SECTION I

TNSTALLATION

A. GENERAL

Installation

of these

powergas

burnersmustconform

to localcodes,or in

theirabsence,theNationalFuel

Gas

Code,

ANSI Z223.IAIFPA54.

In CANADA, "Theequipment

shallbeinstalledin accordance

with the

Provincial

Installation

Requirements,

orintheirabsence,the

CGA 8149.1

andBl49.2Installation

Codesshall

prevail." Authoritieshaving

jurisdiction

shouldbeconsulted

beforeinstallations

are

made.

NOTICE: ANSI or localinstallation

codecompliance

isthe

sole

responsibility

of the

qualified

installer.

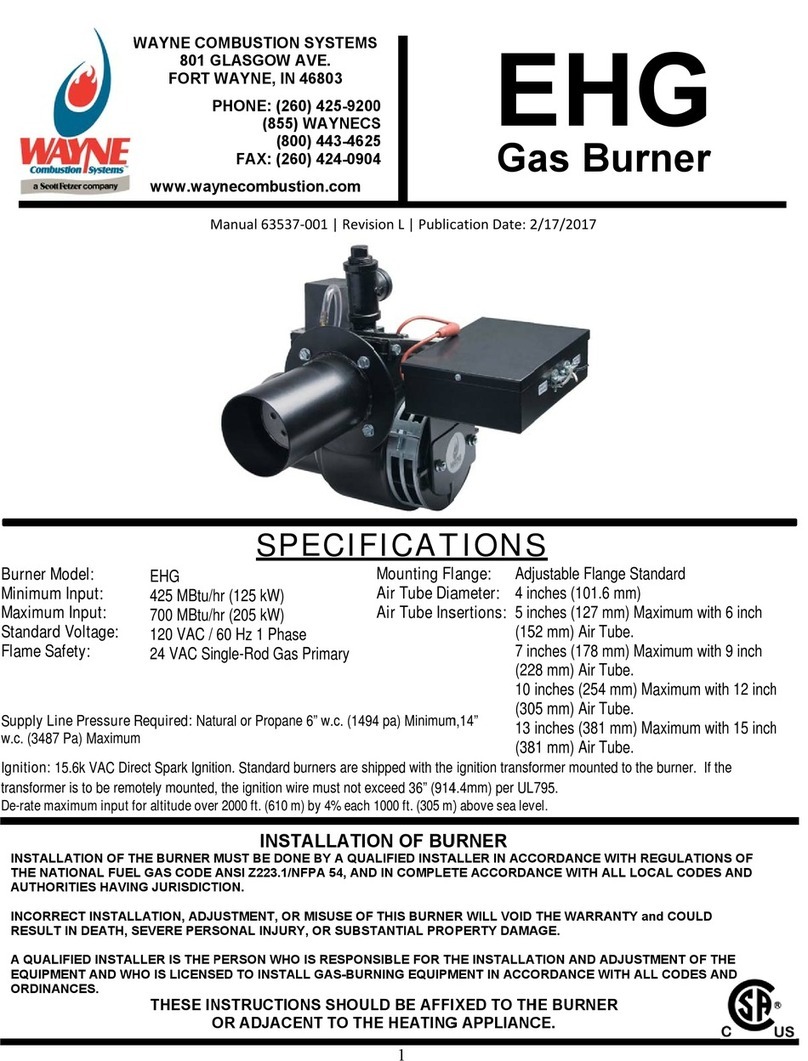

B. VENTILATION

The

EHGburnermodels

covered

bythismanual

shall

not

beinstalledin an

appliancelocatedwhere

normalaircirculationor infiltration

islimitedin

providing

alltheairnecessaryforproper

combustion

and

draft

hood

dilution

air.

Whenthe

heating

applianceisinstalledin atightlyclosedroomwithout

ventilationopeningstooutdoors,

orotherrooms,

provisions

shall

be

made

for supplyingairforcombustion

through

specialopenings,

onenearthefloor

lineandthe

other

near

theceiling.Eachistobesized

on

thebasisof one

squareinch(645

.2mm')ormore

of free

area

each

1,000BTU (.29kW)

input

per

hour.

C.HEATING APPLIANCE INSPECTION

Clean

theappliance

heat

exchangerinterior,

combustionchamberandflue

connections.

Removeall adhering

tars,

scale,dirt and

soot.

Inspecttheheat

exchangerforobviousand

potential

fluegas

leaks.

Cement

all

jointsaround

theappliance

base

and

access

openingstoprevent

airand/orfluegas

leakage

intooroutof thecombustion

chamber.

WarmAir Furnacesx

- Makecertain

theelectricalcharacteristics

of thefan

andlimit switchcorrespond

tothose

required

by thisburner

and

arein

proper

working order.

Hot WaterBoilers* - Makecertain

watertemperatureandaltifude

gauges,

pressure

relief valvesarein proper

working order.

SECTION

I

INSTALLATION

A.GENERAL

Installation

of

these power gas burners must conform to local codes,

or

in

their absence, the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

In

CANADA,

"The

equipment shall be installed

in

accordance with the

Provincial Installation Requirements,

or

in

their absence, the CGA B149.1

and B149.2 Installation Codes shall prevail." Authorities having jurisdiction

should be consulted before installations are made.

NOTICE:

ANSI

or

local installation code compliance

is

the sole

responsibility

of

the qualified installer.

B.

VENTILATION

The

EHG burner models covered by this manual shall not be installed

in

an

appliance located where normal air circulation

or

infiltration

is

limited

in

providing all the air necessary for proper combustion and draft hood dilution

alr.

When the heating appliance is installed in atightly closed room without

ventilation openings

to

outdoors, or other rooms, provisions shall be made

for supplying air for combustion through special openings,

one

near the floor

line and the other near the ceiling. Each

is

to be sized on the basis

of

one

square inch (645.2mm2)

or

more

of

free area each 1,000

BTU

(.29kW) input

per

hour.

C.

HEATING

APPLIANCE

INSPECTION

Clean the appliance heat exchanger interior, combustion chamber and flue

connections.

Remove

all adhering tars, scale, dirt and soot. Inspect the heat

exchanger for obvious and potential flue gas leaks. Cement all joints around

the appliance base and access openings to prevent air and/or flue gas leakage

into

or

out

of

the combustion chamber.

Warm

Air

Fumaces*

-

Make

certain the electrical characteristics

of

the fan

and limit switch correspond to those required

by

this burner and are in

proper

working order.

Hot

Water Boilers* -

Make

certain water temperature and altitude gauges,

pressure

relief

valves are in proper working order.

4