WattMaster OE230 User manual

FILENAME

DATE: B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

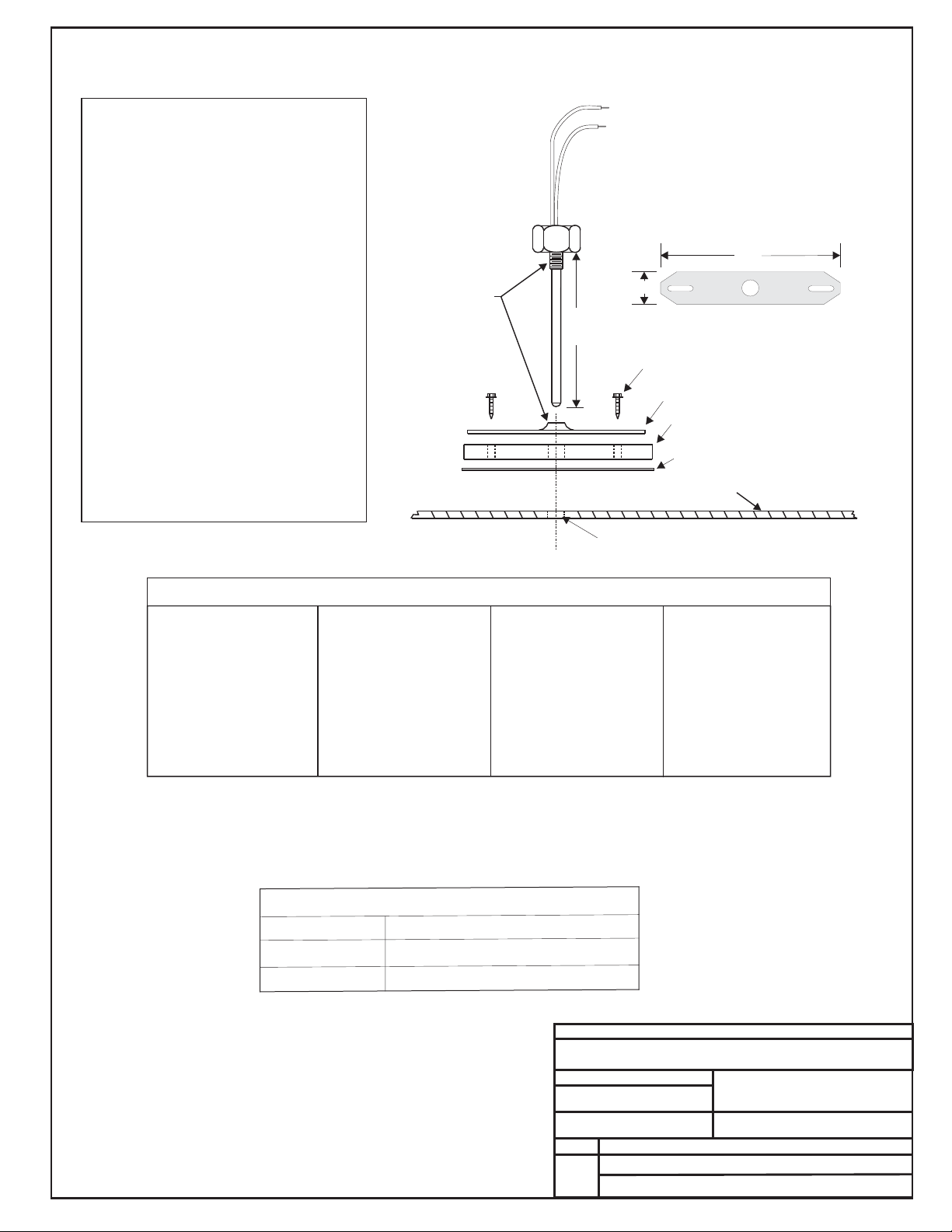

Duct Temperature Sensor

1

JOB NAME

07/13/15

G-DUCSENS1.CDR

OE230 & OE231

Duct Temperature Sensors

OE230 (6" Probe) & OE231 (12" Probe)

Mounting Plate

Gasket

Adhesive Backed Drill Guide

Mounting Template

11-1/2" (OE231)

5-1/2" (OE230) Mounting Plate

4.0"

3/4"

1/4" Hex Head Sheet Metal Screws

Thread

Together

Duct Work

Drill 3/8” Hole In Ductwork For Probe

Leads Are Non-polarized.

Butt Splice Leads To 24 Gauge

Wire Minimum. Connect Leads

To "Analog In" And "Ground"

At Controller.

Notes:

1.)All Wiring To Be In Accordance With

Local And National Electrical Codes

And Specifications.

Temperature Sensor Resistance/Voltage Chart

Temp Resistance* Voltage

F Ohms @ Input*

-10.............93333........4.620

-5...............80531........4.550

0 ...............69822 ........4.474

5 ...............60552 ........4.390

10..............52500........4.297

15..............45902........4.200

20..............40147........4.095

25..............35165........3.982

30..............30805........3.862

35..............27140........3.737

40..............23874........3.605

°

Temp Resistance* Voltage

F Ohms @ Input*°

45..............21094........3.470

50..............18655........3.330

52..............17799........3.275

54..............16956........3.217

56..............16164........3.160

58..............15385........3.100

60..............14681........3.042

62..............14014........2.985

64..............13382........2.927

66..............12758........2.867

68..............12191........2.810

Temp Resistance* Voltage

F Ohms @ Input*°

69..............11906 ........2.780

70..............11652 ........2.752

71..............11379 ........2.722

72..............11136 ........2.695

73..............10878........2.665

74..............10625........2.635

75..............10398........2.607

76..............10158........2.570

78..............9711 ..........2.520

80..............9302..........2.465

82..............8893..........2.407

Temp Resistance* Voltage

F Ohms @ Input*

84..............8514..........2.352

86..............8153..........2.297

88..............7805..........2.242

90..............7472..........2.187

95..............6716..........2.055

100............6047..........1.927

105............5453..........1.805

110 ............4923 ..........1.687

115 ............4449 ..........1.575

120............4030..........1.469

°

125............3656..........1.369

*Chart Notes:

1. Use the resistance column to check the thermistor sensor while disconnected from the controllers (not powered).

2. Use the voltage column to check sensors while connected to powered controllers. Read voltage with meter set on DC volts.

Place the "-"(minus) lead on GND terminal and the "+"(plus) lead on the sensor input terminal being investigated. If the voltage

is above 5.08 VDC, the sensor or wiring is "open." If the voltage is less than 0.05 VDC, the sensor or wiring is shorted.

The Duct Sensor Is Used For Sensing Supply

Or Return Air Temperatures. Location Of The

Sensors Is Very Important In Order To Obtain

Accurate Temperature Readings. The

Following Recommendations Should Be

Followed:

When Used As A Supply Air Sensor The

Sensor Should Be Mounted In The Supply Air

Duct As Close To The HVAC Unit As Possible

And Upstream Of The Bypass Damper (If

Used) For Best Results. For Best Accuracy,

Apply Insulation On The Outside Of The

Ductwork Over The Sensor. This Will Help

Thermal Gradients From Affecting The Sensor.

Supply Air

Return Air

When Used As A Return Air Sensor The

Sensor Should Be Mounted In The Return Air

Duct As Close To The HVAC Unit As Possible

And Upstream Of The Bypass Damper (If

Used) For Best Results. For Best Accuracy,

Apply Insulation On The Outside Of The

Ductwork Over The Sensor. This Will Help

Thermal Gradients From Affecting The Sensor.

See The Systems Installation And Operation

Manual For Other Design Considerations And

Recommendations Regarding Duct

Temperature Sensor Location.

Caution!

Technical Specifications

Sensor Element:

Type III Thermistor 10k ohm @ 77ºF

Accuracy:

±0.4º F between 40º F to 95º F

Range:

-30º F to 150º F

FILENAME

DATE: B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

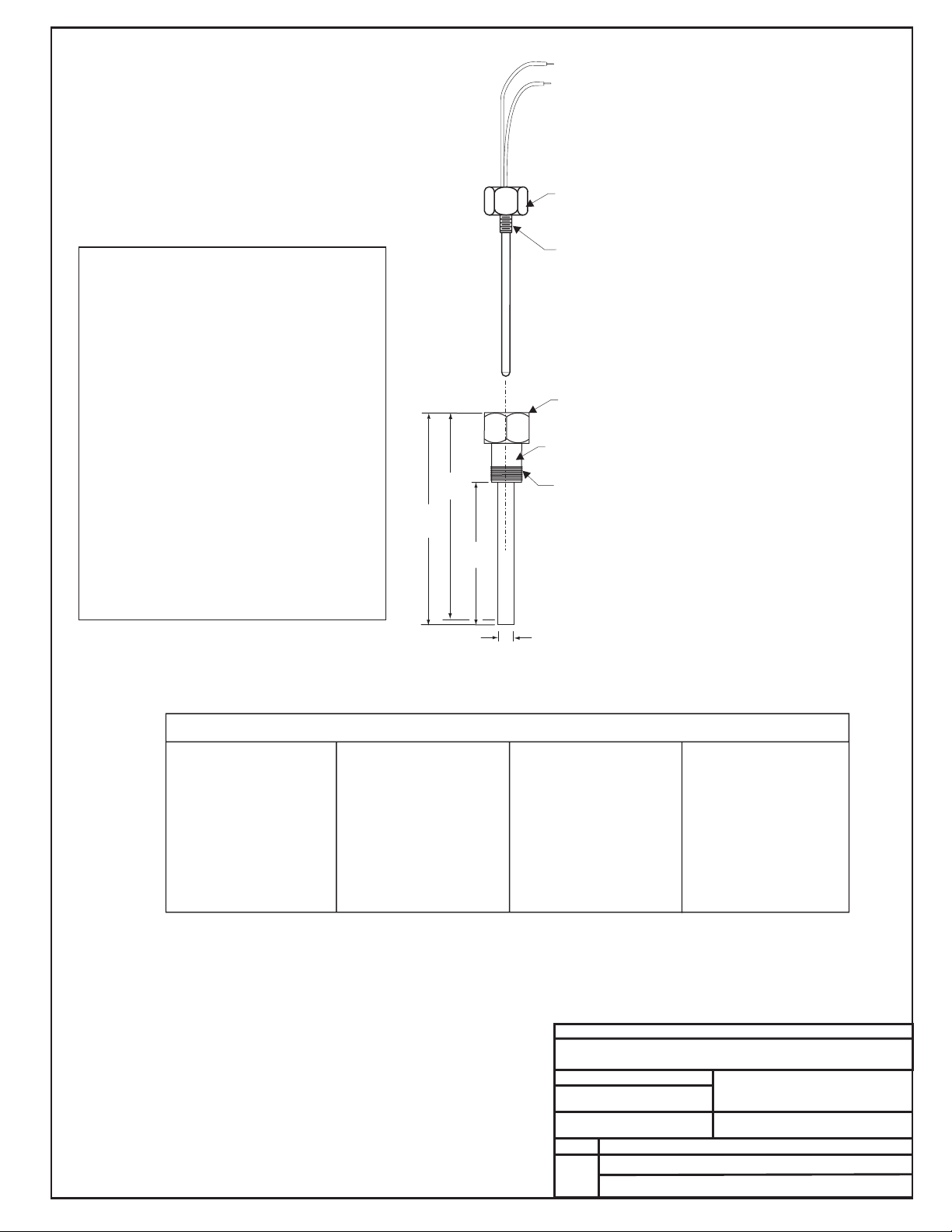

Water Temperature Sensor Thermowell

1

JOB NAME

07/09/04

G-OE291-T-Well.CDR

OE291

OE291 Thermowell Assembly

Using OE230 Temperature Sensor

Notes:

1.)All Wiring To Be In Accordance With

Local And National Electrical Codes

And Specifications.

Temperature Sensor Resistance/Voltage Chart

Temp Resistance* Voltage

F Ohms @ Input*

-10.............93333........4.620

-5...............80531........4.550

0 ...............69822 ........4.474

5 ...............60552 ........4.390

10..............52500........4.297

15..............45902........4.200

20..............40147........4.095

25..............35165........3.982

30..............30805........3.862

35..............27140........3.737

40..............23874........3.605

°

Temp Resistance* Voltage

F Ohms @ Input*°

45..............21094........3.470

50..............18655........3.330

52..............17799........3.275

54..............16956........3.217

56..............16164........3.160

58..............15385........3.100

60..............14681........3.042

62..............14014........2.985

64..............13382........2.927

66..............12758........2.867

68..............12191........2.810

Temp Resistance* Voltage

F Ohms @ Input*°

69..............11906 ........2.780

70..............11652 ........2.752

71..............11379 ........2.722

72..............11136 ........2.695

73..............10878........2.665

74..............10625........2.635

75..............10398........2.607

76..............10158........2.570

78..............9711 ..........2.520

80..............9302..........2.465

82..............8893..........2.407

Temp Resistance* Voltage

F Ohms @ Input*

84..............8514..........2.352

86..............8153..........2.297

88..............7805..........2.242

90..............7472..........2.187

95..............6716..........2.055

100............6047..........1.927

105............5453..........1.805

110 ............4923 ..........1.687

115 ............4449 ..........1.575

120............4030..........1.469

°

125............3656..........1.369

*Chart Notes:

1. Use the resistance column to check the thermistor sensor while disconnected from the controllers (not powered).

2. Use the voltage column to check sensors while connected to powered controllers. Read voltage with meter set on DC volts.

Place the "-"(minus) lead on GND terminal and the "+"(plus) lead on the sensor input terminal being investigated. If the voltage

is above 5.08 VDC, the sensor or wiring is "open." If the voltage is less than 0.05 VDC, the sensor or wiring is shorted.

