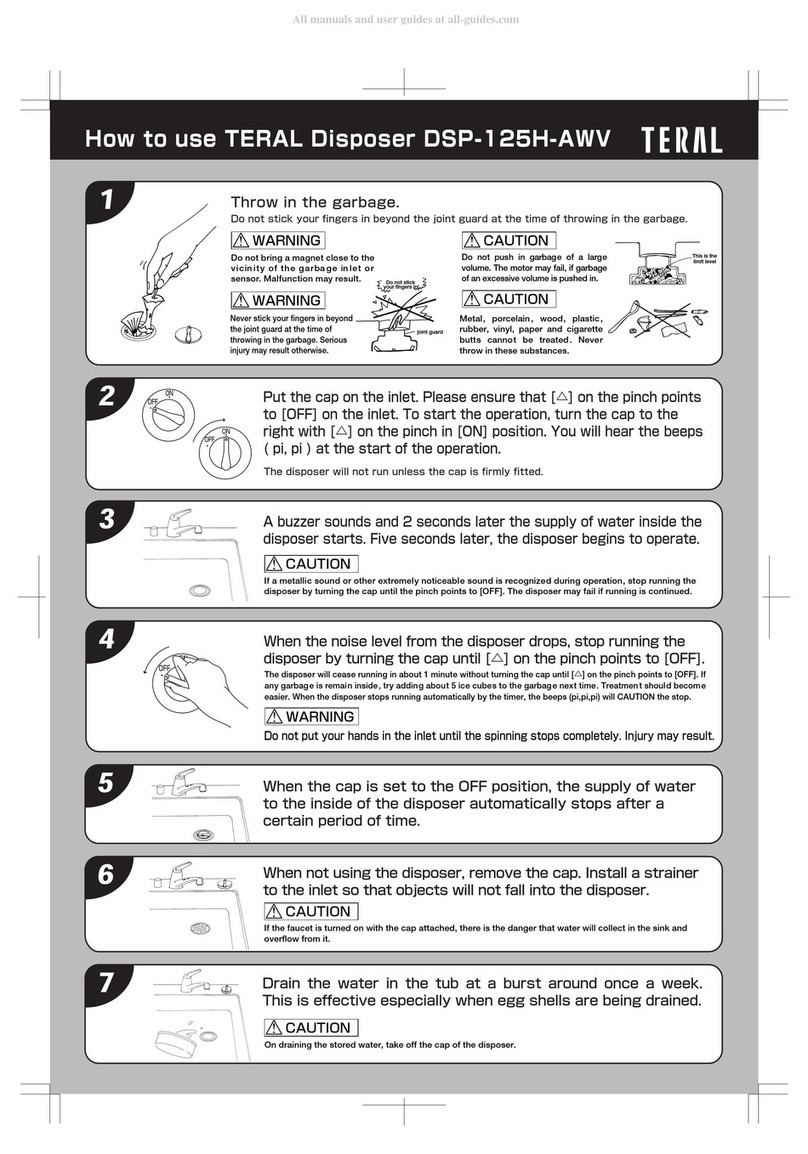

A. Line up disposer under mounting assembly. Guide

hopper projections into mount ring slots. Turn mount

ring about 1/4” to right so that disposer is temporarily

supported (see 6A).

B. Turn mount ring and disposer until disposer elbow

lines up with trap (see 6B).

C. Turn mount ring to the right (counter-clockwise) until

it locks up tight. Tap the mount ring ears with a ham-

mer until the lock position is achieved. Hopper

projections must be to extreme left of mounting slots

(see 6C & 6D).

D. If mount ring is hard to turn, you may add a small

amount of petroleum jelly or liquid soap to hopper pro-

jections. Run water and check for leaks.

6C

6B

ELBOW

TRAP

LOCKING DETAIL

HOPPER PROJECTION IN

“SUPPORTED” POSITION

HOPPER PROJECTION IN

“LOCK” POSITION

MOUNT

RING

.6 C O N N E C T I N G D I S P O S E R T O M O U N T A S S E M B L Y

SLOT PROJECTION

6A

6D

7 . O P E R A T I N G I N S T R U C T I O N S

The Anti-Jam Swivel Impellers make a clicking

sound as they initially swing into place. This

indicates normal operation.

