5

CR4

Table of Contents

Preface ........................................................................................................................................................... 3

General Safety Instructions .......................................................................................................................... 4

1. Technical Description ................................................................................................................................... 6

1.1 Illustration ........................................................................................................................................................ 6

1.2 Machine Description ........................................................................................................................................ 7

1.3. Specifications CR 4 Hatz ................................................................................................................................. 8

1.3. Specifications CR 4 Honda .............................................................................................................................. 9

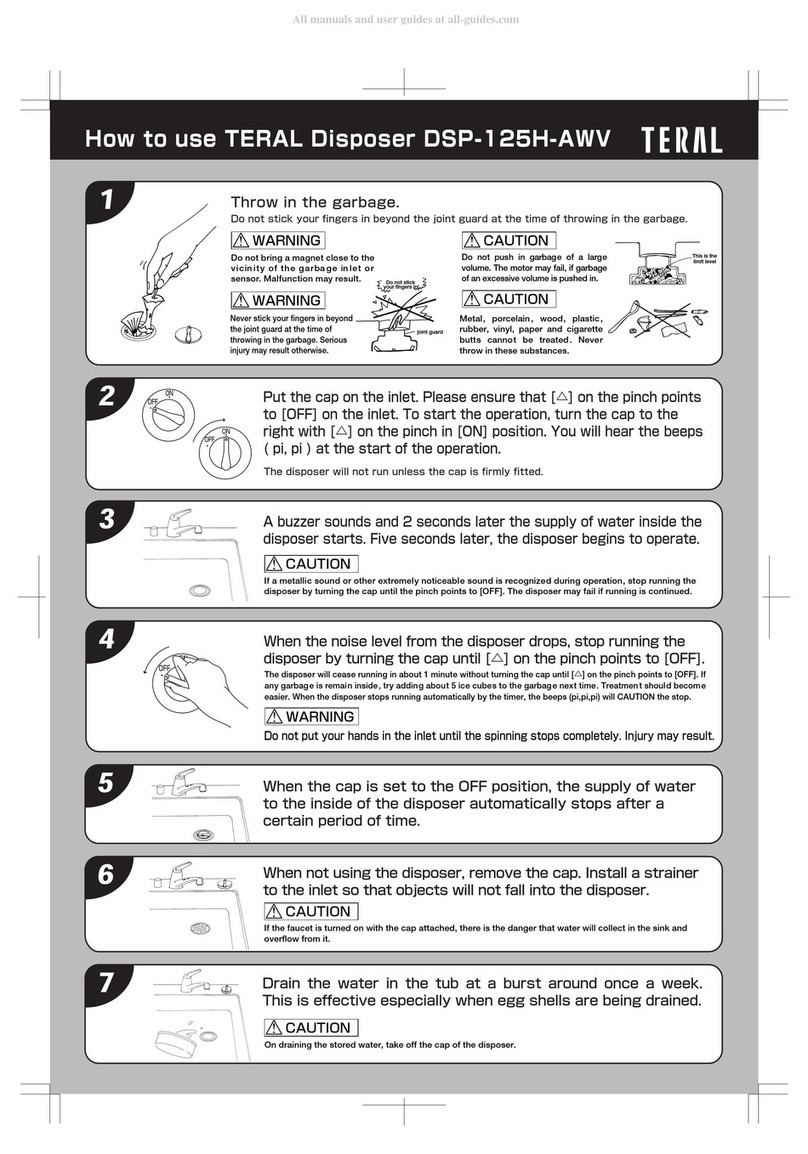

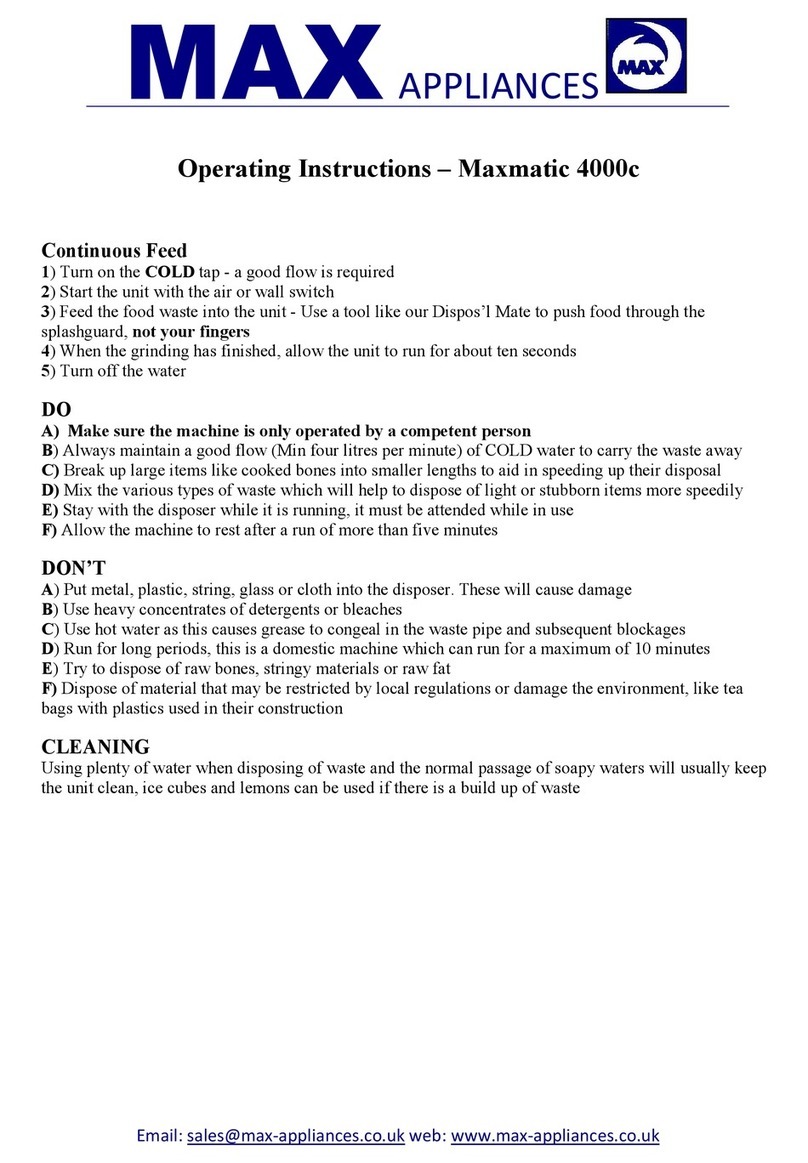

2 Operation ...................................................................................................................................................... 11

2.1 Safety Precautions for the Operation .............................................................................................................. 11

2.2 Transport ........................................................................................................................................................12

2.2.1 Loading by Crane ...........................................................................................................................................12

2.3 Commissioning ...............................................................................................................................................12

2.4 Pre-Start Work ................................................................................................................................................13

2.4.1. Checking the Fuel Level, Hatz Engine ............................................................................................................13

2.4.1.1 Checking the Fuel Level, Honda Engine .........................................................................................................14

2.4.2 Checking the Engine Oil Level ........................................................................................................................15

2.4.2.1 Hatz Engine ....................................................................................................................................................15

2.4.2.2 Honda Engine .................................................................................................................................................15

2.4.3 Fitting the Damper Plate .................................................................................................................................16

2.4.4 Fastening the Undercarriage ..........................................................................................................................17

2.5 Starting ...........................................................................................................................................................18

2.5.1 Starting, Hatz Engine ......................................................................................................................................18

2.5.2 Starting, Honda Engine ...................................................................................................................................19

2.6 Compaction Work ........................................................................................................................................... 20

2.7 Putting the Soil Compactor Out of Operation ..................................................................................................20

