SAK Tillers

Page 9 of 23

Prepare the work:

•Do not drink alcohol; take drugs, or any other substances which may affect your ability to use the

equipment before or when working.

•Make sure that there is sufficient fuel in the tractor to prevent the machine from stopping during work.

•Do not use the equipment under unsafe conditions, e.g. do not make temporary repairs just to start

or keep working; do not work at night if the area is not well illuminated.

When working or executing maintenance activities, remember:

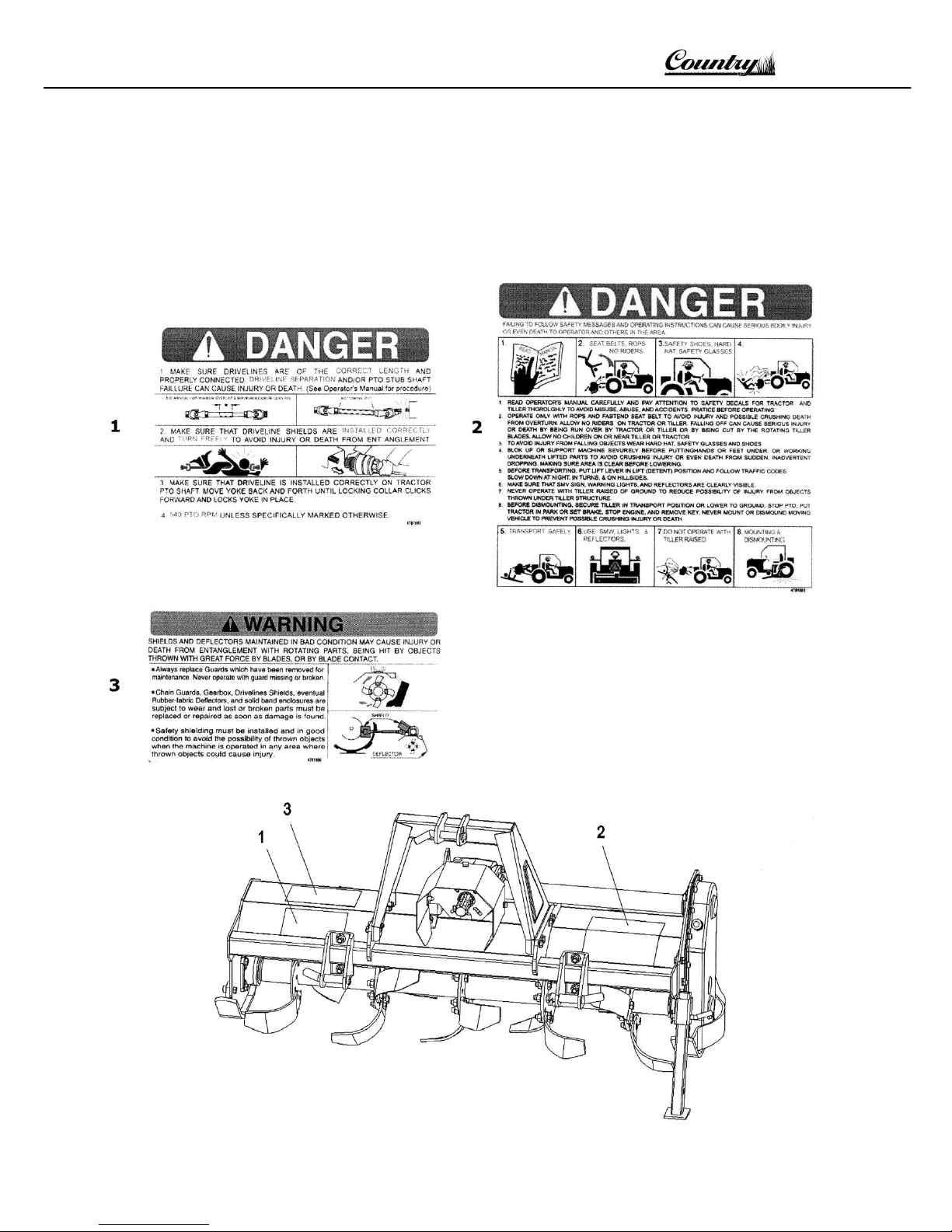

•The labels and stickers providing instructions on the use of the equipment or information on

dangers must not be removed or hidden, and must be legible.

•Do not remove the safety devices, covers and safety guards, unless maintenance activities are

being carried out. If the safety devices must be removed, turn the engine off, remove them

correctly and re-install them before turning the tractor on.

•Do not lubricate, clean or adjust moving parts.

•Use the appropriate tools to execute maintenance or adjustment activities on the equipment.

•Do not use damaged or unsuitable tools, e.g. pliers rather than wrenches etc.

•Prior to carrying out activities on hydraulic lines under pressure, or disconnecting their components,

make sure that the line is no longer under pressure and that it does not contain any hot fluids.

•Check all the fittings and make sure that they are well connected before supplying pressure to the

hydraulic lines.

•Make sure that no tools, clothes or any other materials are left in areas where moving parts are

present when the maintenance and repair activities are completed.

•Do not give directions and make signals at the same time during a manoeuvre. Manoeuvre

directions and signals must be given from one person only.

•Do not unexpectedly call an operator, if not necessary. Do not startle the operator, e.g. by

throwing objects.

•Pay attention to people in the vicinity of the work area, especially children!

•Make sure that nobody is standing in the working range of the equipment.

•Do not use the equipment to lift people.

•When the equipment is not needed, turn the engine off; leave the vehicle on a flat surface, with the

first gear and the parking brake engaged. Disengage the power take off.

•Do not execute any cleaning, lubrication, repair or adjustments when the engine is running and the

equipment is in the raised position.

•Do not work on steep slopes, if the stability of the vehicle can be jeopardised.