The Duct Sensor Is Used For Sensing Entering Or

Leaving Water Temperatures. Location Of The

Sensors Is Very Important In Order To Obtain

Accurate Temperature Readings. The Following

Recommendations Should Be Followed:

When Used As A Supply Water Temperature

Sensor The Sensor Should Be Mounted In The

Supply Water Piping As Close To The Water Coil

As Possible For Best Accuracy, Apply Insulation

On The Outside Of The Piping Over The Sensor.

This Will Help Thermal Gradients From Affecting

The Sensor.

Entering Water

Leaving Water

When Used As A Leaving Water Temperature

Sensor The Sensor Should Be Mounted In The

Return Piping As Close To The Water Coil Outlet

As Possible. For Best Accuracy, Apply Insulation

On The Outside Of The Piping Over The Sensor.

This Will Help Thermal Gradients From Affecting

The Sensor.

See The Systems Installation And Operation

Manual For Other Design Considerations And

Recommendations Regarding Water Temperature

Caution!

1/8 -27 NPSM Internal Thread"

1/8 -27 NPT External Thread"

1/2" NPT External Thread

3.25"

0.5"

5.13"

4.94

OE291 Stainless Steel Thermowell

Leads Are Non-polarized.

Butt Splice Leads To 24

Gauge Wire Minimum.

Connect Leads To

"Analog In" And "Ground"

At Controller.

The OE230 Duct Sensor Threads Into

The OE291 Stainless Steel Thermowell.

The OE291 Thermowell Threads Into A

1/2” FPT Elbow or Tee in the Water Piping

of the Water Coil at Which You wish to

Measure the Water Temperature. The

Pipe must be a minimum of 4” Diameter

or an Extended Tee and Bushing

Configuration Must be Used to

Accommodate the Length of the

Thermowell Assembly.

"

OE230 Temperature Sensor

(Ordered Separately)

CONTROLS

FILENAME

DATE: 07/09/04 B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

G-OE233-W-TempSnsr1a.CDR

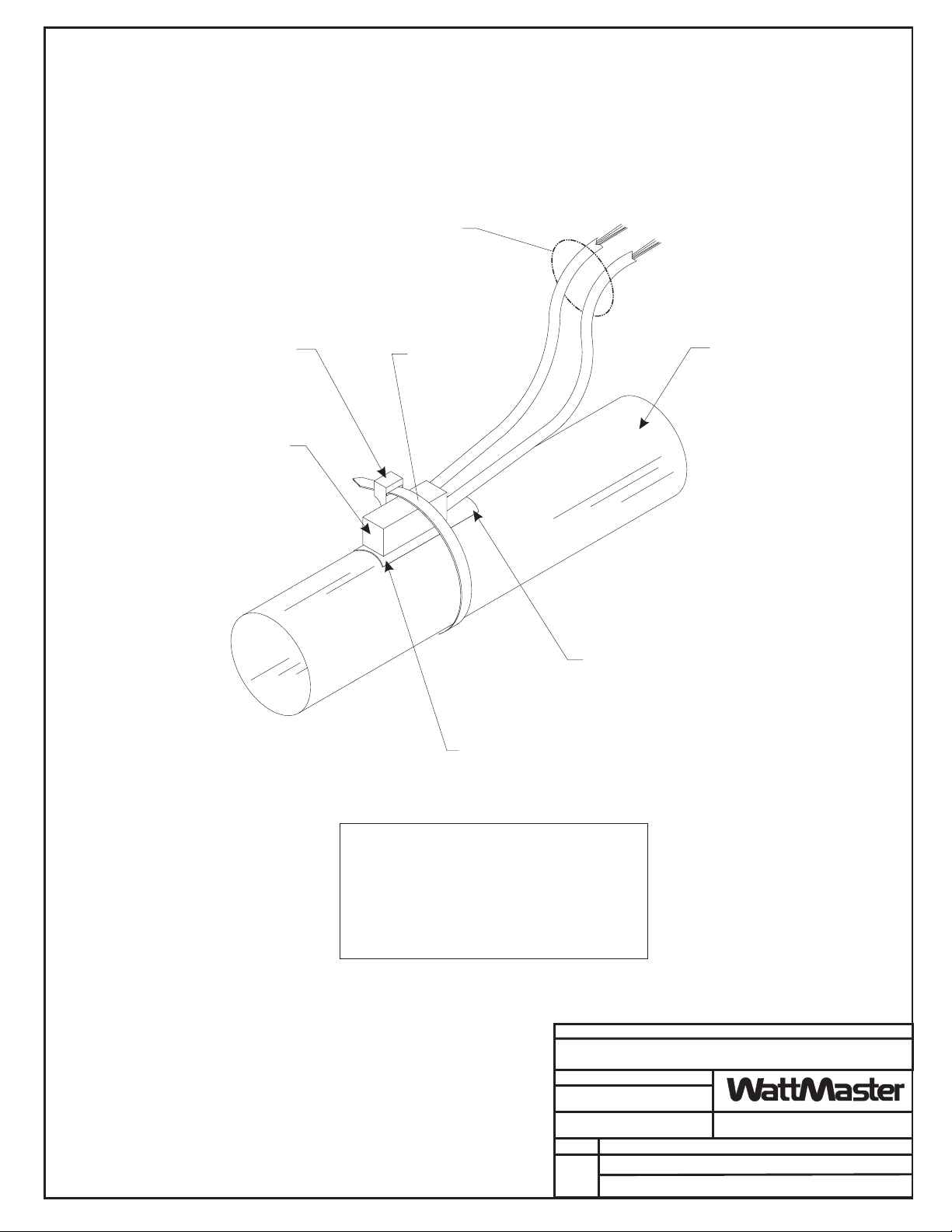

OE233 - Strap-On Temperature

Sensor Kit Installation

1

JOB NAME

Place Between Pipe

And Sensing Element. Pipe Should Be

Clean And Smooth To Provide Proper

Thermal Contact With Sensing Element.

Thermal Mastic

Secure Sensor Element And Thermal

Mastic Strip To Pipe With Supplied

Wire Tie. Be Sure To Tighten Wire Tie

Snugly To Ensure Good Thermal Contact

Between Pipe And Sensing Element.

Butt Splice Or Wire Nut Wire Leads And Extend

Wire To Controller Terminals. Connect One Wire

Lead To Return Water Temperature Or Supply Water

Temperature Terminal At The Controller As Required

By Intended Use. Secure Other Wire Lead To

Ground Terminal At The Controller. See Note 3.

Notes:

1.)Sensor Should Be Mounted At

Location Along Pipe Length

That Best Represents Desired

Temperature Reading.

3.)All Wiring To Be In Accordance

With Local And National Electrical

Codes And Specifications.

2.)Sensing Element Shown

Mounted To Top Of Pipe. The

Sensor Element May Be Located

At Any Location Around Pipe.

Wire Tire

(Supplied)

Sensing Element

(Supplied)

Thermal Mastic Strip

(Supplied)

Supply Or Return

Water Pipe. See Note1&2.

Important Note:

For Accurate Temperature Readings

It Is Necessary To Place Insulation Over

The Sensor After Installation. This Prevents

The Ambient Temperature From Affecting

The Sensor. Insulation Should Cover The

Sensor And Extend 6“ to 12” Beyond Each

End Of The Sensor.

4.)All Wiring To Be In Accordance With

Local And National Electrical Codes

And Specifications.

3.)Gasket Must Be Installed Under Cover

Plate To Provide Raintight Seal.

Rainwater Can Damage Sensor!

Temperature Sensor Resistance/Voltage Chart

Temp Resistance* Voltage

F Ohms @ Input*

-10.............93333........4.620

-5...............80531........4.550

0 ...............69822 ........4.474

5 ...............60552 ........4.390

10..............52500........4.297

15..............45902........4.200

20..............40147........4.095

25..............35165........3.982

30..............30805........3.862

35..............27140........3.737

40..............23874........3.605

°

Temp Resistance* Voltage

F Ohms @ Input*°

45..............21094........3.470

50..............18655........3.330

52..............17799........3.275

54..............16956........3.217

56..............16164........3.160

58..............15385........3.100

60..............14681........3.042

62..............14014........2.985

64..............13382........2.927

66..............12758........2.867

68..............12191........2.810

Temp Resistance* Voltage

F Ohms @ Input*°

69..............11906 ........2.780

70..............11652 ........2.752

71..............11379 ........2.722

72..............11136 ........2.695

73..............10878........2.665

74..............10625........2.635

75..............10398........2.607

76..............10158........2.570

78..............9711 ..........2.520

80..............9302..........2.465

82..............8893..........2.407

Temp Resistance* Voltage

F Ohms @ Input*

84..............8514..........2.352

86..............8153..........2.297

88..............7805..........2.242

90..............7472..........2.187

95..............6716..........2.055

100............6047..........1.927

105............5453..........1.805

110 ............4923 ..........1.687

115 ............4449 ..........1.575

120............4030..........1.469

°

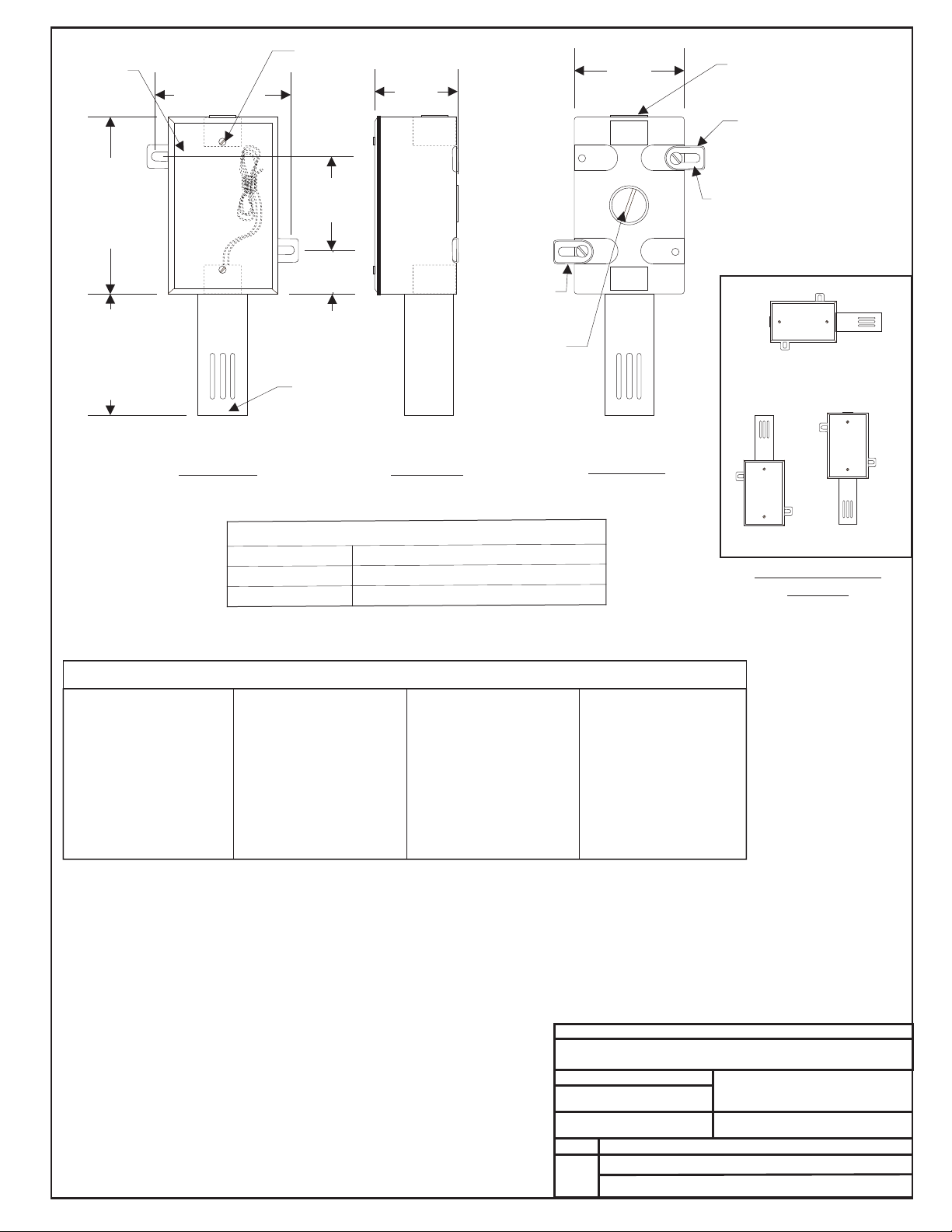

2.)Unused Conduit Opening(s) Must

Have Closure Plugs Installed And Must

Be Coated with Sealing Compound To

Provide Raintight Seal. Water Can

Damage Sensor!

1.)The Outside Air Sensor Must Be

Mounted In A Vertical Position As

Shown (Sensor Tube Pointing

Down).

Sensor Must Be Located

Where It Will Not Be Affected By

Direct Sunlight Or Heat Producing

Equipment. If Possible Mount Under

Roof Eave Or Similar Protected

Location. If Sensor Is Not Located

As Specified, Erroneous Outside Air

Temperature Readings Will Result.

Water Must Not Be

Allowed To Stand In Sensor

Tube. Rainwater Will Damage

Sensor.

*Chart Notes:

1. Use the resistance column to check the thermistor sensor while disconnected from the controllers (not powered).

2. Use the voltage column to check sensors while connected to powered controllers. Read voltage with meter set on DC

volts. Place the "-"(minus) lead on GND terminal and the "+"(plus) lead on the sensor input terminal being investigated. If

the voltage is above 5.08 VDC, then the sensor or wiring is "open." If the voltage is less than 0.05 VDC, the sensor or

wiring is shorted.