2.7.1 Stopping, Hatz Engine ....................................................................................................................................21

2.7.1.1 Stopping, Honda Engine .................................................................................................................................21

3 Maintenance .................................................................................................................................................22

3.1 Safety Precautions for Maintenance Work .....................................................................................................22

3.2 Maintenance Survey .......................................................................................................................................23

3.2.1 Maintenance ...................................................................................................................................................23

3.3 Description of the Maintenance Work .............................................................................................................24

3.3.1 Changing the Engine Oil, Hatz Engine............................................................................................................24

3.3.1.1 Cleaning the Engine Oil Filter, Hatz Engine ....................................................................................................25

3.3.1.2 Changing/Adding Engine Oil, Honda Engine ..................................................................................................26

3.3.2 Cleaning/Replacing the Air Filter Cartridge .....................................................................................................27

3.3.2.1 Hatz Engine ....................................................................................................................................................27

3.3.2.2 Honda Engine .................................................................................................................................................28

3.3.3 Replacing the Fuel Filter .................................................................................................................................29

3.3.3.1 Hatz Engine ....................................................................................................................................................29

3.3.4 Checking the Condition and Tension of the Vibrator V-Belt .............................................................................30

3.3.5 Replacing the V-Belt .......................................................................................................................................30

3.3.6 Changing the Vibrator Oil ............................................................................................................................... 31

3.3.7 Hydraulic Control ............................................................................................................................................31

3.4 Consumables and Quantities .........................................................................................................................32

4 Malfunctions During Operation ...................................................................................................................33

4.1 General ..........................................................................................................................................................33

4.2 Trouble Shooting ............................................................................................................................................34

5 Preserving the Machine ............................................................................................................................... 35

5.1 Preservation Measures ..................................................................................................................................35

5.2 Removing Machine Preservatives ..................................................................................................................35

6 Weber Maschinentechnik GmbH .................................................................................................................36