Westermann WKB 330 User manual

Operating Instructions

chemical-free | effective | sustainable

Weed Brush

WKB 330 Petrol / Battery

2

ENGLISH

Table of contents

Table of contents ... ....................................................................... 2

1 EC declaration of conformity ........................................................... 4

2 Legal information......................................................................... 6

3 Important general information ......................................................... 7

3.1 Scope of delivery................................................................ 7

3.2 Conventions...................................................................... 8

3.2.1 Symbols and signal words ........................................... 8

3.2.1 Pictogram overview .................................................. 9

3.3 Marking on the machine ..................................................... 10

3.3.1 Warning pictographs on the machine ............................ 10

3.4 Spare parts order ............................................................. 11

4 Safety and security............... ...................................................... 12

4.1 Intended use of the machine................................................ 12

4.2 Note on machine name ...................................................... 12

4.3 Operator requirements....................................................... 13

4.4 Danger areas................................................................... 14

4.5 Foreseeable misuse |

Reasonably foreseeable misuse ............................................. 15

4.6 Procedure in case of an emergency ........................................ 15

4.6.1 Personal injury ...................................................... 15

4.6.2 Fire.................................................................... 15

4.6.3 Technical complications ........................................... 15

4.7 Range of application.......................................................... 16

4.7.1 Local requirements................................................. 16

4.7.2 Disposal .............................................................. 16

4.8 Responsibility of the operator .............................................. 17

4.8.1 Obligations of the operator ....................................... 17

4.9 Personnel responsibility...................................................... 18

4.10 Observance of the operating instructions................................. 19

4.11 Residual dangers and safety measures..................................... 20

4.12 Safety markings on the machine............................................ 20

4.13 Personal protective equipment ............................................. 20

5 Safety markings on the machine ..................................................... 21

6 Safety notes for the operator/user .................................................. 22

6.1 General technical data WKB 330 .......................................... 22

6.2 General technical data WKB 330 .......................................... 23

7 Assembly, initial commissioning ...................................................... 24

7.1 Safety and security ........................................................... 24

7.2 Assembly ....................................................................... 24

7.3 Initial commissioning ......................................................... 24

3

ENGLISH

8 Product description..................................................................... 25

9 Commissioning ........................................................................ 26

9.1 Adjusting the handle height................................................. 26

9.1.1 Adjustment procedure ............................................. 26

9.2 Engine Start WKB 330 ........................................................ 26

10 Operation............ .................................................................... 27

10.1 Procedure description ........................................................ 27

10.2 Service interval................................................................ 27

11 Maintenance and servicing ............................................................ 28

11.1 General information .......................................................... 28

11.2 Engine WKB 330 .............................................................. 29

11.4 Replacing the brush element................................................ 30

11.4.1 Removal and attachment of wire brush braids................. 30

11.5 Replacing the V-belt | Tightening the V-belt ............................. 31

11.6Screwttings .................................................................. 31

11.7 Measures after maintenance ................................................ 32

11.8 Note on servicing work....................................................... 32

11.9 List of records ................................................................. 32

12 Residual dangers........... ............................................................. 35

13 Storage conditions...................................................................... 35

14 Cleaning.................................................................................. 36

15 Troubleshooting...... ................................................................... 37

15.1 WKB 330 ....................................................................... 37

16 Decommissioning ....................................................................... 38

16.1 Decommissioning.............................................................. 38

16.2 Disassembly/Disposal......................................................... 38

17 Warranty policy ........................................................................ 39

Warranty policy ........................................................................ 40

18 Spare parts list .... ..................................................................... 40

WKB 330 ... ..................................................................... 41

Detail A ........................................................................ 43

Detail B ........................................................................ 44

Spare parts list....................................................................... 45

Spare parts list....................................................................... 46

20 Overview maintenance ................................................................ 47

Table of contents

4

ENGLISH

1 EC Declaration of Conformity

EC declaration of conformity in accordance with

Machinery Directive 2006/42/EC Annex II 1.A

The manufacturer / distributor:

Westermann GmbH & Co. KG

Schützenhof 23

D – 49716 Meppen

hereby declares that the following product

Product name: WKB 330 / Akku

Make: Westermann GmbH & Co. KG

Serial number: _ _ _ _ _ _

Model / type description: WKB 330

Description: The Westermann weed brush is designed exclusively

for normal use in cleaning heavily littered paved are-

as such as yards, roads and car parks. Any other use is

considered improper. The manufacturer is not liable

for any damage resulting from this! The risk for this is

borne solely by the user.