Outside Air Sensor OE250

Notes:

Closure Plug

CAUTION!

See Note 2

Gasketed Cover

CAUTION!

See Note3

Cover

Mounting

Screw - Typ.

Mounting Tab

& Screw - Typ.

0.21" Dia. x 0.73

Lg. Slot - Typ.

4.50”

2.25”

3.00”

FILENAME

DATE: B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

Outside Air Temperature Sensor

1

JOB NAME

07/13/15

G-OE250-OAS-PDWG.CDR

OE250

Front View Side View Back View

Closure Plug

CAUTION!

See Note 2

Sensor Tube

CAUTION!

See Note 1

Mounting Tab

& Screws - Typ.

Correct

Incorrect

Incorrect

See Note #1

Sensor Mounting

Postion

2.70”

1.13”

2.30”

3.00”

Technical Specifications

Sensor Element:

Type III Thermistor 10k ohm @ 77ºF

Accuracy:

±0.4º F between 40º F to 95º F

Range:

-30º F to 150º F

JOB NAME

FILE NAME

G-OE265-11-SPHUMID1E.PDF

DATE: 08/10/15

PAGE DESCRIPTION

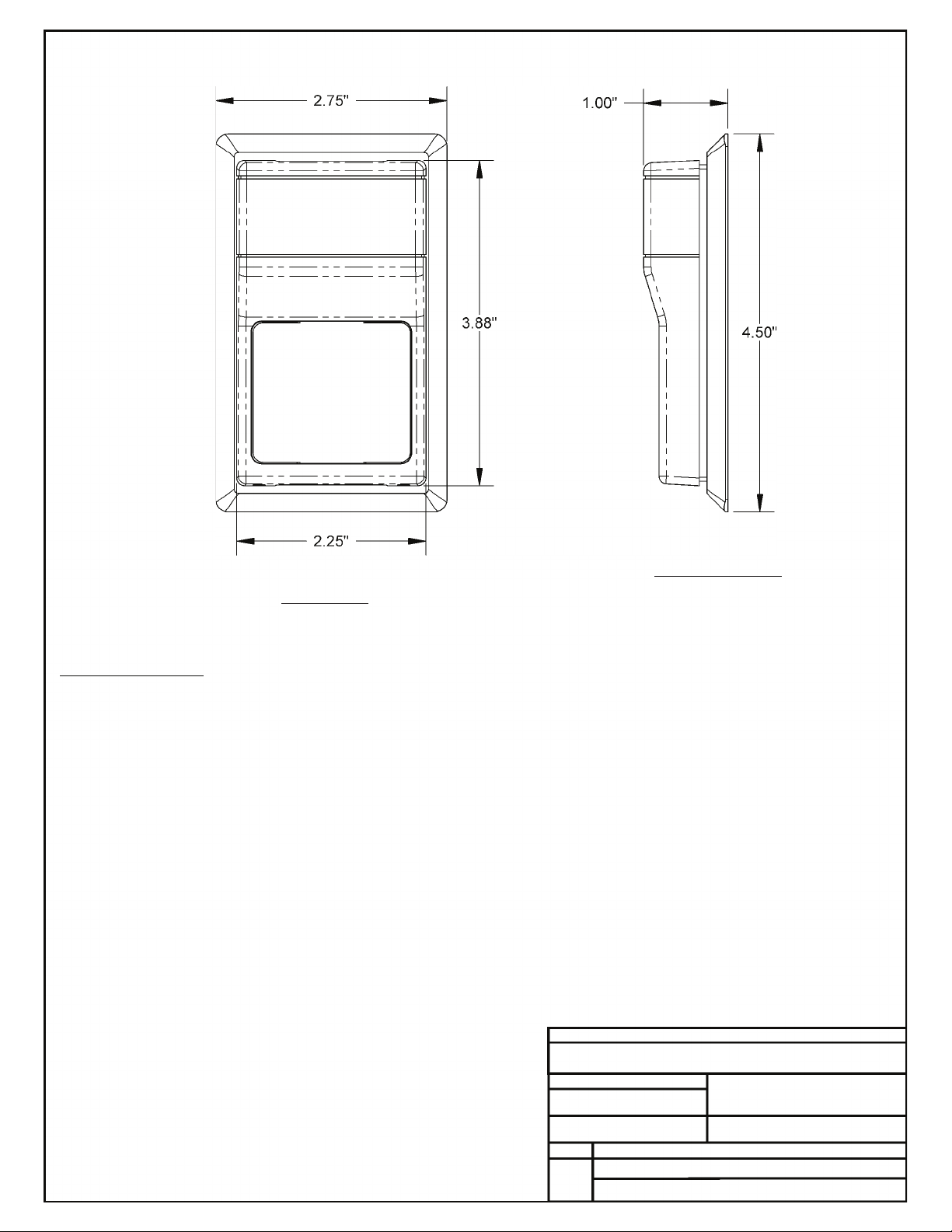

OE265-11

Space Humidity Sensor – 0-5 VDC

DRAWN BY: B. CREWS

Notes:

1.) The sensor is designed to be wall

mounted in rooms where appearance is

important. It may be mounted directly on

dry wall or on any single gang electrical

outlet box with no adapters required.

Toggle bolts or other direct wall mount

screws can be used where conduit is not

required. It includes a detachable

mounting plate. The cover is secured with

tamper-resistant hex screws. The sensor

should be mounted approximately five feet

above the floor, on an interior wall, away

from any heating or cooling generating

devices, and out of the sun. Plug the

wireway hole to prevent false readings by

air drafts within the wall.

2.) All Wiring To Be In

Accordance With Local

And National Electrical

Codes And Specifications.

1 of 2

Installation Instructions:

1.) Place The SpaceHumidity Sensor Where It Is To Be Mounted. See Note 1 Below For Important Mounting Information And Considerations.

2.) Remove The Humidity Sensor Cover By Screwing In The 2 Allen Screws That Secure It To The Base.

3.) Connect All Of The Wires From The Controller Board To The Corresponding Terminal Blocks Per The Wiring Diagram On Page 2 Of This Drawing.

4.) Secure The Cover Onto The Base Housing By Snapping The Cover Onto The Base And Backing Out The 2 Allen Screws.

5.) Verify That You Are Getting A Humidity Reading On Your Control System. Please Note That It May Take Ten To Twenty Minutes For The Sensor

Reading To Stabilize Upon Initial Power Up.

Front View

Right Side View

Notes:

1.) All Wiring To Be In Accordance With Local And

National Electrical Codes And Specifications.

FILENAME

DATE: B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

JOB NAME

2 of 2 Wall Mounted Humidity Sensor - 0-5 VDC

OE265-11

08/10/15

G-OE265-11-SPHUMID1E.CDR

NOTE: RESISTOR IS NOT

REQUIRED FOR CONTROLLERS

THAT HAVE JUMPER

SELECTABLE ANALOG INPUTS.

NOTE: RESISTOR IS REQUIRED

FOR CONTROLLERS THAT DO

NOT HAVE JUMPER

SELECTABLE ANALOG INPUTS.

THE PULL-UP RESISTOR (PUx)

FOR THE ASSOCIATED ANALOG

INPUT MUST BE REMOVED FROM

THE CONTROLLER BOARD FOR

THE SENSOR TO OPERATE

24 VAC or VDC

JUMPER SELECTABLE

STYLE CONTROLLER

TERMINAL. SET FOR 0-5V.

CONNECT TO SPECIFIED AIx

TERMINAL FOR YOUR

APPLICATION. SEE SPECIFIC

WIRING DIAGRAM FOR YOUR

APPLICATION FOR CORRECT

AIX TERMINAL TO BE USED.

CONNECT TO GROUND

TERMINAL FOR YOUR

ANALOG INPUT(S).

INPUTS

ANALOG

0-5v

0-10v

4-20 mA

TB3

AI1

AI1

THERM

0-5VDC Terminal

Label: LB101969

Gnd

Vin

Vo

Not Used

Not Used

RH Output

% VDC

55 ........ 2.75

60 ........ 3.00

65 ........ 3.25

70 ........ 3.50

75 ........ 3.75

80 ........ 4.00

85 ........ 4.25

90 ........ 4.50

95 ........ 4.75

100 ........ 5.00

RH Output

% VDC

5 .......... 0.25

10 .......... 0.50

15 .......... 0.75

20 .......... 1.00

25 .......... 1.25

30 .......... 1.50

35 .......... 1.75

40 .......... 2.00

45 .......... 2.25

50 .......... 2.50

Humidity Sensor

RH/Voltage Chart

GND

GND

Chart Notes

1.) First be sure that the +24 VAC power is being supplied to the

sensor. Second set the meter to DC volts and connect the meter

between ground and the 0-5 VDC input on the controller board or

between the 0-5 VDC output terminal on the sensor and its ground

terminal. Use an accurate humidity measurement device (such as an

aspirating psychrometer) to determine the RH percentage (relative

humidity) .

Use the “Output VDC” column on the chart to read the voltage

corresponding with the RH percentage column just measured. If the

measured voltage is within 3% of what is listed for the corresponding

RH, the sensor is functioning correctly. If it is not you will need to

replace the sensor.

