www.teamWavelength.com© 2001-2013

WLD3343

PAGE 3

WLD3343-00400-O

Supply Voltage (Voltage on Pin 14)

Output Current (See SOA Chart)

Power Dissipation, TAMBIENT = +25˚C

Operating Temperature, case [2]

Storage Temperature

Weight

ELECTRICAL AND OPERATING

SPECIFICATIONS

Volts DC

Amperes

Watts [1]

˚C

˚C

oz

UNITVALUE

+4.5 to +12.5

2.2 or 3

9

- 40 to + 85 [3]

- 65 to +150

0.6

VDD

ILD

PMAX

TOPR

TSTG

WLD3343

ABSOLUTE MAXIMUM RATINGS

RATING SYMBOL

Amps

Volts

Volts

Volts

Volts

Volts

Volts

Volts

Volts

nsec

nsec

MHz

Seconds

Seconds

mA

ppm

%

%

3

3.0

10.0

200

2.2

200

10.6

10.4

10.1

460

320

2.0

(Depends on PD BW)

0.24

0.01

0

OUTPUT

Current, peak, see SOA chart

Compliance Voltage, Laser Diode Load

Compliance Voltage, Laser Diode Load

Compliance Voltage, Laser Diode Load

Compliance Voltage, Laser Diode Load

Compliance Voltage, Laser Diode Load

Compliance Voltage, Laser Diode Load

Compliance Voltage, Laser Diode Load

Compliance Voltage, Laser Diode Load

Rise Time

Fall Time

Bandwidth

Bandwidth

Slow Start - Delay

Slow Start - Ramp

Leakage Current [4]

CONSTANT CURRENT CONTROL

Short Term Stability, 1 hour

CONSTANT POWER CONTROL

Short Term Stability, 1 hour

Long Term Stability, 24 hours

WLD3343-2A UNITSTEST CONDITIONSPARAMETER

ILD = 100 mA, 5 V

ILD = 1.0 Amp, 5 V

ILD = 2.0 Amps, 5 V

ILD = 3.0 Amps, 5 V

ILD = 100 mA,12 V

ILD = 1.0 Amp,12 V

ILD = 2.0 Amp,12 V

ILD = 3.0 Amp,12 V

ILD= Full Scale

ILD= Full Scale

Constant Current, Sine Wave

Constant Power

TAMBIENT = 25˚C

TAMBIENT = 25˚C

TAMBIENT = 25˚C

Notes:

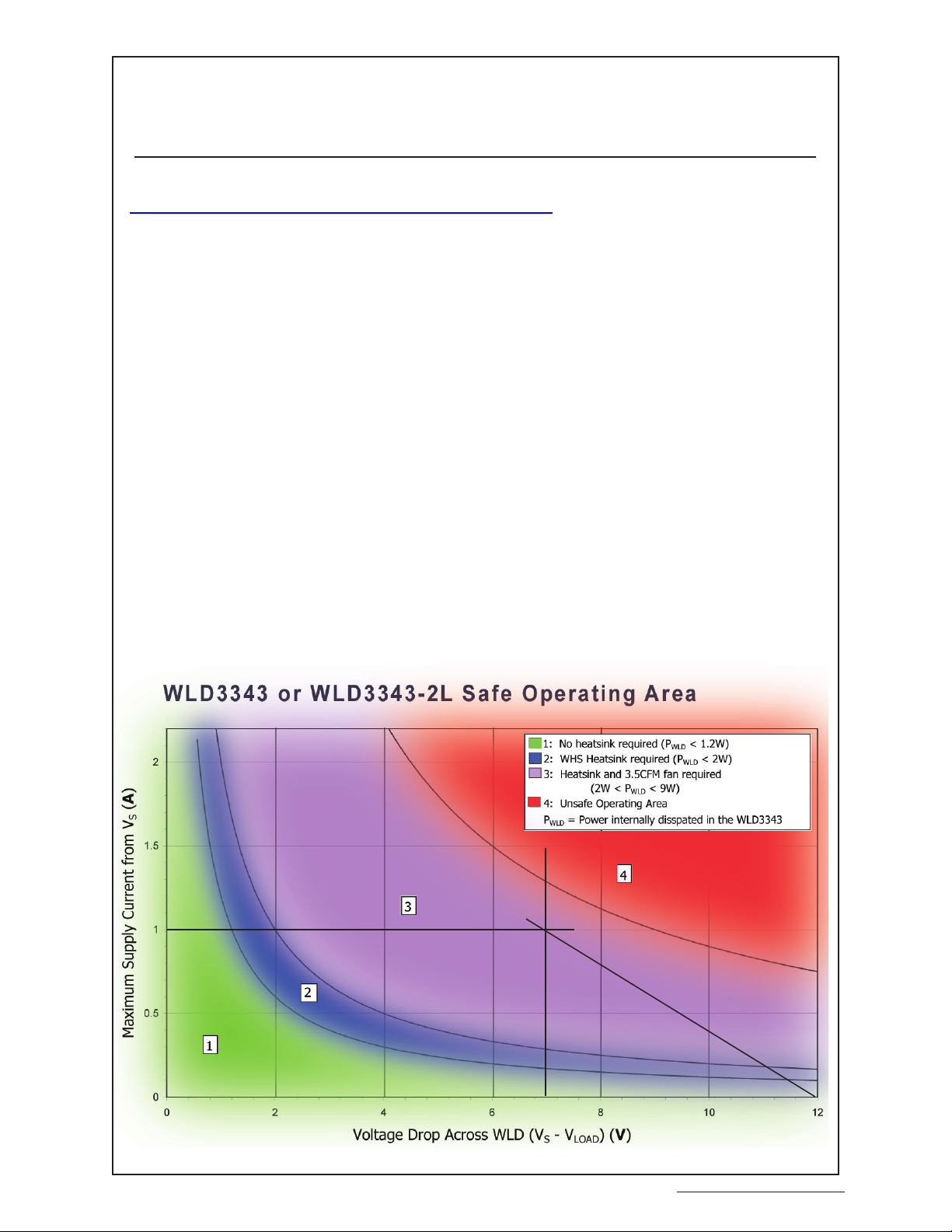

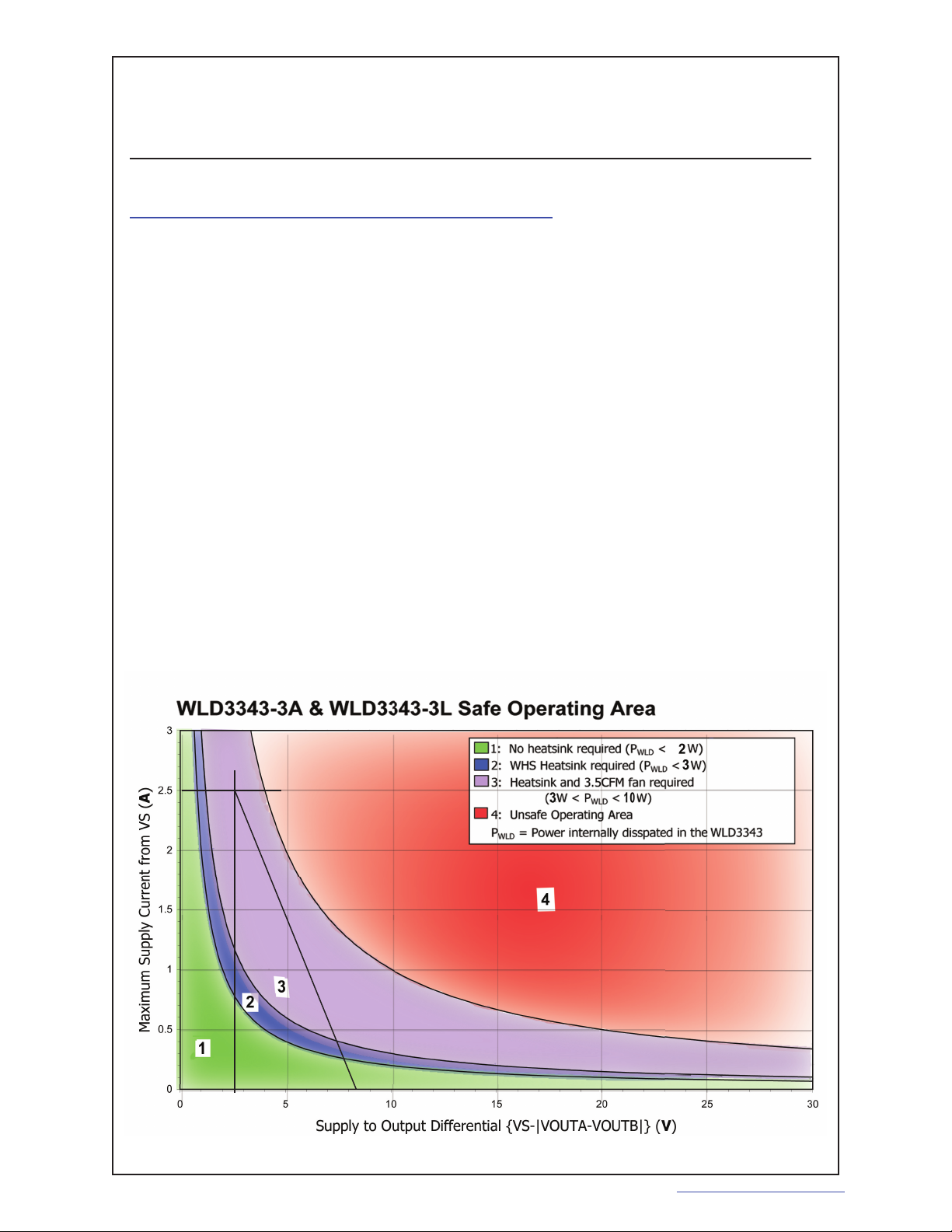

[1] In the WLD3343 and WLD3343-2L models, internal power dissipation is 1.2 W (without heatsink), 2 W (with

heatsink), and 9 W (with heatsink and fan). In the WLD3343-3A and WLD3343-3L models, internal power dissipation

is 2 W (without heatsink), 3 W (with heatsink), and 10 W (with heatsink and fan).

[2] With Revision D forward of the WLD3343, an internal thermostat has been added to activate Shutdown (SHD)

when the internal temperature exceeds 105˚C. The output will be re-enabled after a 250 to 300 msec slow-start once

the internal temperature drops below 95˚C.

[3] Max ambient operating temperature of the WLD3343-3A and WLD3343-3L is 45°C.

[4] Leakage current specification is based on full current set by RSENSE. See page 9 for information on setting the

current range. Minimum turn on current in the 200 mA range is 350 μA. Minimum turn on current in the 2 A range is

12 mA. This specification applies to Rev. E forward.

Noise: To further reduce noise, the WLD3343-2L and WLD3343-3L models are available. Both

are about 2.5 times lower noise than the WLD3343 and WLD3343-3A, respectively. Constant

Power (CP) mode is not available in these models.

0.01

0.05

WLD3343-3A

3.6

3.5

3.0