3

Table of Contents

Section 1

General Information

Receiving Inspection ........................................................ .......................................................... 4

Warranty Information................................................................................................................. 4

Section 2

Installation

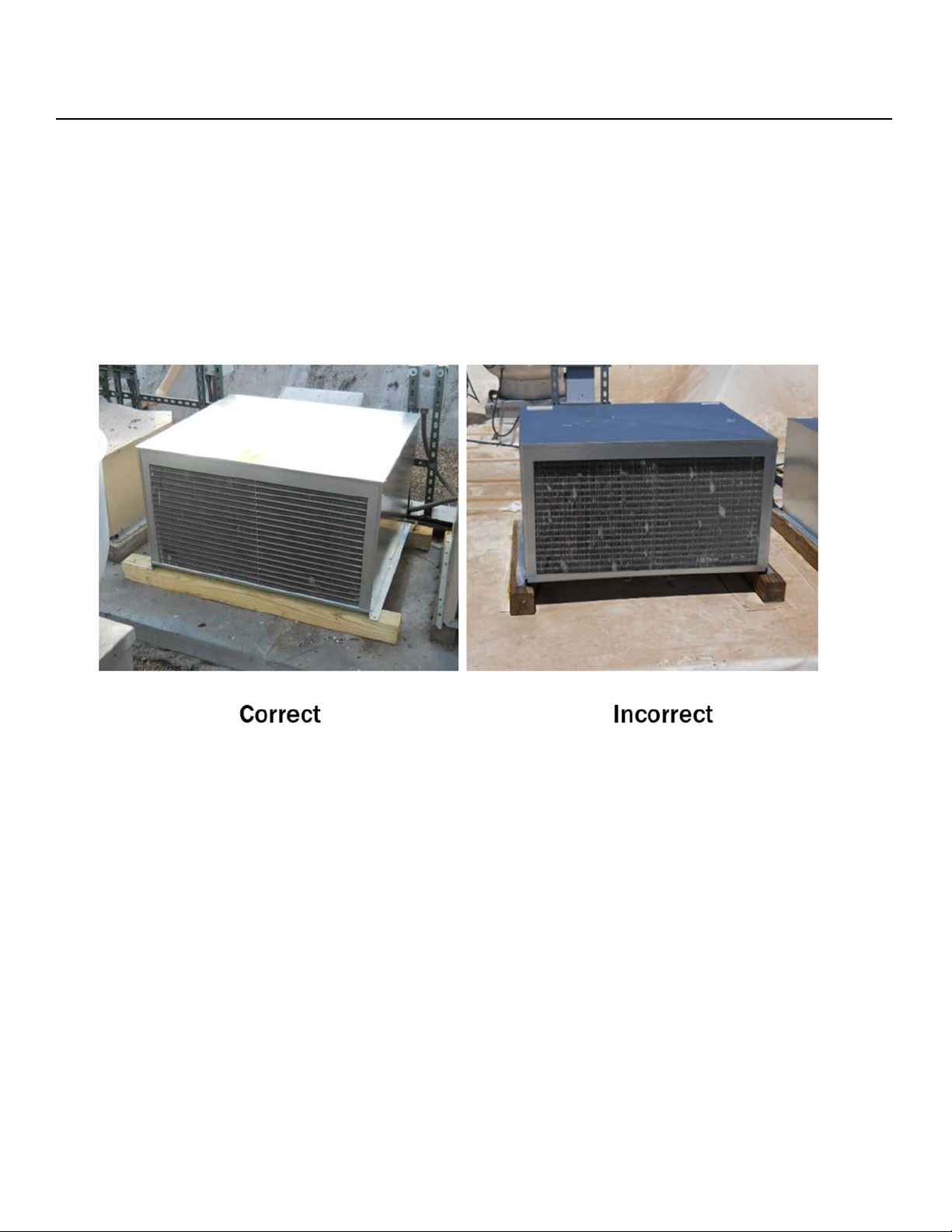

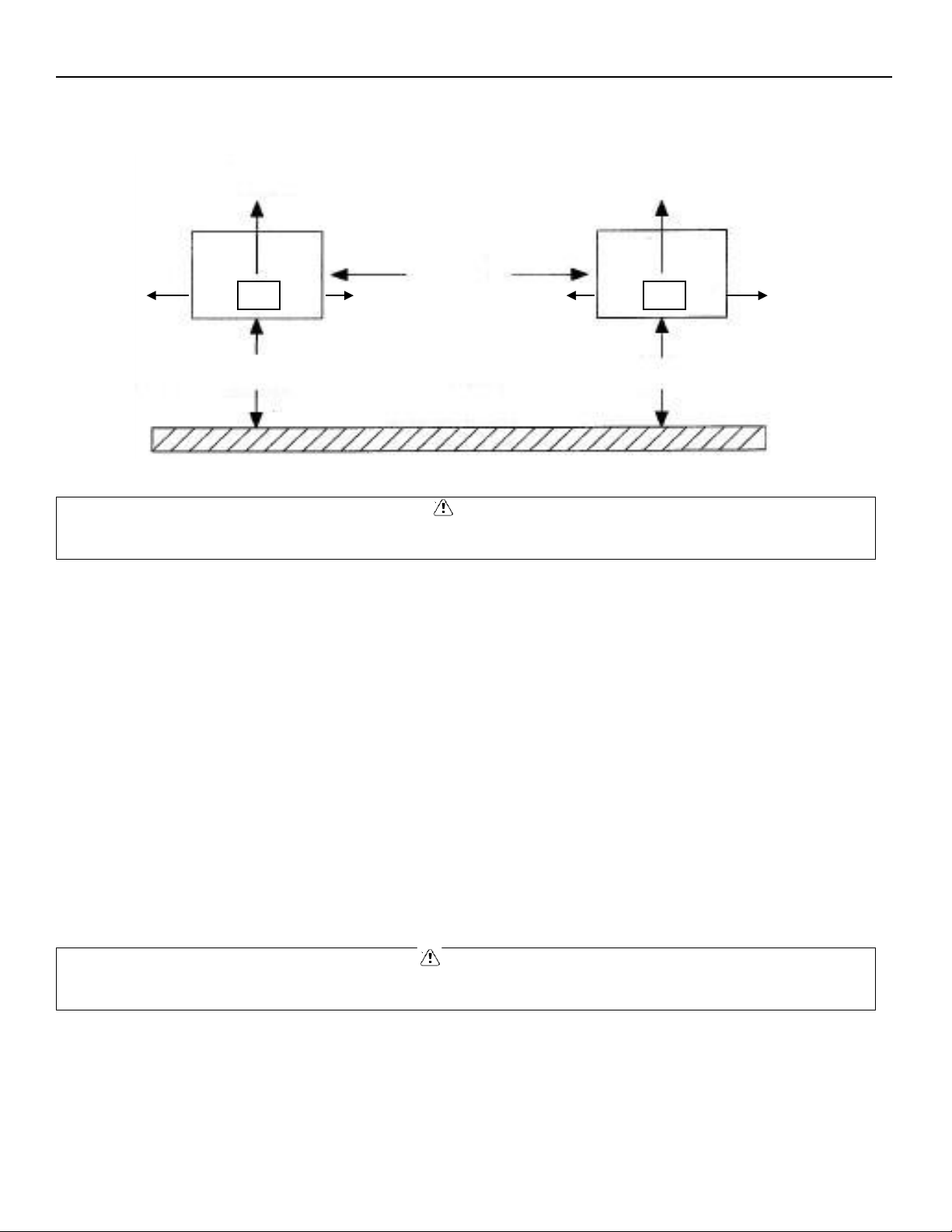

Condensing Units ........................................................................................................................ 5