JOB NAME

FILE NAME

G-OE265-13B-OAHUMID-1E.PDF

DATE: 08/17/11

PAGE DESCRIPTION

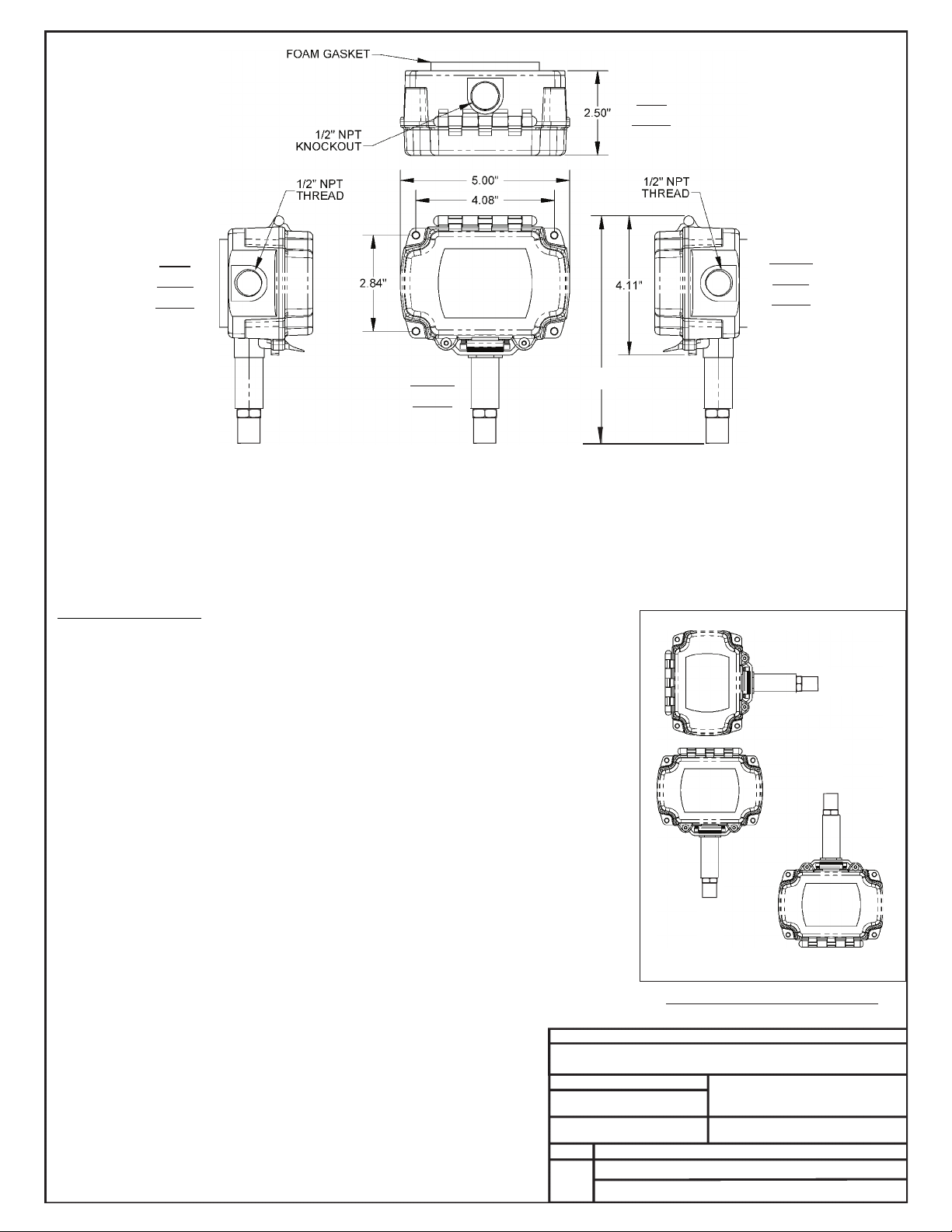

Outside Air Humidity Sensor –0-5 VDC

DRAWN BY: B. CREWS

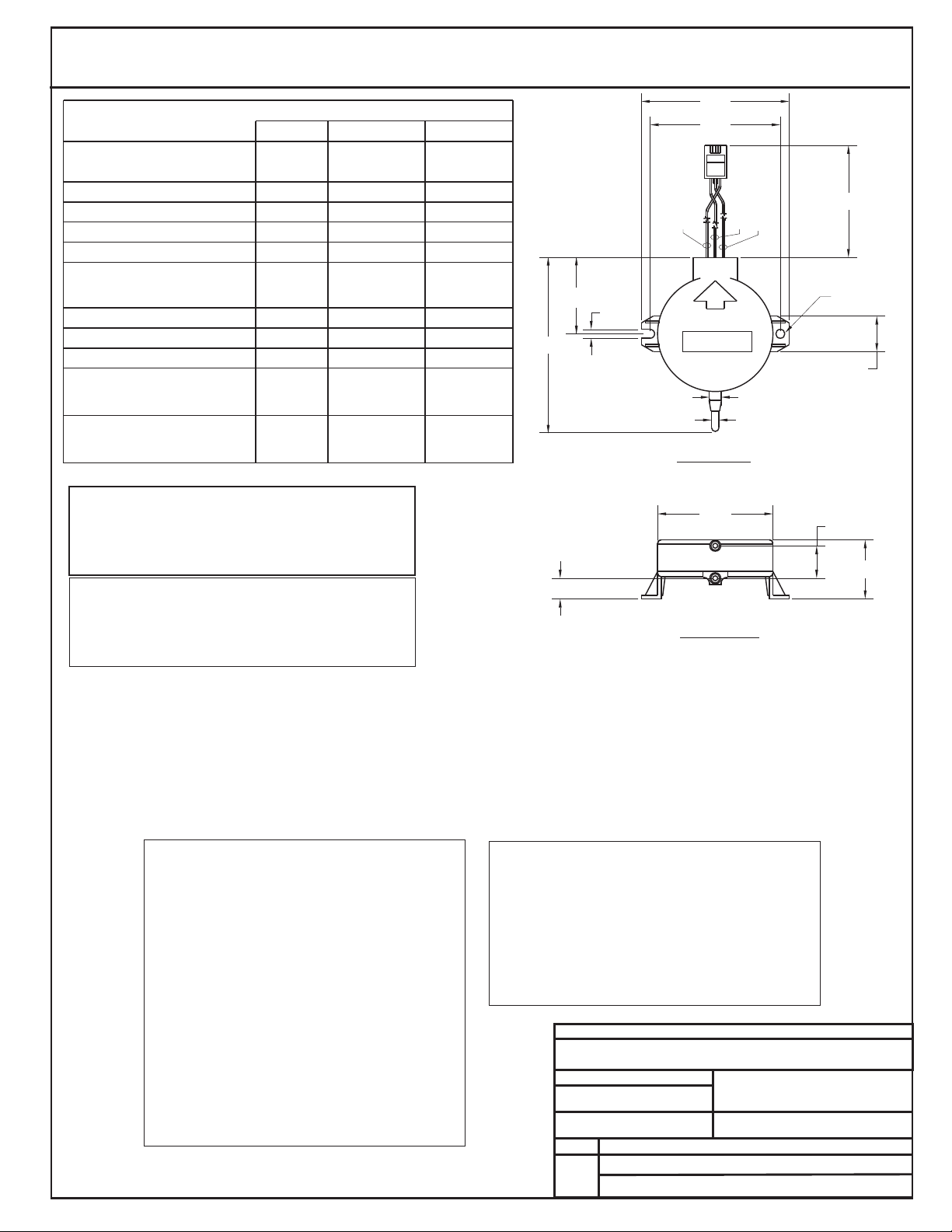

Notes:

1.) The Outside Air Humidity Sensor Must

Be Mounted In A Vertical Position As Shown

(Sensor Tube Pointing Down). Water Must

Not Be Allowed To Stand In Sensor Tube,

it Will Cause Erroneous Sensor

Readings. The Sensor will recover when

it dries out.Sensor Must Be Located

Where It Will Not Be Affected By Direct

Sunlight Or Heat Producing Equipment. If

Possible Mount Under Roof Eave Or Similar

Protected Location.If Sensor Is Not

Located As Specified, Erroneous Outside Air

Humidity Readings Will Result.

2.) Unused Conduit Opening(s) Must

Not be Knocked Out to Prevent Dust

or Insects From Infiltrating the Sensor

Electrical Box.

3.) All Wiring To Be In Accordance

With Local And National Electrical

Codes And Specifications.

1 of 2

Installation Instructions:

1.) Place The Outside Air Humidity Sensor Where It Is To Be Mounted. See Note 1 Below For

Important Mounting Information And Considerations. Mark The (4) Mounting Holes. Secure The

Humidity Sensor By Using The Four #10 X 1.5" Self Tapping Screws Included With The Humidity

Sensor.

2.) Open The Cover by Moving the Latch to the Side And Install Your Conduit Connectors. The

Cover Must Always Be Opened Before Attempting To Punch Out The Knockouts.

3.) Connect The Wires To The Corresponding Sensor Wire Leads Per The Wiring Diagram On

Page 2 Of This Drawing. Insert the Wires Into the Sealant Filled Connectors Provided and Crimp.

Lightly Tug on the Wire to Assure a Good Mechanical Connection

4.) Close The Cover by Pushing Down Until the Latch Snaps Into Place. Be Careful Not To Pinch

The Sensor Wires When Closing The Housing Cover.

5.) Verify That You Are Getting A Humidity Reading On Your Control System. Please Note That It

May Take Ten To Twenty Minutes For The Sensor Reading To Stabilize Upon Initial Power Up.

OE265-13 BAPI

Right

Side

Left

Side

Top

View

Front

View

View

View

7.21

Sensor Mounting Position

INCORRECT

CORRECT

INCORRECT

JOB NAME

FILE NAME

G-OE265-13B-OAHUMID-1E.PDF

DATE: 08/17/11

PAGE DESCRIPTION

OE265-13 BAPI

Outside Air Humidity Sensor –0-5 VDC

DRAWN BY: B. CREWS

2 of 2

Notes:

1.) All Wiring To Be In Accordance With Local And

National Electrical Codes And Specifications.

RH Output

%VDC

55 ........2.75

60 ........3.00

65 ........3.25

70 ........3.50

75 ........3.75

80 ........4.00

85 ........4.25

90 ........4.50

95 ........4.75

100........5.00

RH Output

% VDC

5..........0.25

10 ..........0.50

15 ..........0.75

20 ..........1.00

25 ..........1.25

30 ..........1.50

35 ..........1.75

40 ..........2.00

45 ..........2.25

50 ..........2.50

Humidity Sensor

RH/Voltage Chart

Warning

Be Sure To Observe

Polarity Or Serious

Damage To The

Board Could Result

0-5 VDC Output Wiring (24VAC Power)

*Chart Notes:

1. First, be sure that +24VAC power is being supplied to the sensor. Second check the

sensor output. Set the meter to DC volts and connect the meter between ground

and the 0-5 VDC input terminal on the controller board or between the 0-5 VDC

output on the sensor and its ground wire or you can measure voltage at the 0-5 VDC

and GND terminals on the sensor located at the sensor installtion location.

After measuring the voltage use an accurate humidity measurement device to

determine RH (relative humidity) such as an aspirating psychrometer. Use the

Output VDC column to read the Output Voltage corresponding with the RH

percentage measured with the psychrometer. If the measured voltage is within 3%

of what is listed for the corresponding RH, then the sensor is functioning properly.

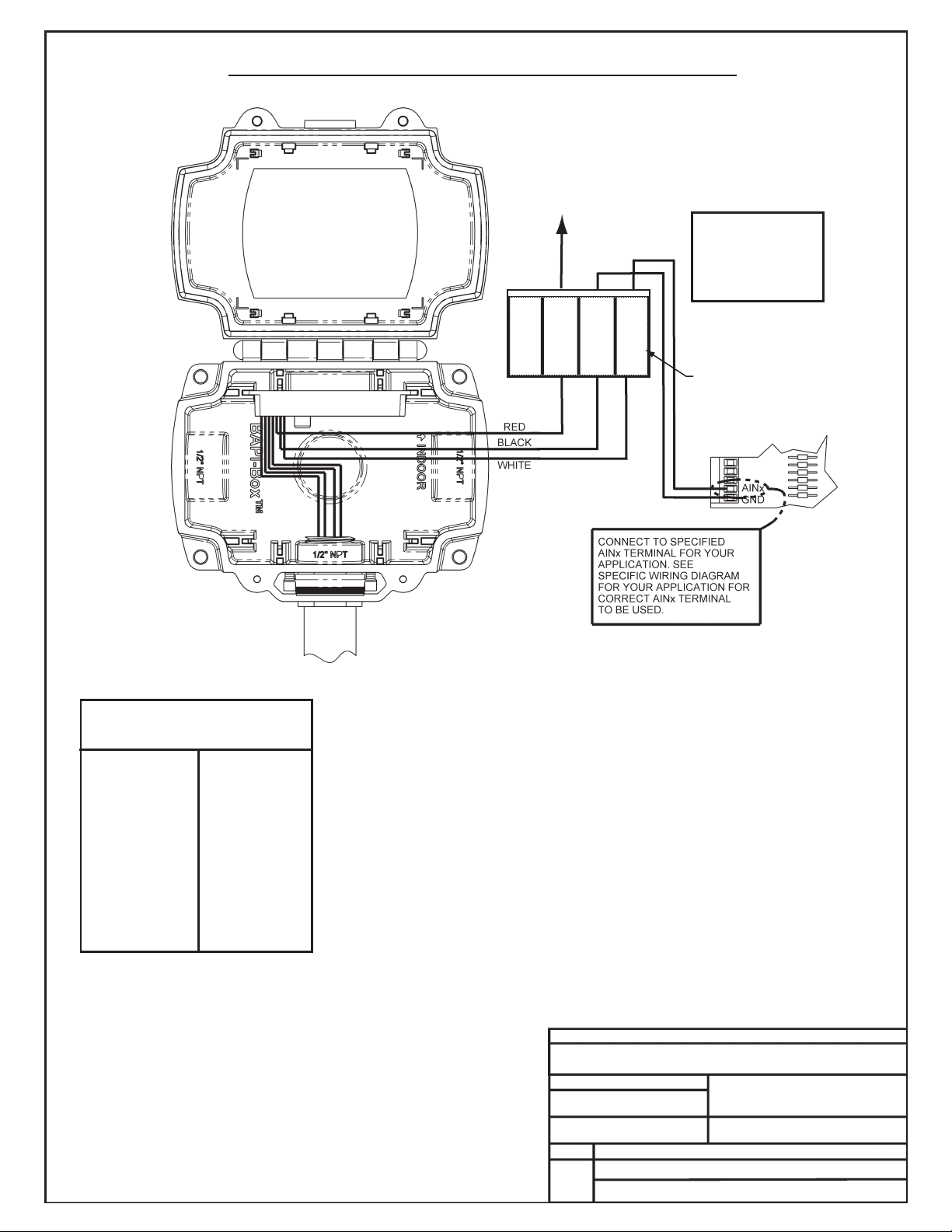

CONNECT TO

24 VAC POWER

0-5VDC Terminal

Label: LB101966

RED

BLK

WHT

Not Used

VACorDC

GND

0-5V

SENSOR TERMINAL

BLOCK

JOB NAME

FILE NAME

G-OE265-14B-RAHUMID-1D.PDF

DATE: 08/28/07

PAGE DESCRIPTION

OE265-14 BAPI

Return Air Humidity Sensor –0-5 VDC

DRAWN BY: B. CREWS

Notes:

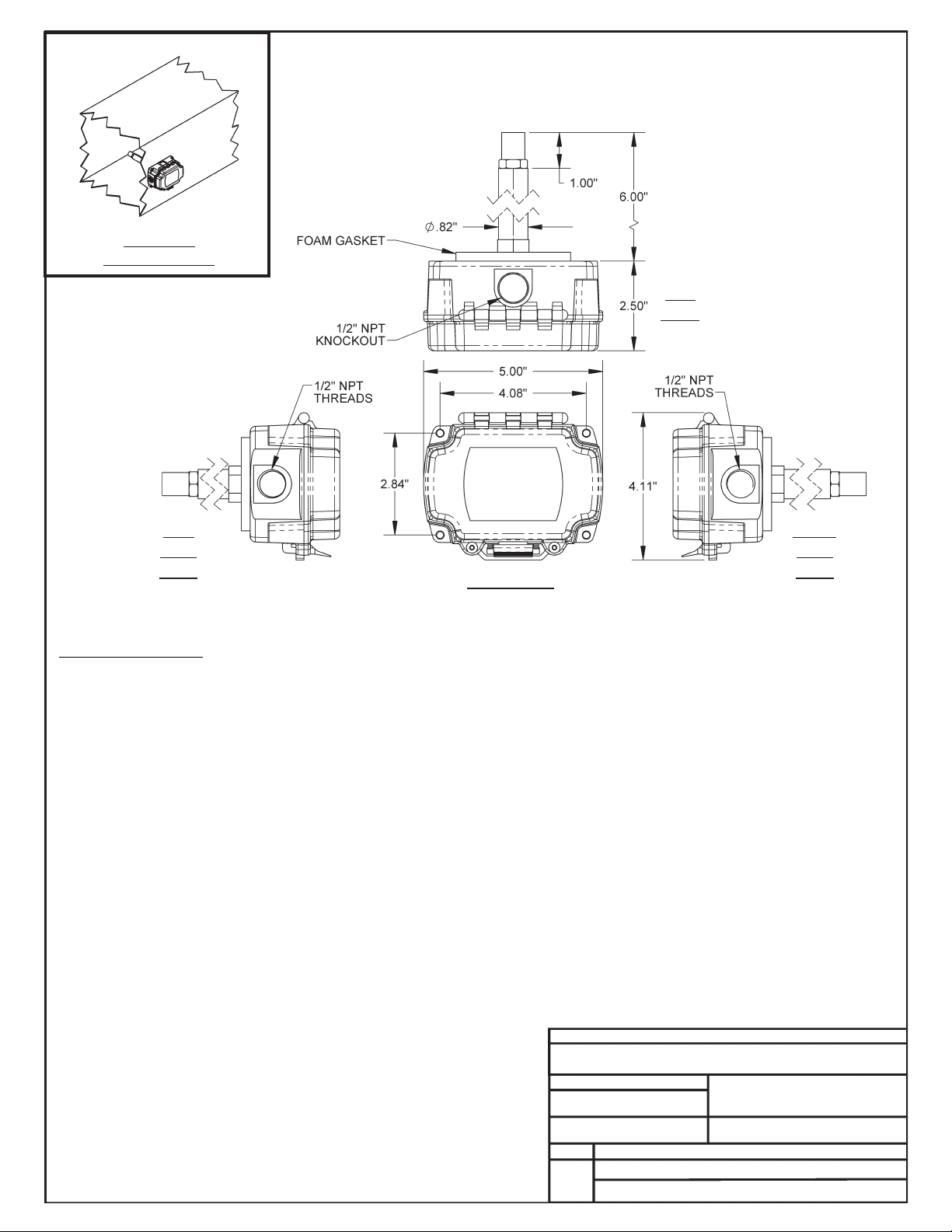

1.) The Sensor Should Be Mounted so

that the 6" Probe is in the Center of the

Return Air Duct. It Should be Mounted

Away from Fans, Elbows, Heating or

Cooling Coils or Other Equipment that

Could Affect the Measurement of

Relative Humidity. Also, the Sensor

Should be Mounted in an Area that

Receives Adequate Air Flow for Proper

Operation. The Sensor may be Mounted

Horizontally or Vertically to the Return Air

Duct. See the Sensor Mounting Diagram

Above.