Intended use also includes compliance with the

operating, maintenance and servicing conditions pre-

scribed by the manufacturer.

The following additional EU directives have been applied:

The protection objectives of the following EC Directive are complied with.

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

Low Voltage Directive 2014/35/EU

5

ENGLISH

1 EC Declaration of Conformity

The following harmonised standards were applied:

EN ISO 12100:2010 Safety of machinery - General principles for

design - Risk assessment and risk reduction

(ISO 12100:2010)

The following other technical specications were applied:

Name and address of the person authorised to compile the technical

documentation:

Westermann GmbH & CO. KG

Mr Alfons Westermann Tel.: 05931 | 496 90 0

Schützenhof 23 E-Mail: info@westermann-germany.com

D-49716 Meppen URL: www.westermann-germany.com

Location: 49716 Meppen

Date: 19.01.2017

_______________________________

(Signature)

Alfons Westermann Managing Director

6

ENGLISH

Issuer: Westermann GmbH & Co.KG

Publisher:

Westermann GmbH & CO. KG

Mr Alfons Westermann Phone: +49 (0) 5931 | 496 90 0

Schützenhof 23 Fax: +49 (0) 5931 | 496 90 99

49716 Meppen E-Mail: info@westermann-germany.com

Internet: www.westermann-germany.com

Managing Director: Alfons Westermann

Form of organisation: Limited partnership

Location: 49716 Meppen

Commercial Register Osnabrück, HRA 100274

Personally liable partner:

Westermann Beteiligungs-GmbH,

HRB Osnabrück no. 100562,

UST-ID no.: 193643718,

Copyright notice:

The contents of this document are protected by copyright under German copyright law and inter-

national treaties.

All copyrights to the contents of this document are owned by UPAS GmbH unless and to the extent

that another author is expressly indicated or obviously recognisable.

The user is not granted or reserved any industrial property rights, rights of use or other rights by the

provision of the contents. The user is prohibited from registering rights of any kind for the know-how

or parts thereof.

The passing on, transfer and other dissemination of the contents of this document to third parties,

the making of copies, duplicates and other reproductions as well as the utilization and other use –

even in part – are prohibited without the prior, express and written consent of the author, unless and

insofar as mandatory statutory provisions permit such use.

Infringements against copyright are illegal, according to §§ 106 ff. Copyright Act and grant the hold-

ers of copyrights claims for injunctive relief and damages.

Subject to change:

The Westermann GmbH & Co. KG reserves the right to change this document and the subject matter

described therein at any time without prior notice, in particular to improve and expand it, provided

andinsofarascontractualagreementsorlegalrequirementsdonotconictwiththis.

2 Legal information

7

ENGLISH

3.1 Scope of supply

The operating manual is part of the working equipment and must be

kept accessible in the immediate vicinity of the machine at all times.

The operating manual contains important information for safe and

effective operation of the machine. Therefore, the operator must

read and understand this operating manual carefully.

The basic requirement for safe working is compliance with all safety

instructions and operating procedures given in this operating manual.

The local accident prevention regulations and general safety regulations

for the specific application must also be observed.

The provided supplier documentation for the installed components

must also be observed.

The illustrations are provided for basic understanding and may deviate

from the actual design.

The manufacturer assumes no liability for damage due to non-obser-

vance of the operating manual, improper use, improperly performed

maintenance or repairs, unauthorised modifications, technical modi-

fications and use of unauthorised spare parts.