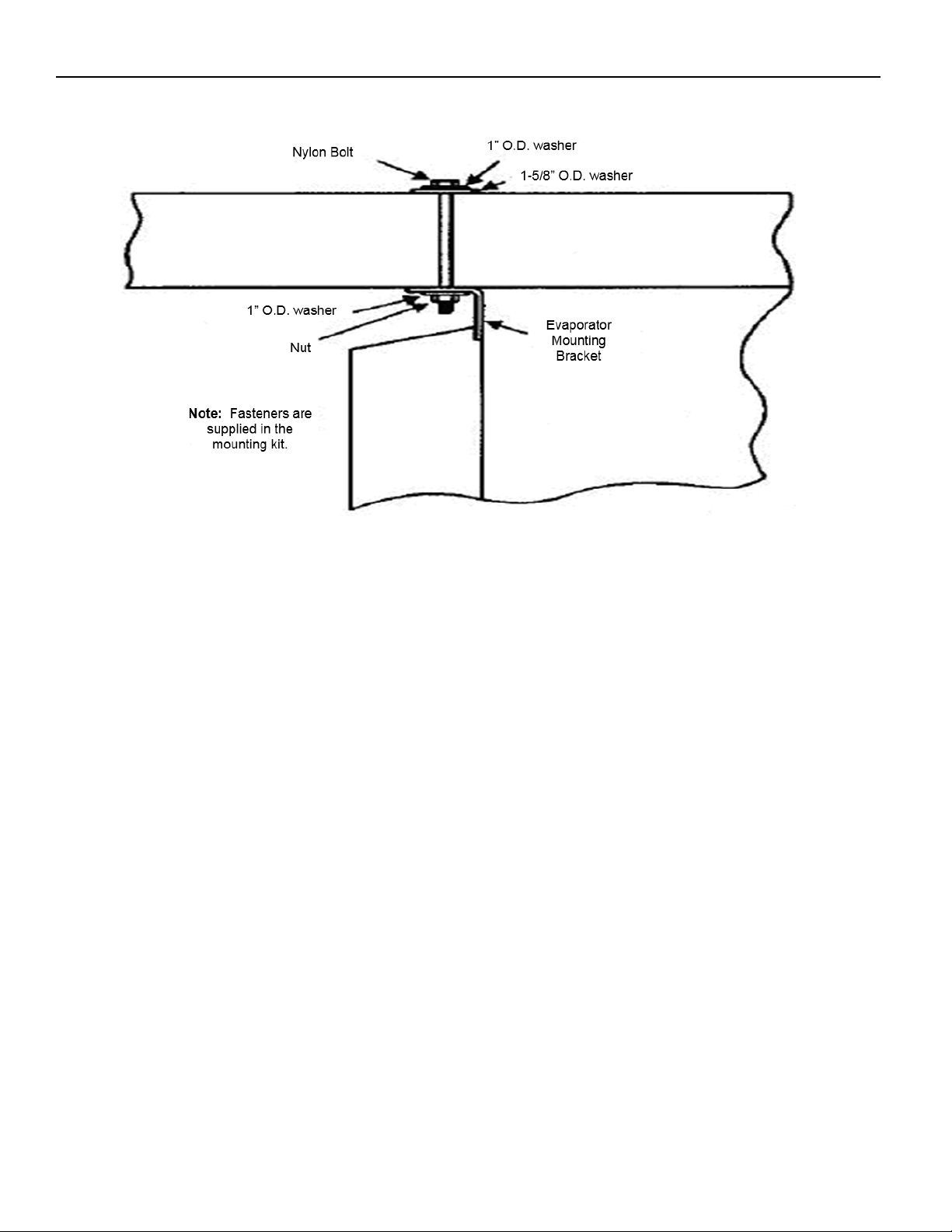

Evaporator Units ......................................................................................................................... 6

Section 3

Wiring

Wiring ......................................................................................................................................... 8

Section 4

Piping

Piping .......................................................................................................................................... 9

Cleanliness .......................................................................................................................... 9

Pipe Supports...................................................................................................................... 9

