Ecosoft MO-1 User manual

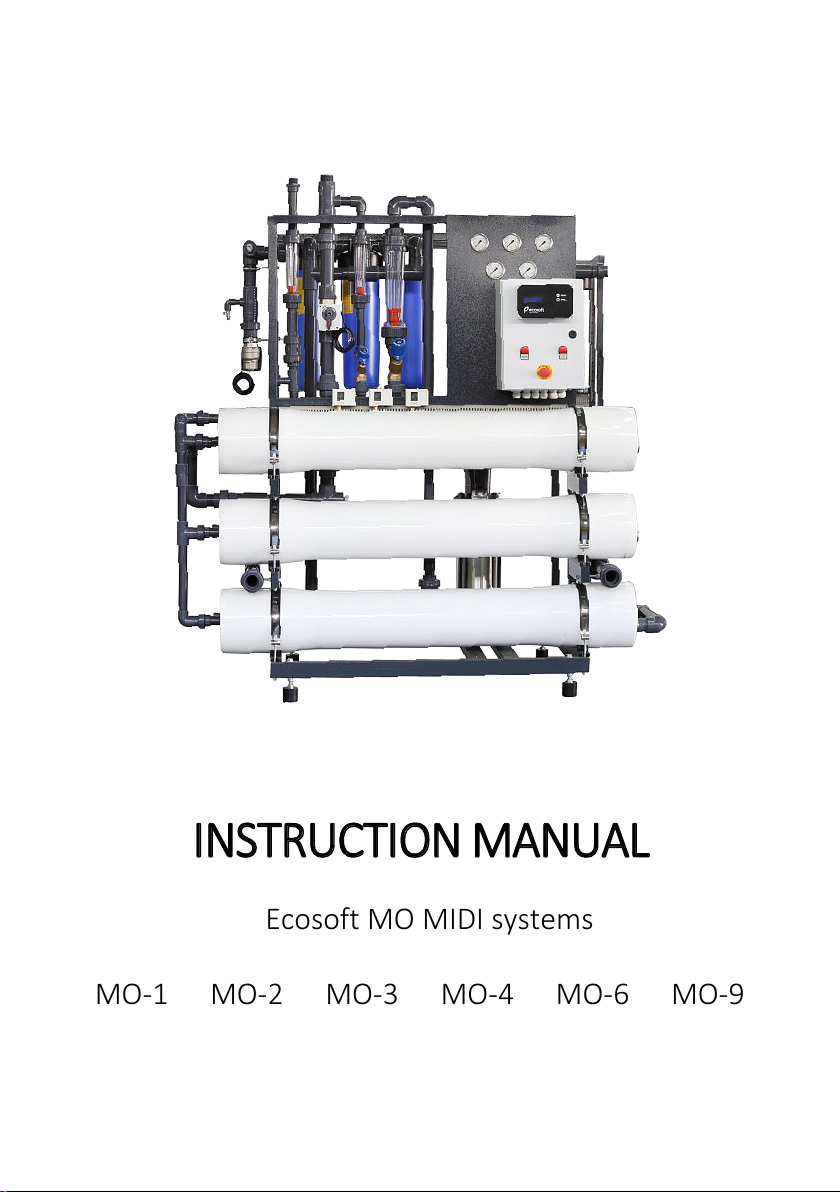

MO-1

MO-2

MO-3

MO-4

MO-6

MO-9

INSTRUCTION MANUAL

Ecosoft MO MIDI systems

C

CO

ON

NT

TE

EN

NT

TS

S:

:

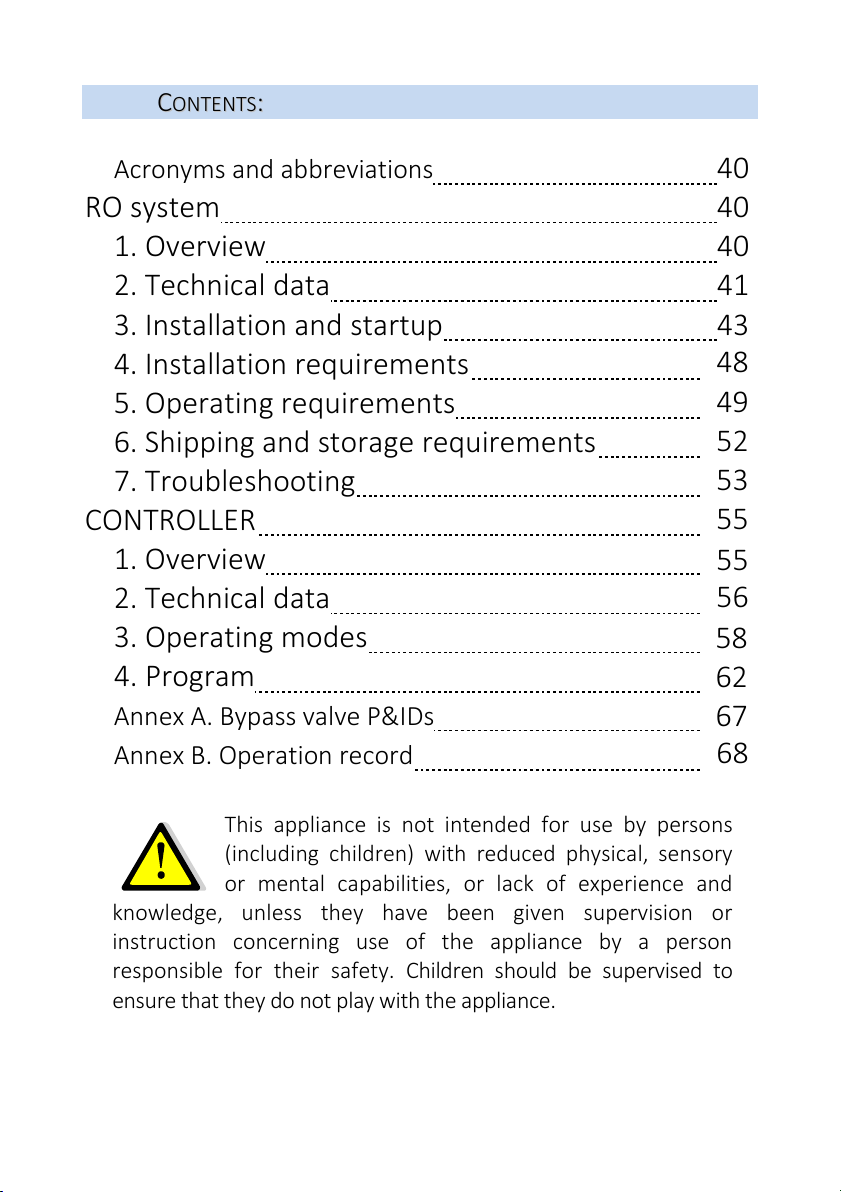

Acronyms and abbreviations 40

RO system 40

1.Overview 40

2. Technical data 41

3. Installation and startup 43

4. Installation requirements 48

5. Operating requirements 49

6. Shipping and storage requirements 52

7. Troubleshooting 53

CONTROLLER 55

1. Overview 55

2. Technical data 56

3. Operating modes 58

4. Program 62

Annex A. Bypass valve P&IDs 67

Annex B. Operation record 68

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person

responsible for their safety. Children should be supervised to

ensure that they do not play with the appliance.