2.) Unused Conduit Opening(s) Must Not

be Knocked Out to Prevent Dust or Insects

From Infiltrating the Sensor Electrical Box.

3.) The Sensor Probe Gasket Must Be

Installed Between the Back of the Sensor

Box and the Duct to Provide an Airtight

Seal.

4.) All Wiring To Be In Accordance With

Local And National Electrical Codes And

Specifications.

1 of 2

Installation Instructions:

1.) Drill a 1" Diameter Hole In The Duct Wall In the Location Where The Humidity Sensor Is To Be Mounted. Insert The Probe Of The Return Air Humidity

Sensor Through The Hole. See Note 1 Below For Important Mounting Information And Considerations. Mark The (4) Mounting Holes. Secure The

Humidity Sensor By Using The Four #10 X 1.5" Self Tapping Screws Included With The Humidity Sensor.

2.) Open The Cover by Moving the Latch to the Side And Install Your Conduit Connectors. The Cover Must Always Be Opened Before Attempting To

Punch Out The Knockouts.

3.) Connect The Wires To The Corresponding Sensor Wire Leads Per The Wiring Diagram On Page 2 Of This Drawing. Insert the Wires Into the Sealant

Filled Connectors Provided and Crimp. Lightly Tug on the Wire to Assure a Good Mechanical Connection

4.) Close The Cover by Pushing Down Until the Latch Snaps Into Place.Be Careful Not To Pinch The Sensor Wires When Closing The Housing Cover.

5.) Verify That You Are Getting A Humidity Reading On Your Control System. Please Note That It May Take Ten To Twenty Minutes For The Sensor

Reading To Stabilize Upon Initial Power Up.

Front View

Right

Side

View

Left

Side

View

Top

View

Mounting

Sensor to Duct

See Note #1

JOB NAME

FILE NAME

PAGE DESCRIPTION

Return Air Humidity Sensor –0-5 VDC

DRAWN BY: B. CREWS

2 of 2

RH Output

%VDC

55 ........2.75

60 ........3.00

65 ........3.25

70 ........3.50

75 ........3.75

80 ........4.00

85 ........4.25

90 ........4.50

95 ........4.75

100........5.00

RH Output

% VDC

5..........0.25

10 ..........0.50

15 ..........0.75

20 ..........1.00

25 ..........1.25

30 ..........1.50

35 ..........1.75

40 ..........2.00

45 ..........2.25

50 ..........2.50

Humidity Sensor

RH/Voltage Chart

Warning

Be Sure To Observe

Polarity Or Serious

Damage To The

Unit Could Result

0-5 VDC Output Wiring (24 VAC Power)

G-OE265-14B-RAHUMID-1D.PDF

DATE: 08/28/07

OE265-14 BAPI

Notes:

1.) All Wiring To Be In Accordance With Local And

National Electrical Codes And Specifications.

*Chart Notes:

1. First, be sure that +24VAC power is being supplied to the sensor. Second check the

sensor output. Set the meter to DC volts and connect the meter between ground

and the 0-5 VDC input terminal on the controller board or between the 0-5 VDC

output on the sensor and its ground wire or you can measure voltage at the 0-5 VDC

and GND terminals on the sensor located at the sensor installtion location.

After measuring the voltage use an accurate humidity measurement device to

determine RH (relative humidity) such as an aspirating psychrometer. Use the

Output VDC column to read the Output Voltage corresponding with the RH

percentage measured with the psychrometer. If the measured voltage is within 3%

of what is listed for the corresponding RH, then the sensor is functioning properly.

CONNECT TO

24 VAC POWER

0-5VDC Terminal

Label: LB101966

RED

BLK

WHT

Not Used

VACorDC

GND

0-5V

SENSOR TERMINAL

BLOCK

General Notes

FILENAME

DATE: B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

Pressure Sensor

1

JOB NAME

2.)All Wiring To Be In Accordance With Local And

National Electrical Codes And Specifications.

08/19/08

G-OE271TRAN1.CDR

OE271

Top View

Side View

OUT

IN

GND

UP

(-)LO

0.35"

0.55"

1.00"

2.20"

0.15" DIA.

0.15"

2.94"

2.50"

0.125" (1/8" Tubing Conn.)

0.200" (3/16" Tubing Conn.)

1.95"

0.60"

12.0" APPROX.

Full Scale Output

(Positive Pressure)

Null Offset

Span*

Minimum Typical Maximum

Hystereisis And Repeatability

Temperature Error

Null +10 To 40 C°°

Stability (1 Year)

Supply Voltage (Vs)

Pressure Overload

Burst Pressure

Positive Pressure (Hi Side)

Negative Pressure (Lo Side)

Positive Pressure (Hi Side)

Negative Pressure (Lo Side)

Non-Linearity

Span +10 To 40 C°°

Common Mode Pressure

0-5“ H O Pressure Range - 5 VDC Operation

2

3.92 VDC

0.17 VDC 0.2-0.3 VDC 0.33 VDC

3.59 VDC 3.91 VDC

±0.05 % Span

4.75 VDC 5.0 VDC 8.0 VDC

15 PSI

25“ H O

2

50“ H O

2

15“ H O

2

25“ H O

2

4.08 VDC

3.95-4.05 VDC

3.65-3.85 VDC

±0.3 % Span ±0.5 % Span

±0.03 % Span

±1.0 % Span

±0.5 % Span

±1.0 % Span

±1.5 % Span

±1.5 % Span

*Span Is The Algebraic Difference Between End Points (Null Offset And Full Scale Output)

The plastic housing on the sensor is electrically

conductive. Avoid contact with any electrical components.

It is acceptable to mount the sensor on grounded sheet

metal such as ductwork, electrical panels, etc.

Use extreme care when mounting the sensor to avoid

damage to the plastic housing. Do not overtighten the

mounting screws! Do not use mounting screws which are

too large for the holes!

Warning!

Warning!

1.) The Airflow Sensor Should Be Mounted In

A Vertical Position As Shown With Arrow Pointing

Up. ( Tubing Connections Pointing Down). If This

Mounting Position Is Not Possible In Your

Application, It May Be Mounted In A Horizontal

Position. When Mounted In A Horizontal Position

Accuracy Will Be Affected By Approximately 2% Full

Scale Null Shift Due To Diaphragm Gravity Effect

Error.

Caution:

1.29"

OUT (Black)

GND (Green)

IN (Red)

OE271

S.P. Sensor

OE271 - For

Applications Requiring 0-5“ H O Pressure Range

2

Airflow Sensor

When The OE271 Is Used As A Duct

It May Be Mounted To The

Ductwork Near The Static Pressure Pickup Tube. If

The Sensor Is Mounted In This Manner, Away

From The Controller, The Modular Plug Must Be

Cut Off And 3-conductor 24 Gauge Minimum Wire

Must Be Butt Spliced Between The Sensor And

The Modular Plug To Extend The Sensor Wire

Length. Total Wire Length Should Not Exceed

100Ft. If Desired The Sensor May Also Be Located

Near The Controller, With The Modular Plug On

The Sensor Directly Connected To The Mating

Controller Jack. When This Method Is Used Tubing

Must Be Run From The Sensor To The Static

Pressure Pickup Tube. Tubing Should Not Exceed

250 Ft. And Must Be Continuous Without Any

Splices.

Static

Pressure Sensor

When The OE271 Is Used As An Airflow

For VAV Applications It Should Be Mounted In The

VAV Box Control Enclosure Near The Box

Controller Board. The Modular Plug should be

Connected To The VAV Controller Board

Connection. Tubing Must Be Run From The

Sensor to The Airflow Pickup Probe Tubing

Connection.

Sensor

Duct Static Pressure Sensor Applications

Mounting Information

VAV Pressure Independent Airflow Sensor

Applications Mounting Information

Notes:

FILENAME

DATE: B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

Airflow Sensor

1

JOB NAME

2.)All Wiring To Be In Accordance With Local And

National Electrical Codes And Specifications.

04/29/02

G-OE274TRAN1.CDR

OE274

Top View

Side View

OUT

IN

GND

UP

(-)LO

0.35"

0.55"

1.00"

2.20"

0.15" DIA.

0.15"

2.94"

2.50"

0.125" (1/8" Tubing Conn.)

0.200" (3/16" Tubing Conn.)

1.95"

0.60"

12.0" APPROX.

Full Scale Output

(Positive Pressure)

Null Offset

Span*

Minimum Typical Maximum

Hystereisis And Repeatability

Temperature Error

Null +10 To 40 C°°

Stability (1 Year)

Supply Voltage (Vs)

Pressure Overload

Burst Pressure

Positive Pressure (Hi Side)

Negative Pressure (Lo Side)

Positive Pressure (Hi Side)

Negative Pressure (Lo Side)

Non-Linearity

Span +10 To 40 C°°

Common Mode Pressure

0-1.5“ H O Pressure Range - 5 VDC Operation

2

3.92 VDC

0.17 VDC 0.2-0.3 VDC 0.33 VDC

3.59 VDC 3.91 VDC

±0.05 % Span

4.75 VDC 5.0 VDC 8.0 VDC

15 PSI

5“ H O

2

10“ H O

2

3“ H O

2

5“ H O

2

4.08 VDC

3.95-4.05 VDC

3.65-3.85 VDC

±0.3 % Span ±0.5 % Span

±0.03 % Span

±1.0 % Span

±0.5 % Span

±1.0 % Span

±1.5 % Span

±1.5 % Span

*Span Is The Algebraic Difference Between End Points (Null Offset And Full Scale Output)

The plastic housing on the sensor is electrically

conductive. Avoid contact with any electrical components.

It is acceptable to mount the sensor on grounded sheet

metal such as ductwork, electrical panels, etc.

Use extreme care when mounting the sensor to avoid

damage to the plastic housing. Do not overtighten the

mounting screws! Do not use mounting screws which are

too large for the holes!

Warning! Warning!

1.) The Airflow Sensor Should Be Mounted In

A Vertical Position As Shown With Arrow Pointing

Up. ( Tubing Connections Pointing Down). If This

Mounting Position Is Not Possible In Your

Application, It May Be Mounted In A Horizontal

Position. When Mounted In A Horizontal Position

Accuracy Will Be Affected By Approximately 2% Full

Scale Null Shift Due To Diaphragm Gravity Effect

Error.

Caution:

OE274 - Applications

Requiring 0-1.5“ H O Pressure Range

2

Airflow Sensor For

1.29"

OUT (Black)

GND (Green)

IN (Red)

±1 % Span

OE274

P.I. Sensor

FILENAME

DATE: B.CREWS

DESCRIPTION:

PAGE DRAWNBY:

RoomSensor

1

JOBNAME

02/05/03

G-RMSENS1.CDR

OE210,OE211,OE212,OE213

0.88“

TemperatureSensorResistance/VoltageChart

TempResistance*Voltage

FOhms@Input*

-10.............93333........4.620

-5...............80531........4.550

0...............69822........4.474

5...............60552........4.390

10..............52500........4.297

15..............45902........4.200

20..............40147........4.095

25..............35165........3.982

30..............30805........3.862

35..............27140........3.737

40..............23874........3.605

°TempResistance*Voltage

FOhms@Input*°

45..............21094........3.470

50..............18655........3.330

52..............17799........3.275

54..............16956........3.217

56..............16164........3.160

58..............15385........3.100

60..............14681........3.042

62..............14014........2.985

64..............13382........2.927

66..............12758........2.867

68..............12191........2.810

TempResistance*Voltage

FOhms@Input*°

69..............11906........2.780

70..............11652........2.752

71..............11379........2.722

72..............11136........2.695

73..............10878........2.665

74..............10625........2.635

75..............10398........2.607

76..............10158........2.570

78..............9711..........2.520

80..............9302..........2.465

82..............8893..........2.407

TempResistance*Voltage

FOhms@Input*

84..............8514..........2.352

86..............8153..........2.297

88..............7805..........2.242

90..............7472..........2.187

95..............6716..........2.055

100............6047..........1.927

105............5453..........1.805

110............4923..........1.687

115............4449..........1.575

120............4030..........1.469

°

RoomSensorTypicalDimensions

*ChartNotes:

1.Usetheresistancecolumntocheckthethermistorsensorwhiledisconnectedfromthecontrollers(notpowered).

