For technical questionsand replacement parts,please call1-800-222-5381.

Thank you verymuch for choosinga Wel-Bilt , Product! Forfuture reference, please

complete the owner'srecord below:

Model: _______________ PurchaseDate: _______________

Save the receipt,warranty and theseinstructions. It isimportant that youread the entire

manual to becomefamiliar with thisproduct before usingit.

This machine isdesigned for certainapplications only. Thedistributor strongly

recommends that thismachine is notmodified and/or usedfor any applicationother than

that for whichit was designed.If you haveany questions relativeto a particular

application, DO NOTuse the machineuntil you havefirst contacted NorthernTool +

Equipment to determineif it canor should beperformed on theproduct.

Before using thisproduct, please readthe following instructionscarefully.

Technical Specifications

SAVETHIS MANUAL

Youwill need thismanual for thesafety warnings andprecautions, assembly, operating,

inspection, maintenance andcleaning procedures, partslist and assemblydiagram.

Keep this manualand invoice ina safe anddry place forfuture reference.

SAFETY RULES

1.Wearproper clothing.Always wear eyeprotection which complieswith currentANSI

standard Z87.1 whenassembling or usingthis AirFile. Wearlong-sleeved shirts, long

pants and hard-toedshoes. Take offany loose fittingjewelry and keeplong hair covered

to prevent beingcaught in movingparts.

2.Wearproper breathing protection.Remember that a"dust mask" isnot a breathing

respirator. Usea respirator thatuses charcoal filtersfor the bestprotection.

3.Keep workarea clean andwell lighted.A dimand/or cluttered workarea invites

personal injury.

4.Keep childrenand pets awayfrom work areas.Children can bea distraction and

should be supervisedby an adultwhen near thework area. Neverallow children to

play with thisproduct even ifit is turnedoff.

Item Description Description

Item

Air Consumption

Air Inlet Diameter

Min. Hose Size

Max. air pressure

Stroke Speed

Accessories

File styles

8.5 CFM

1/4in.- 18NPT

3/8in.

90 PSI

3300 stroke per minute(SPM)

Hex wrench, quick connector

Round, half-round, flat

and triangle

1 of 6

ASSEMBLY

1.Using theHex wrench, slidethe file youwish to workwith into theGuide Key located

at the frontof theAir File Housingand tighten setscrew which youwill find justat the

bottom of thefront section ofthe AirFile housing. Donot over tighten.

2.Attach airsupply to theair inlet basecap of theAir Filehousing, using eithera quick

disconnect, or bysimply screwing theair supply tothe air inletbase cap ofthe air file

housing just infront of theLoop Hanger.

OPERATION

1.With properfile inserted inthe AirFile, and withthe air supplyturned on, carefully

place the fileagainst the pieceof work youare filling.

2.Carefully openthe Slider Valve located ontop of theAir Filehousing.

3.Start witheven strokes andlight pressure. Neverforce theAir File againstthe surface

you are workingwith. Easy, light toucheswill work best.

INSPECTION, MAINTENANCE,AND CLEANING

1.Always makesure the slidervalve is inits "OFF" position,and disconnect thetool

from its compressedair supply beforeperforming any inspection,adjustments,

maintenance, or cleaning.

2.Before eachuse, inspect thegeneral condition ofthe tool. Checkfor loose screws,

misalignment or bindingof moving parts,cracked or brokenparts, damaged airhose,

and any othercondition that mayaffect itssafe operation. Ifabnormal noise or

vibration occurs, havethe problem correctedbefore further use.Do not usedamaged

equipment.

3.Daily: Witha clean cloth,remove all dirt,oil, and greasefrom the tool.If necessary,

you may usea mild detergent.Do not usesolvents, as damagedto the toolmay occur.

Do not immersethe tool inany liquids.

