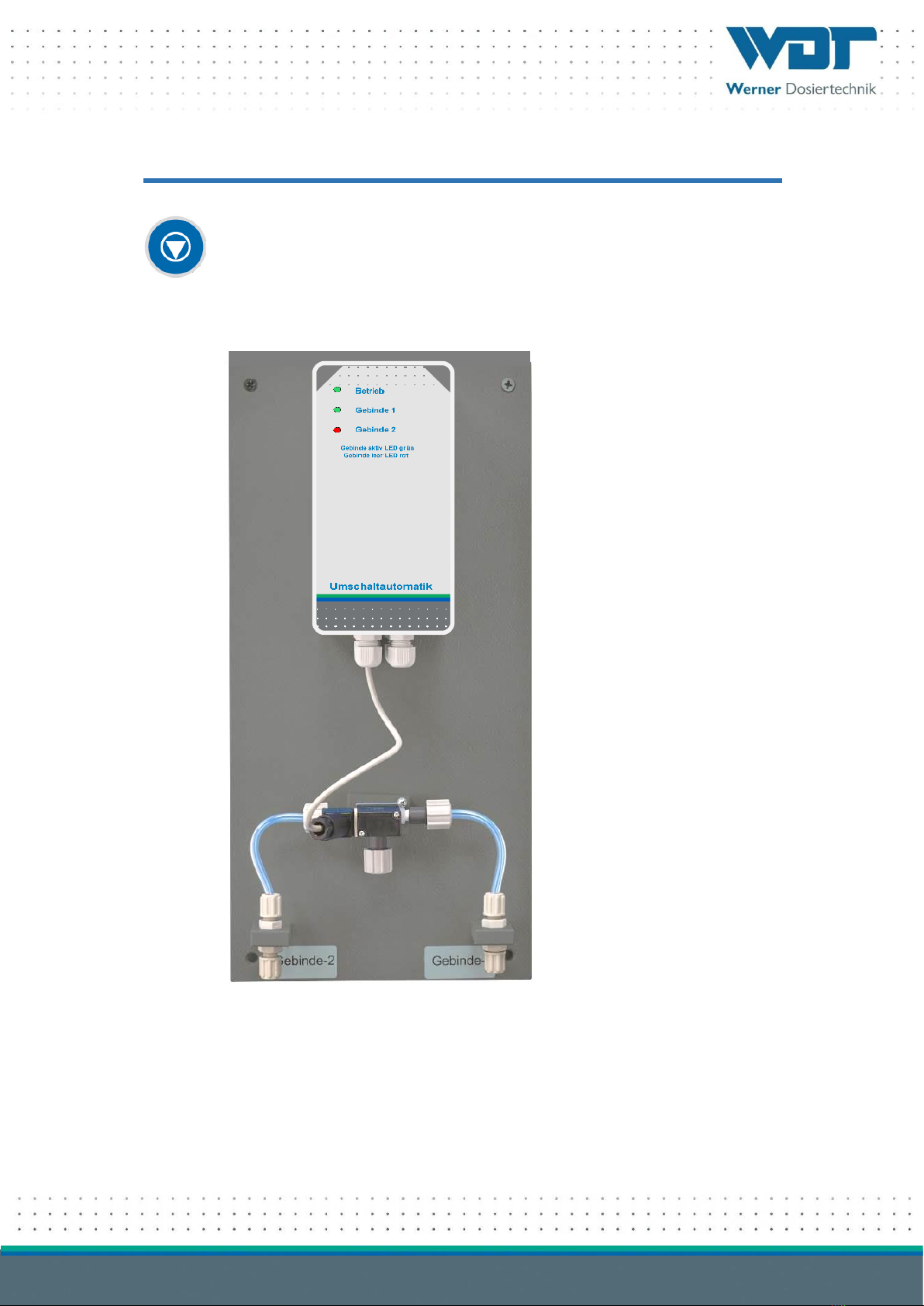

Switch-Over Automatic, type UMAP NT35-R

Index: 03 Date modified: 28/03/2022 OI No.: BA SW 017-03 Umschaltautomatik Typ UMAP NT35-R EN.docx Page 2 of 14

Table of contents

1About these instructions / general .......................................................................................................... 3

1.1 Scope of applicability ........................................................................................................................................3

1.2 Target group .................................................................................................................................................... 3

1.3 Symbols used ...................................................................................................................................................3

1.4 Warranty .........................................................................................................................................................4

1.5 Further information.......................................................................................................................................... 4

1.6 Information regarding support queries.............................................................................................................4

2Safety ...................................................................................................................................................... 5

2.1 Intended use.....................................................................................................................................................5

2.2 Safety notices ................................................................................................................................................... 5

Handling of chemicals, risks to humans and the environment ........................................................................5

Protective measures and rules of conduct ..................................................................................................... 5

3Product description –Functional description –(scope of delivery).......................................................... 6

3.1 Scope of delivery / accessories.........................................................................................................................6

3.2 Product description - Function..........................................................................................................................6

