M600 –User manual –English (EU) –16/05/2018 - ISSUE 3

3

TABLE OF CONTENTS

1SAFETY INFORMATION _______________ 4

1.1 OPERATOR ATTENTION ____________________________________ 4

1.2 CARBON MONOXIDE HAZARDS______________________________ 4

1.3 ELECTRIC SHOCK HAZARDS ________________________________ 4

1.4 FIRE AND BURN HAZARDS _________________________________ 4

1.5 GENERATOR FUEL WARNING _______________________________ 4

2INTRODUCTION ____________________ 5

3IMPORTANT INFORMATION ___________ 5

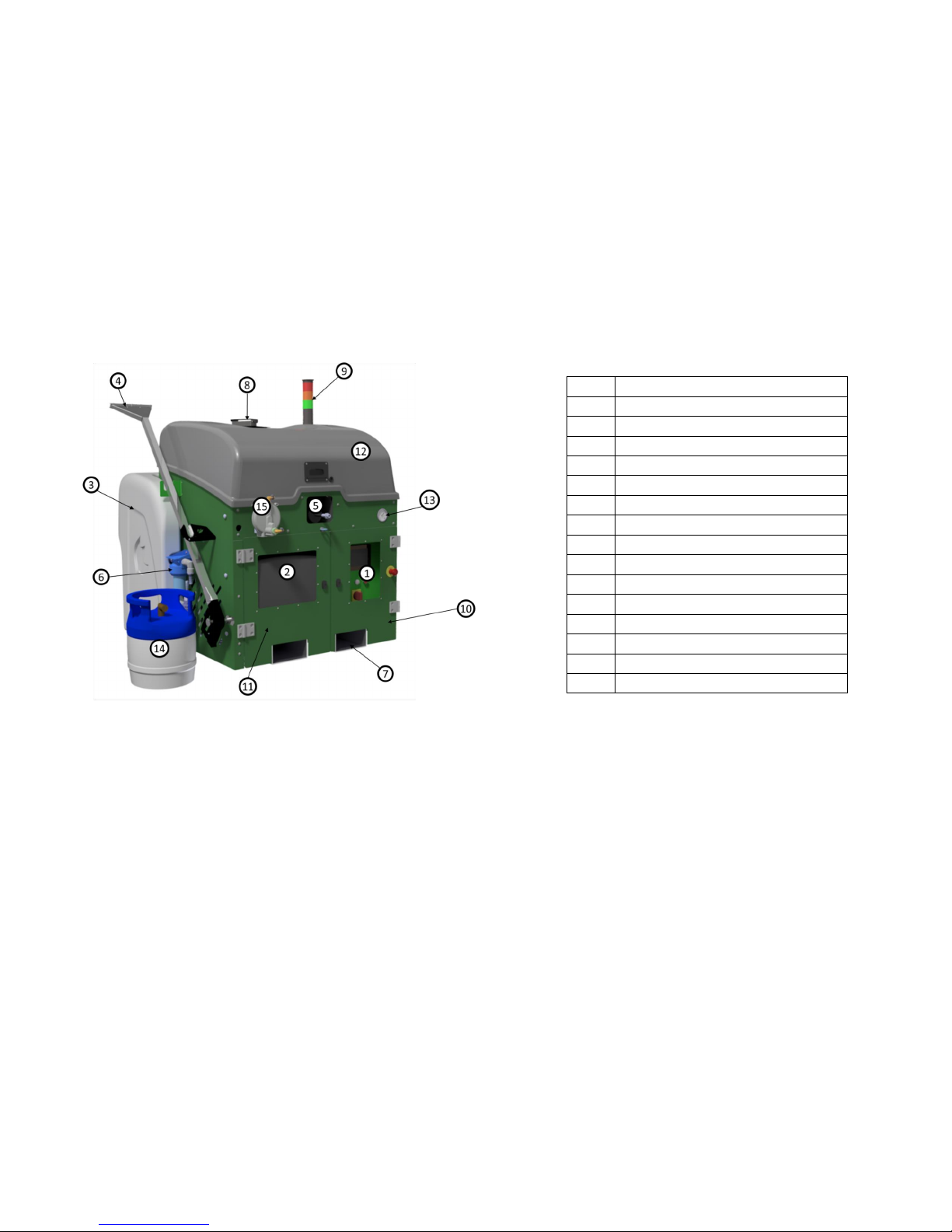

4PRODUCT DESCRIPTION _____________ 6

5FOAMSTREAM® ___________________ 12

5.1 HOW FOAMSTREAM® KILLS WEEDS______________________ 12

5.2 INDICATORS ____________________________________________ 12

5.3 CAUTION –POISONOUS WEEDS ____________________________ 13

THE EFFECT OF THE SYSTEM ON PLANTS ____________________________ 13

6PRE-START CHECKS ________________ 15

7START PROCEDURE ________________ 16

8SCREEN AND PLC NAVIGATION _______ 19

9USING THE M600 __________________ 20

10 FOAMSTREAM® APPLICATION (KILLING

WEEDS) ____________________________ 22

10.1 HOSE REEL ___________________________________________ 22

10.2 SPEED _______________________________________________ 22

10.3 USE OF THE LANCE _____________________________________ 22

10.4 TREATMENT OF THICK WEEDS ____________________________ 23

10.5 TREATMENT ___________________________________________ 23

10.6 CONFIRMATION OF TREATMENT___________________________ 23

10.7 CORRECT POSTURE _____________________________________ 23

11 SHUT-DOWN PROCEDURE ___________ 24

12 BASIC FAULT FINDING______________ 25

13 SERVICE CHECKS AND INTERVALS ____ 30

14 LOADING AND HANDLING ___________ 31

15 SCHEMATICS _____________________ 32

16 WARRANTY_______________________ 37

17 PRODUCT CERTIFICATION ___________ 39