40

A

AC

CR

RO

ON

NY

YM

MS

S

A

AN

ND

D

A

AB

BB

BR

RE

EV

VI

IA

AT

TI

IO

ON

NS

S

CIP Clean-in-place

NC Normally closed

RO Reverse osmosis

FF Forward flush

NO Normally open

TDS Total dissolved solids

GPM Gallon per minute

P&ID Piping and instrumentation diagram

LPMLiter per minute

PCB Printed circuit board

R

RO

O

S

SY

YS

ST

TE

EM

M

1Overview

Ecosoft industrial reverse osmosis systems are used for demi-

neralizing water in industrial, municipal, commercial applications.

Ecosoft RO system can be used to demineralize low to medium salinity

feed water. All parts of the system that are in contact with water have

the necessary certifications for use in food/drinking water applications.

Reverse osmosis system operates as follows. First, raw water is

fed through sediment prefilters to remove particles. The water may

be dosed with antiscalant or other RO chemicals with a dosing pump

at this point. Then, high pressure pump feeds the water into the

membrane module or membrane array, in which feed stream

undergoes separation process and splits into purified and

concentrated streams. Part of the concentrated stream is discharged

to drain, and the rest is fed back to suction end of the high pressure

pump, referred to as concentrate recycle. Drain line is fitted with

drain flow control that limits rate of concentrate discharge and

determines the ratio of purified water (permeate) to waste water

(concentrate). The ratio is called recovery. Recycle line is fitted with

recycle flow control that limits recycle flow rate and creates working

pressure in the membrane array. Rate of permeate production is

proportional to the pressure in the membrane modules.

Commissioning and configuring the RO system includes carefully

adjusting the flow controls to the right settings.

41

Improperly commissioned RO system may fail in the

matter of minutes, including irreparable membrane

failure, hardware failure, and also involves electrical and

pressure hazard. Drain flow rate and recycle flow rates should only

be configured by authorized staff.

Permeate stream comes out via permeate outlet and runs to

permeate tank. Purification process will stop whenever the tank is

full of water (signaled by the float switch) or when any backpressure

in permeate line appears, indicating critical condition. The process

will automatically resume when the full tank signal deactivates.

The system is operated with a process controller, which powers

pump(s) and valves so as to carry out service or membrane rinse in the

necessary times. The controller reads signals from pressure switches,

float switch, permeate conductivity and temperature, and external

inhibition. Depending on these signals, it chooses to run in service, rinse

membranes, go to standby, or go to fault mode. Permeate conductivity

and temperature data are displayed to the operator. Depending on

system model, it can be additionally equipped with:

–antiscalant/chemical dosing pumps

–additional electric valve for raw water mixing or membrane

permeate rinsing (see Annex A)

R

RO

O

S

SY

YS

ST

TE

EM

M

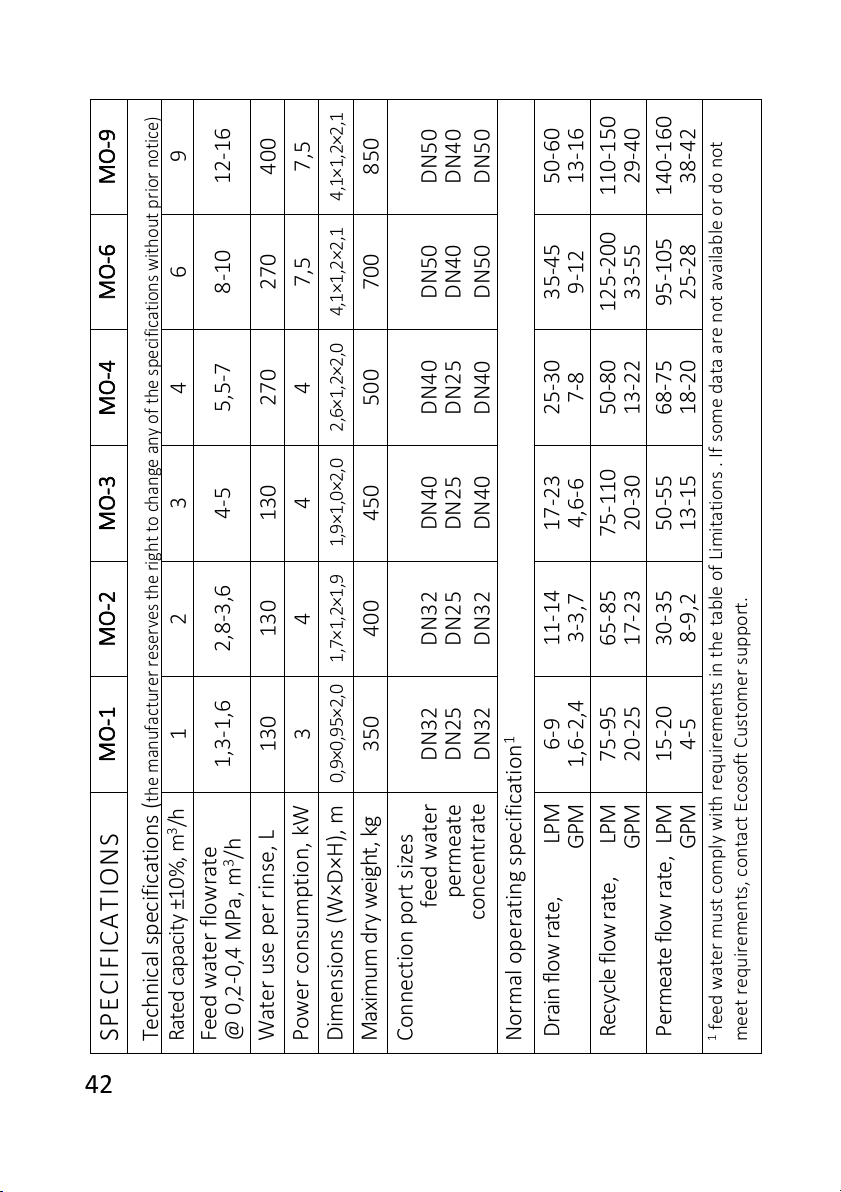

2Technical data

Tap feed water must be pre-filtered from fine particulates

and residual chlorine before entering the RO system. Well

water may contain impurities such as hardness, iron,

manganese, silica, hydrogen sulfide that can quickly lead to membrane

failure. Some of these challenges can be addressed by using injection of

antiscalant. Perform a detailed laboratory analysis of your well water

and consult a water treatment specialist to see if you need additional

equipment for treating your well water.

