PostProcess Technologies, Inc. • www.postprocess.com • REV A | page 4

List of Figures

Figure 1. Location of Master Power Switch 9

Figure 2. Master Power Switch “ON” 9

Figure 3. Power Connector 9

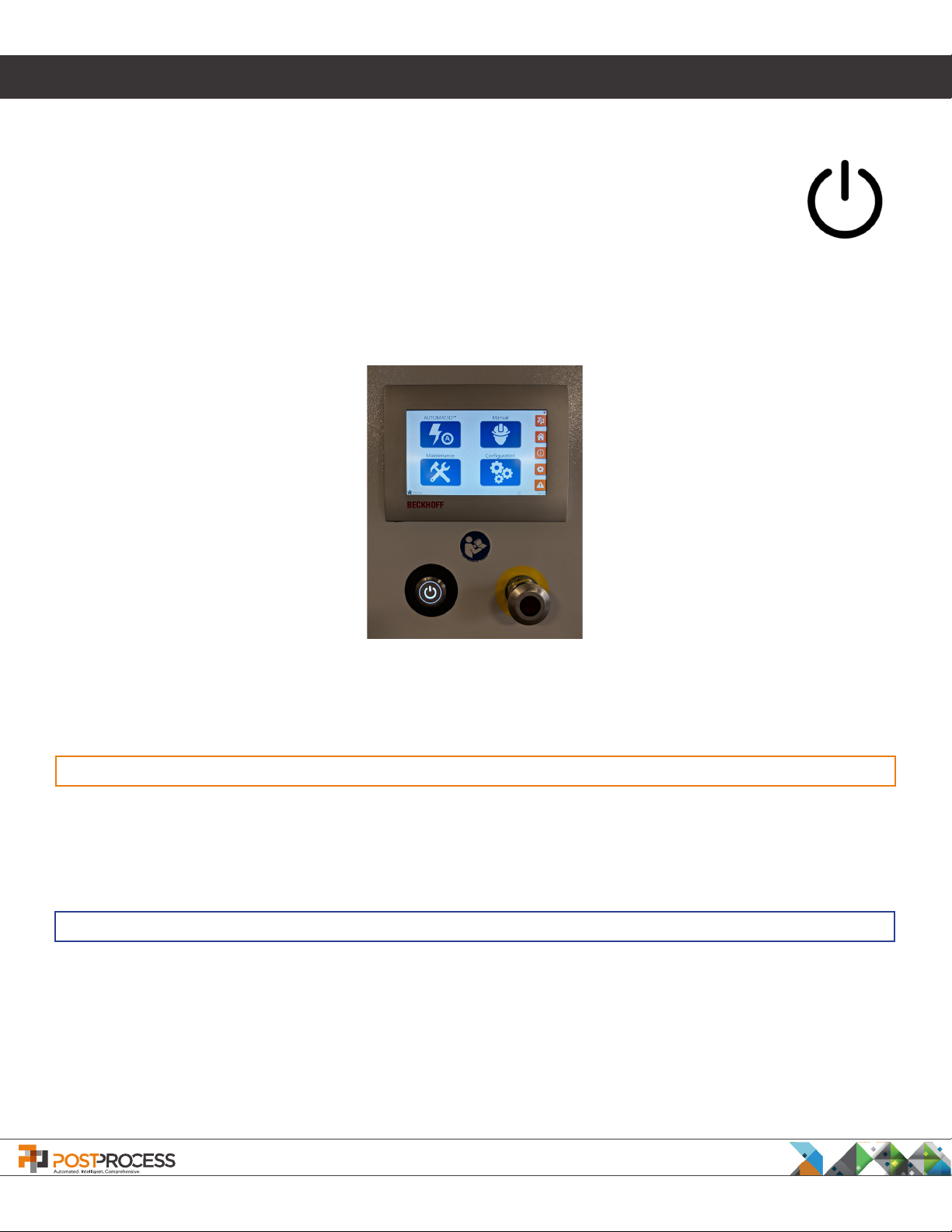

Figure 4. Controller Screen, Power Button, and Emergency Stop Button 10

Figure 5. Automatic Operation Screen - Setup/Start 11

Figure 6. Auto Setup Screen 12

Figure 7. Hardware Status 13

Figure 8. System Information Screen 14

Figure 9. Features Enabling Screen 14

Figure 10. Auto-Temperature Conguration Screen 15

Figure 11. Recipe Save As Screen 16

Figure 12. Recipe Overwrite Warning Screen 17

Figure 13. Enter Recipe Name Screen 17

Figure 14. Recipe Selection Screen 17

Figure 15. Auto Run Screen 18

Figure 16. Auto Run Warning Screen 19

Figure 17. Home Screen 20

Figure 18. Manual Operations Screen 20

Figure 19. Manual Motion Screen 22

Figure 20. Filter Screen Maintenance Screen 23

Figure 21. pH Sensor 25

Figure 22. pH Sensor Maintenance Screen 25

Figure 23. Dosatron Maintenance Screen 26

Figure 24. Dosatrons 27

Figure 25. Alarms and Warnings Screen 28

Figure 26. Dosatrons Conguration 30

Figure 27. Caster with Ratchet 32

Figure 28. Conguration Screen 35

Figure 29. Level 1 Agitation Valve Conguration Screen 35

Figure 30. Agitation Valve Conguration Screen 36

Figure 31. Segments Screen 36

Figure 32. Run Time Screen 37

Figure 33. Taper Screen 37

Figure 34. Level 0 Screen 38

Figure 35. System Conguration Screen 38

Figure 36. Auto-Temperature Conguration Screen 39

Figure 37. Heater Conguration Screen 40

Figure 38. Heater Conguration Screen 2 41

Figure 39. Over Temperature Conguration Screen 41