2

CASH VALVES™ TYPE LTC CRYOGENIC REVERSE ACTING TEMPERATURE REGULATOR

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS

OPERATING INSTRUCTIONS

Temperature Adjustment

The temperature regulator can be set to

cut-off the flow of gas at any temperature

from 0 to -40°F (-17 to -40°C) temperature

range. To adjust the cut-off temperature turn

the temperature adjustment wheel (10) in a

counter-clockwise direction to set the regulator

at a higher temperature. Turn the wheel in a

clockwise direction to set the regulator at a

lower temperature. The wheel is mounted on

ball bearings to eliminate friction and ensure

easy operation.

MAINTENANCE INSTRUCTION

CAUTION

Before attempting to replace any spare parts,

be sure to shut off all pressure connections to

the valve. With the valve closed however, system

pressure could still be locked between the shut

off valve and the inlet and/or outlet sides of the

regulator. Before proceeding with any valve

service, be certain to relieve the pressure from

both sides of the regulator.

When properly applied and correctly installed

the Type LTC Temperature Regulator should

require very little attention or maintenance.

However, the Type LTC, like every mechanical

device, deserves some care to ensure

continued dependability and to protect the

long service life for which it was designed.

When attention is required use only genuine

Cash Valve replacement parts.

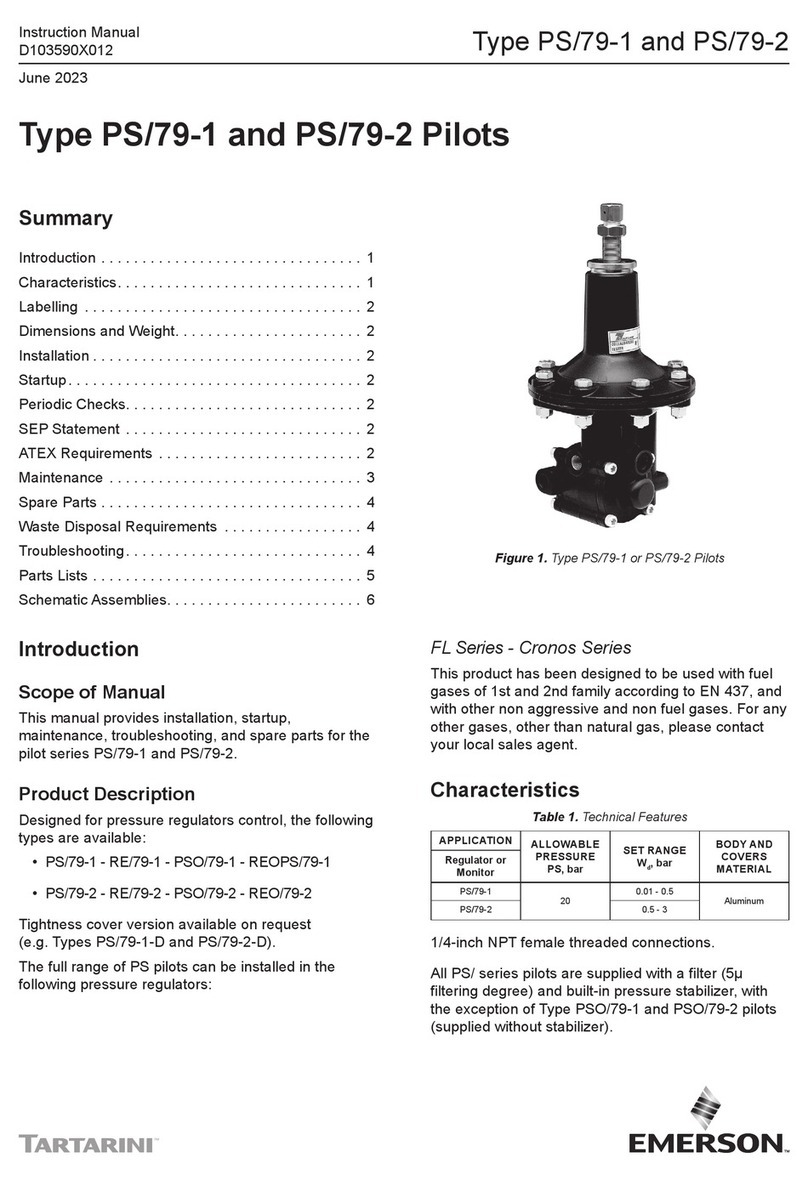

Refer to the Type LTC Regulator cut

away view for parts identification during

maintenance procedures.