42

MO-9

Technical specifications (

the manufacturer reserves the right to change any of the specifications without prior notice)

9

-12 16

400

7,5

4,1×1,2×2,1

850

DN50

DN40

DN50

Normal operating specification1

-50 60

-13 16

-

110-150

29 40

-

140-160

38 42

1feed water must comply with requirements in the table of Limitations . If some data are not available or do not

meet requirements, contact Ecosoft Customer support.

MO-6

6

-8 10

270

7,5

4,1×1,2×2,1

700

DN50

DN40

DN50

-35 45

-9 12

-

125-200

33 55

-

-

95 105

25 28

MO-4

4

5,5-7

270

4

2,6×1,2×2,0

500

DN40

DN25

DN40

-

-

25 30

7 8

-50 80

-13 22

-68 75

-18 20

MO-3

3

-4 5

130

4

1,9×1,0×2,0

450

DN40

DN25

DN40

17-23

4,6-6

-

-

75 110

20 30

-50 55

-13 15

MO-2

2

2,8-3,6

130

4

1,7×1,2×1,9

400

DN32

DN25

DN32

-11 14

-3 3,7

-65 85

-17 23

-30 35

-8 9,2

MO-1

1

1,3-1,6

130

3

0,9×0,95×2,0

350

DN32

DN25

DN32

-6 9

1,6-2,4

-75 95

-20 25

-

-

15 20

4 5

SPECIFICATIONS

Rated capacity ±10%, m3/h

Feed water flowrate

@ 0,2-0,4 MPa, m3/h

Water use per rinse, L

Power consumption, kW

Dimensions (W×D×H), m

Maximum dry weight, kg

Connection port sizes

feed water

permeate

concentrate

Drain flow rate, LPM

GPM

Recycle flow rate, LPM

GPM

Permeate flow rate, LPM

GPM

43

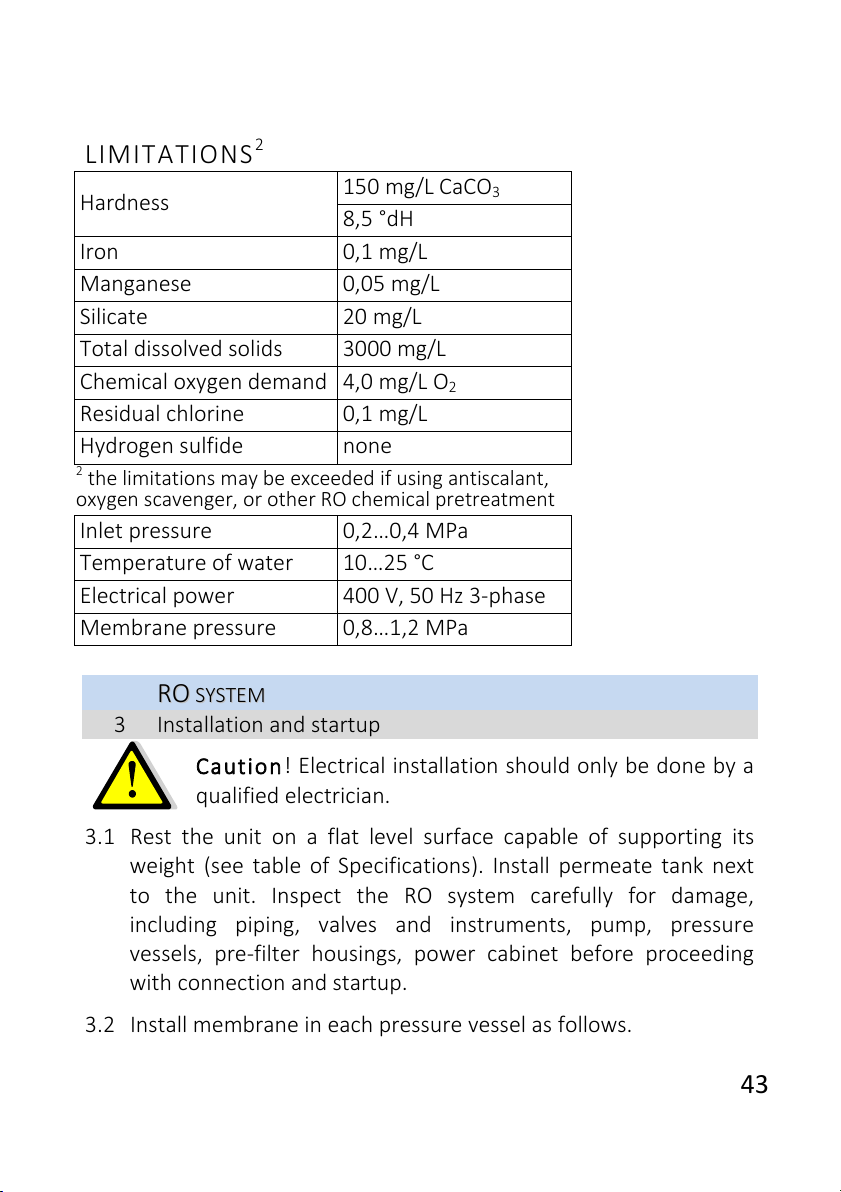

LIMITATIONS2

Hardness

150 mg/L CaCO3

8,5 °dH

Iron

0,1 mg/L

Manganese

0,05 mg/L

Silicate

20 mg/L

Total dissolved solids

3000 mg/L

Chemical oxygen demand

4,0 mg/L O2

Residual chlorine

0,1 mg/L

Hydrogen sulfide

none

2the limitations may be exceeded if using antiscalant,

oxygen scavenger, or other RO chemical pretreatment

Inlet pressure

0,2…0,4 MPa

Temperature of water

10…25 °C

Electrical power

400 V, 50 Hz 3-phase

Membrane pressure

0,8…1,2 MPa

R

RO

O

S

SY

YS

ST

TE

EM

M

3Installation and startup

Caution! Electrical installation should only be done by a

qualified electrician.

3.1 Rest the unit on a flat level surface capable of supporting its

weight (see table of Specifications). Install permeate tank next

to the unit. Inspect the RO system carefully for damage,

including piping, valves and instruments, pump, pressure

vessels, pre-filter housings, power cabinet before proceeding

with connection and startup.

3.2 Install membrane in each pressure vessel as follows.

44

Remove PVC piping with the pressure vessel ports. To remove

PVC pipes, take apart pipe unions at the pressure vessel ports. If

necessary, also loosen next closest downstream union to

remove the entire piping fragment leading to the vessel.

