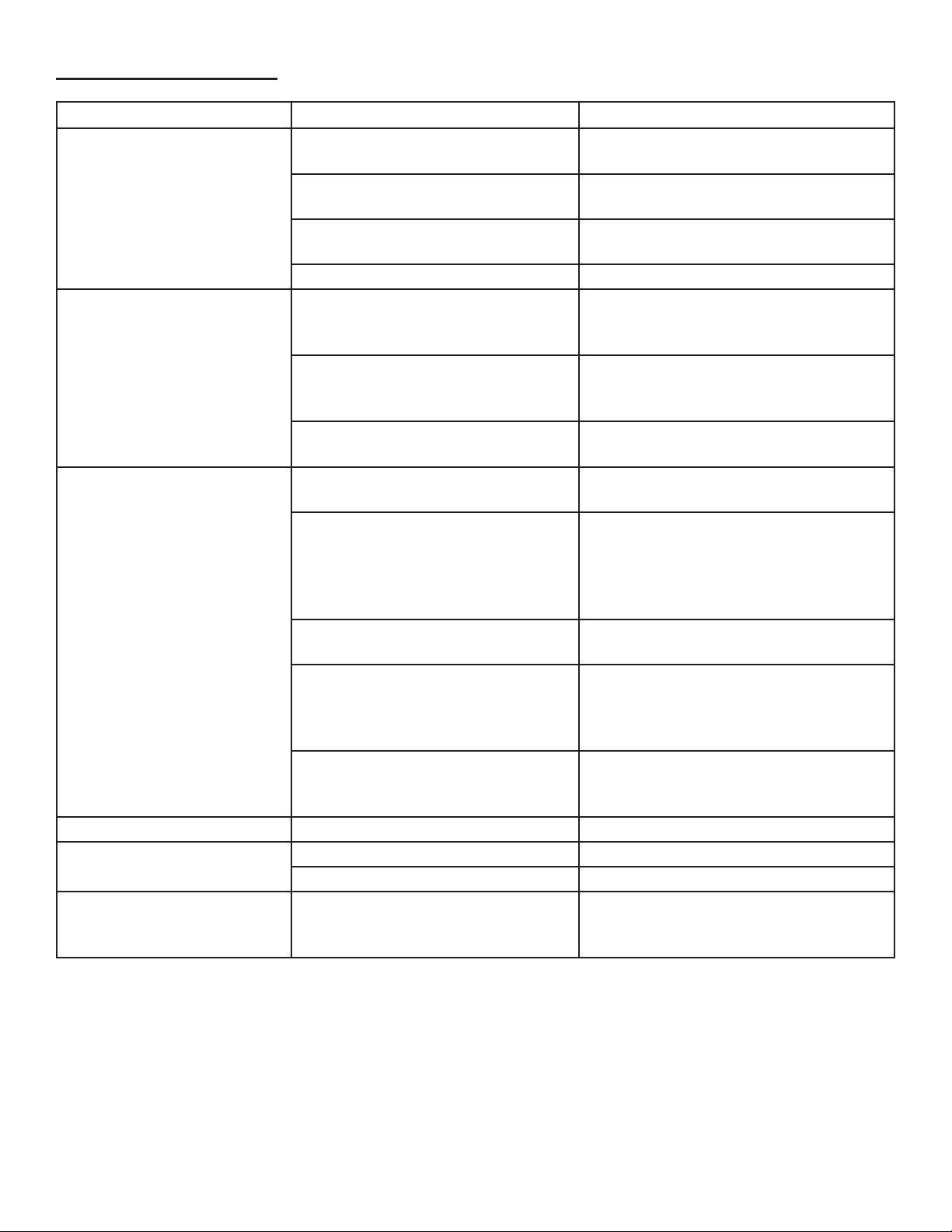

TROUBLESHOOTING

PROBLEM: CHECK THIS: SOLUTION:

Hard drive punch will not

operate

Check that the power cord is

plugged into an appropriate outlet

Plug cord into outlet

Check voltage of power outlet

(120VAC, 60Hz)

If necessary, nd an alternate outlet

with the appropriate voltage

Check the wiring between the fuse

connector on the PCB (page 9)

Reconnect, if necessary

Check relay switch on Main PCB Reconnect, if necessary

Main power is functioning but

hard drive punch won’t oper-

ate (Main PCB)

Check main power cable to see if it

is properly connected to the Main

PCB (page 9)

Reconnect, if necessary

Check the Main PCB’s printed

circuit and wire disconnection of

transformer

If there is a problem with the circuit and/

or transformer, replace with new one

Check the electrical contacts on the

main control switch

Reconnect, if necessary

Main power is okay, but hard

drive punch is not working

(electrical)

NOTE: Photo sensor should

be connected with the main

PCB during testing.

Check the outlet for correct voltage,

120V

Use different outlet, if necessary

Check wire connection between

photo sensor and Main PCB (page

9). If there is no output signal from

Main PCB, hard drive punch will not

operate.

Reconnect cable to sensor and Main

PCB

Photo sensor could be dirty Remove photo sensor (page __) and

clean it with a soft cloth

Photo sensor sensitivity may need

to be reset

Sensitivity measurement distance

should be .4 inch (10mm). If distance

is less than .4 inch, replace the photo

sensor

Check power relay contacts Reconnect, or replace main PCB power

relay if necessary. If printed circuit is

damaged, replace the main PCB.

Full light will not go off Check waste bin to see if it’s full Empty waste bin

Door Open light will not go

off

Check cabinet door Close door

Check safety shield Close safety shield

Punching die is not moving

properly

Remove cover, check limit switches

to see if they’re properly connected

to the power board

Reconnect switches, if necessary