3 Important general information

8

ENGLISH

3.2 Conventions

3.2.1 Symbols and signal words

Symbol / signal word Meaning

Indicates the handling and effects of the safety

information.

Alerts you to a dangerous situation that, if not

avoided, will result in death or serious injury.

Alerts you to a dangerous situation that, if not

avoided, may result in death or serious injury.

Alerts you to a dangerous situation that, if not

avoided, may result in minor or moderate injury.

Indicates possible damage to property and other

important information.

DANGER

!

NOTICE

WARNING

!

CAUTION

!

3 Important general information

9

ENGLISH

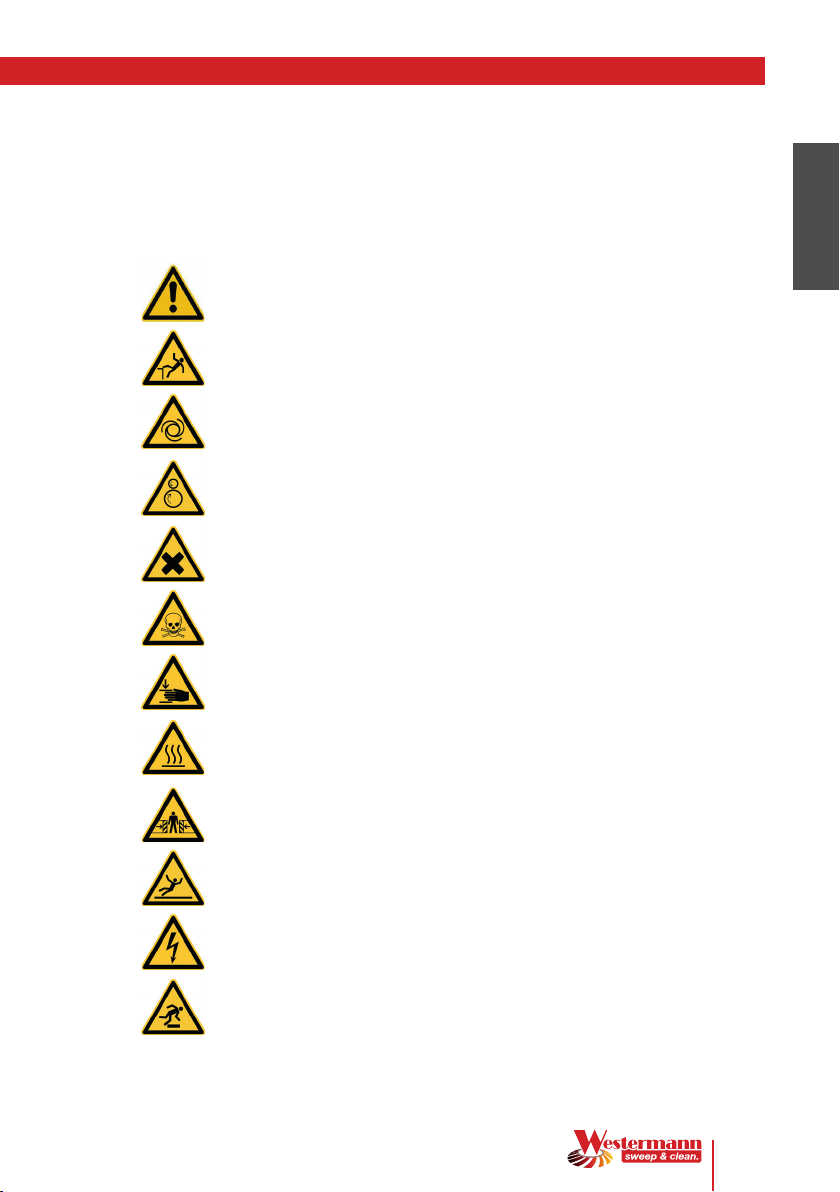

3.2.2 Pictogram overview

The safety instructions contained in this operating manual, which can cause danger

to persons and the machine if ignored, are specially marked with the following

pictograms.

