Recommended Precautions

-Only trained and authorised operators should be permitted to use the machine

-Operators must read and obey the instructions displayed on the machine

-Never operate machine on uneven ground or a ramp

-Never operate machine on the edge of a raised dock or platform

-Never operate machine with any covers or guards removed

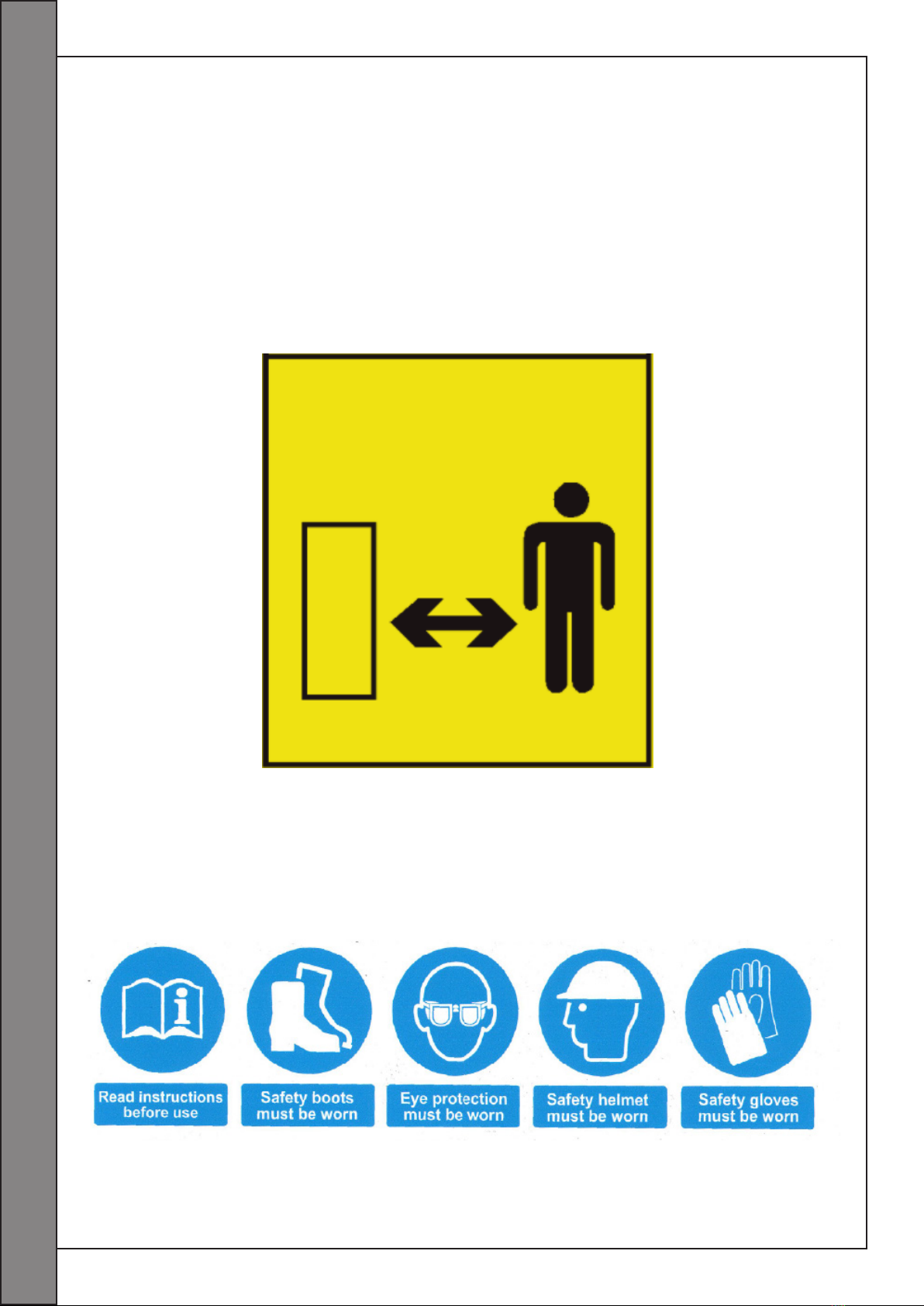

-Anyone other than the operator must keep 2 meters clear of the machine whilst

it is in operation

-Ensure the working area around the machine is clear of obstructions before use

-Before connecting machine to mains supply, ensure voltage and frequency

correspond with thats listed on the range plate

-Do not use extension leads to connect machine to mains supply

-Do not operate if power supply lead and insulation is damaged

-Do not connect a damp power plug or socket

-Ensure the supply socket is fitted with a residual current device

-Ensure there is complete continuity between the machine and an effective

earthing

6