Servicing The Valve Pull Rod Packing (16)

The valve yoke nut should be kept tight. Should

it become necessary to replace the pull rod

packing proceed as follows:

1. Remove the yoke assembly (9) from

the valve body (19) by removing the

yoke nut (13).

2. Remove the spacer (14), female adapter (15),

the two worn packing seals (16), and the

male adapter (17).

3. Replace the packing seals and reassemble

in reverse order. Tighten the yoke

nut securely.

Servicing the Thermal System

The thermal system used on the Type LTC

Temperature Regulator is serviced only as

a complete assembly except for the bulb

bushing (2) and the bulb gasket (3). The

thermal system is set at the factory to operate

only at the temperature range stamped on

the nameplate which is affixed to the bellows

housing. If it is necessary to install a new

thermal system, the procedure listed below

should be followed.

1. Shut off the vaporizer system.

2. Completely loosen the bushing nut (5), then

take the bulb (1) out of the bulb bushing (2).

3. Turn the temperature adjustment wheel (10)

to its lowest position (counter-clockwise).

4. Remove the screws (8) retaining the bellows

housing (7) to the yoke (9), then lift the

housing from the yoke.

Note: The bellows housing (7) may be under slight

spring tension. Exercise care when removing

the housing.

5. Position the new bellows housing (7) on top

of the spring, aligning the screw holes in the

housing with those in the yoke.

6. Using three 10-32 x 1" screws inserted

in alternate holes in the bellows flange,

tighten the screws evenly to draw the

bellows housing (7) down until it contacts

the yoke (9). Install the shorter standard

screws (8) in the remaining holes, then

replace the 10-32 x 1" slave screws with the

standard screws.

Note: An alternative method of installing the new

bellows housing to the yoke would be to cool the

thermal bulb to approximately -40°F (-40°C) allowing

the bellows to contract and thereby permitting the

standard screws to be installed.

7. Install the new thermal system bulb (1) in

its original position and lighten the bulb

bushing nut (5).

8. Turn the temperature adjustment wheel

clockwise to its original position or

approximately .675 inches above the

lowest position.

INSTALLATION INSTRUCTIONS

Type LTC Regulator is to be installed between

the vaporizer and the service line (or final line)

regulator. The valve should be installed in a

horizontal position with the bellows housing

upright. For other installation requirements

consult the factory. For ease of operation and

maintenance, it is suggested that manual

shut-off valves be installed upstream and

downstream from the valve. Before installing

the valve, the piping should be thoroughly

flushed out to remove any foreign material.

Install the valve so that the arrow cast on the

valve body points in the direction of flow. Use

a compatible sealant on the male pipe threads

and do not over tighten the valve connections.

Exercise care when tightening the unions to

ensure that the gaskets located in the union

ends are properly positioned.

Bulb Installation

Install the thermostatic bulb at a point that is

downstream from the vaporizer but upstream

from the temperature regulator. When a

thermometer is to be installed in the line, it

should be placed directly after the bulb in the

pipe line or at the same level as the bulb in a

tank. The standard bulb is shown in the cut

away view of the valve. A copper well is strongly

recommended for each cryogenic temperature

regulator installation, both for the protection

of tho bulb and to allow for the removal of

the capillary bulb without depressurizing

the system.

To install the bulb, remove the bulb bushing

from the bulb. Insert the bulb and fasten

by tightening the nut onto the bushing. The

preferred bulb installation position is with the

end of the bulb below horizontal. Although the

horizontal position is permissible, care must

be exercised to NEVER INSTALL THE BULB

WITH THE END OF THE BULB ABOVE THE

BULB FLANGE.

Note: The flexible armored capillary tubing connecting

the bulb and valve must not be cut, kinked, mashed

or twisted. II may, however, be bent on a 4" radius

or larger. During installation the tubing can be

fastened permanently to a rigid location, however,

never connect the capillary tubing to steam pipes,

cold water lines or other locations where the tubing

would be subject to extreme temperatures. It is

recommended that a single coil ot tubing be made

next to the regulator to absorb vibrations occurring in

the pipe lines.