The BILTMORE is a pressure-balancing mixer which delivers

a predetermined mix of hot and cold water by compensating

for pressure fluctuations in the hot and cold water supplies.

The BILTMORE features a poppet design valve as part of a

replaceable balancing cartridge. The poppet-type construc-

tion offers two distinct advantages: It will not stick due to lime

build-up or foreign particles in the supply water, and it has a

quick reaction time. The adjustable maximum temperature

stop prevents overadjustment of the handle.

Safety feature: Should either supply fail, the BILTMORE

closes either hot or cold supply water, to prevent a continued

spray of all hot or all cold water.

Capacity ..................................4.6 gpm @ 45 psi

[15 L/min @ 310 kPa Differential]

Maximum Static Pressure ..............125 psig [862 kPa]

Maximum Inlet Temperature..................180°F [82°C]

Inlet and Outlet Sizes ............1/2″sweat or NPT thread

Rough-in Guide ..................................All Models

Handle Rotation Stop............................All Models

Compliance .....................................ASSE 1016

Certified ..........................................CSA B125

The BILTMORE is particularly recommended for shower

and shower/tub installations in hotels, motels, high-rise

apartments, condominiums, and single-family housing.

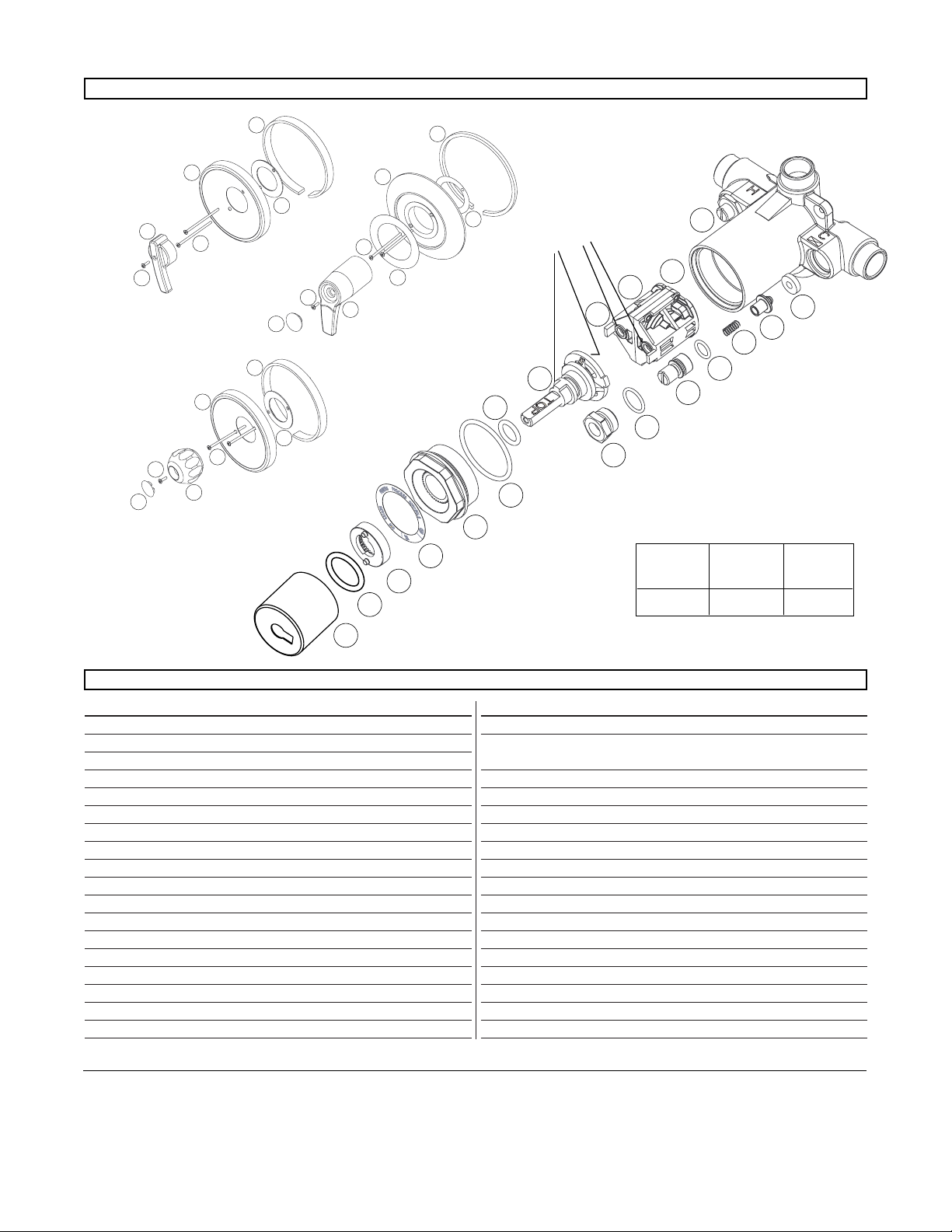

Pressure balancing valve (Type P) senses incoming water

pressures and compensates for fluctuations in either to stabi-

lize outlet temperature (1). The entire balancing poppet assem-

bly is contained in a Celcon chamber (2). This chamber is

replaceable as a complete cartridge. The hot and cold are

mixed by the action of the mixing plate (3). As the temperature

adjustment stem is rotated from shutoff to maximum hot water

discharge temperature, the mixing plate passes the required

proportion of hot and cold water to produce the desired water

temperature. With the adjustment stem in its full clockwise

position, shutoff is obtained by closing off both supplies.

The maximum temperature limit stop (located on the bonnet)

allows the user to set the desired maximum discharge temper-

ature. This mixer does not compensate for supply water tem-

perature changes, so any variation in the water temperature

will affect the control point and the maximum discharge tem-

perature setting.

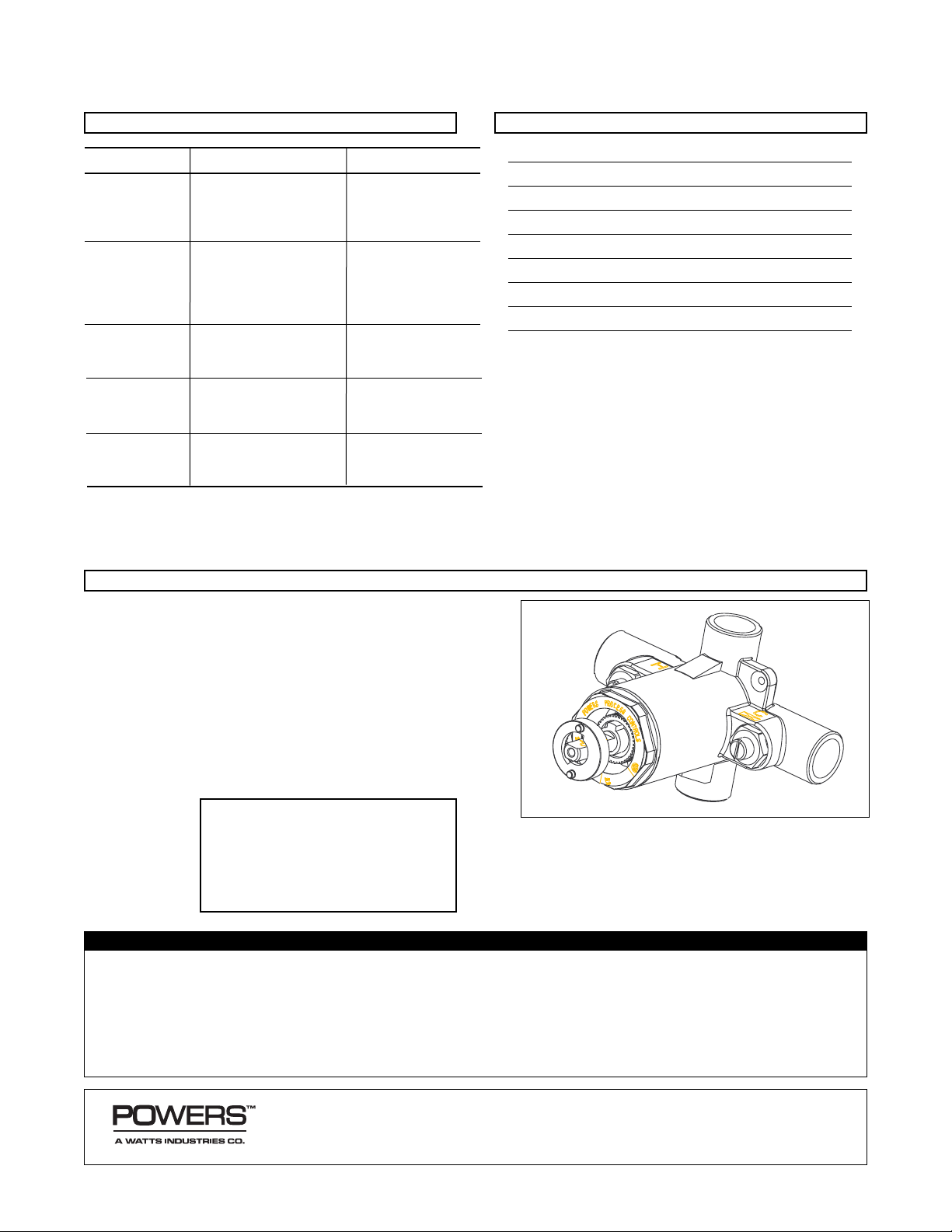

CAUTION: Maintenance of the unit requires resetting of

the maximum temperature adjustment stop. As inlet condi-

tions (pressures and temperatures) vary from site to site and

season to season, failure to properly adjust the maximum tem-

perature adjustment stop can result in excessive hot water

delivery.