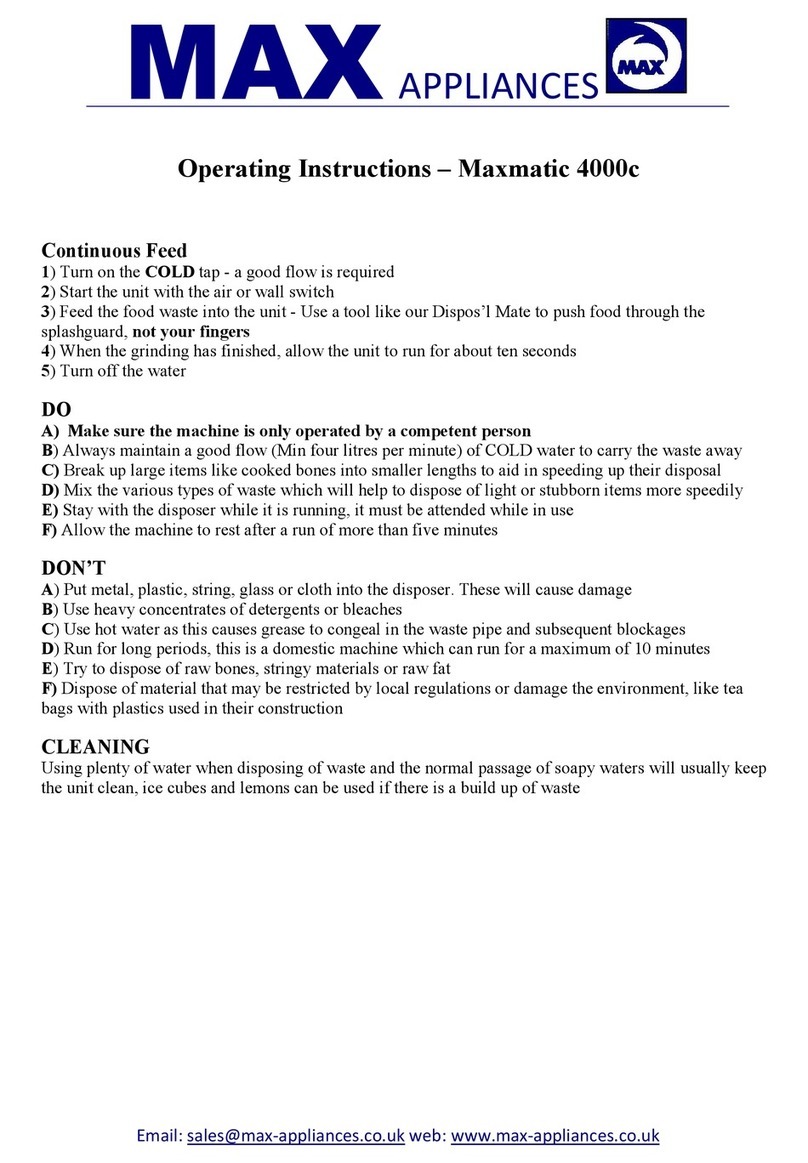

A. Remove sink stopper. Turn on a medium flow of cold

water.

B. Turn switch to ON position; your motor is turning at full

speed and ready to use.

C. Scrape in food waste. Down the drain go table scraps,

peelings, rinds, seeds, pits, small bones and coffee

grounds. To speed up food waste disposal, cut or

break up large bones, rinds and cobs. Large bones

and fibrous waste require considerable grinding time

and are more easily thrown away with other trash. Do

not be alarmed that the disposer slows down while

grinding. The disposer is actually increasing torque

(grinding power) and is operating under normal condi-

tions.

D. Before turning disposer off, let water and disposer run

for approximately 15 seconds after shredding or

grinding stops. This assures that all waste is thor-

oughly flushed through trap and drain.

E. It is not recommended to use hot water while running

disposer. Cold water will keep waste and fats solid so

disposer can flush away particles.

TIPS FOR SUCCESSFUL OPERATION

A. Be sure disposer is empty before using your dishwasher so it may drain properly.

B.

You may want to leave the stopper in the drain when not in use to prevent utensils and foreign objects from falling into the disposer.

C. Your disposer is ruggedly built to give you many years of trouble free service. It will handle all normal food wastes,

but it will NOT grind or dispose of such items as plastic, tin cans, bottle caps, glass, china, leather, cloth, rubber, string,

clam and oyster shells, aluminum foil or feathers.

Before seeking repair or replacement, we rec-

ommend that you review the following:

LOUD NOISES: (Other than those during grinding of small

bones and fruit pits): These are usually caused by acci-

dental entry of a spoon, bottle cap or other foreign object.

To correct this, turn off electrical switch and water. After

disposer has stopped, remove splash guard, remove

object with long handled tongs, and replace splash guard.

UNIT DOES NOT START: Unplug power cord or turn

either the wall switch or breaker box switch to “OFF” posi-

tion, depending on your model and wiring configuration.

Remove stopper and/or splash guard. Check to see if

turntable will rotate freely using a wooden broom handle. If

turntable rotates freely, replace splash guard and check

reset button to see if it has been tripped. Reset button is

red and located on the front of the disposer. Push button in

until it clicks and remains depressed.

If reset button has not been tripped, check for shorted or

broken wire connecting to disposer. Check electrical

power switch, fuse box or circuit breaker. If wiring and

electrical components are intact, the unit may have internal

problems that require service or replacement.