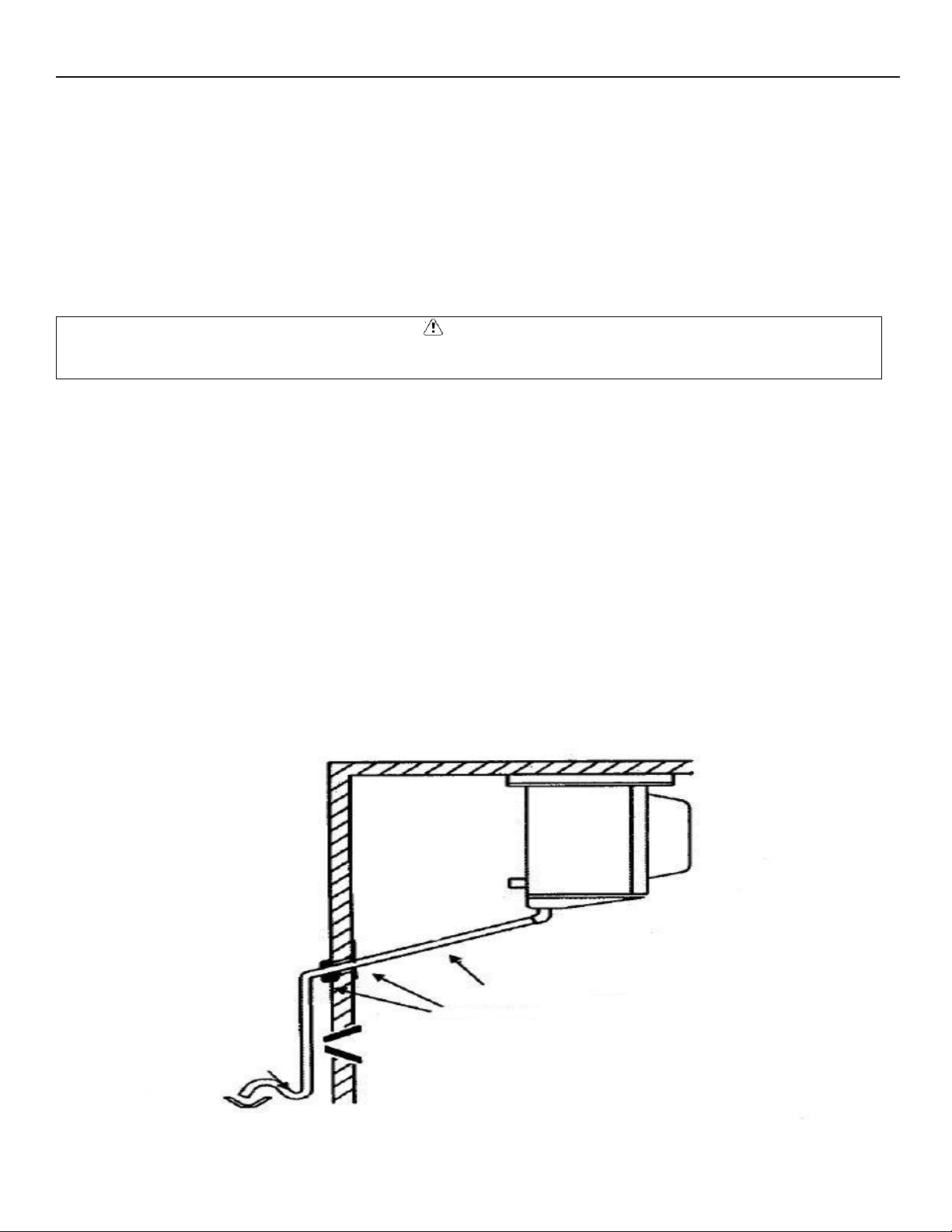

Oil Traps ............................................................................................................................ 10

Drain Lines ........................................................................................................................ 10

Pre-Charged Lines ............................................................................................................. 11

Leak Testing .............................................................................................................................. 12

PR Models ......................................................................................................................... 12

PC Models ......................................................................................................................... 13

PCL Models ....................................................................................................................... 13

System Evacuation .................................................................................................................... 13

PR Models ......................................................................................................................... 13

PC Models ......................................................................................................................... 13

PCL Models ....................................................................................................................... 14

Refrigerant Charging ................................................................................................................. 14

Section 5

Operational Start-Up

Pre-Start Checks........................................................................................................................ 15

Compressor Mounts.................................................................................................................. 15

Start-Up .................................................................................................................................... 16

Compressor Superheat.............................................................................................................. 16

Evaporator Superheat ............................................................................................................... 17

Johnson Control Thermostat..................................................................................................... 18

Three button Touch Pad ................................................................................................... 18

Parameter Codes And Modes of Operation...................................................................... 19

Basic Menu........................................................................................................................ 23

Advanced Menu................................................................................................................ 24

Setting Up A Regular Or Timed Defrost Off-Cycle............................................................. 26

Troubleshooting................................................................................................................ 29

Electric Defrost Timer................................................................................................................ 31

Section 6

Maintenance

Preventive Maintenance Tasks.................................................................................................. 33

P.O.E. Lubricants ....................................................................................................................... 33

Section 7

Troubleshooting

Evaporator ................................................................................................................................ 34

Condensing Unit........................................................................................................................ 35

System Start-Up Checklist........................................................................................................................... 37