8

TYPICAL GAS SUPPLY

INSTALLATION

■A manual shut-off valve must be installed outdoors,

and be accessible, not in the “built-in” structure. An

additional manual shut-off valve indoors should be

installed in the branch fuel line in an accessible

location near the supply line.

CAUTION: If young children are in the area, a locking

valve should be considered.

■Pipe compound should be used which is resistant to the

action of natural gas when gas connections are made.

■The gas connections must be firmly attached to rigid,

permanent construction.

The information provided in this manual is general

for typical installations.We cannot cover all possible

installation ideas.We recommend prior to installation

that you contact your municipality for local building

codes and your local fire department for installation

verification.You can also call Weber-Stephen Products

Co. at 1-888-33SUMMIT (1-888-337-8664) and we will try

and answer any questions you may have.

Gas line piping

■If the length of line required does not exceed 50 feet,

use a 5/8" O.D. tube. One size larger should be used

for lengths greater than 50 feet.

■Gas piping may be copper tubing, type K or L;

polyethylene plastic tube, with a minimum wall

thickness of .062 inch; or standard weight

(schedule 40) steel or wrought iron pipe.

■Copper tubing must be tin-lined if the gas contains

more than 0.3 grams of hydrogen sulfide per 100 cubic

feet of gas.

■Plastic tubing is suitable only for outdoor,

underground use.

■Gas piping in contact with earth, or any other material

which may corrode the piping, must be protected

against corrosion in an approved manner.

■Underground piping must have a minimum of 18" cover.

Test connections

All connections and joints must be thoroughly tested for

leaks in accordance with local codes and all listed

procedures in the latest edition of ANSI Z223.1.

DANGER

Do not use an open flame to check for gas

leaks. Be sure there are no sparks or open

flames in the area while you check for gas

leaks. This will result in a fire or explosion

which can cause serious bodily injury or death,

and damage to property.

WE RECOMMEND THAT THIS INSTALLATION BE

DONE BY A LICENSED PROFESSIONAL.

General Specifications for Piping

Note - Contact your local municipality for building

codes regulating outdoor gas barbecue installations.

In absence of Local Codes, you must conform to the

latest edition of ANSI Z223.1.

■This barbecue is designed to operate at 4.5 inches of

water column pressure. Use only the regulator

supplied with the cooking module. If you have any questions, contact the Weber-Stephen

Customer Service Center at 1-888-33-SUMMIT

(1-888-337-8664).

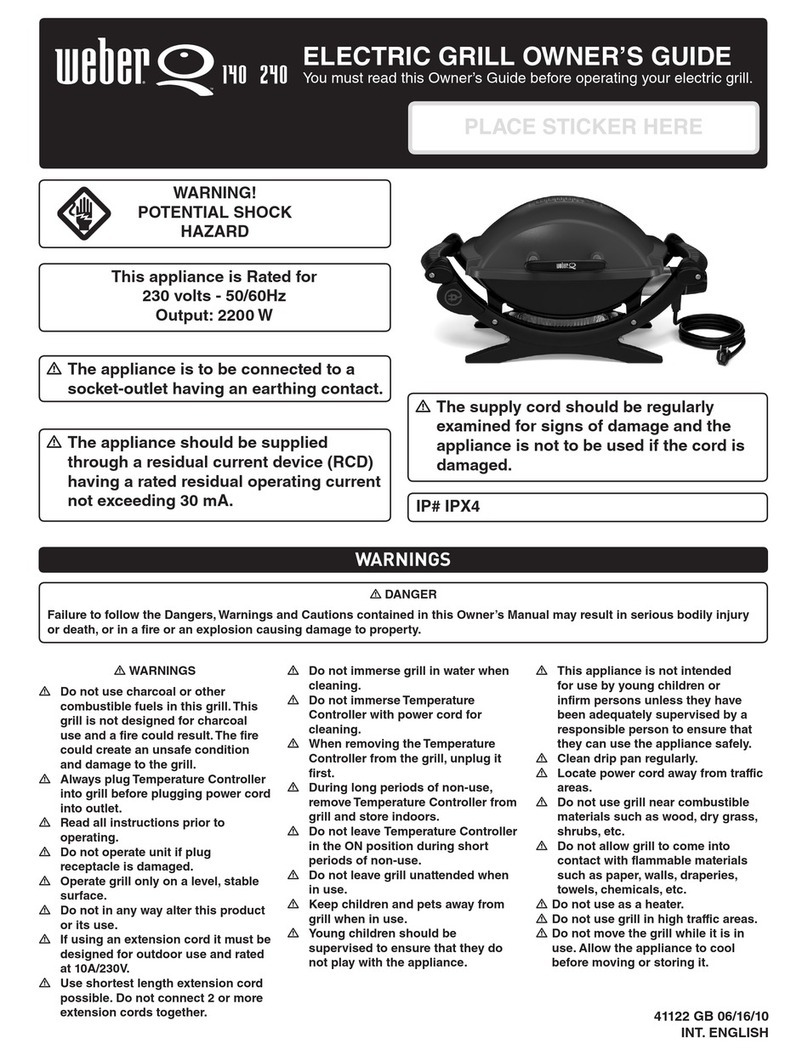

BUILT-IN SLEEVE GAS

LINE LOCATIONS

Side Burner Tolerances

A1

19⁄32”

B8”

DIMENSIONS

+ 1⁄16

- 1⁄16

+ 1⁄16

- 1⁄16

BUILT-IN SLEEVE GAS LINE

LOCATIONS

The dimensions shown indicate the location of the gas line

inlet flange in the sleeve. The support members of the built-

in structure must not impede passage of the gas lines.

Area should be kept clear of sharp, jagged, or extremely

abrasive surfaces to avoid possible damage to gas supply

lines. Exercise caution when pulling gas lines through

built-in structure.

Note: Leave an access in the structure for gas supply

and regulator service.

Figure 6

B

A