2.Usethevoltagecolumntochecksensorswhileconnectedtopoweredcontrollers.ReadvoltagewithmetersetonDCvolts.Placethe

"-"(minus)leadonGNDterminalandthe"+"(plus)leadonthesensorinputterminalbeinginvestigated.Ifthevoltageisabove5.08

VDC,thenthesensororwiringis"open."Ifthevoltageislessthan0.05VDC,thesensororwiringisshorted.

O

O O

A

A A

O

O O

R

R R

L

L L

M

M M

E

E E

E

E E

C

C C

W

W W

R

R R

R

R R

OVR

OVR OVR

0.25“

TMP

GND

AUX

OUT

2.00“

WallCut-OutDimensions

WhenSensorIsToBe

MountedWithout

HandyBox(ByOthers)

2.75“

OE210 OE211 OE212 OE213

RoomSensor-Plain RoomSensor

WithOverride RoomSensor

WithSetpointAdjust RoomSensor

WithSetpointAdjust

&Overide

Caution:

TheRoomSensorIs

SuppliedWithAMylar

FilmCoatingOnThe

SensorPlateThat

ProtectsThePlateFrom

MarringAndDamage

DuringShipmentAnd

Installation.After

InstallationOfThe

SensorIsCompleted,

ThisMylarFilmMustBe

RemovedForProper

SensorOperation.

Notes:

FILENAME

DATE: B. CREWS

DESCRIPTION:

PAGE

DRAWN BY:

Static Pressure Pickup Tube

1

JOB NAME

04/29/02

G-SPUTUBE1.CDR

OE290

In Order To Obtain Accurate Static Pressure Readings

The Static pressure Pickup Probe Should Be Mounted

Per The Following Recommendations:

1.)The Probe Should Be Mounted In a Straight Section

Of Ductwork Approx. 2/3 The Length Of the Supply Duct,

Downstream Of The HVAC Unit.

2.)The Probe Should Not Be Mounted Less Than 3 Duct

Diameters Downstream Or Not Less Than 2 Duct

Diameters Upstream Of Any Elbow or Takeoff.

See The Systems Installation And Operation Manual For

Other Design Considerations And Recommendations

Regarding Static Pressure Pickup Tube Location.

Caution!

1.)The Static Probe(OE290) Is Supplied With A 14“

Length Of Tubing For Connection To The Static

Pressure Sensor. The Static Pressure Sensor

(OE271) Is Designed To Be Mounted Adjacent To The

Location Where The Static Pickup Tube Is Mounted

And Wired Back To The Controller Board. The Static

Pressure Sensor Can Also Be Mounted Close To The

Controller Board And Tubing (By Others) Routed

From The Sensor To The Static Pickup Probe. Be

Sure Not To Kink The Tubing Between The Static

Pickup Probe And The Static Pressure Sensor.

Static Pressure Pickup Tube OE290

Mounting Plate

Gasket

Adhesive Backed Drill Guide

Mounting Template

2-3/4“ Mounting Plate

4.0"

3/4"

1/4" Hex Head Sheet Metal Screws

Thread

Together

1/8“ MPT

Threaded Pipe

Duct Work

Drill 5/16" Hole In Ductwork For Probe

1/4“ Barb Fitting

1/4“ O.D. X 3/16” I.D. x 14” Long - Fire Rated Tubing

Slide Over 1/4“ Barb Fitting

Tubing Not To Exceed 250 Ft. Length.

Do Not Splice Tubing.

Connect This End Of Tubing To “Hi”

Port Of Pressure Sensor

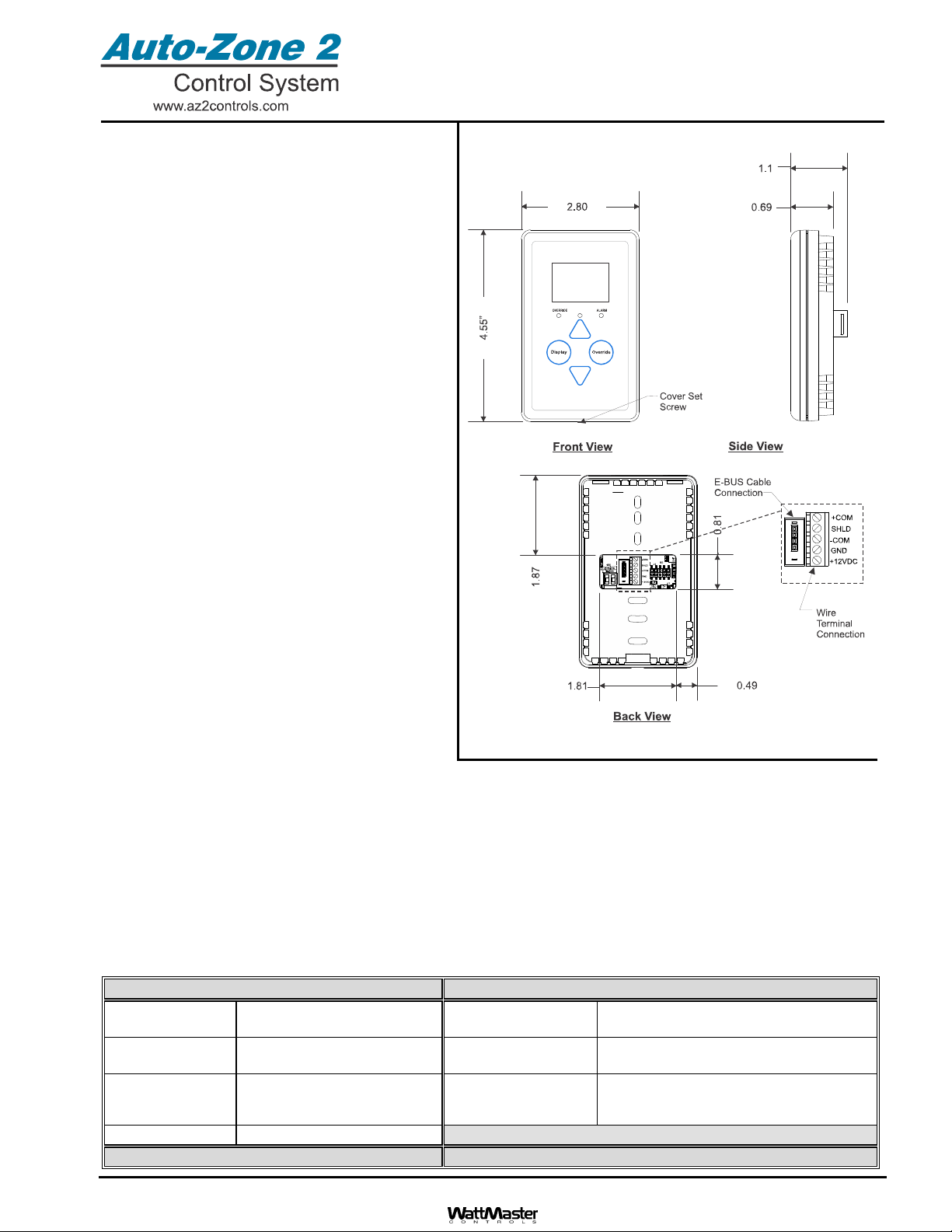

Form: AZ2-OE217-02-03-EBUS-DRS-1D.doc Page 1 of 1

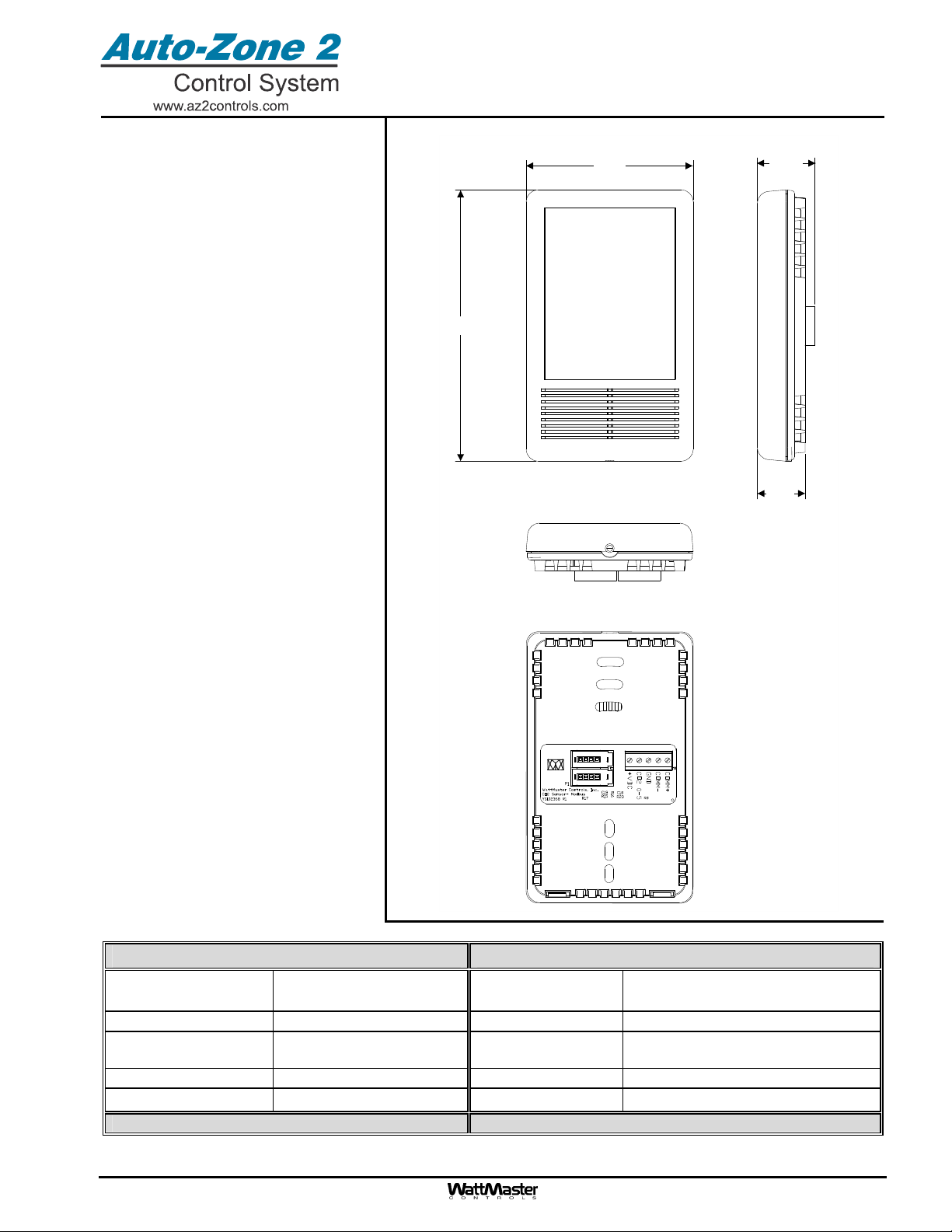

Description

The OE217 series of Touch Screen E-BUS Digital

Room Sensors are used to sense Space Temperature

only or Space Temperature & Space Humidity. The

Space Temperature Sensor only model (OE217-02) is

used with the AZ 2 Main Controller, GPC-XP Controller

or the Zone/VAV Controller. The (OE217-03) model

senses both Space Temperature & Humidity and is

only used with the AZ 2 Main Controller or GPC-XP

Controller.

Besides sensing Temperature & Humidity, the E-BUS

Digital Room Sensors also provide these other useful

features:

• User Friendly Graphical LCD Display with LED

Backlight

• Display the Current Space and Outdoor Air

Temperature

• Display the Current Space Humidity and

Outdoor Air Relative Humidity (OE217-03 Model

Only)

• Display the current Zone Setpoint Temperature

• Equipped With Push Buttons for Changing the

Zone Setpoint Temperature

• Equipped With an Override Button for Forcing

the AZ 2 Main Controller into Occupied

Operation from Unoccupied Operation

• Provides graphics to indicate the mode of

operation

• Provides LEDs to indicate Schedule Override,

Button Push, and Alarms

The sensors connect to the AZ 2 Main Controller,

GPC-XP Controller or, Zone/VAV Controllers using E-

BUS cables connected between the controller and the

sensor or to the wire terminals using (4) conductor

cable. The E-BUS cables are available in multiple lengths to fit your job requirements. The E-BUS cables or (4) conductor

cable should not run in conduit with other AC line voltage wiring or with any conductors carrying highly inductive loads.

Mounting

The Digital Room Sensor is designed to be mounted to a vertical, 2” x 4” electrical box recessed in the wall. If the wall

cannot be penetrated, a plastic surface mount box such as those made by WiremoldTM, may be used to mount the

sensor to the wall surface. The Sensor is mounted by removing the front cover and fastening the housing base to the

electrical box using the supplied (2) 6/32” x 1” machine screws. The E-BUS cable is then plugged into the E-BUS

connector or the or (4) conductor cable is wired to the wire terminals. The cover is then placed onto the housing base

and the Allen Screw on the bottom of the base is adjusted to hold the cover in place.

OE217-02 & OE217-03 E-BUS

Digital Room Sensor

Technical Data OE217-02 & OE217-03 E-BUS Digital Room Sensor

Sensor Element Type III Thermistor 10k ohm

@ 77 F or Sensirion Device

Display 112 x 64 Monochrome Graphical LCD

w/LED Backlight

Sensor Reading

Range

40F to 120F

RH = 0-100%

Connection E-BUS Connector or

Wire Terminals

Ambient

Temperature

Limits

-40F to 180FWeight 3.2 oz.

Accuracy RH +/-3%, Temp +/- .8F

Three Year Warranty WattMaster reserves the right to change specifications without notice

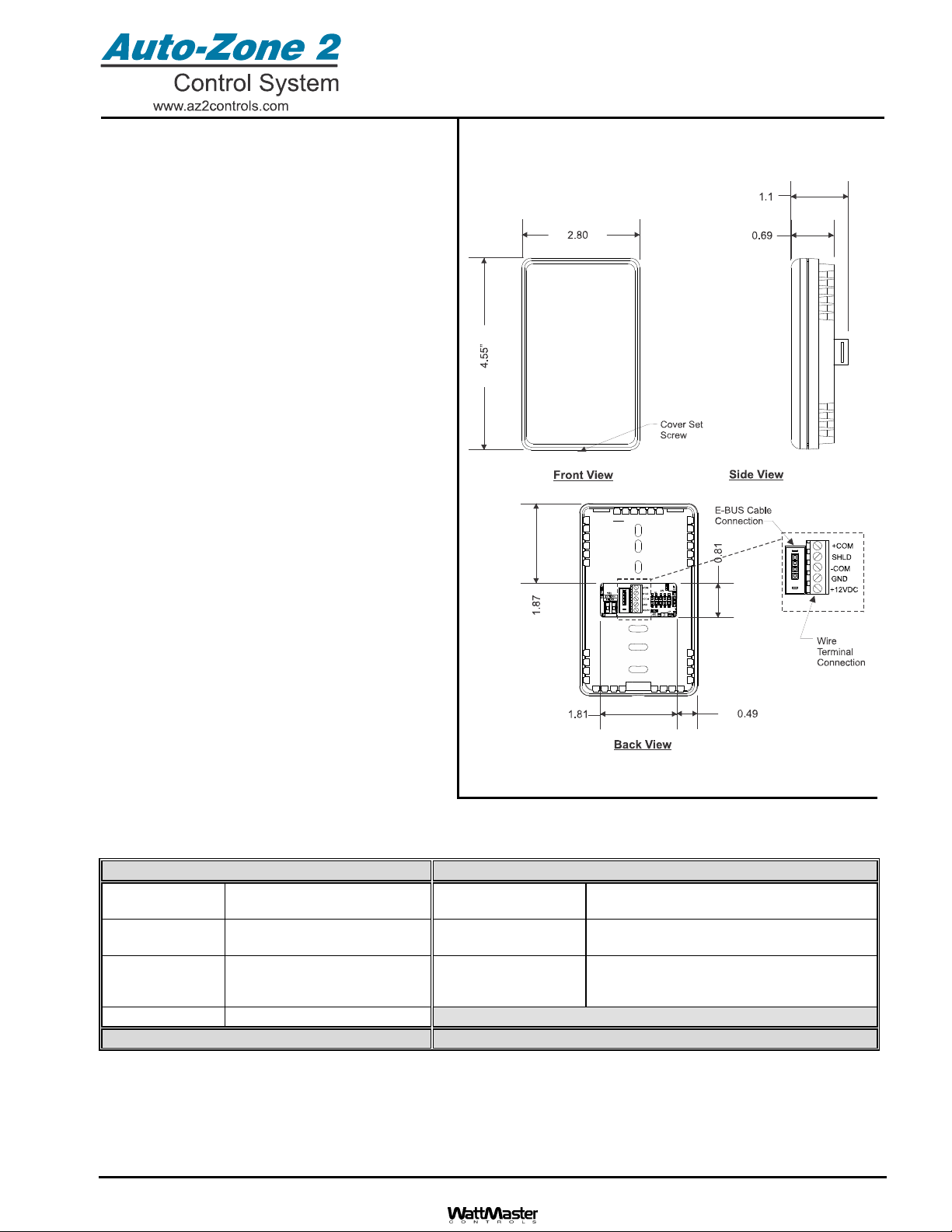

Form: AZ2-OE217-04-EBUS-DRS-1D.doc Page 1 of 1

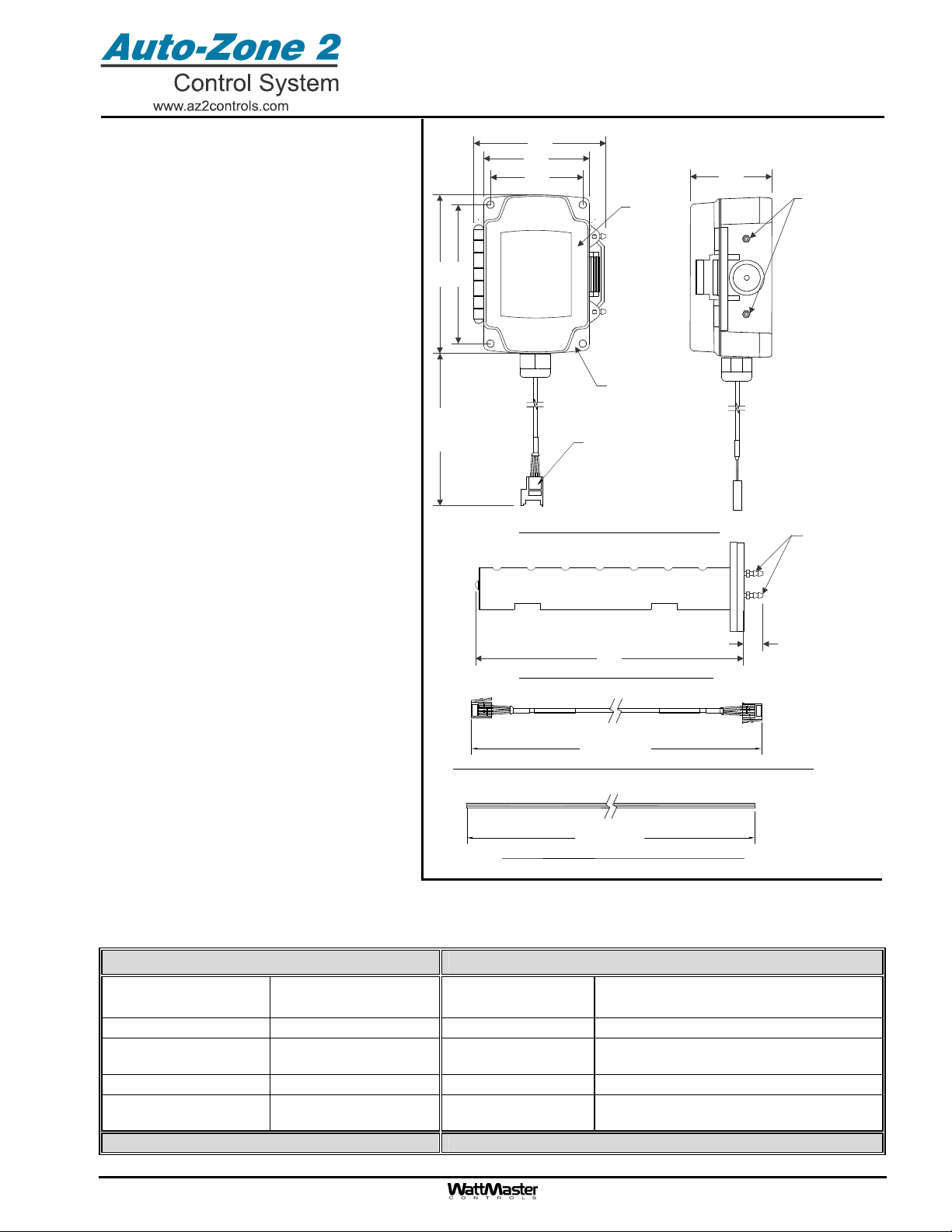

Description

The OE217-04 E-BUS Digital Room

Temperature/Humidity Sensor Without Display is used

to sense Space Temperature & Space Humidity in

locations or applications where a display and its

associated features are not wanted or needed.

Because it has no display it does not have the

override, status or setpoint display capabilities that the

OE217-02 & OE217-03 have.

This sensor can be used with either the AZ 2 Controller

(OE630-23-AZ2) or the GPC-XP Controller (OE338-23-

GPCXP). It cannot be used with the Zone/VAV

Controllers (OE326-23D-AZ2 or OE326-23I-AZ2).

The sensors connect to the AZ 2 Main Controller, or

GPC-XP Controller using E-BUS cables connected

between the controller and the sensor or to the wire

terminals using (4) conductor cable. The E-BUS cables

are available in multiple lengths to fit your job

requirements. The E-BUS cables or (4) conductor

cable should not run in conduit with other AC line

voltage wiring or with any conductors carrying highly

inductive loads.

Mounting

The Digital Room Sensor is designed to be mounted

to a vertical, 2” x 4” electrical box recessed in the

wall. If the wall cannot be penetrated, a plastic

surface mount box such as those made by

WiremoldTM, may be used to mount the sensor to

the wall surface. The Sensor is mounted by

removing the front cover and fastening the housing

base to the electrical box using the supplied (2)

6/32” x 1” machine screws. The E-BUS cable is then

plugged into the E-BUS connector or the or (4)

conductor cable is wired to the wire terminals. The

cover is then placed onto the housing base and the

Allen Screw on the bottom of the base is adjusted to

hold the cover in place.

OE217-04 E-BUS Digital

Room Temp/Humidity Sensor

Without Display

Technical Data OE217-04 E-BUS Digital Room Temp/Humidity Sensor

Sensor Element Type III Thermistor 10k ohm

@ 77 F or Sensirion Device

Display None

Sensor Reading

Range

40F to 120F

RH = 0-100%

Connection E-BUS Connector or

Wire Terminals

Ambient

Temperature

Limits

-40F to 180FWeight 3.2 oz.

Accuracy RH +/-3%, Temp +/- .8F

Three Year Warranty WattMaster reserves the right to change specifications without notice

Form: AZ2-OE256-05—EBUS-CO2Sensor-1C.doc Page 1 of 1

Description

The Wall Mounted E-BUS CO2Sensor

(OE256-05) is used in conjunction with the

AZ 2 Controller (OE630-23-AZ2) or GPC-

XP Controller (OE338-23-GPCXP) to

monitor and control CO2levels in the

building environment.

Some typical applications are:

Demand Control Ventilation

Controlling ventilation in a building

where the occupancy varies

frequently

Controlling ventilation based on CO2

levels to ensure excess outside air

is not causing energy waste

To ensure good air distribution

throughout building zones

The OE256-05 is used for monitoring room

CO2levels and is designed for permanent

wall mounting in the conditioned space. It

connects to the AZ 2 or GPC-XP Controller

using an EBC E-BUS cable. It can be daisy

chained with the 217-02 E-BUS Digital

Room Temperature Sensor for applications

requiring both a room CO2sensor and

room temperature sensor.

The OE256-05 CO2 Sensor uses non-

dispersive infrared (NDIR) technology. The

CO2 Sensor’s accuracy is 50 ppm @1000

ppm or 2% of the measured value and has

a measurement range of 0-2000 ppm.

Mounting

The OE256-05 CO2 Sensor utilizes a sub-

base mounting plate with either terminal

blocks or E-BUS connection, providing for

quick and easy mounting and wiring. The

wall-mounted sensor’s sub-base is

compatible with standard junction boxes. A

locking screw secures the assembly to the

wall.

4.54

2.80 0.96

0.80

OE256-05 E-BUS Digital

CO2Sensor – Wall Mounted

Technical Data OE256-05 – CO2Sensor

Input Power 12-34 VDC Power Consumption 30 mW Maximum Average

1.25 W Peak Power

Operating Temperature 14to 122F Operating Humidity 5-95% RH Non-Condensing

Sample Method Diffusion Or Flow—through

50-100 ml/min Measurement Range 0 to 2000 ppm

Sensitivity <20 ppm Resolution 1 ppm

Analog Output 0-5 VDC Communications E-BUS

One Year Warranty WattMaster reserves the right to change specifications without notice

Form: AZ2-OE256-07-E-BUS-DUCT-CO2-01B.doc Page 1 of 1

Description

The Duct Mounted E-BUS Digital CO2Sensor is

used with the AZ 2 Controller (OE630-23-AZ2) or

the GPC-XP Controller (OE338-23-GPCXP) to

monitor and control Return Air CO2levels in the

building environment.

Some typical applications are:

Demand Control Ventilation

Controlling ventilation in a building where

the occupancy varies frequently

Controlling ventilation based on CO2

levels to ensure excess outdoor air is not

causing energy waste

To ensure good air distribution throughout

building zones

The OE256-07 is used for monitoring duct CO2

levels and is designed for permanent mounting in

the Return Air duct. It utilizes an aspiration box to

accurately capture CO2levels in the duct. It con-

nects to the AZ 2 or GPC-XP Controller by using

an E-BUS cable with E-BUS connectors.

The OE256-07 CO2 Sensor uses non-dispersive

infrared (NDIR) technology and has a measure-

ment range of 0-2000 ppm.

Mounting

The OE256-07 CO2 Sensor is housed in an aspi-

ration box. A conduit clamp is provided to help

seal the opening where the sensor cabling pene-

trates the aspiration box housing. The sensor has

an E-BUS connector for connecting it to the pro-

vided EBC E-BUS cable. The EBC E-BUS Cable

connects to the AZ 2 or GPC-XP Controller or E-

BUS Hub and then to the AZ 2 or GPC-XP Con-

troller. The sensor and aspiration box assembly

is mounted and secured to the ductwork with the

(2) supplied sheet metal screws. The remote

pickup tube assembly is mounted separately to

the ductwork by first cutting a 11/4” diameter hole

in the ductwork wall. The remote pickup tube is

then inserted into the hole. The remote pickup

tube is then secured to the ductwork by inserting (2) supplied sheet metal screws through the (2) mounting holes in the remote

pickup tube mounting plate and securing the remote pickup tube assembly by screwing it to the ductwork using a manual or

powered screw driver to tighten the screws. Using the supplied 10 ft. long tubing, connect the remote pickup tube to the aspi-

ration box assembly, cutting the tubing to fit.