Remove the lid at the feed end of pressure vessel. First, remove

spiral retaining ring by pulling bent tab towards the center of

circle. If the pressure vessel lid is retained by half rims, remove

the fastening screws and pull half rims out of circular groove.

Take out the lid with membrane adapter.

Observe direction of arrow on pressure vessel when

installing membrane. Use glycerol or a similar RO-

compatible lubricant as needed. Avoid touching

membrane with hands. Use sterile rubber gloves when handling

membrane.

Make a cut in membrane packaging bag and insert membrane in

the pressure vessel brine seal last. Central tube of the

membrane has to mate with membrane adapter installed at the

concentrate end of pressure vessel. If necessary, remove the lid

at the concentrate end before installing the membrane.

If installing multiple membranes in one vessel, proceed with the

next membrane in a similar fashion, after installing membrane

connector in central tube of first membrane’s rear end. Couple

the second membrane with the connector, then push it forward

all the way in the pressure vessel.

After the membrane(s) are installed in the pressure vessel,

install the lid back in place. Put spiral retaining ring (or half rims)

in the groove, fasten half rims with screws. Re-assemble the RO

system in reverse order.

3.3 Connect raw water pipe from water main/pump to the entry

solenoid of the RO system. Recommended pipe size is at least

that of the connection port, plastic/composite pipe or rigid non-

kinking hose. Use appropriate fittings as necessary. Connect

45

drain tube or hose with drain outlet of the RO system and run it

to drain pipe. Ensure air gap at the end of drain line to prevent

backsiphonage. Connect tube or hose to permeate outlet and

extend it to permeate tank. Cut or bore an aperture at the top

of tank wall, install pipe gland and pull the permeate tube

through the gland (note: run permeate line to drain when

carrying out initial membrane rinse).

It is strongly recommended to use short runs of pipe or

hose the size of which matches or exceeds that of the

connection port.

3.4 Put the float switch inside permeate tank after moving ballast

the necessary length up the cord to provide enough level

difference between activated and deactivated position. After the

first filling of the tank, verify that the float switch activates and

deactivates in the right positions.

3.5 If the RO system has permeate rinse enabled, install the

necessary piping. If using service interruption by external signal

(microswitch), remove conductor connecting terminals 6 and 7

together on controller PCB. Then, run wire from microswitch

inside the controller housing and connect to the terminals. If

using antiscalant or other RO chemicals, refer to dosing pump’s

instruction booklet for information concerning the dosing pump.

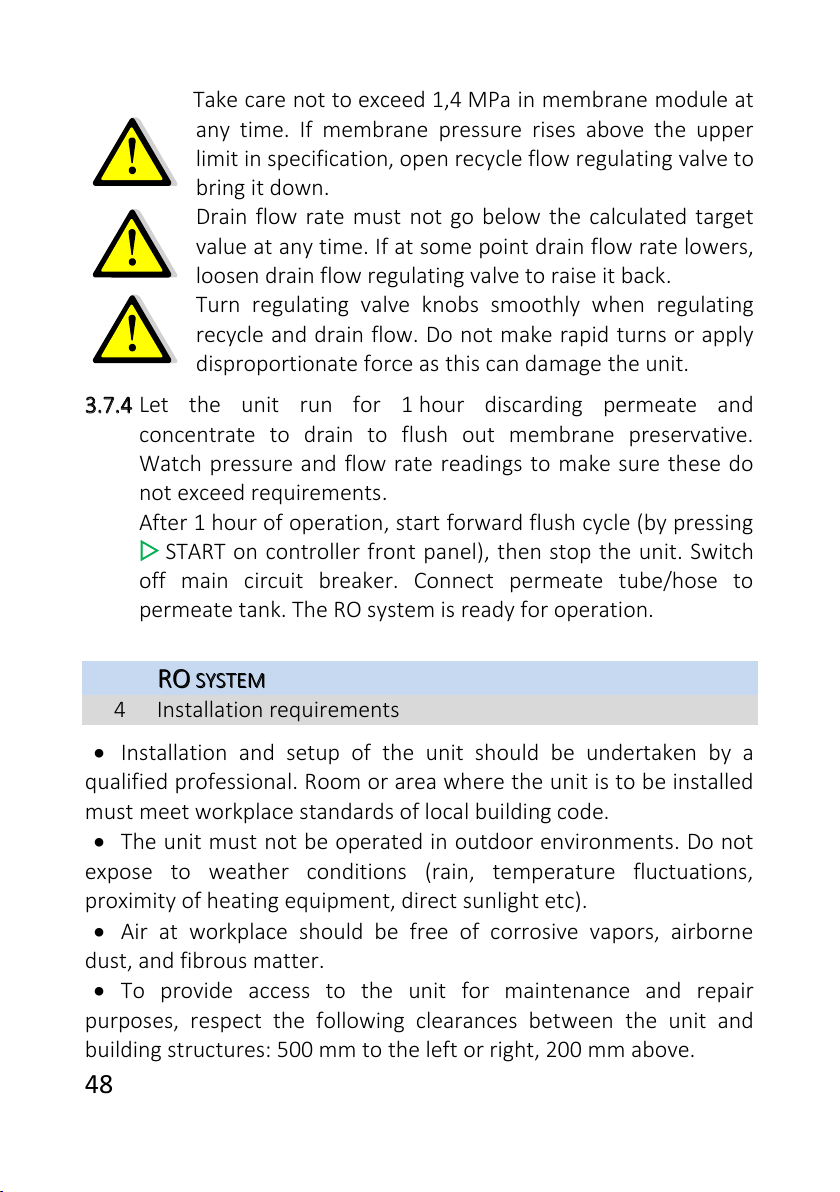

3.6 Run power to the RO system. Pull power cable inside power

cabinet of the RO system through a gland in cabinet wall.

Connect three phases and neutral to leftmost screw terminal

block in the bottom row. Switch on main circuit breaker in the

top row. Check protection relay status. Any LED signal except

green light on indicates some power supply fault. Green LED

indicates proper power supply. See pictures of the electrical panel.

46

Top DIN rail in the power cabinet

Bottom DIN rail in the power cabinet

Main circuit

breaker

Controller

circuit breaker

Protection

relay

Pump

contactor

3-phase

power

connection

47

3.7 Start up the system as follows :

3.7.1 Ensure recycle and drain flow regulating valves are fully open

before starting. Run the permeate tube to drain for the

duration of the first run of the RO system.

3.7.2 Switch on controller circuit breaker to start the RO system.

After the controller starts up and the unit starts to operate,

tighten drain regulating valve until drain rotameter reading

meets specification (see table of Specifications). Then, start

turning down recycle regulating valve. This will raise pressure in

the membrane module shown on pressure gauge. Stop when

recycle flow rate meets specification or pressure in the

membrane module reaches above upper limit (see table of

Specifications).