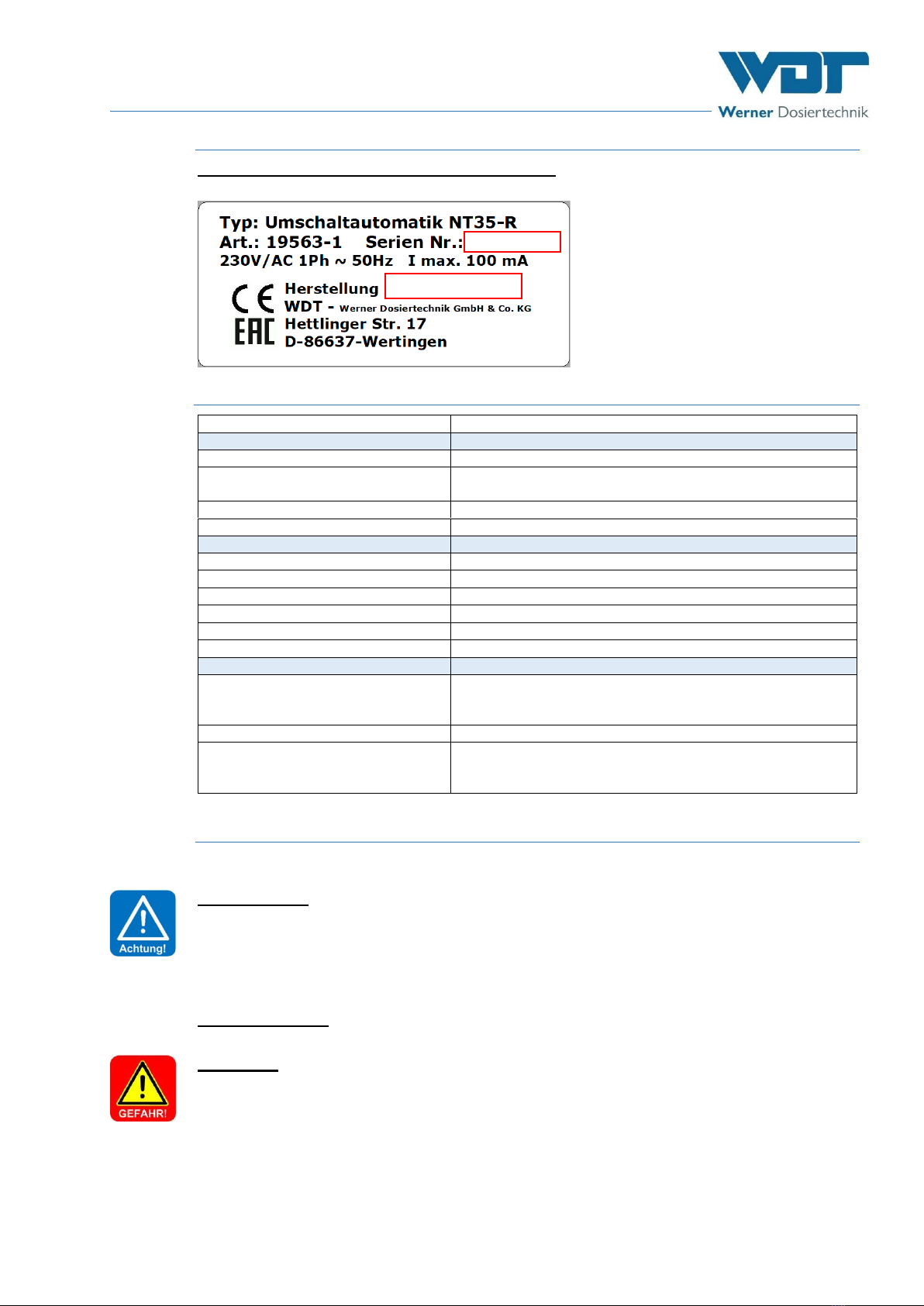

3.3 Identification of the device / identification plate ...............................................................................................7

3.4 Technical data .................................................................................................................................................. 7

3.5 Transport / storage .........................................................................................................................................7

4Installation / Commissioning / Operation ............................................................................................... 8

4.1 Select the installation site..................................................................................................................................8

4.2 Installation instructions / installation.................................................................................................................8

4.3 Commissioning................................................................................................................................................. 8

4.4 Description of the control ................................................................................................................................9

4.5 Replenish consumables.....................................................................................................................................9

5Maintenance, care, faults ....................................................................................................................... 10

5.1 Device maintenance .......................................................................................................................................10

Open and close the housing.........................................................................................................................10

5.2 Trouble-shooting............................................................................................................................................10

6Decommissioning –Storage –Disposal................................................................................................. 11

6.1 General ..........................................................................................................................................................11

6.2 Decommissioning of the switch-over automatic..............................................................................................11

6.3 Disposal of used parts and operating materials...............................................................................................11

7Documents............................................................................................................................................ 12

7.1 Declaration of conformity ..............................................................................................................................12

7.2 Wiring diagrams.............................................................................................................................................13

7.3 Spare part list .................................................................................................................................................13

8Appendices............................................................................................................................................ 14

Imprint:

All rights reserved

© Copyright by WDT –Werner Dosiertechnik GmbH & Co KG

Edition: see footer

Reproduction of any kind and translation into other languages, even in excerpts, are only permitted with the express

authorisation of the company WDT - Werner Dosiertechnik GmbH & Co. KG. Subject to technical modifications

These operating instructions are an English translation of the original German version by the company WDT.

Responsible for the content:

Co. WDT - Werner Dosiertechnik GmbH & Co. KG

Hettlinger Str. 17; D-86637 Wertingen-Geratshofen

Phone: +49 (0) 82 72 / 9 86 97 –0 Fax: +49 (0) 82 72 / 9 86 97 –19

Email: info@werner-dosiertechnik.de