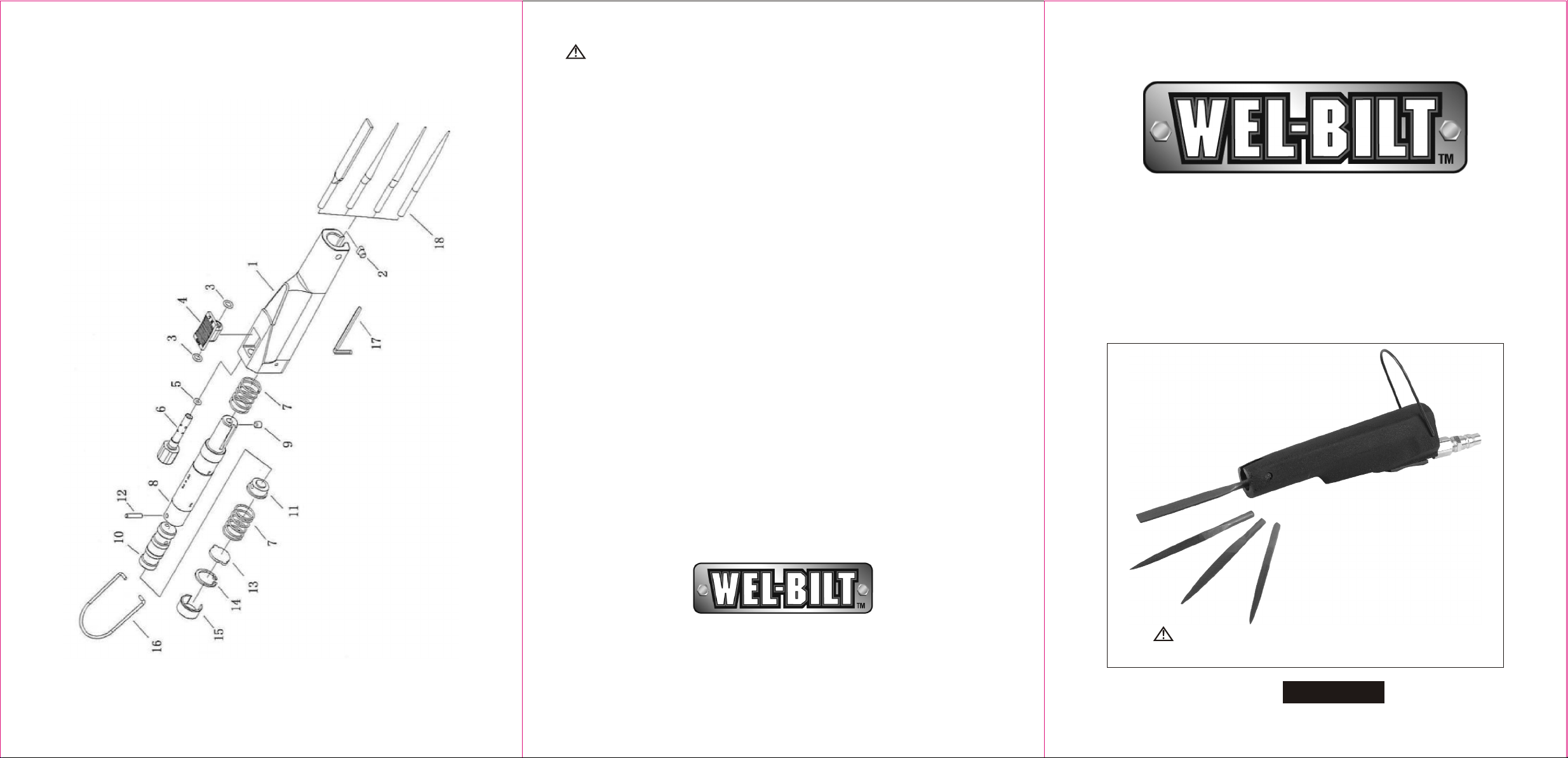

Diagram

Description

Part No. Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Air File Housing

Guide Key

O-Ring (Large)

Slider Valve

O-Ring (Small)

Valve Nipple

Spring

Cylinder

Set Screw

1

1

2

1

1

1

2

1

1

Piston

Plug

Spring

Filter

Retaining Ring

Air Inlet Base Cap

Loop Hanger

Hex Wench

Files

1

1

1

1

1

1

1

1

4

Description

Part No. Qty.

3 of 6

Fig. 1

5.Store idletools properly. Keep thisAir Fileout of thereach of children.

6.Do notuse theAir File ifunder the influenceof alcohol orprescription drugs. Doing

so may causedamage to thetool, or personalinjury.Do not usethis or anytool if you

are tired. Usecommon sense atall times.

7.Check fordamaged parts. Beforeusing thisAir File, carefullycheck for anyparts

that may bemissing or damagedand any otherconditions that mayaffect the

operation of thistool. Replace orrepair damaged andworn parts immediatelyusing

only qualified repairfacility.

8.Always usethe proper tools.This airfile was designedfor a specifictask. Do

not alter thistool, or useit for apurpose for whichit was notintended.

9.Be carefulwhen connecting/disconnecting airsupply.It is recommendedto use

quick disconnects (notincluded) rather thanscrew-on air connections.

10.Avoidaccidental starts. Besure all Filesare securely fastenedin thisAir File

before plugging inor turning onair supply.

11.Use compressed aironly.Clean, dry, regulated compressedair at 90PSI. Never

use oxygen, carbondioxide, combustible gases,or any otherbottled gas asa power

source for thistool.

12.Always disconnectair supply whenthis tool isnot being used.

13.Use onlyfiles that comewith this tool.Using or alteringanother file foruse with

this tool couldcause personal injury.

NOTE: Thewarnings, cautions, andinstructions discussed inthis instruction manual

cannot cover allpossible conditions andsituations that mayoccur. Itmust be

understood by theoperator that commonsense and cautionare factors thatcannot

be built intothis product butmust be suppliedby the operator.

Before using, readand understand powertool owner's manual,observing all safety

rules and instruction.Failure to heedall safety rules,instructions and warningscan

result in seriousbodily injury.

SET UP

NOTE: If youare not usingan automatic oilersystem, before operation,add a fewdrops

of PneumaticToolOil to theairline connection.Add a fewdrops more afterhour of

continual use.

1.You will needto prepare a1/4in. air connector(included) to connectto the InletBase

Cap on theair file. Firstwrap the 1/4in.air connector withpipe thread sealtape (not

included) before threadingit into theinlet. Connect the3/8in. ID airsource hose (not

included) to aquick-disconnect coupler andthen to theAir File.

2.Set theair pressure onthe regulator (notincluded) to 90PSI. Do notexceed the

recommended air pressureof 90 PSI.

3.Check theair connection forleaks. Disconnect fromthe air source.

2 of 6