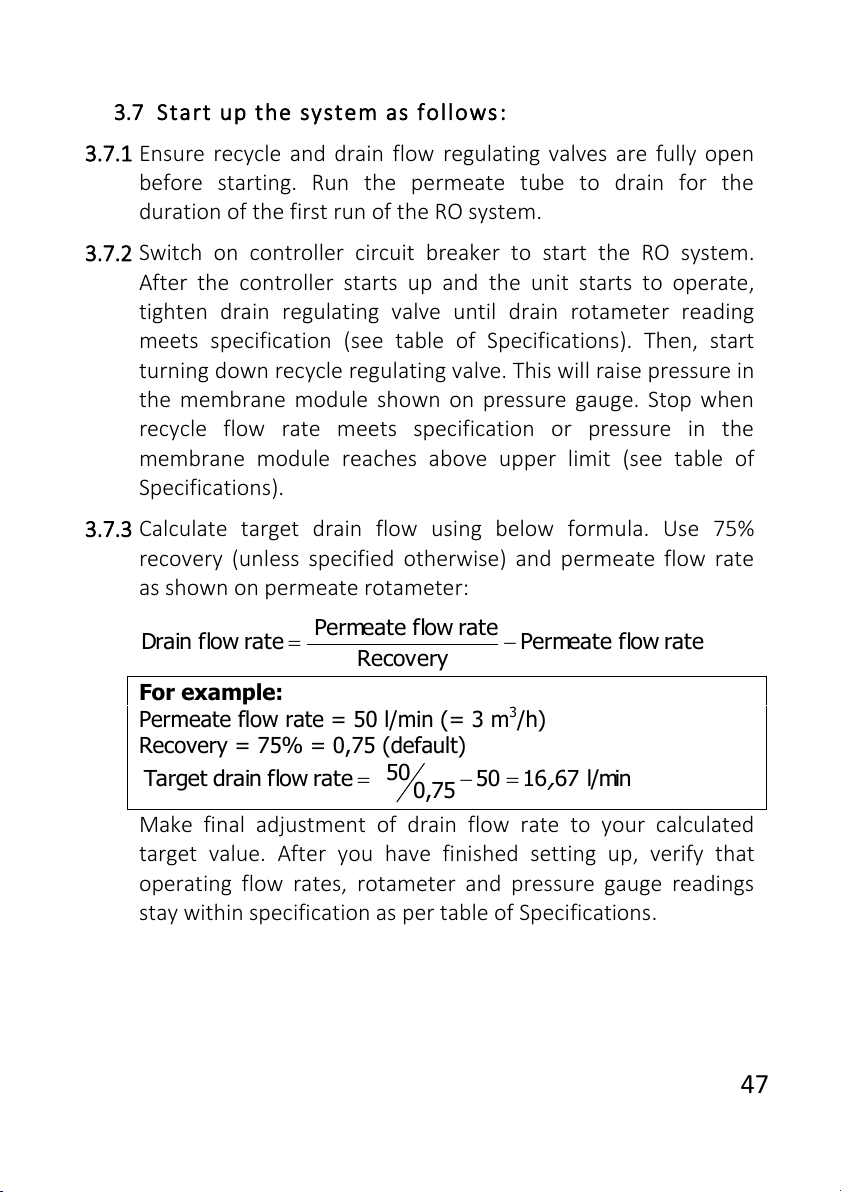

3.7.3 Calculate target drain flow using below formula. Use 75%

recovery (unless specified otherwise) and permeate flow rate

as shown on permeate rotameter:

rateflowPermeate

Recovery

rateflowPermeate

rateflowDrain

For example:

Permeate flow rate = 50 l/min (= 3 m3/h)

Recovery = 75% = 0,75 (default)

l/min671650

75,0

50

rateflowdrainTarget

,

Make final adjustment of drain flow rate to your calculated

target value. After you have finished setting up, verify that

operating flow rates, rotameter and pressure gauge readings

stay within specification as per table of Specifications.

48

Take care not to exceed 1,4 MPa in membrane module at

any time. If membrane pressure rises above the upper

limit in specification, open recycle flow regulating valve to

bring it down.

Drain flow rate must not go below the calculated target

value at any time. If at some point drain flow rate lowers,

loosen drain flow regulating valve to raise it back.

Turn regulating valve knobs smoothly when regulating

recycle and drain flow. Do not make rapid turns or apply

disproportionate force as this can damage the unit.

3.7.4 Let the unit run for 1 hour discarding permeate and

concentrate to drain to flush out membrane preservative.

Watch pressure and flow rate readings to make sure these do

not exceed requirements.

After 1 hour of operation, start forward flush cycle (by pressing

�START on controller front panel), then stop the unit. Switch

off main circuit breaker. Connect permeate tube/hose to

permeate tank. The RO system is ready for operation.

R

RO

OS

SY

YS

ST

TE

EM

M

4 Installation requirements

�Installation and setup of the unit should be undertaken by a

qualified professional. Room or area where the unit is to be installed

must meet workplace standards of local building code.

�The unit must not be operated in outdoor environments. Do not

expose to weather conditions (rain, temperature fluctuations,

proximity of heating equipment, direct sunlight etc).

�Air at workplace should be free of corrosive vapors, airborne

dust, and fibrous matter.

�To provide access to the unit for maintenance and repair

purposes, respect the following clearances between the unit and

building structures: 500 mm to the left or right, 200 mm above.

49

Electrical connections must comply with local electrical code.

Make sure to follow applicable grounding and insulation rules.

Supply, drain, and delivery pipework must comply with local

plumbing code and have sufficient flow capacity. Drain line of the

unit must be separated from floor drain with an air gap.

Construction material or inside lining of permeate tank must be

resistant to water corrosion (e. g. stainless steel, polypropylene).

Tank should be installed next to the unit.

Antiscalant pump suction line length should not exceed 1,5 m.

Refer to dosing pump’s manual to adjust pump’s settings if it has not

been factory configured.

R

RO

O

S

SY

YS

ST

TE

EM

M

5Operating requirements

5.1 Operator of the unit must strictly follow these guidelines and

general electrical safety precautions.

If power supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified

person in order to avoid hazard.

5.2 When operating the unit, ensure that pressure and flow rates

are within specification limits and that power supply is clean and

uninterrupted.

5.3 Perform the following at least once a month:

–verify that readings on pressure gauges and rotameters fall

within the specified range per requirements specification;

–verify tightness of hydraulic connections and integrity of parts.

5.4 In order to monitor performance of the RO machine, regularly

keep record of operation and write down parameter readings. Use

membrane manufacturer’s software tools for normalization to

control for fluctuations of pressure, temperature, and other

operating conditions.

50

5.5 Change polypropylene cartridge when it has clogged. Pressure

drop of 0,1 MPa or greater on the sediment filter indicates that filter

cartridge needs to be replaced as soon as possible.

