5 | P a g e

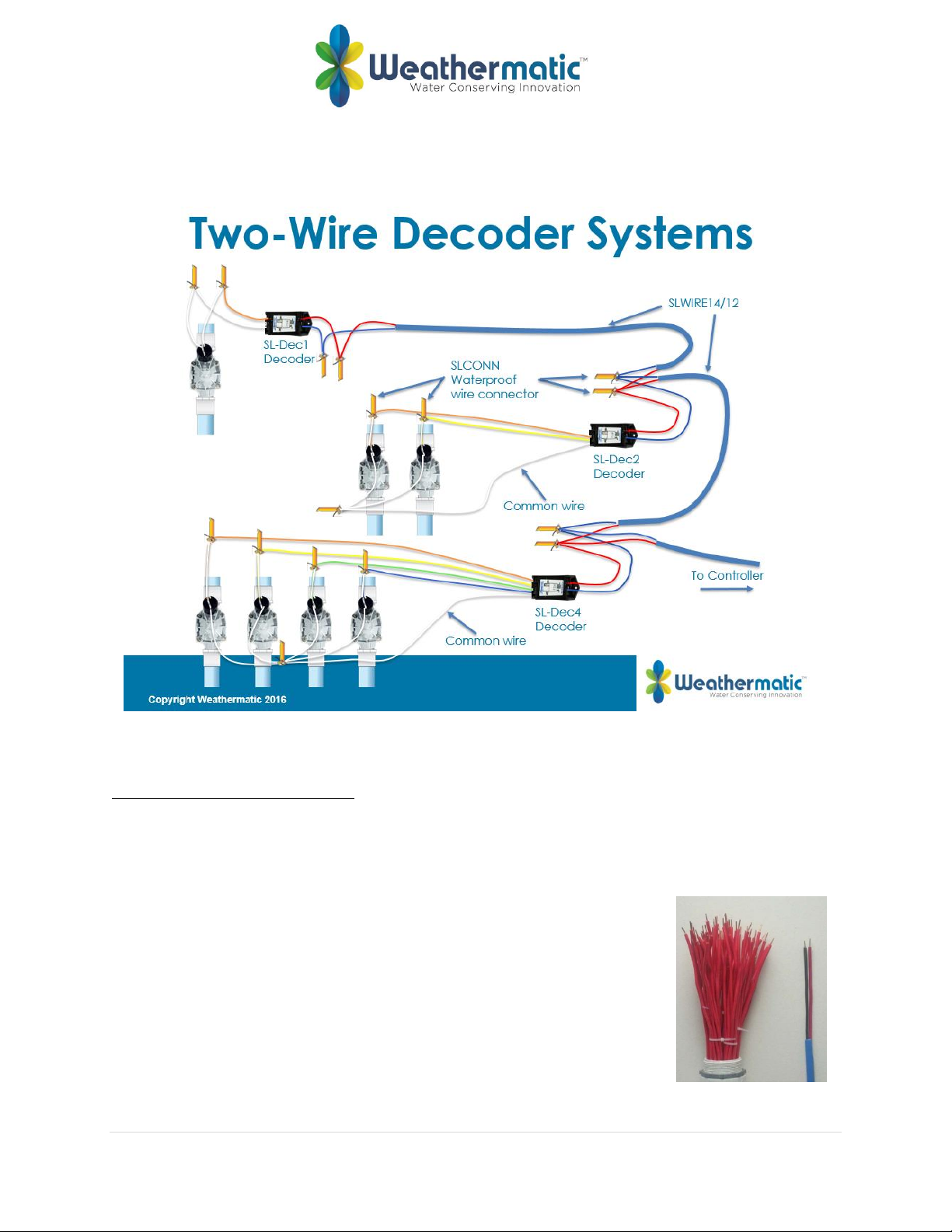

It is suggested that a continuous loop be laid out around the site. This usually follows the main water

lines. The loop will start at the SmartLine® controller and continue around the site and then return to

the controller. This provides the best communication and power path for the system. The loop provides

a redundant path for the power and signal allowing the system to continue operation if the loop is cut.

Branches can come off the main loop and they do not need to be looped back to the main trunk line.

These branches can be other loops, stars or single dead-end lines. The system will work with most wiring

configurations if the wire length requirements are met.

WIRE SIZES

The configuration and size of the wire conductor used will determine the maximum length a wire path

can run. The chart below summaries these distances:

Star Configuration - Wire distance to the furthest decoder, no loop:

Wire Size (Gauge) #18 #16 #14 #12

Wire Length (feet) 1,000 2,000 4,000 6,000

Loop Configuration - Wire distance to the furthest decoder in the loop:

Wire Size (Gauge) #18 #16 #14 #12

Wire Length (feet) 2,000 4,000 10,000 10,000

NOTE: Maximum total wire path length is 10,000 feet

TWO-WIRE

Weathermatic recommends the use of Weathermatic SLWIRE12 or SLWIRE14 cable specifically designed

for an irrigation control system and complying with the following specifications:

•Conductors must be soft drawn, annealed, solid copper conforming to ASTM 33

•Conductor insulation must be 4/64-inch thick polyvinyl chloride (PVC) conforming to UL #493

•The two insulated conductors laid in parallel and encased in a single outer jacket of 3/64-inch thick,

high-density, sunlight resistant polyethylene conforming to ICEA S-61-402 and NEMA WC5, having a

minimum wall thickness of .045-inch

•The two conductors must be color-coded: normally one conductor red and the other black. Both

conductors shall be the same size.

HOW TO SPECIFY:

Weathermatic SmartWire™ Wire

SLWIRE-122 –12 gauge, 2 conductors with poly outer jacket, available in 1,000 or 2,500 feet rolls, blue

outer jacket is standard (other outer jacket color options are availble as special order but can be

expensive)

SLWIRE-142 –14 gauge, 2 conductors with poly outer jacket, available in 1,000 or 2,500 feet rolls, blue

outer jacket is standard (other outer jacket color options are availble as special order but can be

expensive)

WEATHERMATIC SMARTWIRE™ SURGE ARRESTOR

Weathermatic SLGDT gas discharge tube lightning arrestors must be used on all two-wire grids. The

SLGDT lightning arrestor attaches directly to the two-wire system and helps dissipate static electricity

generated by a nearby lightning strike. While Weathermatic components have lightning arresting

features, the SLGDT provides an extra measure of protection.