Contents

Overview.............................................................................................................................................................................................. 1

Key Features .................................................................................................................................................................................. 1

Package Contents........................................................................................................................................................................ 2

Safety Precaution......................................................................................................................................................................... 2

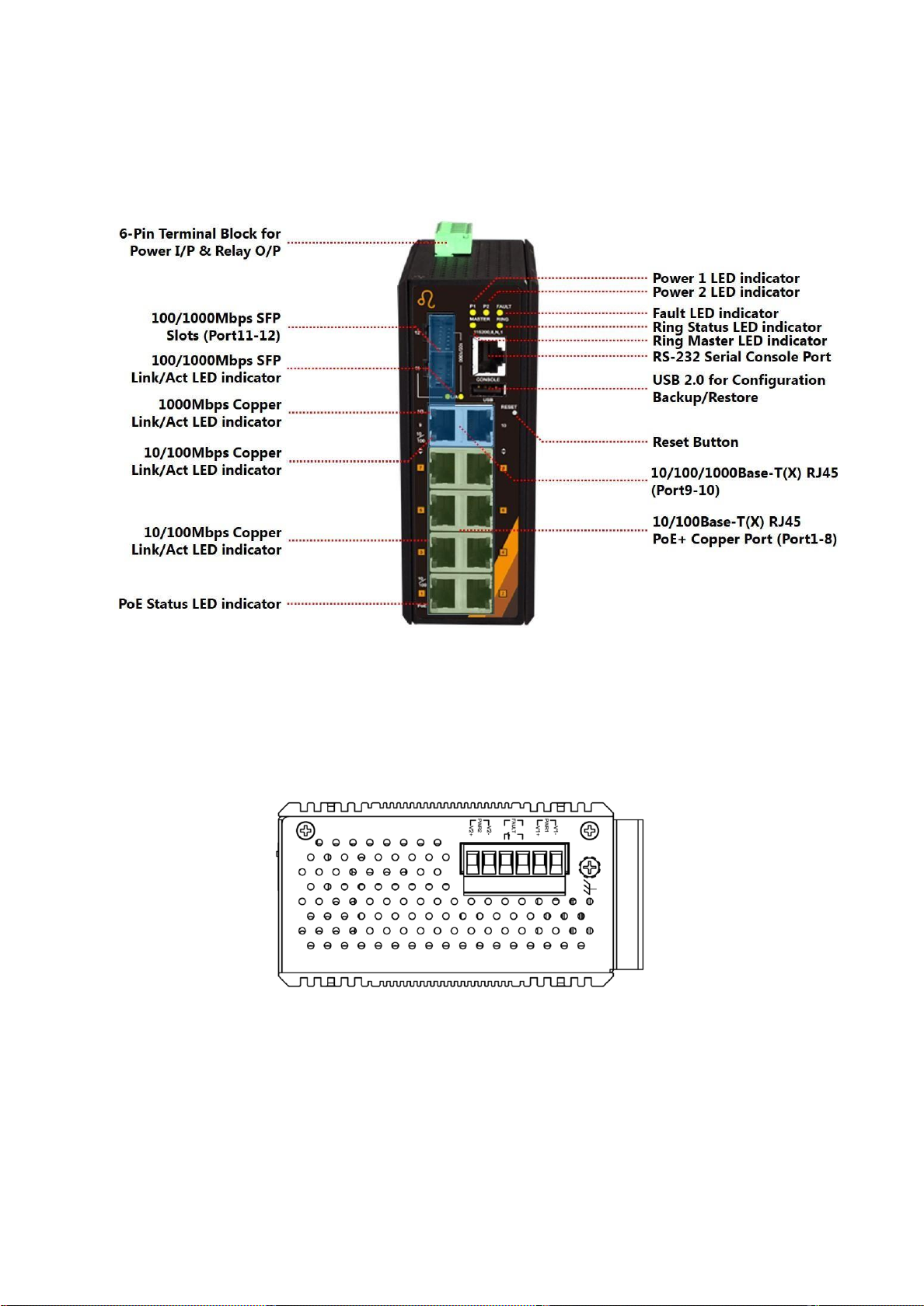

Hardware Description .................................................................................................................................................................... 3

Physical Dimensions................................................................................................................................................................... 3

Front Panel ..................................................................................................................................................................................... 4

Top View ......................................................................................................................................................................................... 4

LED Indicators ............................................................................................................................................................................... 5

Ethernet Ports ............................................................................................................................................................................... 7

Cabling............................................................................................................................................................................................. 8

Wiring the Power Inputs.........................................................................................................................................................10

Wiring the Fault Alarm Contact ...........................................................................................................................................11

Grounding Note.........................................................................................................................................................................11

Mounting Installation...................................................................................................................................................................12

DIN-Rail Mounting ...................................................................................................................................................................12

Wall Mounting............................................................................................................................................................................14

Hardware Installation ...................................................................................................................................................................16

Installation Steps .......................................................................................................................................................................16

Maintenance and Service ...........................................................................................................................................................17

Trouble Shooting ...........................................................................................................................................................................18