5.6 Perform CIP or another suitable chemical cleaning protocol

when any of the following conditions are encountered:

–normalized permeate flow rate drops 10-15% of its initial value;

–normalized conductivity of permeate increases 10-15% of initial

value, raw water conductivity remaining at the same level;

–normalized pressure drop along the membrane module

increases 10-15% of its initial value.

5.7 After installing freshly cleaned membrane, perform 1 hour

rinse discarding all permeate and concentrate. If chemical cleaning

fails to restore normalized flow or rejection to design specifications,

membrane element is irreparably fouled and has to be replaced.

5.8 To prevent microbial contamination, the unit should be

operated for at least 1 hour a day. In case 48 hours or longer

shutdown is to occur, membrane should be treated with preservative

solution. Preservative treatment is accomplished by circulating 1%

sodium metabisulfite solution through the membrane module for

30 minutes or by preparing metabisulfite solution of the above

strength in the module. Before resuming operation of a machine that

had been treated with preservative, rinse the membrane.

Do not use raw water with over 0,1 mg/L of free chlorine

without pre-treatment with activated carbon or other means

of dechlorination. Chlorine will destroy the membrane.

5.9 To replace sediment filter cartridge proceed as follows:

–remove the power from the unit;

–shut off water supply and relieve pressure;

–screw off filter bowl and remove it, taking care not to spill

water on parts of the unit;

51

–remove spent cartridge from the bowl, place a clean one inside

and screw the bowl back on.

Do not torque over 2 kgf×m

when tightening bowl.

5.10 To replace membrane element proceed as follows:

–remove the power from the unit;

–shut off water supply and relieve pressure;

–disconnect feed, permeate, and concentrate tube connections

at membrane module outlets;

–remove caps from the pressure vessel;

–push the membrane element from the feed end towards the

discharge end (in the direction of the arrow). Extract the membrane

element by pulling it at the discharge end of the vessel;

–install new membrane element, observing flow direction as

indicated by the arrow;

–fasten the caps and re-connect tubes back to the vessel.

Do not perform any maintenance, repair, cleaning, moving

the unit or ancillary units (permeate tank, media filters etc),

when the unit is connected to power and water supply.

Do not subject pressure vessel to mechanical impact

(shocks, static load etc).

The manufacturer shall not be held liable for any damages

incurred by the owner of the unit or any third party due to

failure to adhere to the safety precautions or installation

guidelines herein.

52

R

RO

O

S

SY

YS

ST

TE

EM

M

6Shipping and storage requirements

The unit must be stored indoors. Ambient air quality must

meet workplace standards.

Carry out preservative treatment of membrane elements

when preparing for an extended downtime.

The RO machine in its original packaging can be shipped by all

types of air, sea or ground transport.

During transportation, the unit must be protected from

exposure to low temperatures and jolts/vibration.