432 1

3M

E-BUS CONNECTOR

FEMALE END

SENSOR

HOUSING

HINGED

COVER

BRASS BARB

FITTINGS FOR

0.170 I.D. TUBING

BRASS BARB

FITTINGS FOR

0.170 I.D. TUBING

EBC-10F

"WATTMASTER EBUS" "WATTMASTER EBU S"

EBC-10F

432 1

3M

432 1

3M

120.00” APPROX.

120.00” APPROX.

E-BUS CONNECTOR EXTENSION CABLE WITH MALE ENDS (PROVIDED WITH SENSOR)

0.170 I.D. TUBING

(

PROVIDED WITH SENSOR

)

FIRE RATED

CO2 PICKUP TUBE (PROVIDED WITH SENSOR)

CO2 SENSOR, HOUSINGAND CABLEASSEMBLY

5.00"

3.31"

4.12"

2.55”

13.00"

APPROX.

8.25" 0.55”

4.06"

2.81”

OE256-07 E-BUS Digital

CO2Sensor – Duct Mounted

Technical Data OE256-07 Duct Mounted E-BUS CO2Sensor

Input Power 12-34 VDC Power Consumption 30 mW Maximum Average

1.25 W Peak Power

Operating Temperature 14to 122FOperating Humidity 5-95% RH Non-Condensing

Sample Method Flow-Through

50-100 ml/min Measurement Range 0 to 2000 ppm

Sensitivity <20 ppm Resolution 1 ppm

Accuracy 50 ppm @ 1000 ppm

or 2% measured value Communications E-BUS

One Year Warranty WattMaster reserves the right to change specifications without notice

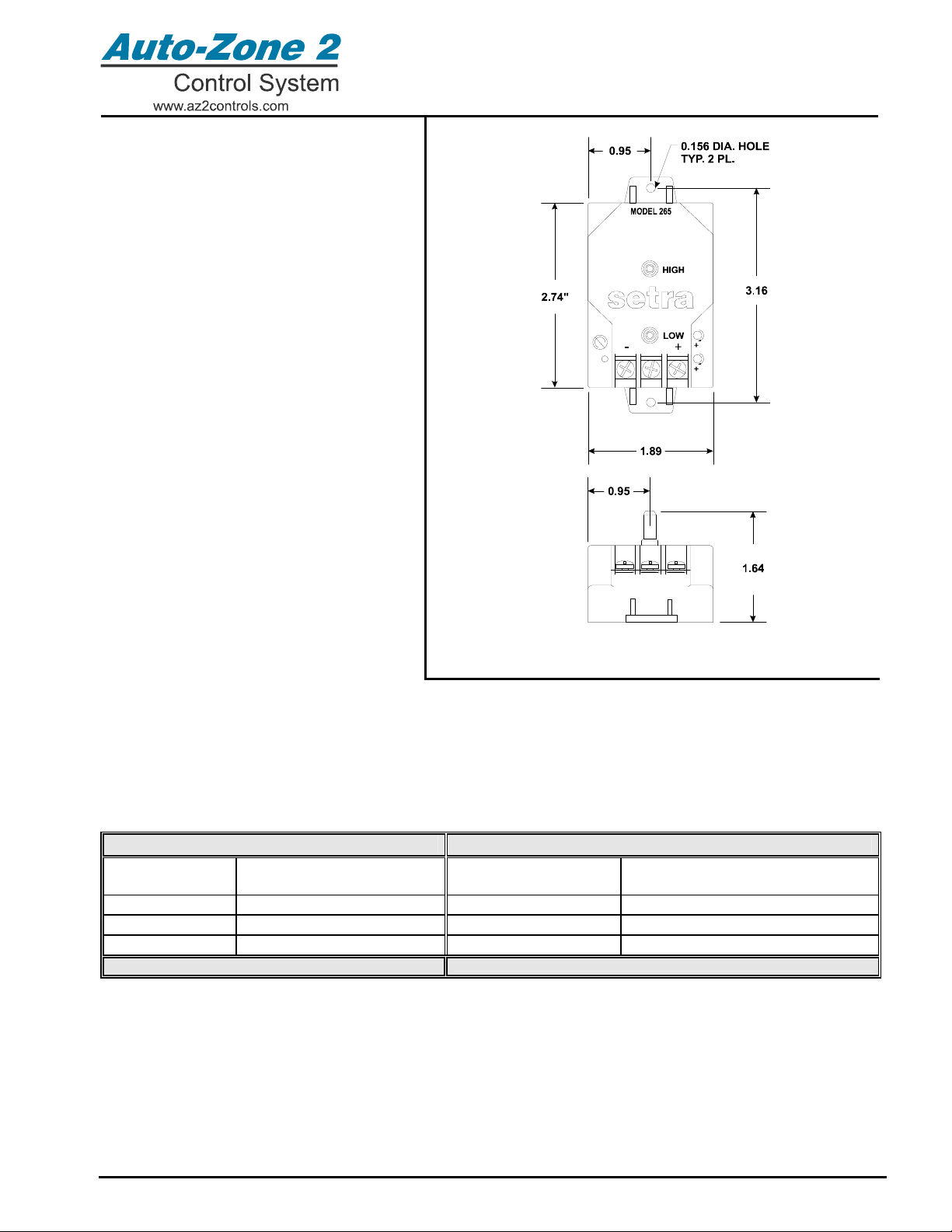

Form: AZ2-OE258-01-BPS-01B.doc Page 1 of 1

Description

The OE258-01 Building Static Pressure

Sensor is used to sense static pressure in

applications where monitoring of building

static pressure is required to insure the

building maintains the proper air

pressurization.

The OE258-01 Building Pressure Sensor

case is molded from fire retardant glass filled

polyester. The sensor utilizes a tensioned

stainless steel diaphragm and insulated

stainless steel electrode. This arrangement

allows up to 10 PSI overpressure without

damage to the unit. The sensor provides a

0.0 to 5.0 VDC output in response to a –0.25

to +0.25 inch WC pressure differential.

Accuracy is 1% of full scale of the sensor.

For easy wiring the OE258-01 Building

Static Pressure Sensor has (3) 6-32 screw

terminal wiring connectors. The sensor has

(2) ¼” barbed fittings provided for the

connection of tubing to the high and low

pressure ports.

The OE258-01 Static Pressure Sensor is

designed to be mounted to a flat surface by

means of the (2) 0.156 diameter holes

provided in the sensor casing. For accurate

readings the sensor must be mounted in a

vertical position.

OE258-01 Building Static

Pressure Sensor

Technical Data OE258-01 Building Static Pressure Sensor

Operating

Pressure Range -0.25” WC to +0.25” WC

Pressure Differential Power Input

Power Output 24 VDC

0 to 5 VDC

Operating Temp 0F to 150FHysteresis 0.1% of full scale

Circuit 3 Wire Non-repeatability

0.05% of full scale

Accuracy 1% of full scale Weight 3 ounces

Eighteen Month Warranty WattMaster reserves the right to change specifications without notice

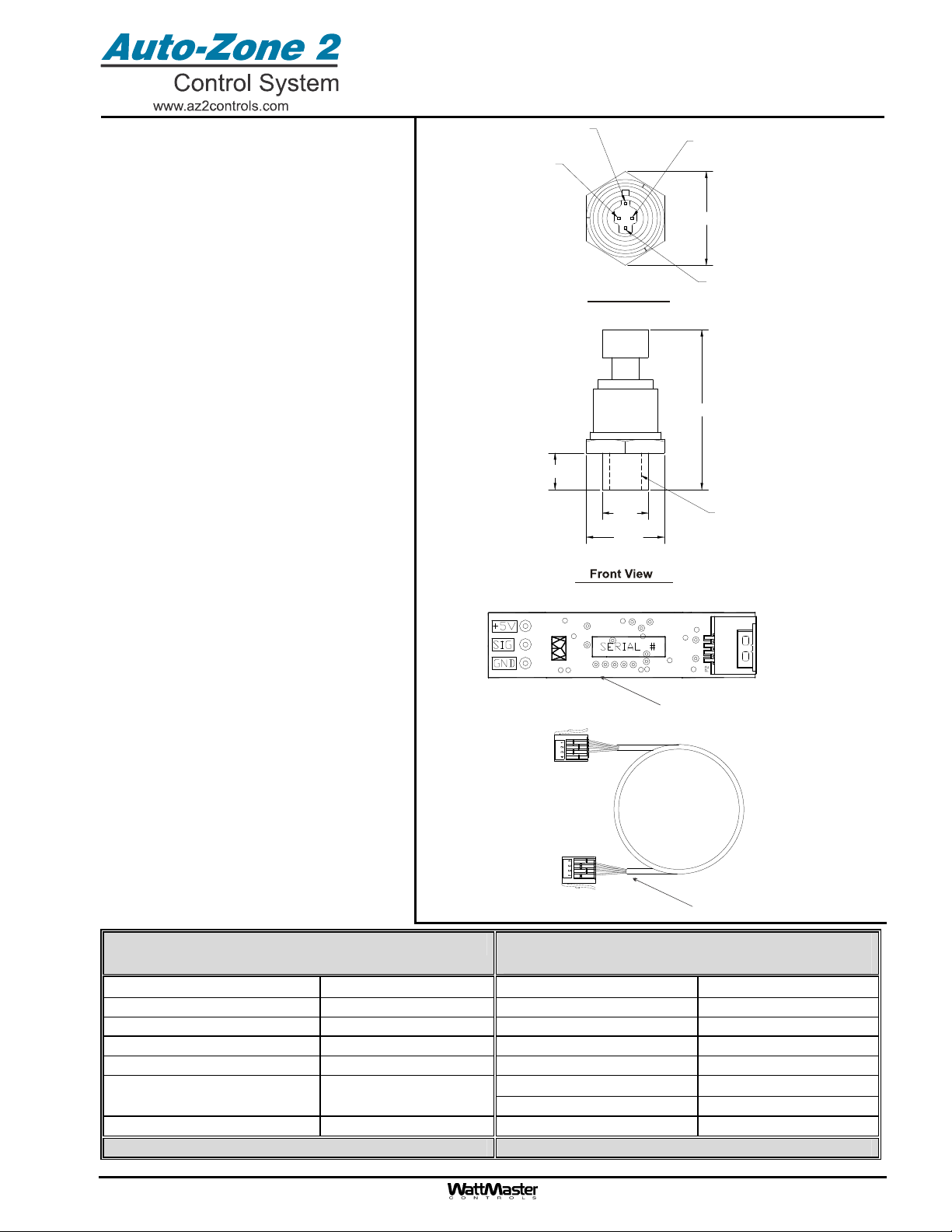

Form: AZ2-OE275-03-A-SuctPressSensorKit-1B.doc Page 1 of 1

Description

The OE275-03 Suction Pressure Transducer Kit

is comprised of the OE275-01 Suction Pressure

Transducer, an E-BUS Adapter Board, and a 3

foot EBC E-BUS cable. It is required for any AZ

2 Controller application with DX Cooling that

requires Dehumidification. The Suction

Pressure Transducer is used to measure

suction pressure at the HVAC unit’s DX

evaporator coil suction line. This suction line

pressure is converted to saturated refrigerant

temperature by the AZ 2 Controller. This

temperature is used by the AZ 2 Controller to

accurately control the compressors to provide

optimum performance from the system during

Dehumidification operation.

The Suction Pressure Transducer connects to

the E-BUS Adapter Board’s V, SIG, and GND

terminals through a cable. The cable is supplied

with a 3-pin Packard mating connector for

attachment to the sensor on one end and has 3

color-coded stripped wires on the other end.

The stripped wire ends can be spliced to other

wires to extend the wiring length when required.

The EBC E-BUS Cable connects to the E-BUS

Adapter Board. This cable must then connect to

the AZ 2 Controller directly or to an AZ 2

Expansion Board connected to the AZ 2

Controller.

The OE275-03 Suction Pressure Transducer’s

metal wetted parts are made from stainless

steel and Haynes 214 alloy. The Suction

Pressure Transducer is weather resistant.

Connection to the pressure source is

accomplished by screwing the 1/4” SAE female

Schrader fitting on the Suction Pressure

Transducer onto a 1/4” Schrader male valve

fitting (by others) that is welded into the suction

line. The Suction Line Transducer provides a

0.5 to 4.5 VDC output in response to a 0 to 250

PSIG pressure. Transducer accuracy is 0.25%

of the full scale of the transducer.

OE275-03

Suction Pressure Transducer Kit

Technical Data OE275-03 Suction

Pressure Transducer Kit

Operating Pressure Range -0 to 250 PSI Gauge Power Input 5 VDC

Operating Temp -40F to 185FSignal Output 0.5 to 4.5 VDC

Wetted Parts Construction Stainless Steel Electrical Cable Connection 3 Pin Packard Connector

Sensor Construction Haynes 214 Alloy Electrical Cable Length 3 Feet

Pressure Fitting Construction Stainless Steel Accuracy 0.25% of Full Scale

Pressure Fitting Size 1/4” SAE Female

Schrader Fitting Hysteresis 0.1% of Full Scale

Non-repeatability 0.05% of Full Scale

Weight 2.3 Ounces Response Time 0.05% of Full Scale

Three Year Warranty WattMaster reserves the right to change specifications without notice

2.18

0.50

0.63

1.28

1.06

1/4” SAE Femal

e

Schrader Fitting

Common

(Black)

Not Used

(Red)

+ Excitation

- Output

(White)

Top View

EBC E-BUS Cable

E-BUS Adapter Board

This manual suits for next models

1