WDT POOLKLAR Touch Basic

English translation of the original German version of the operation manual - Version 1.1 (HW CB36 –FW V1.0.0) 2021_07_09 2/38

Table of contents

1About this manual .........................................................................................................................................................................4

1.1 Scope of applicability................................................................................................................................................................4

1.2 Target group .............................................................................................................................................................................4

1.3 Storage of the manual ..............................................................................................................................................................4

1.4 Further information..................................................................................................................................................................4

1.5 Symbols used............................................................................................................................................................................4

2Safety.............................................................................................................................................................................................5

2.1 Intended use.............................................................................................................................................................................5

2.2 Safety notices............................................................................................................................................................................5

3Important facts about swimming pool water properties ..............................................................................................................6

3.1 Auxiliary hygiene parameters ...................................................................................................................................................6

3.2 pH value....................................................................................................................................................................................6

3.3 Redox voltage ...........................................................................................................................................................................6

3.4 free chlorine .............................................................................................................................................................................6

3.5 combined chlorine....................................................................................................................................................................6

4Scope of delivery –device description ..........................................................................................................................................7

4.1 Scope of delivery.......................................................................................................................................................................7

4.2 Check for transport damage.....................................................................................................................................................7

4.3 Identification of the device.......................................................................................................................................................7

4.4 Device description ....................................................................................................................................................................7

5Installation.....................................................................................................................................................................................8

5.1 Select the installation site.........................................................................................................................................................8

5.2 Mounting the device on the wall..............................................................................................................................................8

5.3 Voltage supply ..........................................................................................................................................................................8

5.4 Installation notices....................................................................................................................................................................8

5.5 Measuring water prefilter.........................................................................................................................................................8

5.6 Temperature sensor .................................................................................................................................................................8

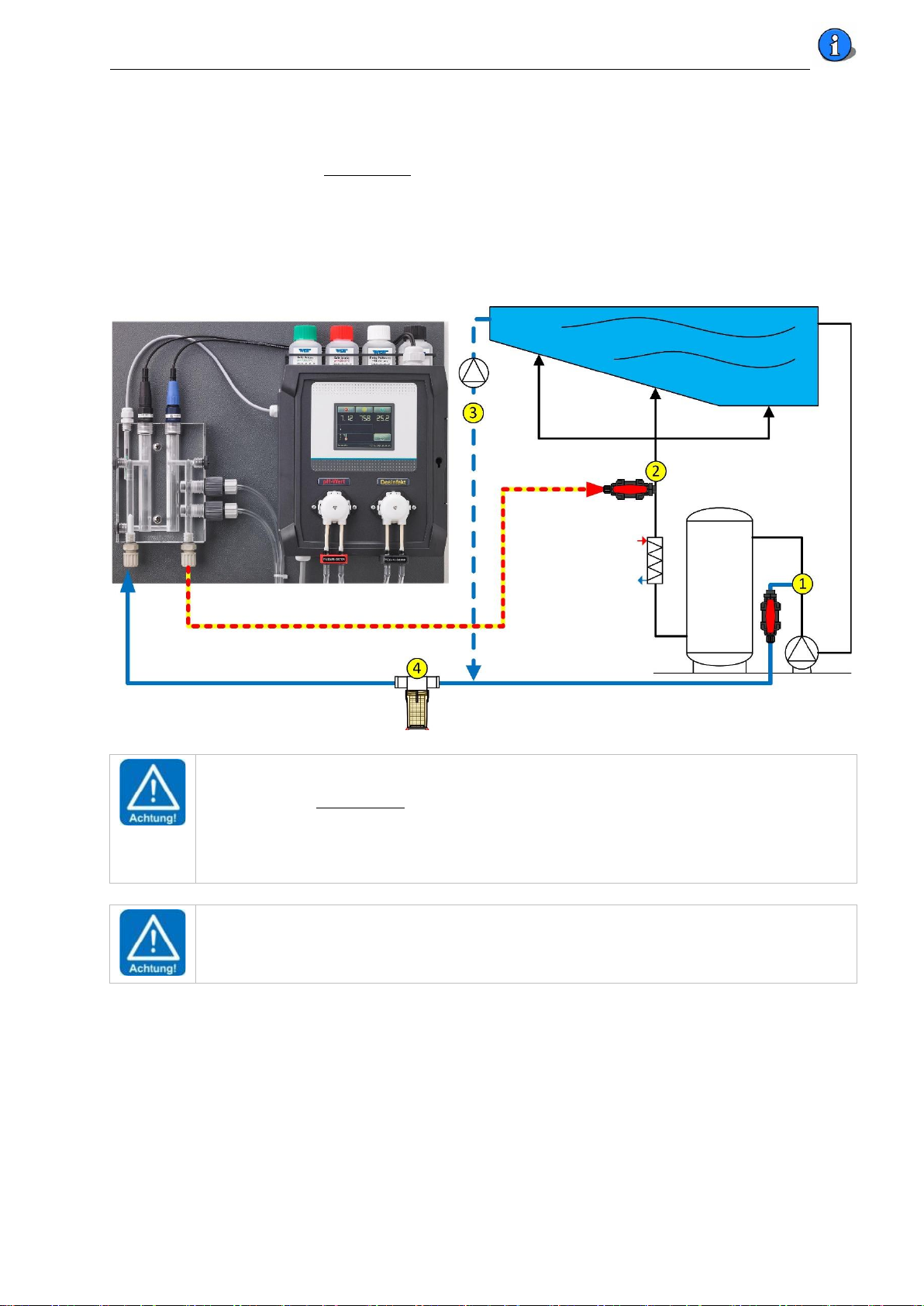

5.7 Installation suggestion..............................................................................................................................................................9

6Notices regarding commissioning and ongoing operation ..........................................................................................................10

6.1 Control parameters.................................................................................................................................................................10

6.2 pH and redox electrode ..........................................................................................................................................................10

6.3 Dosing head(s) ........................................................................................................................................................................10

6.4 Measuring cell flow.................................................................................................................................................................10

6.5 Chemicals................................................................................................................................................................................10

6.6 Disinfectants ...........................................................................................................................................................................11

6.7 Fresh water replenishment.....................................................................................................................................................11

6.8 Floor cleaning .........................................................................................................................................................................11

7Electrical connection ...................................................................................................................................................................12

7.1 Open and close the housing ...................................................................................................................................................12

7.2 Insert lines ..............................................................................................................................................................................12

7.3 Overview of the connection diagram .....................................................................................................................................13

7.3.1 The I/O board CB36............................................................................................................................................................13

7.3.2 The HMI_eDIPTFT32 V1.0 display adapter.........................................................................................................................14

7.3.3 The MV_Aptr_CB-36_V1.0 measuring amplifier................................................................................................................15

7.4 External functions...................................................................................................................................................................15

7.4.1 Input External OFF –release contact .................................................................................................................................15

7.4.2 Temperature control..........................................................................................................................................................15

8Operating the touch screen.........................................................................................................................................................16

8.1 The statuses in automatic mode.............................................................................................................................................17

8.1.1 Status 1. Dosing –dosing delay..........................................................................................................................................17

8.1.2 Status pH stop dosCL –pH priority dosing.........................................................................................................................17

8.1.3 Status Auto (automatic).....................................................................................................................................................17

8.1.4 Status standby ...................................................................................................................................................................17

8.1.5 Time Limit - Dosing time monitoring alarm .......................................................................................................................18