53

R

RO

O

S

SY

YS

ST

TE

EM

M

7Troubleshooting

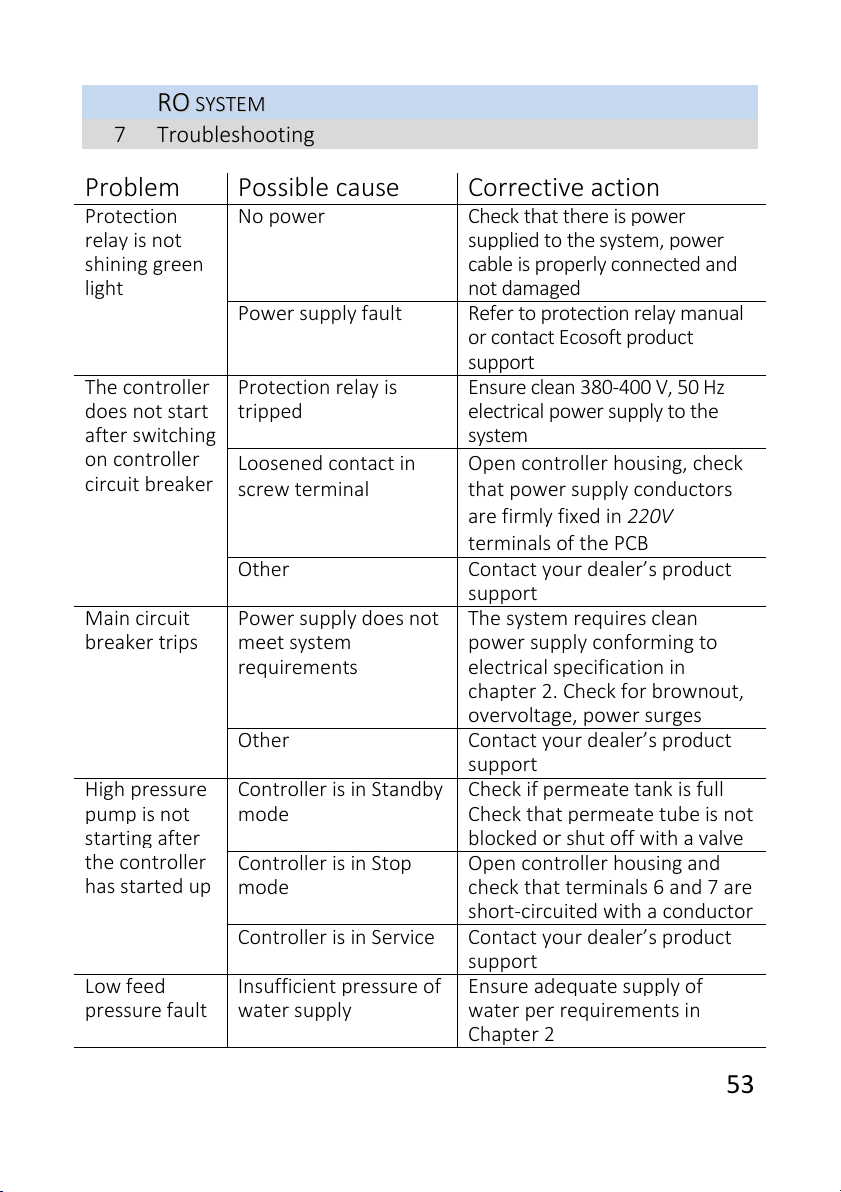

Problem

Possible cause

Corrective action

Protection

relay is not

shining green

light

No power

Check that there is power

supplied to the system, power

cable is properly connected and

not damaged

Power supply fault

Refer to protection relay manual

or contact Ecosoft product

support

The controller

does not start

after switching

on controller

circuit breaker

Protection relay is

tripped

Ensure clean 380-400 V, 50 Hz

electrical power supply to the

system

Loosened contact in

screw terminal

Open controller housing, check

that power supply conductors

are firmly fixed in 220V

terminals of the PCB

Other

Contact your dealer’s product

support

Main circuit

breaker trips

Power supply does not

meet system

requirements

The system requires clean

power supply conforming to

electrical specification in

chapter 2. Check for brownout,

overvoltage, power surges

Other

Contact your dealer’s product

support

High pressure

pump is not

starting after

the controller

has started up

Controller is in Standby

mode

Check if permeate tank is full

Check that permeate tube is not

blocked or shut off with a valve

Controller is in Stop

mode

Open controller housing and

check that terminals 6 and 7 are

short-circuited with a conductor

Controller is in Service

Contact your dealer’s product

support

Low feed

pressure fault

Insufficient pressure of

water supply

Ensure adequate supply of

water per requirements in

Chapter 2

54

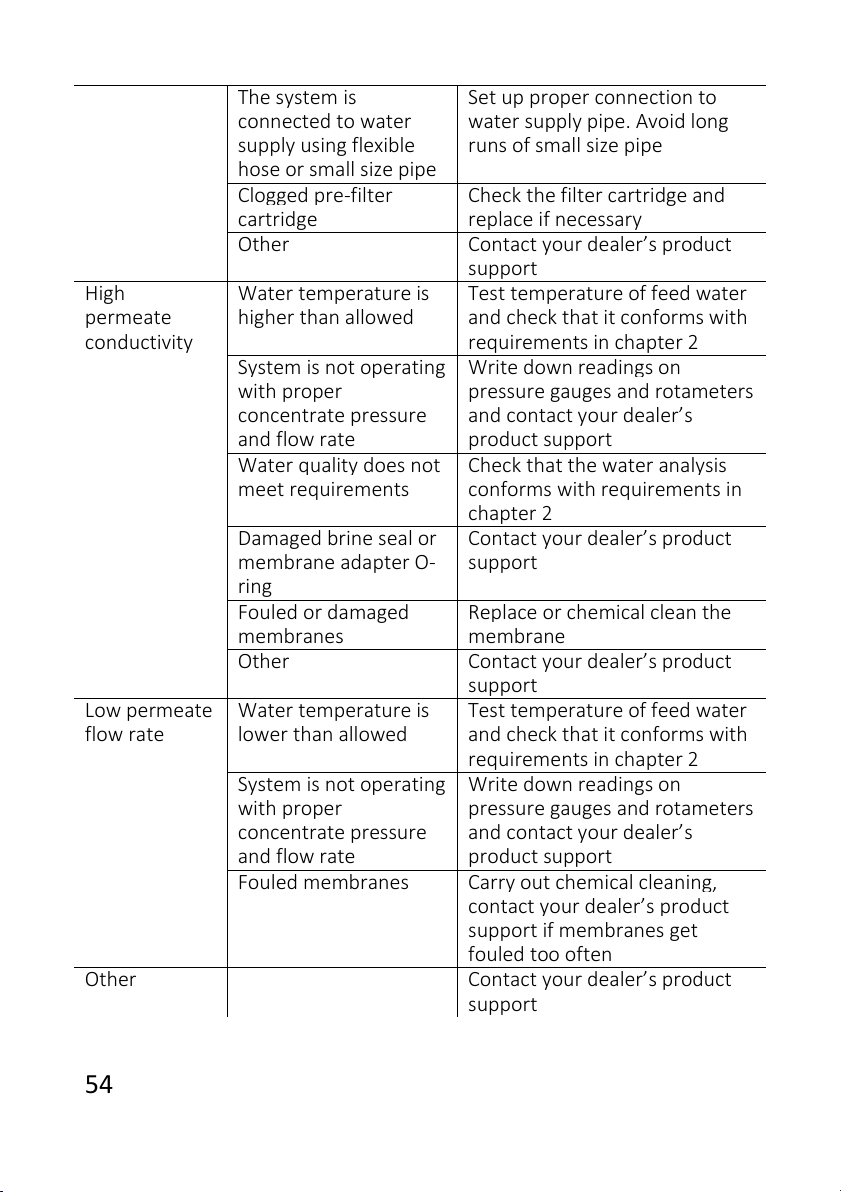

The system is

connected to water

supply using flexible

hose or small size pipe

Set up proper connection to

water supply pipe. Avoid long

runs of small size pipe

Clogged pre-filter

cartridge

Check the filter cartridge and

replace if necessary

Other

Contact your dealer’s product

support

High

permeate

conductivity

Water temperature is

higher than allowed

Test temperature of feed water

and check that it conforms with

requirements in chapter 2

System is not operating

with proper

concentrate pressure

and flow rate

Write down readings on

pressure gauges and rotameters

and contact your dealer’s

product support

Water quality does not

meet requirements

Check that the water analysis

conforms with requirements in

chapter 2

Damaged brine seal or

membrane adapter O-

ring

Contact your dealer’s product

support

Fouled or damaged

membranes

Replace or chemical clean the

membrane

Other

Contact your dealer’s product

support

Low permeate

flow rate

Water temperature is