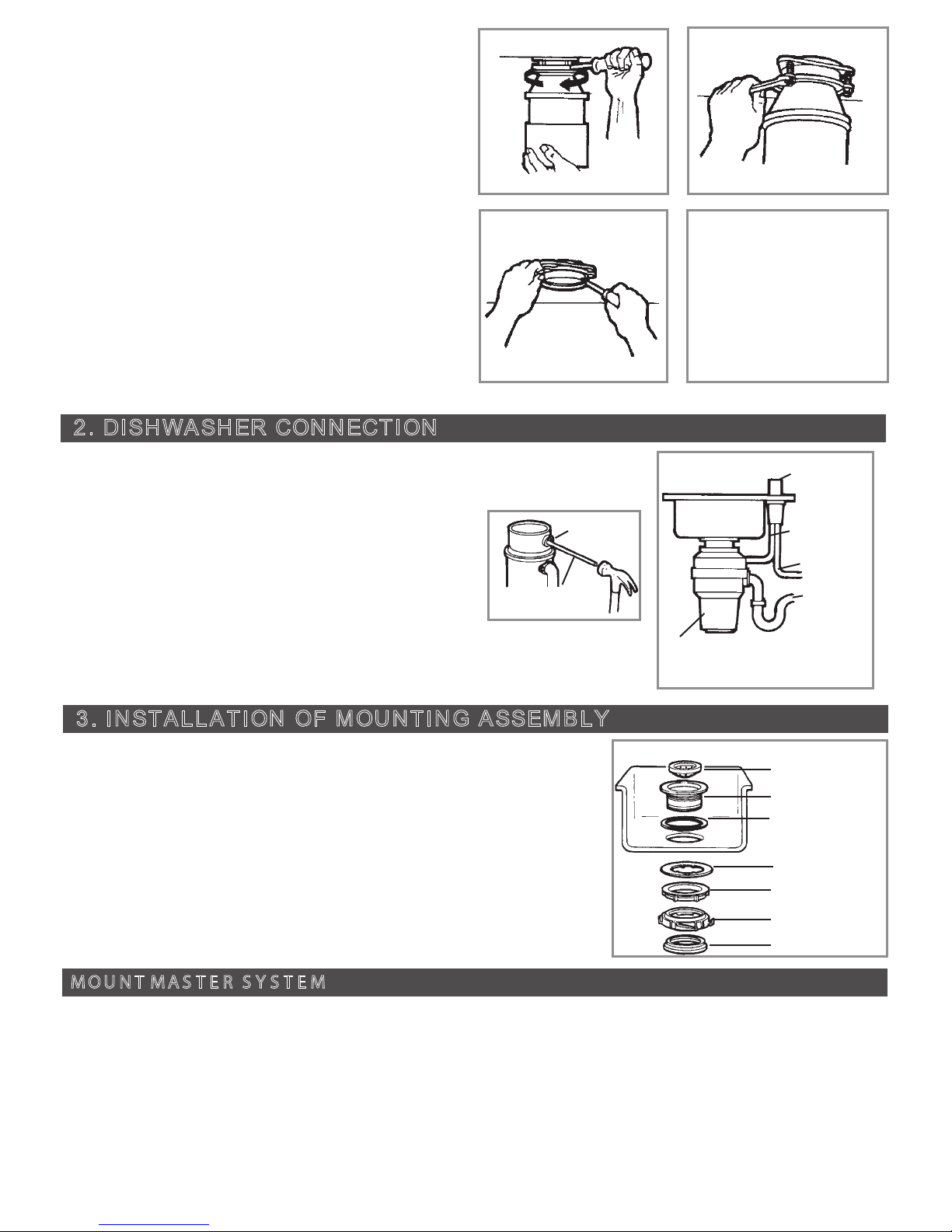

IF TURNTABLE DOES NOT ROTATE FREELY: Turn off

disposer, then check for any foreign object lodged between

the turntable and grind ring. Dislodge object by rotating

table with a wooden broom handle (see 8A) and remove

object. If no foreign object is present, there may be inter-

nal problems.

8A

TURNTABLE

REMOVE

SPLASH

GUARD

9 . T R O U B L E S H O O T I N G

LEAKS:

If the unit leaks at the top, it may be

due to:

1.

Improper sealant of sink flange

(gasket, caulking, putty or tightening).

2.

Support ring not tightened

properly.

3. Defective or improperly installed

cushion mount.

If unit leaks at the waste elbow, leak

may be due to improper tightening of

elbow flange screws.

D. NEVER put lye or chemical drain cleaners into the disposer, as they cause serious corrosion of metal parts. If used,

resulting damage can be easily detected and all warranties are void.

F.

Do not lubricate your disposer. The motor is permanently

lubricated. The disposer is self cleaning and scours its

internal parts with each use.