TECHNICAL INSTRUCTIONS

BILTMORE Series 900

Pressure-Balancing Valves

Model 3

Form TI 900 v5

P902 P905

P909 P910

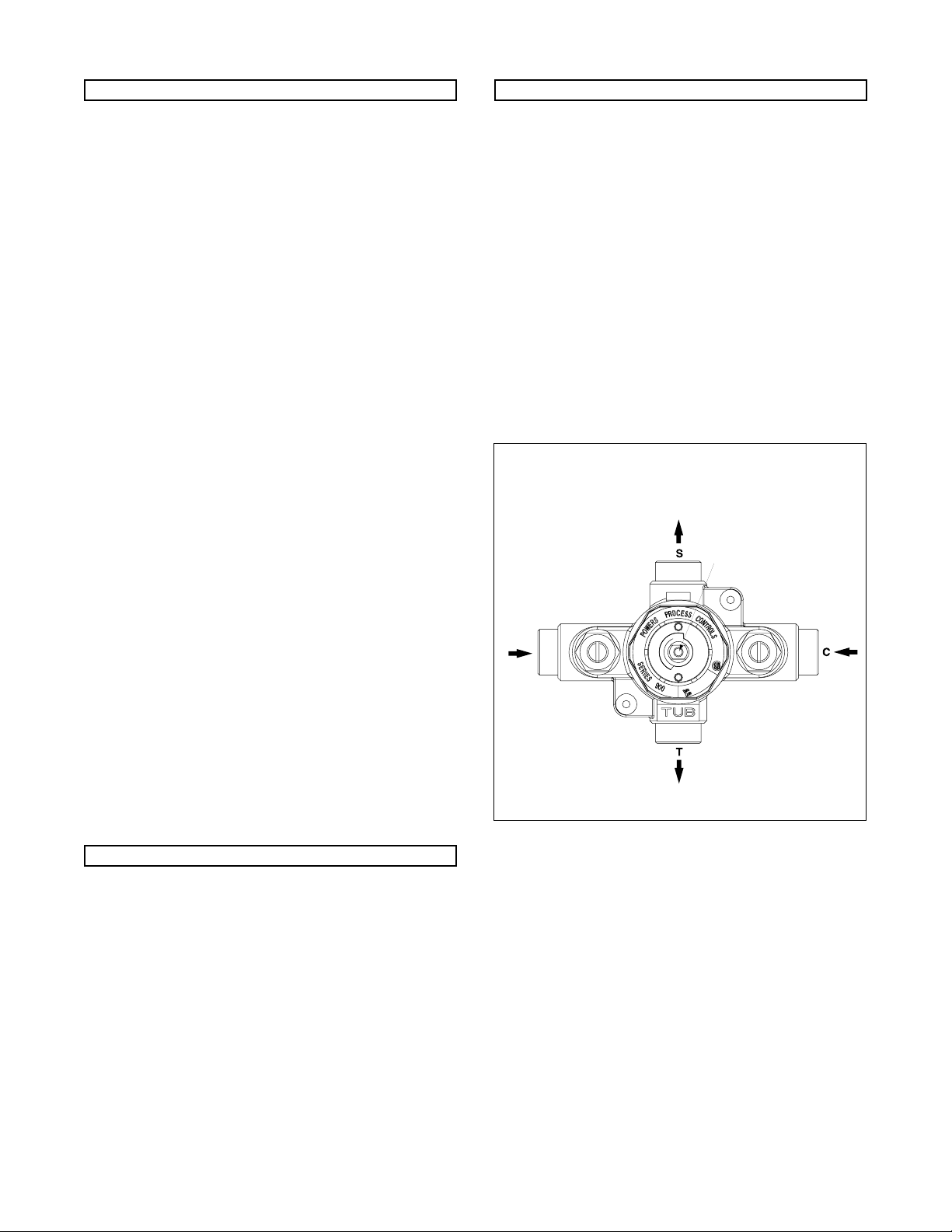

Figure 1 COLD WATER

SUPPLY

HOT WATER

SUPPLY

BALANCING

POPPETS

MIXING PLATE

OPERATION (See Figure 1)

APPLICATION

SPECIFICATIONS

DESCRIPTION