lower than allowed

Test temperature of feed water

and check that it conforms with

requirements in chapter 2

System is not operating

with proper

concentrate pressure

and flow rate

Write down readings on

pressure gauges and rotameters

and contact your dealer’s

product support

Fouled membranes

Carry out chemical cleaning,

contact your dealer’s product

support if membranes get

fouled too often

Other

Contact your dealer’s product

support

55

C

CO

ON

NT

TR

RO

OL

LL

LE

ER

R

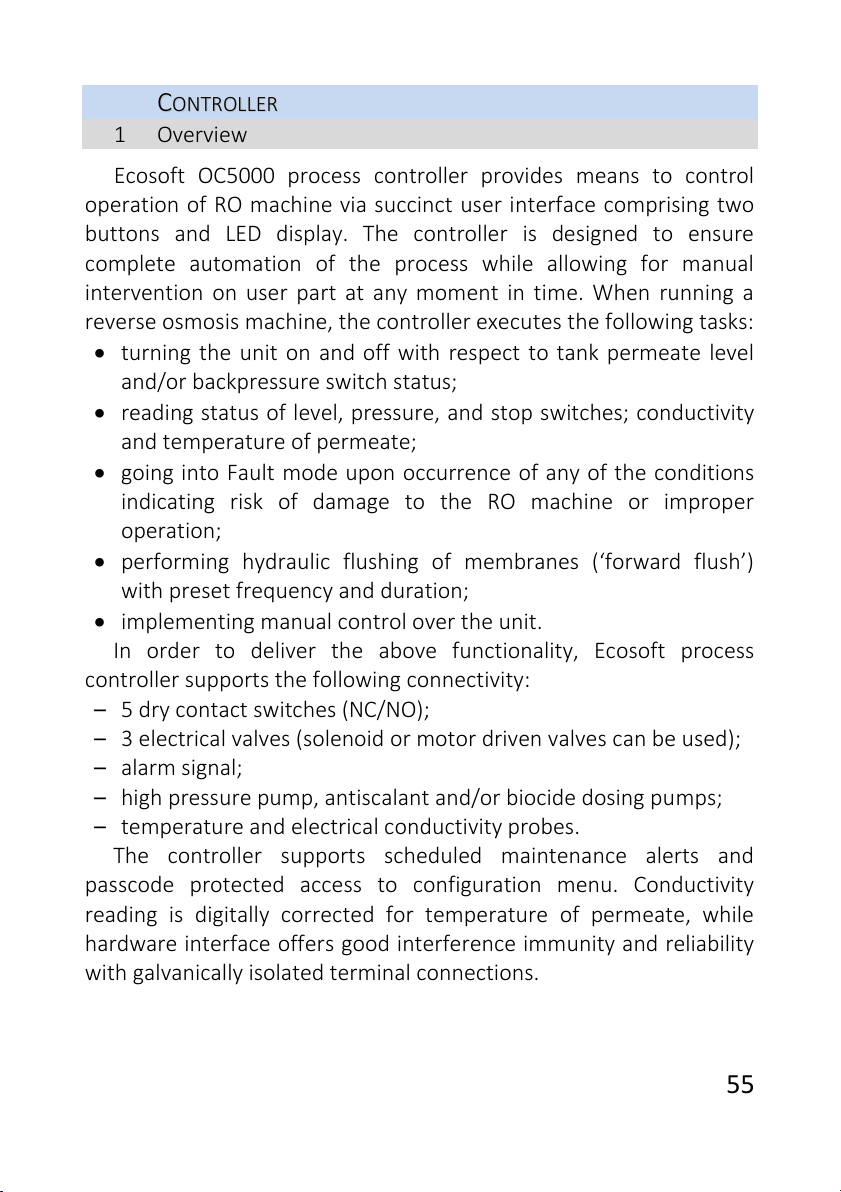

1Overview

Ecosoft OC5000 process controller provides means to control

operation of RO machine via succinct user interface comprising two

buttons and LED display. The controller is designed to ensure

complete automation of the process while allowing for manual

intervention on user part at any moment in time. When running a

reverse osmosis machine, the controller executes the following tasks:

turning the unit on and off with respect to tank permeate level

and/or backpressure switch status;

reading status of level, pressure, and stop switches; conductivity

and temperature of permeate;

going into Fault mode upon occurrence of any of the conditions

indicating risk of damage to the RO machine or improper

operation;

performing hydraulic flushing of membranes (‘forward flush’)

with preset frequency and duration;

implementing manual control over the unit.

In order to deliver the above functionality, Ecosoft process

controller supports the following connectivity:

–5 dry contact switches (NC/NO);

–3 electrical valves (solenoid or motor driven valves can be used);

–alarm signal;

–high pressure pump, antiscalant and/or biocide dosing pumps;

–temperature and electrical conductivity probes.

The controller supports scheduled maintenance alerts and

passcode protected access to configuration menu. Conductivity

reading is digitally corrected for temperature of permeate, while

hardware interface offers good interference immunity and reliability

with galvanically isolated terminal connections.

56

C

CO

ON

NT

TR

RO

OL

LL

LE

ER

R

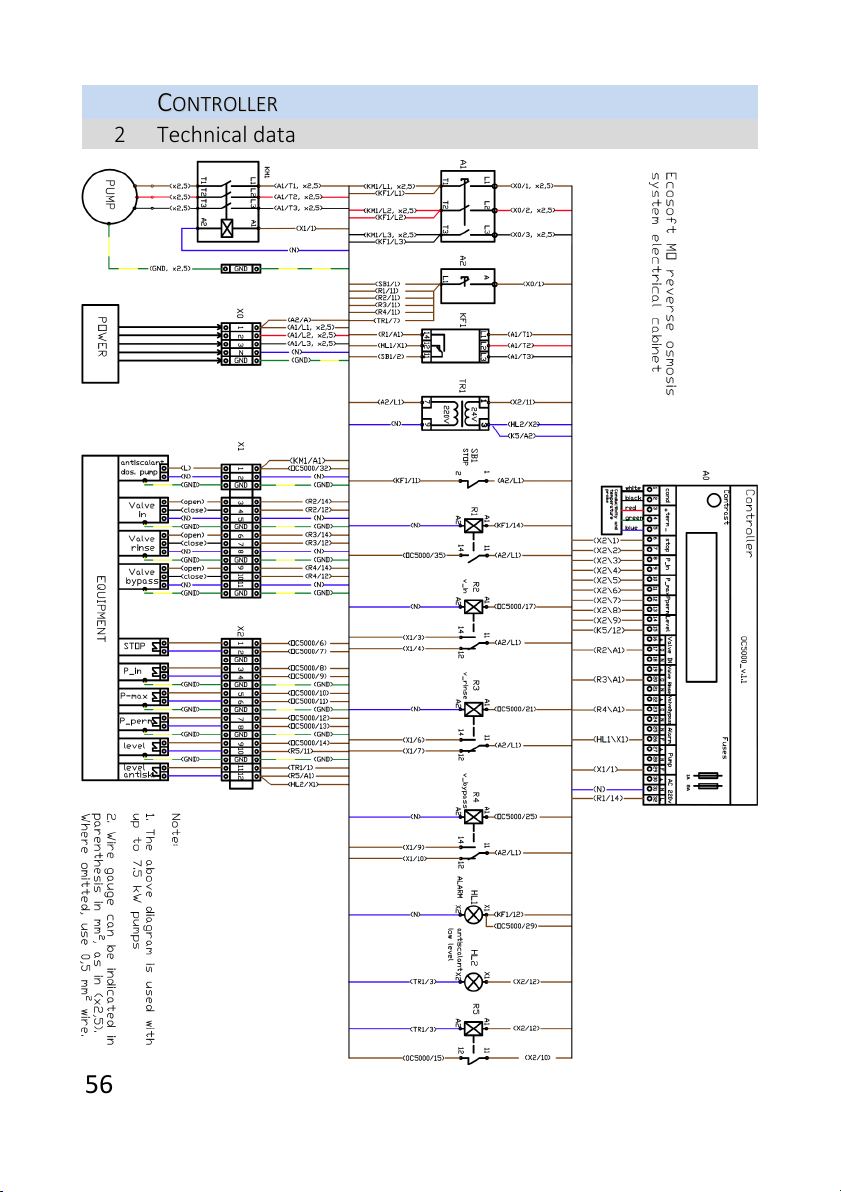

2Technical data

This manual suits for next models

5

Table of contents

Other Ecosoft Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Interactive Instruments

Interactive Instruments Jet Stream 500 instruction manual

NTN

NTN MD10 Series instruction manual

IRO

IRO Stella 290 operating instructions

GREER Company

GREER Company MicroGuard RCI 510 Operation

Synventive

Synventive 16SVH installation guide

Idex

Idex PULSAFEEDER DGF1 operating instructions