Pictogram Importance

General warning sign

Falling hazard

Automatic start-up hazard

Opposing rollers hazard (Entanglement risk)

Harmful or irritating substances hazard

Toxic substances hazard

Hand injuries hazard

Hot surface hazard

Crushing hazard

Slip hazard

Electrical voltage hazard

Obstacles on the ground hazard

3 Important general information

10

ENGLISH

3 Important general information

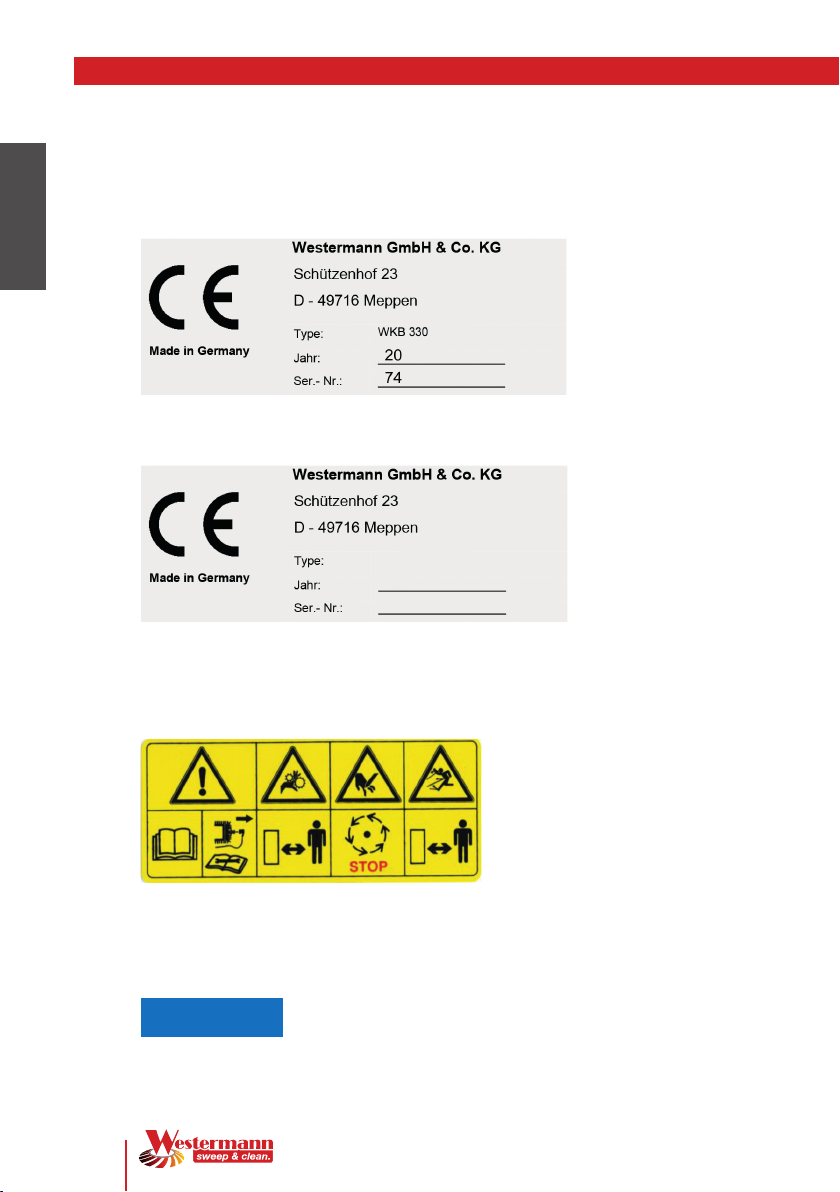

3.3 Markings on the machine

The WKB 330 Weed brush has a nameplate that contains all

basic data. Components and accessories from suppliers have their

own nameplates.

(WKB 330 )

(WKB 330 Battery)

3.3.1 Warning pictogram on the machine

Article number: AUF-00-00016

Labels must always be kept clean. Missing or damaged

labels must be replaced.

NOTICE

WKB 330 Akku

20XX

75XXX

Table of contents

Other Westermann Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions